Page 1

NOTA: El manual en

español aparece después

del manual en inglés.

Automatic

Washers

Installation/Operation

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

W446I

Part No. 38970R10

November 2004

Page 2

Page 3

WARNING

For your safety and to reduce the risk of

fire or an explosion, do not store or use

gasoline or other flammable vapors and

liquids in the vicinity of this or any other

appliance.

IMPORTANT: Read the complete

INSTALLATION/OPERATION INSTRUCTIONS

before using the washer.

W022E

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT38970

1

Page 4

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970

Page 5

Table of

Contents

Replacement Parts.............................................................................. 5

Safety Information.............................................................................. 7

Explanation of Safety Messages........................................................... 7

Important Safety Instructions ............................................................... 7

Installation........................................................................................... 9

Meter Case............................................................................................ 9

Models Prepped for Card Reader..................................................... 9

Dimensions and Specifications............................................................. 10

Before You Start................................................................................... 11

Tools ................................................................................................ 11

Electrical .......................................................................................... 11

Water................................................................................................ 11

Installing the Washer............................................................................ 11

Step 1: Remove the Shipping Brace and Shipping Plug.................. 11

Step 2: Wipe Out Inside of Washtub ............................................... 12

Step 3: Connect Fill Hoses............................................................... 12

Step 4: Connect Drain Hose to Drain Receptacle............................ 13

Step 5: Position and Level the Washer ............................................ 15

Step 6: Connect the Washer to Electrical Power ............................. 15

Step 7: Add Water to the Washer .................................................... 16

Step 8: Check Lid Switch ................................................................ 16

Step 9: Check Installation................................................................ 16

Electrical Requirements........................................................................ 17

Grounding Instructions .................................................................... 18

Water Supply Requirements................................................................. 20

Water Temperature .......................................................................... 20

Water Pressure ................................................................................. 20

Risers................................................................................................ 21

Drain Facilities...................................................................................... 21

Additional Washer Security.................................................................. 22

Operation............................................................................................. 25

Operation Instructions for Electromechanical Washers ....................... 25

Step 1: Add Detergent...................................................................... 25

Step 2: Load Laundry....................................................................... 25

Step 3: Close Lid.............................................................................. 25

Step 4: Select Temperature Switch .................................................. 26

Step 5: Set Fabric/Cycle Selector .................................................... 26

Step 6: Start Washer......................................................................... 26

Indicator Lights................................................................................ 27

Operation Instructions for Electronic Display Control Washers.......... 28

Step 1: Add Detergent...................................................................... 28

Step 2: Load Laundry....................................................................... 28

Step 3: Close Lid.............................................................................. 28

Step 4: Set Fabric Selector............................................................... 29

Step 5: Set Wash Temperature......................................................... 29

Step 6: Insert Money or Card........................................................... 29

Indicator Lights................................................................................ 30

© Copyright 2004, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

38970

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Operation Instructions for MDC Washers............................................ 31

Step 1: Add Detergent...................................................................... 31

Step 2: Load Laundry....................................................................... 31

Step 3: Close Lid.............................................................................. 31

Step 4: Set Fabric Selector and Wash Temperature......................... 32

Step 5: Insert Money or Card........................................................... 32

Step 6: Start Washer......................................................................... 33

Indicator Lights................................................................................ 33

Operation Instructions for NetMaster Washers.................................... 34

Step 1: Add Detergent...................................................................... 34

Step 2: Load Laundry....................................................................... 34

Step 3: Close Lid.............................................................................. 34

Step 4: Set Fabric Selector............................................................... 35

Step 5: Set Wash Temperature......................................................... 35

Step 6: Insert Money or Card........................................................... 35

Step 7: Start Washer......................................................................... 36

Indicator Lights................................................................................ 36

Maintenance ........................................................................................ 37

Variable Water Level Control .............................................................. 37

User-Maintenance Instructions............................................................. 38

Cold Weather Care........................................................................... 38

Care of Your Washer ....................................................................... 38

Replacing Hoses............................................................................... 38

Filter Screens ................................................................................... 38

Reinstallation of Shipping Materials ............................................... 38

Motor Overload Protector..................................................................... 38

Before You Call for Service................................................................. 39

If Service Is Required........................................................................... 40

Information for Handy Reference......................................................... 41

Installer Checklist............................................................... Back Cover

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970

Page 7

Replacement Parts

If replacement parts are required, contact the source

from which you purchased your washer, or contact:

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

Phone: (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

38970

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Notes

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970

Page 9

Safety Information

Indicates an imminently hazardous

situation that, if not avoided, will cause

severe personal injury or death.

DANGER

Indicates a hazardous situation that, if not

avoided, could cause severe personal

injury or death.

WARNING

Indicates a hazardous situation that, if not

avoided, may cause minor or moderate

personal injury or property damage.

CAUTION

Explanation of Safety Messages

Throughout this manual and on machine decals, you

will find precautionary statements (“DANGER,”

“WARNING,” and “CAUTION”) followed by specific

instructions. These precautions are intended for the

personal safety of the operator, user, servicer, and

those maintaining the machine.

Important Safety Instructions

Save These Instructions

WARNING

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023

1. Read all instructions before using the washer.

2. Refer to the GROUNDING INSTRUCTIONS in

the INSTALLATION manual for the proper

grounding of the washer.

3. Do not wash articles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, or other

flammable or explosive substances as they give

off vapors that could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. THE

GAS IS FLAMMABLE, DO NOT SMOKE OR

USE AN OPEN FLAME DURING THIS TIME.

6. Do not allow children to play on or in the washer.

This appliance is not intended for use by young

children or infirm persons without supervision.

Young children should be supervised to ensure

that they do not play with the appliance.

38970

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

Safety Information

7. Before the washer is removed from service or

discarded, remove the lid to the washing

compartment.

8. Do not reach into the washer if the wash tub or

agitator is moving.

9. Do not install or store the washer where it will be

exposed to water and/or weather.

10. Do not tamper with the controls.

11. Do not repair or replace any part of the washer, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that you understand and have the

skills to carry out.

12. To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power source.

13. Use your washer only for its intended purpose,

washing clothes.

14. ALWAYS disconnect the washer from electrical

supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord.

15. Install the washer according to the

INSTALLATION INSTRUCTIONS. All

connections for water, drain, electrical power and

grounding must comply with local codes and be

made by licensed personnel when required. Do

not do it yourself unless you know how!

16. To reduce the risk of fire, clothes which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, etc. or anything

containing wax or chemicals such as in mops and

cleaning cloths, must not be put into the washer.

These flammable substances may cause the

fabric to catch on fire by itself.

17. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

18. Keep your washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have your washer checked by a

qualified service person.

19. If the supply cord is damaged, it must be replaced

by a special cord or assembly available from the

manufacturer or its service agent.

20. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

21. Loading door MUST BE CLOSED any time the

washer is to agitate or spin. DO NOT bypass the

loading door switch by permitting the washer to

agitate or spin with the loading door open. A

brake will stop the washtub within seconds if the

loading door is opened during spinning. If the

washtub does not stop when the loading door is

opened, remove the washer from use and call the

service person.

22. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. To reduce the risk of poisoning or chemical

burns, keep them out of the reach of children at

all times (preferably in a locked cabinet). Heed

all warnings or precautions.

23. Always follow the fabric care instructions

supplied by the garment manufacturer.

24. Never operate the washer with any guards and/or

panels removed.

25. DO NOT operate the washer with missing or

broken parts.

26. DO NOT bypass any safety devices.

27. Failure to install, maintain, and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNINGS and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the washer.

Always contact your dealer, distributor, service agent

or the manufacturer about any problems or conditions

you do not understand.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970

Page 11

Installation

Meter Case

The factory mounted coin meter case does not include

the service door lock, slide, coin drawer, coin drawer

lock or keys. These parts must be ordered (at extra

cost) according the purchaser’s requirements direct

from the manufacturer of your choice.

NOTE: You have the option of using a screw type

lock or a 1/4 turn lock on the meter case service

door. If you choose to use a screw lock, then the

special bracket (located inside the meter case) must

be used. DO NOT use the special bracket if a

1/4 turn lock is used.

Coin Drawer Security – For additional security, drill

out the two pilot holes on each side of the front of the

meter case to 6,4 or 7,9 mm (1/4 or 5/16 inch) holes

and install a bicycle lock through these holes.

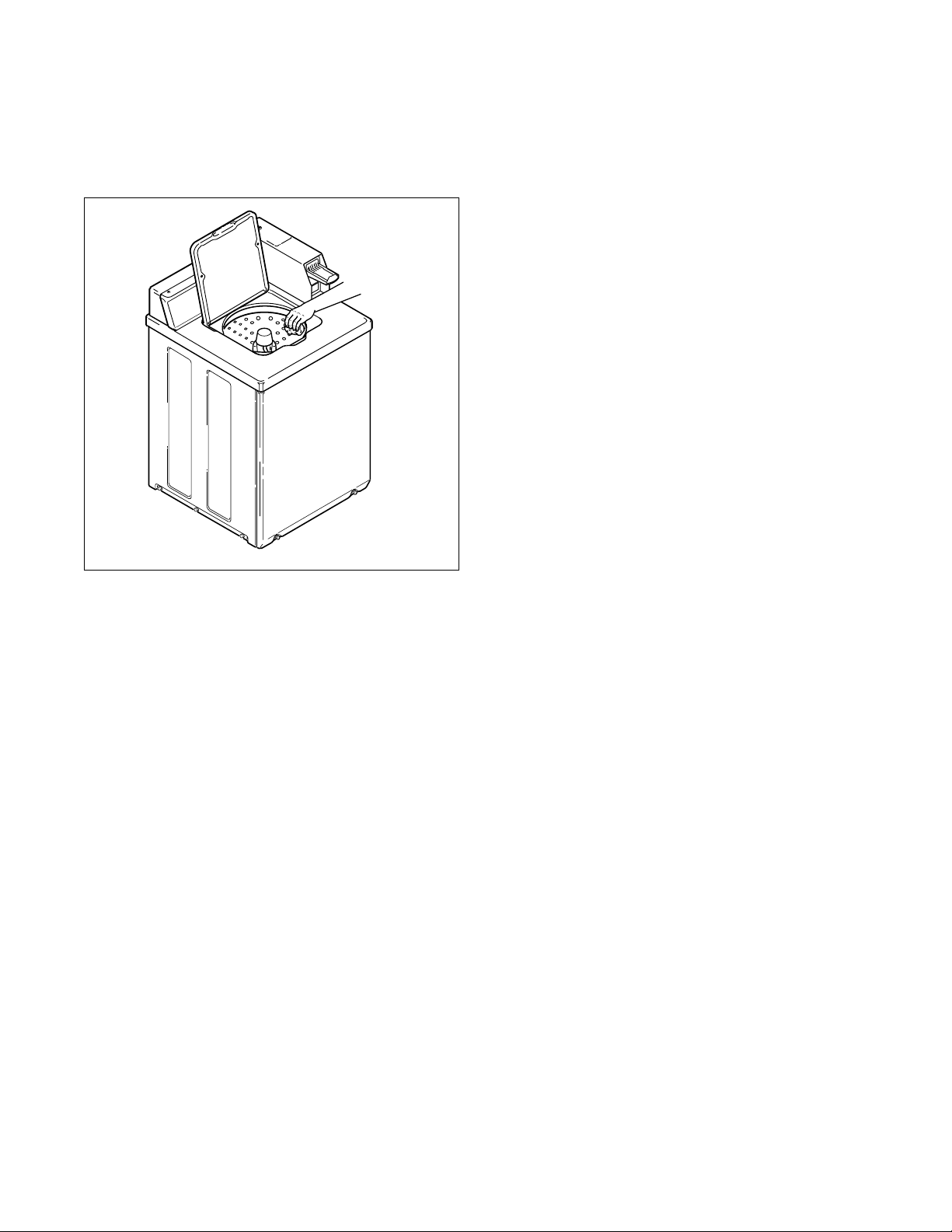

Models Prepped for Card Reader

The machine is shipped from the factory with the

Electronic Control Diagnostic Harness Assembly

unplugged. To avoid unauthorized manual

programming or vending, perform the following steps.

