Page 1

Spicer

Axles & Brakes

P/N: SHAIS139

Removal and Installation Instructions for ES-165-6H and ES-165-10H

Anchor Pin Replacement

Shown below are important instructions for the removal and replacement of the anchor pins on the ES165-6H and 16510H brakes on Neoplan Transit Buses. These parts and procedures are only for the Dana models listed in the charts.

WARNING: The long-term effects of non-asbestos fibers have not been determined. Therefore, precautions

should be used when handling these materials.

Follow safety precautions to ensure your safety while working on vehicle.

BRAKE SHOE AND ANCHOR PIN REMOVAL:

1. Perform steps necessary for drum removal.

2. Remove cap screws and dustshield, if applicable.

3. Remove retaining ring and washer from drum side of each anchor pin.

4. To allow removal of anchor pin, cut lock wire and remove cap screws from spider.

5. Remove upper anchor pin with a brass drift or a mallet.

6. Rotate upper shoe around cam end, disengage roller end from cam, then unhook return spring from shoe and remove

upper shoe.

7. Remove lower anchor pin with a brass drift or a mallet and remove lower shoe.

®

Fig. 1A Fig. 1B

8. With emery cloth or file clean rust and debris from around the anchor pin bore area of the brake spider. See figure 1A

and 1B.

Page 2

Fig. 2 Fig. 3

9. With emery cloth or file clean rust and debris from around the anchor pin bore area on the brake shoes. See Figure 2.

10. With emery cloth clean the anchor pin bushings in the shoe and the brake spider. See Figure 3.

Note: These areas should be cleaned sufficiently so the brake shoes install freely over the brake spider.

BRAKE SHOE AND ANCHOR PIN INSTALLATION PROCEDURE:

1. Install grease fitting in anchor pins and lubricate anchor pin surface and anchor pin bushings with a light film of grease

prior to installation in spider. See figure 4.

Fig. 4 Fig. 5

CAUTION: Use only grease conforming to NLGI grade #1, high-temperature, waterproof, Do Not Lubricate the

cam head surface. For efficient operation, this surface must remain free of oil, grease or other contaminants.

2. Lubricate roller recess of the shoes with a light coat of grease prior to installation

3. Place the upper shoe in position on the spider, and install upper anchor pin with the grease fitting toward the frame rail

of the vehicle. See Figure 5.

Note: The shoe should slide freely over the spider. If there is any interference grind or file the anchor pin area of

the shoe and the spider.

Fig. 6 (Frame side) Fig. 7 (Drum side)

Page 3

4. Install washer and retaining ring on the anchor pin. (Same side as grease fitting on the anchor pin). See figure 6.

5. Install washer and a retaining ring on the drum side of the anchor pin. See figure 7.

6. Connect return spring to upper shoe.

7. Position lower shoe for installation on spider (partially installed with shoe roller end disengaged from cam), then

connect return spring to lower shoe.

8. Complete the installation of lower shoe and install anchor pin with grease fitting toward the frame rail side of the

vehicle.