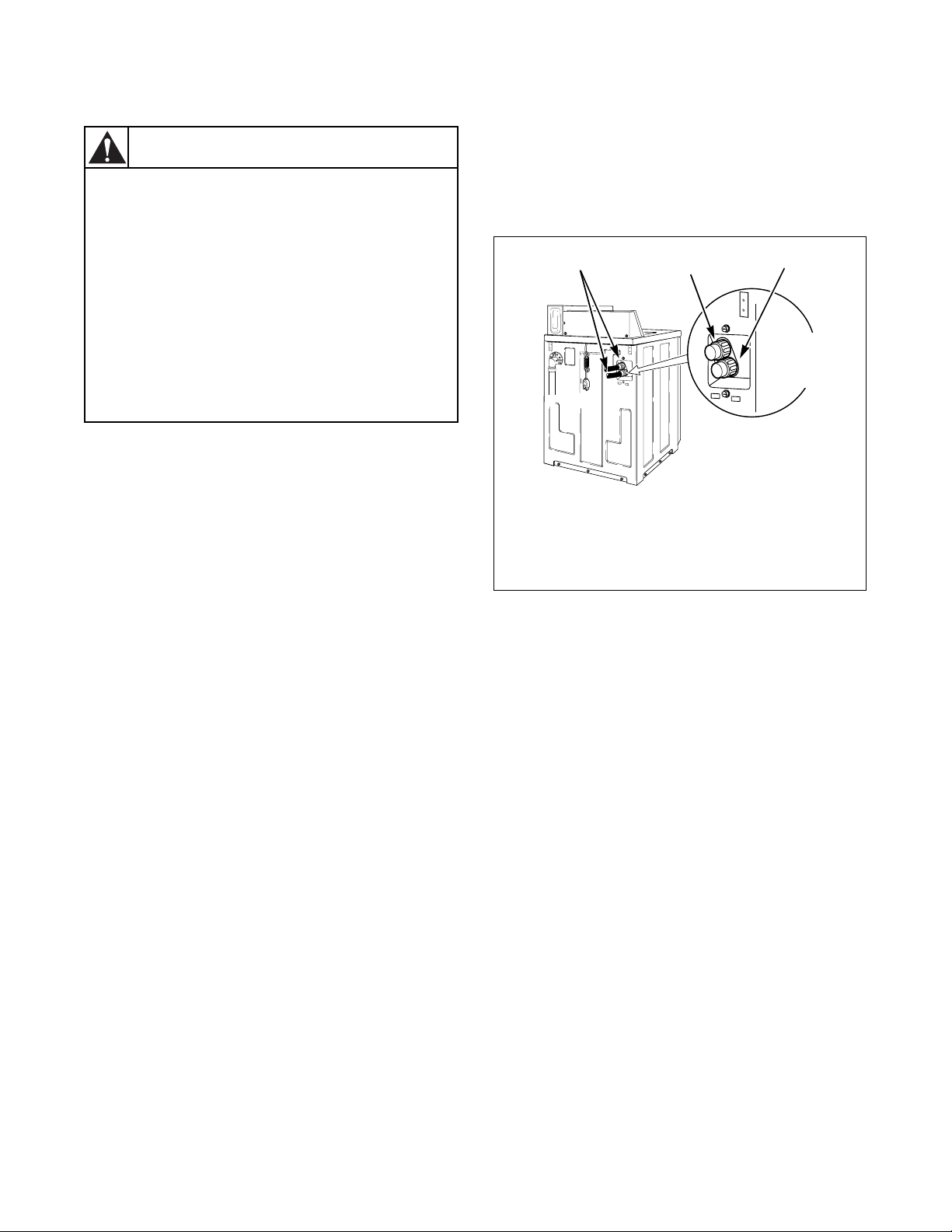

1. Open service door. Refer to Figure 1.

2. Locate diagnostic harness on electronic control.

3. Plug connectors for “white/black” wire and “red/

blue” wire together.

1

1 Service Door

Figure 1

FLW6R

38970

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Installation

Dimensions and Specifications

74,47 cm (30,5 in.)

1

129,54 cm (51 in.)

108,59 cm (42,75 in.)

91,05 cm (35,88 in.)

73,02 cm (28,75 in.)

109,22 cm (43 in.)

1 Pilot Hole

74,47 cm (30,5 in.)

65,09 cm (25,63 in.)

11,11 cm

(0,44 in.)

66,04 cm (26 in.)

71,12 cm (28 in.)

METERED MODELS

109,22 cm (43 in.)

73,02 cm (28,75 in.)

91,05 cm (35,88 in.)

W553I

129,54 cm (51 in.)

107,65 cm (42,38 in.)

10

65,09 cm (25,63 in.)

11,11 cm

(0,44 in.)

66,04 cm (26 in.)

71,12 cm (28 in.)

NONMETERED MODELS

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

W543I

38970

Page 13

Installation

Before You Start

Tools

For most installations, the basic tools you will need

are:

1

1 Wrench

2 Screwdriver

3 Pliers

4 Level

2

4

D074I

Installing the Washer

NOTE: If the washer is delivered on a cold day

(below freezing), or is stored in an unheated room

or area during the cold months, do not attempt to

operate it until the washer has had a chance to

warm up.

Step 1: Remove the Shipping Brace and

3

Shipping Plug

IMPORTANT: Install dryer before washer. This

allows room for attaching exhaust duct.

Remove the shipping brace from under the lid. The

plastic shipping plug will be released from the base of

the washer when removing the cardboard base from

the washer.

IMPORTANT: The shipping brace and plug should

be saved and must be reinstalled whenever washer

is moved or transported to a new location. This will

prevent damage to washer components.

Do not tilt washer to front or sides when moving.

Figure 2

Electrical

Washer needs a 120 Volt, 60 Hertz, polarized three slot

effectively grounded receptacle. For more detailed

information, refer to section on Electrical

Requirements.

Water

Washer needs two standard 19,05 mm (3/4 inch) water

supply faucets with a pressure between 138 and

827 kPa (20 and 120 pounds per square inch). For

more detailed information, refer to section on Wa ter

Supply Requirements.

Refer to User-Maintenance section for instructions on

reinstalling shipping brace and shipping plug.

1

2

TLW520N

1 Shipping Brace

2 Shipping Plug

TLW520N

38970

Figure 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Installation

Step 2: Wipe Out Inside of Washtub

Prior to first wash, use an all purpose cleaner or a

detergent and water solution and a damp cloth to

remove shipping dust from inside of washtub.

W396I

Figure 4

W396I

Step 3: Connect Fill Hoses

Refer to section on Water Supply Requirements

before connecting fill hoses.

The appliance is to be connected to the water mains

using new hose-sets and the old hose-sets should not

be reused.

Turn on the water supply faucets and flush the lines for

approximately two minutes to remove any foreign

materials that could clog the screens in the water

mixing valve. (This is especially important when

installing your washer in a newly constructed or

renovated building.)

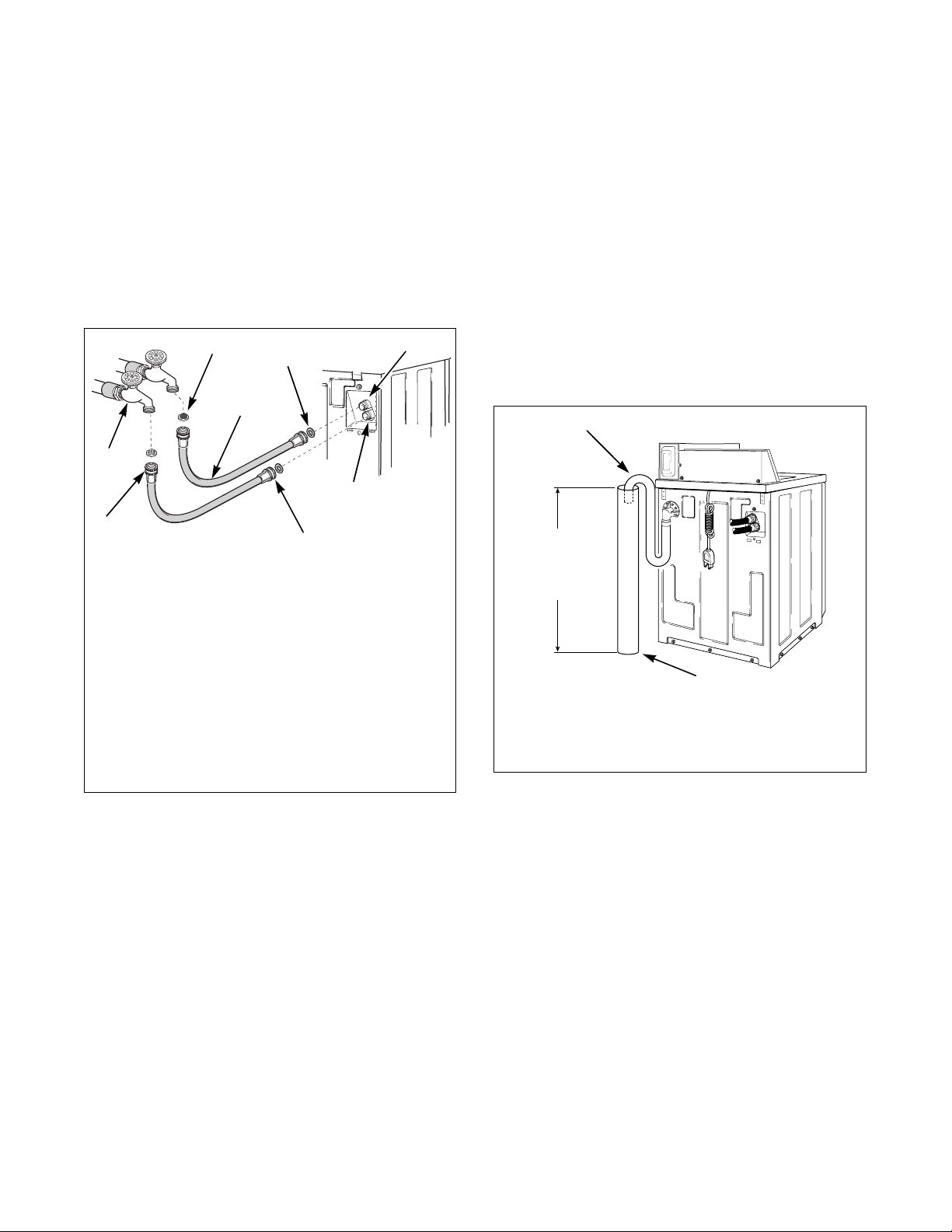

Hoses Without Metric Coupling

Insert rubber washers and filter screens (from

accessories bag) in water fill hose couplings (two

hoses supplied with washer). Connect fill hoses to

water supply faucets. Then connect the hoses to the

hot and cold valve connections at the rear of the

washer. Refer to Figure 5.

IMPORTANT: Thread hose couplings onto valve

connections finger tight, then turn 1/4 turn with

pliers. DO NOT cross thread or overtighten

couplings.

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970

Page 15

Installation

HOT

COLD

C

H

2

1

3

4

5

6

7

8

Hoses With Metric Coupling

Connect the BLACK colored hose coupling end of the

fill hoses (with filter screens) to the water supply

faucets. Then connect end of hoses with the brass

colored hose couplings to the hot and cold water

mixing valve connections at rear of washer.

IMPORTANT: Thread hose couplings onto valve

connections finger tight, then turn 1/4 turn with

pliers. DO NOT cross thread or overtighten

couplings.

TLW1988N

1 Filter Screen (Screen must be facing

outward)

2 Fill Hose

3 Rubber Washer (Plain)

4 Cold Water Connection

5 Hot Water Connection

6 Install this end of hose to valve connections

at rear of washer.

7 Install this end of hose to water supply

faucet. (Black colored coupling for metric)

8 Faucet

Figure 5

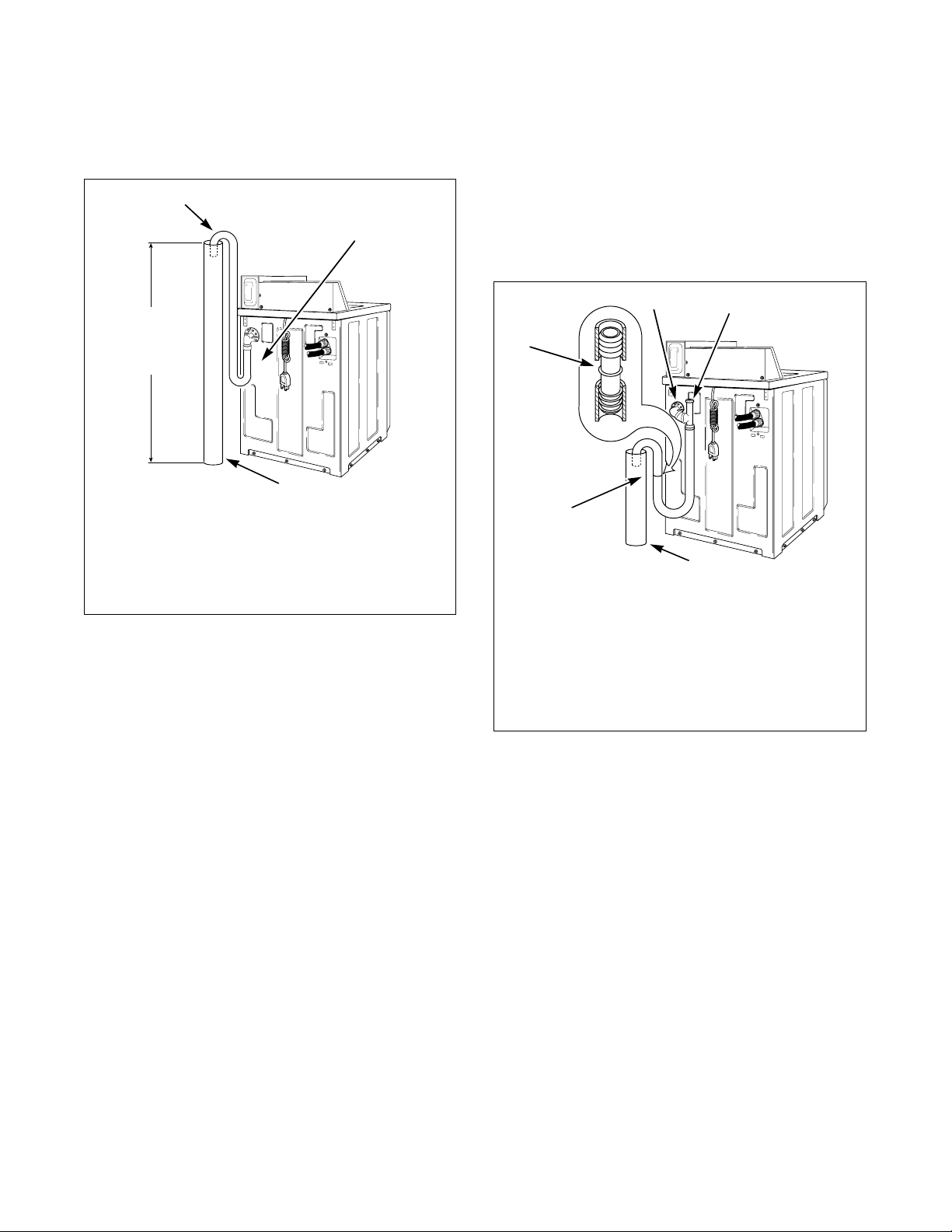

Step 4: Connect Drain Hose to Drain

Receptacle

Refer to section on Drain Facilities before connecting

drain hose to drain receptacle.

Remove the drain hose from its shipping position on

the rear of the washer by unhooking the hose from the

retainer clamp.

Follow the instructions for your type of drain

receptacle (high standpipe or low standpipe) to

properly install the drain hose.

IMPORTANT: Drain receptacle must be capable of

handling a minimum of 3,8 cm (1-1/2 inch) outside

diameter drain hose.

1

RECOMMENDED

STANDPIPE

HEIGHT

92 cm MINIMUM

(36 inches)

2

1 Drain Hose

2 Standpipe

Figure 6

W294I

W294I

IMPORTANT: Hoses and other natural rubber

parts deteriorate after extended use. Hoses may

develop cracks, blisters or material wear from the

temperature and constant high pressure they are

subjected to.

All hoses should be checked on a yearly basis for

any visible signs of deterioration. Any hose showing

the signs of deterioration listed above should be

replaced immediately. All hoses should be replaced

every five years.

38970

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

Installation

High Standpipe Installation

No. 562P3 Siphon Break Kit and No. 25863 Hose

Coupling are not required for this type of installation.

1

2

MAXIMUM

STANDPIPE

HEIGHT NOT TO

EXCEED 1,5 m

(5 feet)

1 Drain Hose

2 Cut drain hose off this end to fit the washer

installation.

3 Standpipe

{

3

W296I

Figure 7

Low Standpipe Installation

No. 562P3 Siphon Break Kit and No. 25863 Hose

Coupling are required for this type of installation. This

kit is available (as optional equipment at extra cost)

through an authorized dealer or parts distributor.

Installation instructions are supplied with the kit.

OPTIONAL: Raise the standpipe to the recommended

height of 92 cm (36 inches).

1

5

2

{

4

3

W295I

1 Drain Hose Elbow

2 562P3 Siphon Break Kit

3 Standpipe

4 Cut hose in this area and install No. 25863

hose coupling.

5 25863 Hose Coupling

14

Figure 8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970

Page 17

Installation

W214I

2

1

3

5

4

Step 5: Position and Level the Washer

Position washer so it has sufficient clearance for

installation and servicing.

Place rubber cups on all four leveling legs.

Place washer in position on a clean, dry, and

reasonably firm floor. Installing the washer on any

type of carpeting is not recommended.

Loosen locknuts and adjust the two front leveling legs.

Once adjusted, tilt the unit forward on front legs and

lower back down into position to set the rear selfleveling legs.

Washer must not rock. After washer is at desired

height, tighten locknuts securely against bottom of

washer base. If these locknuts are not tight, washer

will not remain stationary during operation.

Improper installation or flexing of weak floor will

cause excessive vibration.

Do not slide washer across floor once the leveling legs

have been extended, as legs and base could become

damaged.

Step 6: Connect the Washer to Electrical

Power

Refer to the following section on Electrical

Requirements before connecting the washer to an

electrical power source.

D254I

D254I

Figure 10

NOTE: For areas with uneven floors, a No. 566P3

Adjustable Rear Leg Extension Kit is available as

optional equipment at extra cost.

Verify that washer does not rock.

W214I

1 Leveling Leg

2 Washer Base

3 Locknut

4 Rubber Cup

5 15 mm (1/2 inch) Clearance Between

Washers

38970

Figure 9

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

Installation

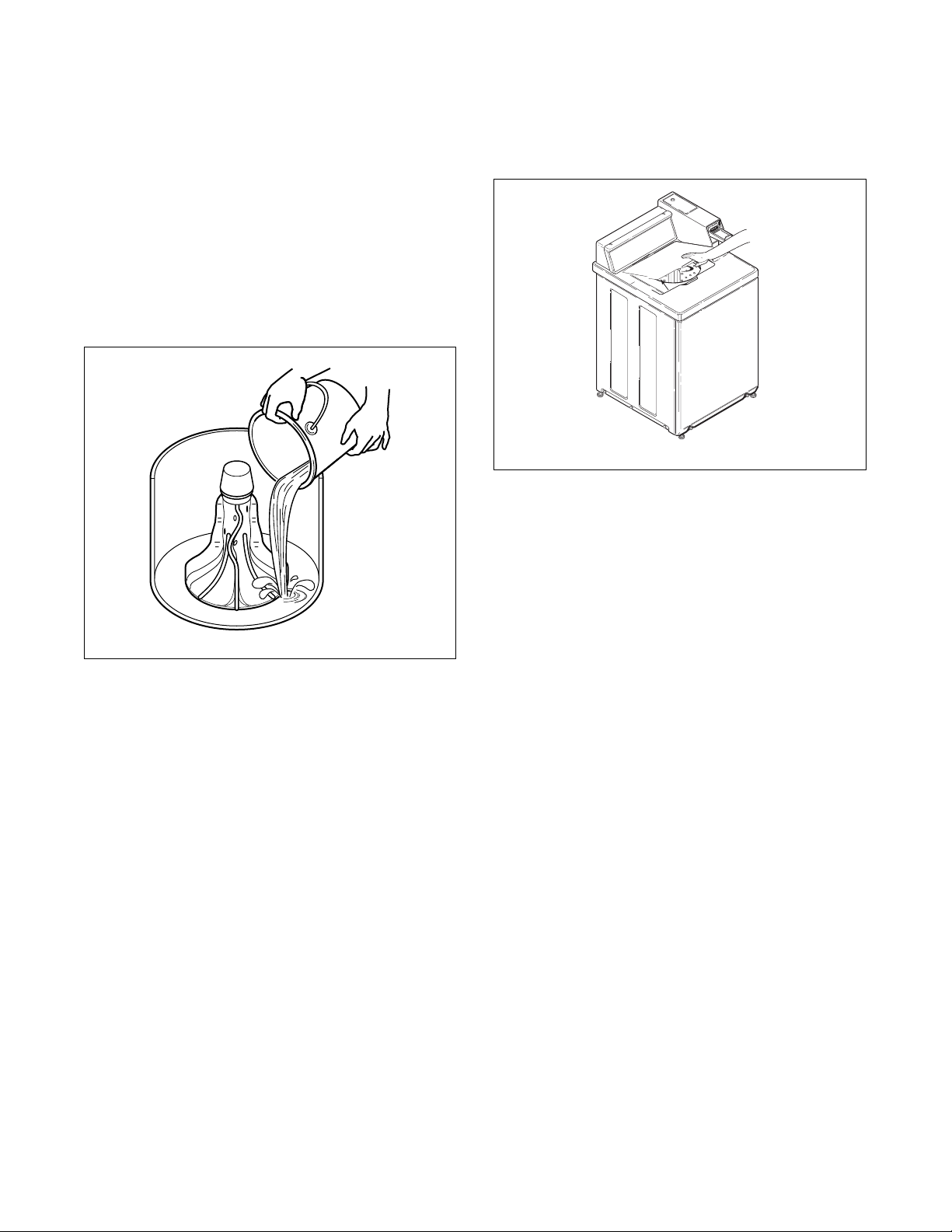

Step 7: Add Water to the Washer

To prevent damage to pump, do not run washer before

adding at least one quart water to the tub. If the washer

is run before any water is added, the pump seal may

overheat, causing the pump to leak. Once installed, the

water retained in the drain system from the previous

cycle will provide sufficient cooling to prevent pump

seal damage.