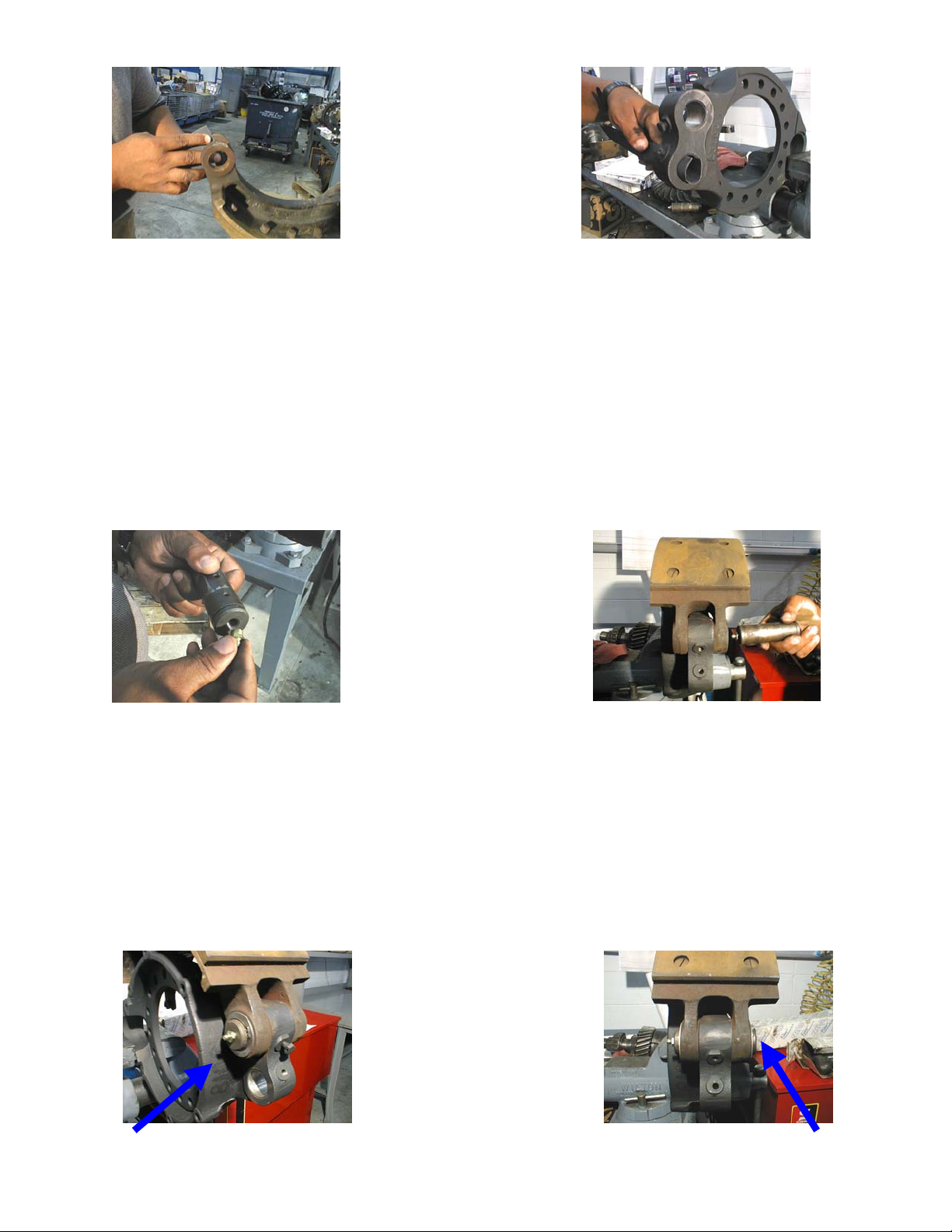

Fig. 8 Fig. 9

9. Install 1/4-24 by 3/8" cap screws and apply Loctite to threads. Tighten cap screws 120-150 in.-lbs. See figure 8.

10. Lubricate anchor pin with high temperature, waterproof grease conforming to NGLI grade #1. Lubricate until grease is

visible between the brake shoe and spider. Wipe off any excess grease. See figure 9.

13. Install dustshield. Secure with cap screws if applicable. Tighten screws to 150-180 in.-lbs.

14. Install brake drums and wheels.

15. Adjust brakes.

Listed below are the Dana service manuals that contain more detailed installation and removal information for the models

referenced in this document. These publications can also be found on our web site at http://www.

spicerparts.com

Service Manual Reference Chart

Model Series Manual Number

ES165-6H, ES165-10H BRSM--0033

For spec’ing or service assistance, call 1-800-621-8084 24 hours a day, 7 days a week.

Or visit our web site at:

SHAIS139A Copyright Dana Corporation, 2002 Commercial Vehicle Axle Division

JULY 2002 All Rights Reserved. P.O. Box

Printed in U.S.A. www.dana.com Toledo, Ohio 43697-0321

http://www.spicerparts.com

Dana Corporation

Loading...

Loading...