NOTE: The agitator should not be removed except

for service. The washtub is designed to be selfcleaning.

Step 8: Check Lid Switch

Washer should stop filling, agitating and spinning

when lid is opened.

TLW1974N

TLW1974N

Figure 12

Step 9: Check Installation

Refer to Installer Checklist on the back cover of this

manual and make sure that washer is installed

correctly.

Figure 11

TLW524N

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970

Page 19

Installation

To reduce the risk of fire, electric shock,

serious injury or death, all wiring and

grounding MUST conform with the latest

edition of the National Electrical Code,

ANSI/NFPA No. 70, and such local

regulations as might apply. It is the

customer’s responsibility to have the

wiring and fuses checked by a qualified

electrician to make sure the laundry room

has adequate electrical power to operate

the washer.

W227

WARNING

Electrical Requirements

NOTE: The wiring diagram is located in the

control hood.

NOTE: Refer to the washer nameplate for proper

voltage and Hertz the washer is designed to operate

on. Refer to Figure 51 for nameplate location.

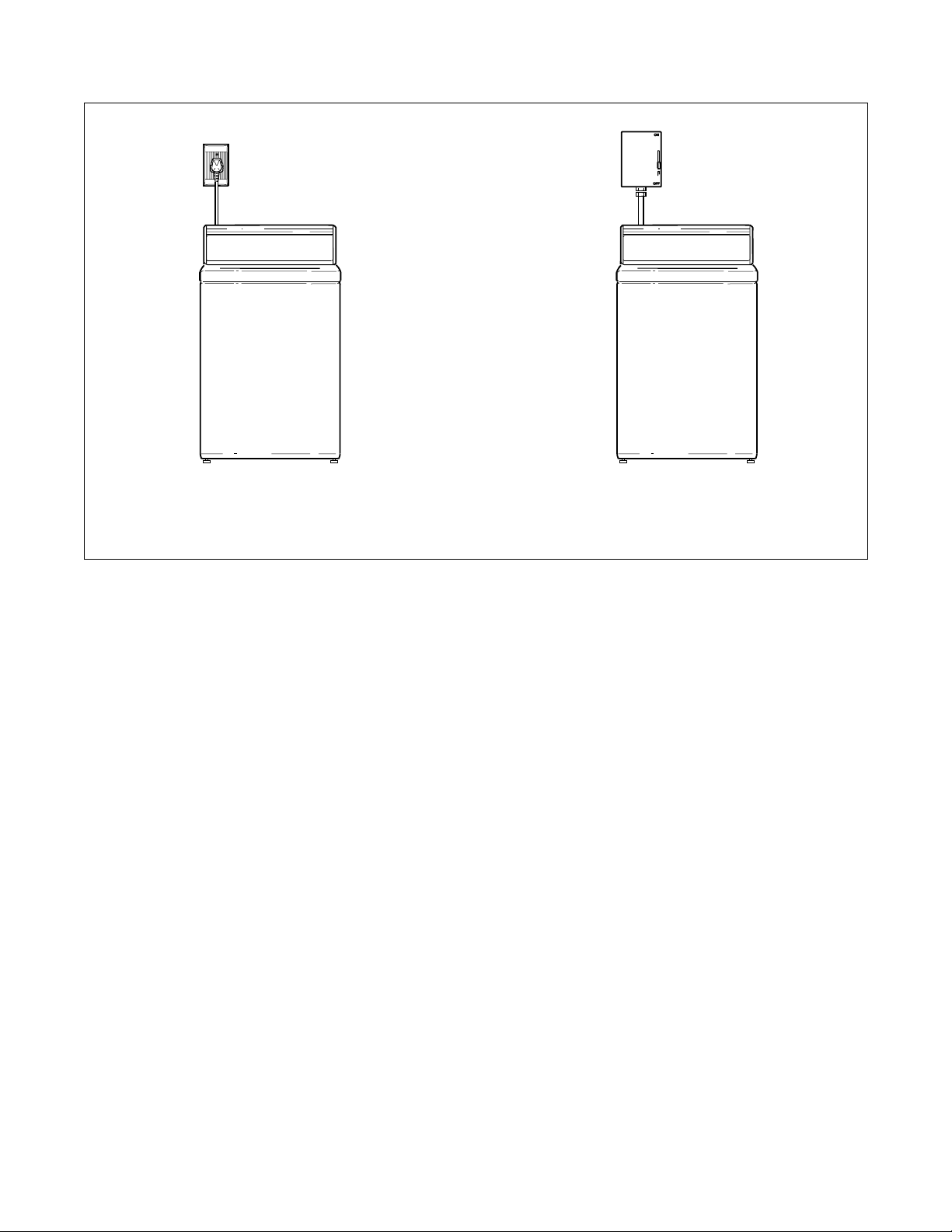

120 Volt, 60 Hertz with 3-Prong Grounding Plug

The washer is designed to be operated on a separate

branch, polarized, three-wire, effectively grounded,

120 Volt, 60 Hertz, AC (alternating current), circuit

protected by a 15 ampere fuse, equivalent fusetron or

circuit breaker.

1

120 ± 12

V.A.C.

5

4

STANDARD 120 VOLT, 60 HERTZ,

3-WIRE EFFECTIVELY GROUNDED CIRCUIT

1 L1

2 Ground

3 Neutral Side

4 Round Grounding Prong

5 Neutral

2

120 ± 12

V.A.C.

3

0

V.A.C.

D799I

The three-prong grounding plug on the power cord

should be plugged directly into a polarized three-slot

effectively grounded receptacle rated 110/120 Volts

AC (alternating current) 15 Amps. Refer to Figure 14

to determine correct polarity of the wall receptacle.

DO NOT OVERLOAD

CIRCUITS

DO NOT USE

ADAPTER

DO NOT USE AN

EXTENSION CORD

Figure 13

38970

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 14

DO NOT OPERATE OTHER APPLIANCES ON

THE SAME CIRCUIT. DO NOT OVERLOAD

CIRCUITS!

WARNING

To reduce the risk of an electric shock or

fire, DO NOT use an extension cord or an

adapter to connect the washer to the

electric power source.

W082

D009I

17

Page 20

Installation

NOTE: Some models come without an electrical

plug installed. If washer is not hard wired (refer to

Figure 15), a suitable plug that meets local

electrical standards, including earthing

requirements, must be installed. Refer to the

washer nameplate for proper voltage and Hertz the

washer is designed to operate on. Refer to

Figure 51.

100 Volt/50 Hertz

The washer is designed to be operated on a separate

polarized three-wire, earth (grounded) 100 Volt,

50 Hertz, single-phase electrical circuit protected by a

15 ampere fuse, equivalent fusetron or circuit breaker.

DO NOT OPERATE OTHER APPLIANCES ON

THE SAME CIRCUIT WHEN THE WASHER IS

OPERATING.

100 Volt/60 Hertz

The washer is designed to be operated on a separate

polarized three-wire, grounded 100 Volt, 60 Hertz,

single-phase electrical circuit protected by a

15 ampere fuse, equivalent fusetron or circuit breaker.

DO NOT OPERATE OTHER APPLIANCES ON

THE SAME CIRCUIT WHEN THE WASHER IS

OPERATING.

240 Volt/50 Hertz

The washer is designed to be operated on a separate

polarized three-wire, earth (grounded) 240 Volt,

50 Hertz, single-phase electrical circuit protected by a

10 ampere fuse, equivalent fusetron or circuit breaker.

DO NOT OPERATE OTHER APPLIANCES ON

THE SAME CIRCUIT WHEN THE WASHER IS

OPERATING.

240 Volt/60 Hertz

The washer is designed to be operated on a separate

polarized three-wire, grounded 240 Volt, 60 Hertz,

single-phase electrical circuit protected by a

10 ampere fuse, equivalent fusetron or circuit breaker.

DO NOT OPERATE OTHER APPLIANCES ON

THE SAME CIRCUIT WHEN THE WASHER IS

OPERATING.

Grounding Instructions

The washer must be grounded. In the event of

malfunction or breakdown, grounding will reduce the

risk of electric shock by providing a path of least

resistance for electric current. The washer is equipped

with a cord having an equipment-grounding conductor.

Some models are also equipped with a three-prong

grounding plug. The washer must be plugged or hard

wired into an appropriate power source that is properly

installed and grounded in accordance with all local

codes and ordinances.

WARNING

Improper connection of the equipmentgrounding conductor can result in a risk

of electric shock. Check with a qualified

electrician or service person if you are in

doubt as to whether the washer is

properly grounded.

W300

DO NOT modify the plug provided with the washer –

if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

If the laundry room’s electrical supply does not meet

the above specifications and/or if you are not sure the

laundry room has an effective ground, have a qualified

electrician or your local electrical utility company

check it and correct any problems.

WARNING

Any disassembly requiring the use of

tools must be performed by a suitably

qualified service person.

W299

230 Volt/50 Hertz

The washer is designed to be operated on a separate

polarized three-wire, earth (grounded) 230 Volt,

50 Hertz, single-phase electrical circuit protected by a

10 ampere fuse, equivalent fusetron or circuit breaker.

DO NOT OPERATE OTHER APPLIANCES ON

THE SAME CIRCUIT WHEN THE WASHER IS

OPERATING.

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970

Page 21

Installation

W403I

PLUG

W403I W402I

HARD WIRED

W402I

NOTE: Electrical receptacle must be located so that it is easily accessible with machine in place. If machine is hard

wired, an intermediate shut-off box with a 3,5 mm gap is required (Standard IEC 60335-1, Clauses [22.2][24.3]).

Figure 15

38970

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Page 22

Installation

Under certain conditions, hydrogen gas

may be produced in a hot water system

that has not been used for two weeks or

more. HYDROGEN GAS IS EXPLOSIVE. If

the hot water system has not been used

for such a period and before using the

washer, turn on all hot water faucets and

let the water flow from each for several

minutes. This will release any

accumulated hydrogen gas. The gas is

flammable. Do not smoke or use an open

flame during this time.

W029

WARNING

Water Supply Requirements

Water supply faucets must fit standard 19,1 mm

(3/4 inch) female garden hose couplings. DO NOT

USE SLIP-ON OR CLAMP-ON CONNECTIONS.

NOTE: Water supply faucets should be readily

accessible to permit turning them off when washer

is not being used.

Water Temperature

Cold:

NOTE: Longer inlet hoses are available (as

optional equipment at extra cost) if the hoses

(supplied with the washer) are not long enough for

the installation. Order hoses as follows:

No. 20617 Inlet Hose (2,44 m) (8 feet)

No. 20618 Inlet Hose (3,05 m) (10 feet)

1

1 Water Inlet Hoses

2 Cold Water Connection

3 Hot Water Connection

2

Figure 16

3

WATER

MIXING

VALVE

W293I

W293I

Recommended cold water temperature is 10° to

24° Celsius, 50° to 75° Fahrenheit.

Hot:

Recommended hot water temperature is 60° to

66° Celsius, 140° to 150° Fahrenheit.

Warm:

Mixture of hot and cold water. (Warm water

temperature is dependent upon the water temperature

and the pressure of both the hot and cold water supply

lines.)

IMPORTANT: Turn off water supply faucets after

check-out and demonstration. Owner should turn

off water supply whenever there will be an

extended period of non-use.

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Water Pressure

Pressure must be a minimum of 138 to 827 kPa

(20 to a maximum of 120 pounds per square inch)

static pressure measured at the faucet.

NOTE: Water pressure under 138 kPa (20 pounds

per square inch) will cause an extended fill time in

the washer.

38970

Page 23

Installation

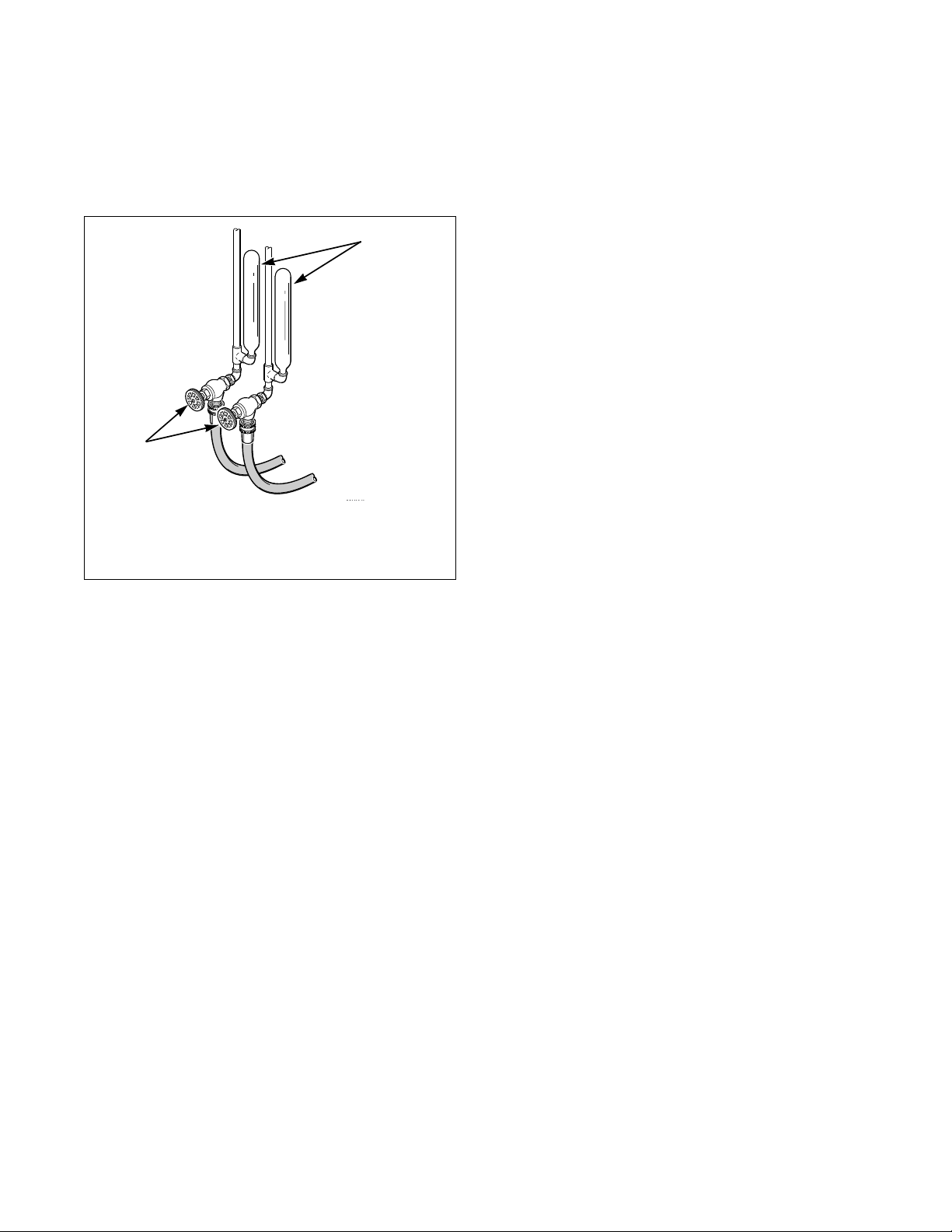

Risers

Risers (or air cushions) may have to be installed if the

pipes knock or pound when flow of water stops. The

risers are more efficient when installed as close as

possible to the water supply faucets. Refer to Figure 17.

1

2

W005I

1 Risers (Air cushions)

2 Water Supply Faucets

Figure 17

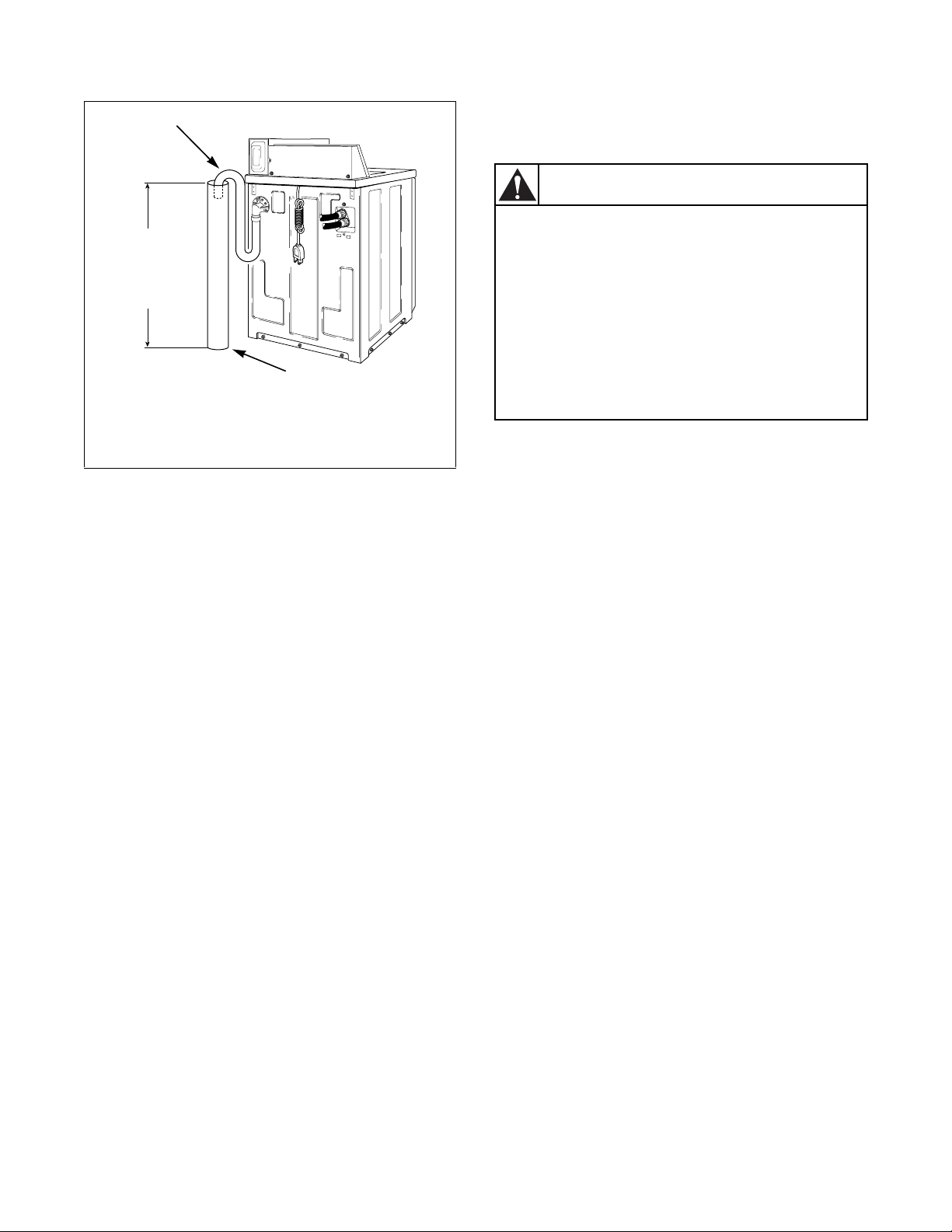

Drain Facilities

IMPORTANT: The drain hose installation is a very

important factor in the washer installation. If care

is not taken when the drain hose is installed, a

siphoning action can be started which will cause

water to be siphoned from the washer during the

cycle.

End of drain hose should never be in water as

siphoning action can be started that will cause

water to be siphoned back into the washer.

The curved end of drain hose MUST be installed

even with or above the height of the cabinet top of

the washer to prevent siphoning (refer to Figure 18).

If the drain facility is lower than the cabinet top, a

siphon break kit, Part No. 562P3, must be installed

in the drain hose to prevent this siphoning action

and drain hose MUST be cut to fit the washer

installation (refer to Figure 7). Use one No. 25863

Hose Coupling to splice hose. The No. 562P3 Siphon

Break Kit and No. 25863 Hose Coupling are

available as optional equipment at extra cost.

The standpipe or drain receptacle must be capable of

handling a minimum of 3,8 cm (1-1/2 inches) outside

diameter drain hose. The drain hose should fit loose

within the standpipe (it should not be a snug fit). Never

install the drain hose into a “sealed” drain system as

air cannot escape and will restrict the water from being

drained from the washer. A sealed drain system may

also allow water to be pumped back into the washer

during agitation. Both of these conditions may result

in flooding of the washer.

38970

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

Installation

1

RECOMMENDED

STANDPIPE

HEIGHT

92 cm MINIMUM

(36 inches)

1 Drain Hose

2 Standpipe

2

Figure 18

W294I

W294I

Additional Washer Security

(Coin Models Only)

WARNING

To reduce the risk of electric shock, fire,

explosion, serious injury or death:

• Disconnect electric power to the washer

before servicing.

• Never start the washer with any guards/

panels removed.

• Whenever ground wires are removed

during servicing, these ground wires

must be reconnected to ensure that the

washer is properly grounded.

W003

Located on the service door of the washer is a flat

Phillips head screw. During shipment, this screw is

used to attach the service door to the meter case. For

additional security, this screw can be reinstalled inside

the control hood of your washer.

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970

Page 25

Installation

Any disassembly requiring the use of

tools must be performed by a suitably

qualified service person.

W299

WARNING

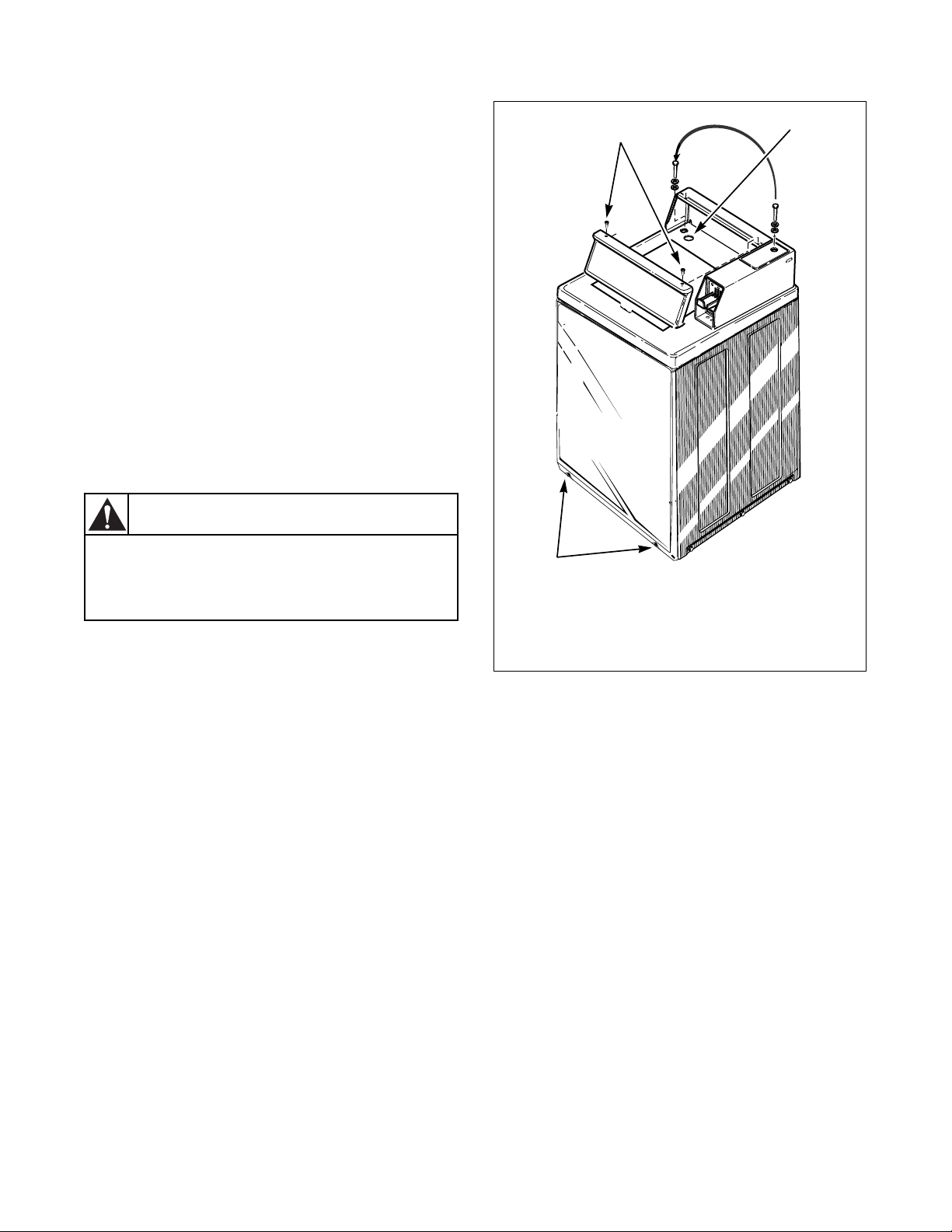

The following list is the procedure required to install

the Phillips head screw and tamper-resistant screws:

1. Remove the Phillips head screw from service

door (refer to Figure 19).

2. Remove two screws holding control panel to

control hood (refer to Figure 19).

3. Tilt control panel forward and lay on a protective

pad to prevent scratching of cabinet top.

4. Insert Phillips head screw down through double

“D” hole in left rear corner of cabinet top (inside

control hood) until it engages retainer nut located

on left rear corner gusset of cabinet (refer to

Figure 19).

5. Finger tighten screw.

IMPORTANT: Do not use a power driver to tighten

screw. Torque of a power driver could over-tighten

screw causing damage to cabinet assembly.

NOTE: Tamper-resistant screws, bits and bit

holder are available as optional equipment at extra

cost.

6. Secure control panel to control hood using two

No. 8 tamper-resistant screws, Part No. 35528.

7. Remove two screws holding front panel to base

of washer and install two No. 12 tamper-resistant

screws, Part No. 35527.

1

2

W276I

3

W276I

1 35528 No. 8 Screws

2 Double “D” Hole

3 35527 No. 12 Screws

Figure 19

Bit (No. 8 screws) Part No. 281P4

Bit (No. 12 screws) Part No. 282P4

Bit Holder (3/8 drive) Part No. 24161

Control Panel Tamper-Resistant Screw, Part No. 35528

38970

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Front Panel Tamper-Resistant Screw, Part No. 35527

23

Page 26

Notes

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970

Page 27

Operation

Operation Instructions for

Electromechanical Washers

IMPORTANT: Prior to first wash, use an allpurpose cleaner or a detergent and water solution

and a damp cloth to remove shipping dust from

inside of washtub.

IMPORTANT: Remove all sharp objects from

laundry to avoid tears and rips to items during

normal machine operation.

Step 1: Add Detergent

Pour measured amount of detergent into washtub. See

package directions.

NEVER POUR UNDILUTED BLEACH DIRECTLY

ON LAUNDRY. Follow package directions when

using bleach.

If desired, fabric softener may be added to rinse water

when RINSE light comes on.

Step 2: Load Laundry

Load dry clothes loosely into washtub – DO NOT

overload!

When washing large items such as shag rugs and

bedspreads, add several small items to balance wash

load.

W392I

Figure 21

Step 3: Close Lid

Figure 20

Washer will not operate with lid open.

W395I

W394I

Figure 22

38970

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Page 28

Operation

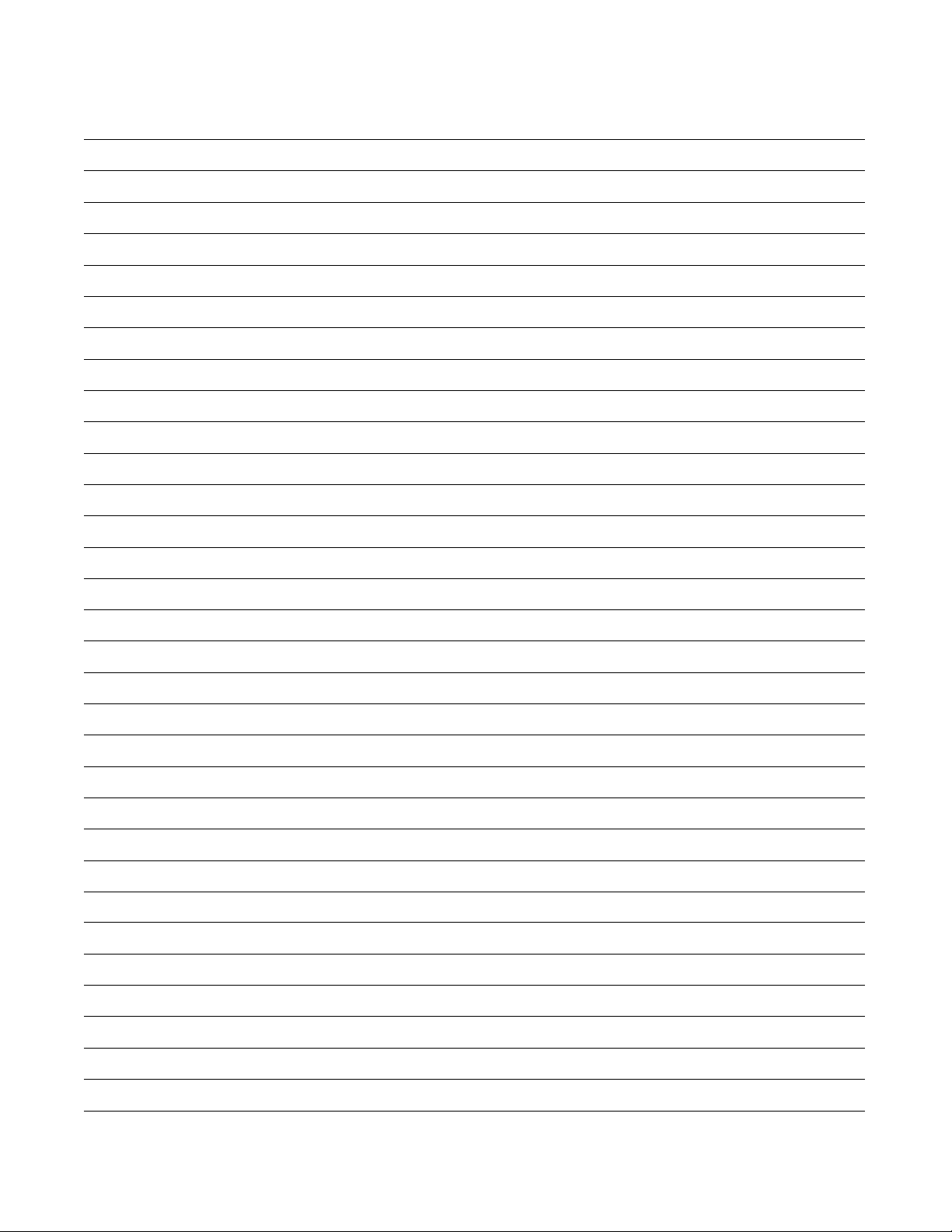

Step 4: Select Temperature Switch

One Speed Washers

Set at either HOT/NORMAL, WARM/PERM PRESS

or COLD/SPECIAL.

Two Speed Washers

Set at HOT (COLD rinse), WARM (COLD rinse) or

COLD (COLD rinse).

WARM / PERM PRESS

HOT

NORMAL

ONE SPEED WASHERS TWO SPEED WASHERS

COLD

SPECIAL

W385I

W385I W384I

Figure 23

WARM

HOT

WASH TEMPERATURE

COLD

W384I

Step 5: Set Fabric/Cycle Selector

NOTE: Setting may be changed at any time during

the cycle.

Step 6: Start Washer

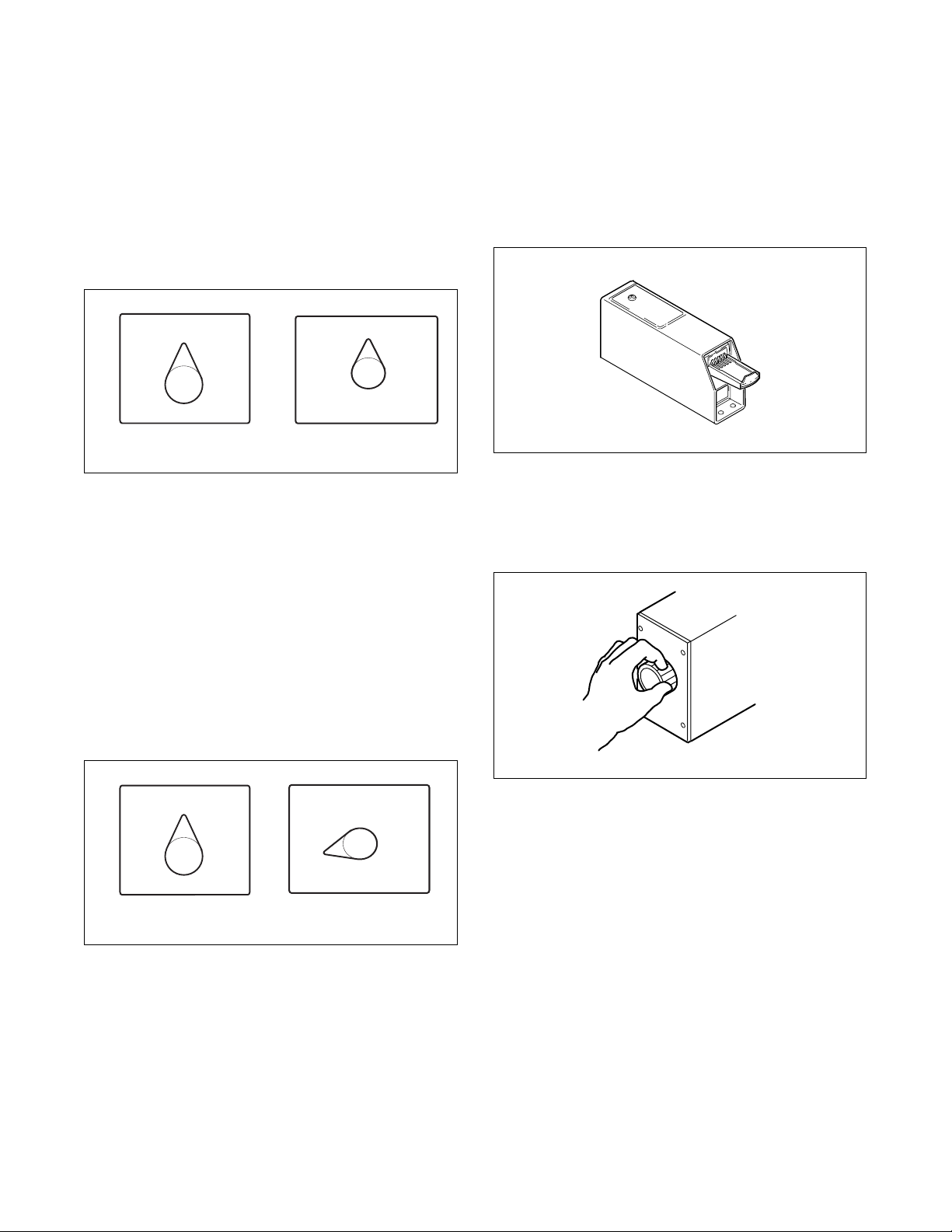

Metered Models

Insert money. Place coin(s) in slide and carefully push

in as far as possible and then pull slide out as far as

possible. (IN USE light will come on indicating start

of cycle.)

W297I

Figure 25

Nonmetered Models

Push timer knob in (IN USE light will come on

indicating start of cycle.)

One Speed Washers

Set at either HOT/NORMAL, WARM/PERM PRESS

or COLD/SPECIAL.

Two Speed Washers

Set Regular loads at NORMAL or PERM PRESS. Set

Delicate loads at DELICATE.

WARM / PERM PRESS

HOT

NORMAL

ONE SPEED WASHERS TWO SPEED WASHERS

COLD

SPECIAL

W385I

W385I W386I

Figure 24

PERM PRESS

NORMAL DELICATE

FABRIC SELECTOR

W386I

D774I

D774I

Figure 26

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970

Page 29

Operation

Indicator Lights

IN USE

This light will remain on while washer is in use.

RINSE

This light will be on during the rinse portion of the

cycle.

SPIN

This light will be on during the final spin only. Washer

will stop automatically at end of cycle. (SPIN light and

IN USE light will go out indicating end of cycle.)

Leave loading door open after removing laundry.

IMPORTANT: If washer fails to operate properly

after installation, make sure electrical service and

water supply faucets are turned on. Are all the

controls properly set? Have a qualified service

person refer to the wiring diagram (located inside

of washer control hood), check for broken, loose or

incorrect wiring.

Should washer stop, but IN USE, RINSE or SPIN light

remain on, the motor overload protector may have

cycled. Refer to page 38.

WARNING

To reduce the risk of bodily injury, do not

remove laundry from washer until all

lights are out, and all moving parts have

stopped.

W092

The washer will stop (pause) shortly before the first

spin and final spin.

38970

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

27

Page 30

Operation

Operation Instructions for

Electronic Display Control Washers

IMPORTANT: Prior to first wash, use an allpurpose cleaner or a detergent and water solution

and a damp cloth to remove shipping dust from

inside of washer.

IMPORTANT: Remove all sharp objects from

laundry to avoid tears and rips to items during

normal machine operation.

Step 1: Add Detergent

Pour measured amount of detergent into washtub. See

package directions.

NEVER POUR UNDILUTED BLEACH DIRECTLY

ON LAUNDRY. Follow package directions when

using bleach.

If desired, fabric softener may be added to rinse water

when RINSE light comes on.

Step 2: Load Laundry

Load dry clothes loosely into washtub – DO NOT

overload!

When washing large items such as shag rugs and

bedspreads, add several small items to balance wash

load.

W392I

Figure 28

Step 3: Close Lid

Figure 27

Washer will not operate with lid open.

W395I

TLW525N

Figure 29

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970

Page 31

Operation

Step 4: Set Fabric Selector

Push touchpad for NORMAL, PERM PRESS or

DELICATES. Light indicates selection.

W338IE0B

Figure 30

Step 5: Set Wash Temperature

Push touchpad for HOT, WARM or COLD. Light

indicates selection.

Step 6: Insert Money or Card

To Insert Money

Check pricing as seen on digital display. LID MUST

BE CLOSED TO START WASHER.

W388I

Figure 32

To Insert Card

Insert card into opening. Follow directions on display.

DO NOT REMOVE THE CARD UNTIL DISPLAY

READS “REMOVE CARD.” LID MUST BE

CLOSED TO START WASHER.

38970

W338IE1C

Figure 31

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

M330I

Figure 33

29

Page 32

Operation

Indicator Lights

WA S H

WASH is lit at the beginning of a Wash cycle and will

remain lit until the Wash cycle is complete.

RINSE

RINSE is lit at the beginning of the Rinse or Extra

Rinse cycle and will remain lit until the cycle is

complete.

SOAK

SOAK is lit at the beginning of all Pause cycles.

During a Wash Pause cycle, the display will light

WASH SOAK and during a Rinse or Extra Rinse

Pause cycle, the display will light RINSE SOAK.

SPIN

SPIN is lit for all Spin cycles. During a Wash Spin

cycle, the display will light WASH SPIN and during

an Extra Rinse Spin Cycle, the display will light

RINSE SPIN. At the beginning of Final Spin, the

display will light SPIN.

PRICE

PRICE is lit to indicate that value displayed is the vend

price remaining to be satisfied. Once the vend price is

satisfied, the word PRICE will go off.

TIME REMAINING

TIME REMAINING is lit to indicate that the number

displayed by two digits and the colon is the time

remaining in the current cycle. It will light at the start

of the cycle and remain lit until the cycle is completed.

INSERT COINS

INSERT COINS is lit to prompt the user for coins to

satisfy the vend price. When INSERT COINS is lit, the

three digits and decimal point show the vend price

remaining to be satisfied.

UNBALANCE

UNBALANCE is lit and will flash when the washer is

in a Spin mode and the lid is opened.

IMPORTANT: If washer fails to operate properly

after installation, make sure electrical service and

water supply faucets are turned on. Are all the

controls properly set? Have a qualified service

person refer to the wiring diagram (located inside

of washer control hood) and check for broken,

loose or incorrect wiring.

Should washer stop, but IN USE, RINSE or SPIN light

remain on, the motor overload protector may have

cycled. Refer to page 38.

WARNING

To reduce the risk of bodily injury, do not

remove laundry from washer until all

lights are out, and all moving parts have

stopped.

W092

The washer will stop (pause) shortly before the first

spin and final spin.

30

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970

Page 33

Operation

Operation Instructions for

MDC Washers

IMPORTANT: Prior to first wash, use an allpurpose cleaner, or a detergent and water solution,

and a damp cloth to remove shipping dust from

inside of washer.

IMPORTANT: Remove all sharp objects from

laundry to avoid tears and rips to items during

normal machine operation.

Step 1: Add Detergent

Pour measured amount of detergent into washtub.

Refer to package directions.

NEVER POUR UNDILUTED BLEACH DIRECTLY

ON LAUNDRY. Follow package directions when

using dry bleach.

If desired, fabric softener may be added to rinse water

when RINSE light comes on.

Step 2: Load Laundry

Load dry clothes loosely into washtub – DO NOT

overload!

When washing large items such as shag rugs and

bedspreads, add several small items to balance wash

load.

W392I

Figure 35

Step 3: Close Lid

Washer will not operate with lid open.

38970

W395I

Figure 34

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

TLW525N

Figure 36

31

Page 34

Operation

Step 4: Set Fabric Selector and Wash

Temperature

Push touchpad for NORMAL/HOT, NORMAL/

WARM, PERM PRESS/WARM or DELICATES/

COLD. Light indicates selection.

FLW1920N

FLW1920N

Figure 37

Step 5: Insert Money or Card

To Insert Money

Check pricing as seen on digital display.

W388I

Figure 38

To Insert Card

Insert card into opening.

32

Figure 39

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

DRY1927N

38970

Page 35

Operation

Step 6: Start Washer

After vend price has been satisfied, push the START

pad. LID MUST BE CLOSED TO START WASHER.

FLW1923N

Figure 40

Indicator Lights

WA S H

WASH is lit at the beginning of a Wash cycle and will

remain lit until the Wash cycle is complete.

RINSE

RINSE is lit at the beginning of the Rinse cycle and

will remain lit until the cycle is complete.

SPIN

SPIN is lit for all Spin cycles.

38970

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

33

Page 36

Operation

Operation Instructions for

NetMaster Washers

IMPORTANT: Prior to first wash, use an allpurpose cleaner, or a detergent and water solution,

and a damp cloth to remove shipping dust from

inside of washer.

IMPORTANT: Remove all sharp objects from

laundry to avoid tears and rips to items during

normal machine operation.

Step 1: Add Detergent

Pour measured amount of detergent into washtub.

Refer to package directions.

NEVER POUR UNDILUTED BLEACH DIRECTLY

ON LAUNDRY. Follow package directions when

using dry bleach.

If desired, fabric softener may be added to rinse water

when RINSE light comes on.

Step 2: Load Laundry

Load dry clothes loosely into washtub – DO NOT

overload!

When washing large items such as shag rugs and

bedspreads, add several small items to balance wash

load.

W392I

Figure 42

Step 3: Close Lid

Figure 41

Washer will not operate with lid open.

W395I

TLW525N

Figure 43

34

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970

Page 37

Operation

Step 4: Set Fabric Selector

Push touchpad for NORMAL, PERM PRESS or

DELICATES. Light indicates selection.

Figure 44

Step 5: Set Wash Temperature

Push touchpad for HOT, WARM or COLD. Light

indicates selection.

Step 6: Insert Money or Card

To Insert Money

Check pricing as seen on digital display.

W524I

W388I

Figure 46

To Insert Card

Insert card into opening. DO NOT REMOVE THE

CARD UNTIL “REMOVE CARD” LED is lit.

38970

W525I

Figure 45

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

M343I

Figure 47

35

Page 38

Operation

Step 7: Start Washer

After vend price has been satisfied, push the START

pad. LID MUST BE CLOSED TO START WASHER.

W526I

Figure 48

Indicator Lights

WA S H

WASH is lit at the beginning of a Wash cycle and will

remain lit until the Wash cycle is complete.

RINSE

RINSE is lit at the beginning of the Rinse or Extra

Rinse cycle and will remain lit until the cycle is

complete.

SPIN

SPIN is lit for all Spin cycles.

ADD COINS/INSERT CARD

ADD COINS/INSERT CARD is lit to prompt the user

to insert coins or a card to satisfy the vend price. When

ADD COINS/INSERT CARD is lit, the digits and

decimal point show the vend price remaining to be

satisfied.

REMOVE CARD (Card Models Only)

REMOVE CARD flashes after the START pad has

been pressed and the vend has been deducted from the

card.

36

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970

Page 39

Maintenance

To reduce the risk of electric shock,

disconnect the electrical power to the

washer before attempting to service.

W094

WARNING

Variable Water Level Control

The washer is equipped with a variable water level

pressure switch (located inside the control hood)

which allows the owner to adjust the water fill level

height in the washtub from 254.0, 279.4 or 330.2 mm

(10, 11 or 13 inches).

IMPORTANT: If the 25.4 cm (10 inch) water

conservation setting is selected, washing

performance and machine reliability may be

reduced.

When the washer leaves the factory, the pressure

switch is set for approximately 279.4 mm (11 inches)

of water.

To adjust the pressure switch, proceed as follows:

4. Carefully reinstall the control panel.

5. Reconnect the electrical power to the washer.

6. Run the washer through a cycle and observe the

water fill level.

WARNING

Any disassembly requiring the use of

tools must be performed by a suitably

qualified service person.

W299

1

2

1. Remove the two control panel attaching screws

and lift the assembly up and out of the slots in the

cabinet top.

2. Lay the control panel face down (on protective

padding) on top of the washer.

3. Rotate the cam on the pressure switch clockwise

to lower the water fill height, or

counterclockwise to raise the height. Refer to

Figure 49.

IMPORTANT: The cam has three settings. The

setting on the left raises water level to 254.0 mm

(10 inches). Middle setting raises water level to

279.4 mm (11 inches). The setting on the right

raises water level to 330.2 mm (13 inches).

4

W157I

3

W157I

1 Cabinet Top

2 Rotating Cam

3 Pressure Switch

4 Pressure Hose

Figure 49

38970

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37

Page 40

Maintenance

User-Maintenance Instructions

Cold Weather Care

If the washer is delivered on a cold day (below

freezing), or is stored in an unheated room or area

during the cold months, do not attempt to operate the

washer until it has had a chance to warm up.

Care of Your Washer

Use only a damp or sudsy cloth for cleaning the

control panel. Some cleaning products may harm the

finish on the control panel. Wipe the panel dry after

cleaning.

Wipe the washer cabinet as needed. If detergent,

bleach or other washing products are spilled on the

cabinet, wipe immediately. Some products will cause

permanent damage if spilled on the cabinet.

Do not use scouring pads or abrasive cleansers.

The washtub will need no particular care though it

may need rinsing or wiping after some unusual loads

have been washed. This also may be necessary if too

little detergent has been used.

Leave the loading door open to allow the inside of the

washer to dry out after use. This helps prevent musty

odors from developing.

Reinstallation of Shipping Materials

Shipping Brace

The shipping brace in the lid opening should be saved

and reinstalled whenever the washer is moved. To

reinstall the brace, open the washer lid and place the

brace over the washer agitator, placing the back of the

brace into the lid opening first.

Shipping Plug

The plastic shipping plug should be saved and

reinstalled any time the washer is moved. The plug fits

into two openings: The base opening and the shipping

plug opening on the bottom of the movable pivot dome.

The plug MUST be inserted into both openings to

prevent damage to the washer. In order to accomplish

this, the shipping plug opening must be directly lined

up with the base opening. Refer to Fig ure 50.

1

4

The agitator should not be removed except for service.

The washtub is designed to be self cleaning.

Replacing Hoses

Hoses and other natural rubber parts deteriorate after

extended use. Hoses may develop cracks, blisters or

material wear from the temperature and constant high

pressure they are subjected to.

All hoses should be checked on a yearly basis for any

visible signs of deterioration. Any hose showing the

signs of deterioration listed above should be replaced

immediately. All hoses should be replaced every five

years.

Filter Screens

Check the filter screens in the fill hoses for debris or

damage annually. Clean or replace them if necessary.

If the washer is filling with water slower than normal,

check the filter screens. Clean or replace them if

necessary.

Order filter screen Part No. F270300 from the nearest

authorized parts distributor.

2

TLW1945N

3

TLW1945N

1 Shipping Plug Opening

2 Base Opening

3 Shipping Plug

4 Shipping Brace

Figure 50

Motor Overload Protector

The internal overload protector will stop the motor

automatically in the event of an overload.

The overload protector will reset itself in two or three

minutes and the motor will restart automatically.

If the overload protector stops motor again, remove the

washer from use and call the service person to correct

the problem.

38

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970

Page 41

Before You Call for Service

You may save time and money by checking the

following:

If the Washer:

Maintenance

Won’t

Fill

Won’t

Start

Won’t

Agitate

Won’t

Spin

••••

••••

••••

••••

••••

••••

•

•

•

••

Possible Reason – Do This to Correct

Place coin(s) in slide or drop (metered models only).

Push timer knob in to start the washer (nonmetered

models only).

Be sure the power cord is plugged all the way into the

electrical outlet.

Close the loading door.

Check the laundry room fuse or circuit breaker.

Has the motor overload protector cycled? Refer to

page 38.

Turn on the hot and cold water faucets.

Was the last spin completed?

Water is siphoned from the washer during the cycle.

Refer to page 21.

Are the controls properly set?

••

•

Have a qualified electrician check polarity and

grounding. Refer to page 17.

Clean the screens in the water mixing valve and the filter

screens in the fill hoses.

38970

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

39

Page 42

Maintenance

If Service Is Required

If service is required, contact the nearest Factory

Authorized Service Center.

If you are unable to locate an authorized service center

or are unsatisfied with the service performed on your

unit, contact:

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

Phone: (920) 748-3121

1

When calling or writing about your unit, PLEASE

GIVE THE MODEL AND SERIAL NUMBERS. The

model and serial numbers are located on the

nameplate. The nameplate will be in the location

shown in Figure 51.

Please include a copy of your bill of sale and any

service receipts you have.

WARNING

To reduce the risk of serious injury or death,

DO NOT repair or replace any part of the

unit or attempt any servicing unless

specifically recommended in the usermaintenance instructions or in published

user-repair instructions that you understand

and have the skills to carry out.

W329

1 Nameplate

40

W138P

Figure 51

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

W138P

38970

Page 43

Information for Handy Reference

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

Date Purchased

Model Number Serial Number

Dealer’s Name

Dealer’s Address Phone Number

Service Agency

Service Agency Address Phone Number

NOTE: Record the above information and keep your sales slip. Model and serial numbers are

located on the nameplate.

Maintenance

38970

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

41

Page 44

Page 45

Lavadoras

automáticas

Instalación/operación

Guarde estas instrucciones para referencia en el futuro.

(Si esta máquina cambia de dueño, asegúrese de que este manual vaya con la misma).

www.comlaundry.com

W446I

Pieza No. 38970R10

Noviembre 2004

Page 46

Page 47

Para su seguridad y para reducir el riesgo

de incendio o explosión, absténgase de

guardar o utilizar gasolina u otros líquidos

o vapores inflamables cerca de ésta o de

cualquier otra máquina.

IMPORTANTE: Lea completamente las

INSTRUCCIONES DE INSTALACIÓN/

OPERACION antes de usar la lavadora.

ADVERTENCIA

W022SD

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT38970 (SP)

45

Page 48

Notas

46

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970 (SP)

Page 49

Tabla de

contenido

Repuestos............................................................................................. 49

Información de seguridad .................................................................. 51

Explicación de los mensajes de seguridad............................................ 51

Instrucciones de seguridad importantes................................................ 51

Instalación ........................................................................................... 55

Caja del medidor................................................................................... 55

Modelos preparados para lector de tarjetas .......................................... 55

Dimensiones y especificaciones ........................................................... 56

Antes de empezar.................................................................................. 57

Herramientas.................................................................................... 57

Aspectos eléctricos........................................................................... 57

Agua................................................................................................. 57

Instalación de la lavadora ..................................................................... 57

Paso 1: Retire la abrazadera y el tapón de envío ............................. 57

Paso 2: Limpie el interior de la cuba de colada ............................... 58

Paso 3: Conecte las mangueras de llenado ...................................... 58

Paso 4: Conecte la manguera de desagüe al receptáculo

de desagüe ...................................................................................... 60

Paso 5: Sitúe y nivele la lavadora .................................................... 61

Paso 6: Conecte la lavadora a la corriente eléctrica......................... 62

Paso 7: Añada agua a la lavadora .................................................... 63

Paso 8: Verifique el interruptor de la tapa ....................................... 63

Paso 9: Revise la instalación............................................................ 63

Requisitos eléctricos............................................................................. 64

Instrucciones para la puesta a tierra................................................. 66

Requisitos de suministro de agua ......................................................... 67

Temperatura del agua....................................................................... 67

Presión de agua ................................................................................ 67

Tubos verticales ascendentes ........................................................... 68

Instalaciones de desagüe....................................................................... 68

Seguridad adicional de la lavadora....................................................... 69

Operación ............................................................................................ 71

Instrucciones de operación para lavadoras electromecánicas............... 71

Paso 1: Añada detergente................................................................. 71

Paso 2: Introduzca la colada ............................................................ 71

Paso 3: Cierre la tapa ....................................................................... 71

Paso 4: Seleccione una temperatura en el conmutador.................... 72

Paso 5: Ajuste el selector de tela/ciclo............................................. 72

Paso 6: Arranque la lavadora ........................................................... 72

Luces indicadoras............................................................................. 73

© Copyright 2004, Alliance Laundry Systems LLC

Reservados todos los derechos. Ninguna sección del presente manual puede reproducirse ni transmitirse en forma

alguna ni a través de ningún medio sin el consentimiento expreso por escrito del editor.

38970 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

47

Page 50

Instrucciones de operación para lavadoras con control electrónico

en pantalla........................................................................................... 74

Paso 1: Añada detergente................................................................. 74

Paso 2: Introduzca la colada ............................................................ 74

Paso 3: Cierre la tapa ....................................................................... 74

Paso 4: Fije el selector de tela.......................................................... 75

Paso 5: Seleccione la temperatura de lavado................................... 75

Paso 6: Inserte monedas o tarjeta..................................................... 75

Luces indicadoras............................................................................. 76

Instrucciones de operación para lavadoras MDC................................. 77

Paso 1: Añada detergente................................................................. 77

Paso 2: Introduzca la colada ............................................................ 77

Paso 3: Cierre la tapa ....................................................................... 77

Paso 4: Ajuste el selector de telas y la temperatura de lavado......... 78

Paso 5: Inserte monedas o tarjeta..................................................... 78

Paso 6: Arranque la lavadora ........................................................... 79

Luces indicadoras............................................................................. 79

Instrucciones de operación para lavadoras NetMaster ......................... 80

Paso 1: Añada detergente................................................................. 80

Paso 2: Introduzca la colada ............................................................ 80

Paso 3: Cierre la tapa ....................................................................... 80

Paso 4: Fije el selector de tela.......................................................... 81

Paso 5: Seleccione la temperatura de lavado................................... 81

Paso 6: Inserte monedas o tarjeta..................................................... 81

Paso 7: Arranque la lavadora ........................................................... 82

Luces indicadoras............................................................................. 82

Mantenimiento .................................................................................... 83

Control del nivel de agua variable........................................................ 83

Instrucciones de mantenimiento del usuario......................................... 84

Cuidado en clima frío....................................................................... 84

Cuidado de la lavadora..................................................................... 84

Reemplazo de mangueras ................................................................ 84

Rejillas del filtro .............................................................................. 84

Reinstalación de materiales de envío............................................... 85

Protector de sobrecarga del motor ........................................................ 85

Antes de llamar al servicio técnico....................................................... 86

Si es necesario efectuar el servicio....................................................... 87

Información de referencia rápida.......................................................... 88

Lista de comprobacíon del instalador............................ Contraportade

48

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970 (SP)

Page 51

Repuestos

Si se necesitan repuestos, comuníquese con el lugar

donde compró la lavadora o con:

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

Teléfono: (920) 748-3950

para averiguar el nombre y la dirección del distribuidor

de repuestos autorizado más cercano.

38970 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

49

Page 52

Notas

50

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38970 (SP)

Page 53

Información de seguridad

Indica una situación de peligro inminente

que, si no se evita, ocasionará lesiones

personales graves o la muerte.

PELIGRO

Indica una situación de peligro que, si no

se evita, podría ocasionar lesiones

personales graves o la muerte.

ADVERTENCIA

Indica una situación de peligro que, si no

se evita, puede ocasionar lesiones

personales leves o moderadas, o daños a

la propiedad.

PRECAUCIÓN

Explicación de los mensajes de

seguridad

En este manual y en las calcomanías de la máquina,

encontrará avisos de precaución ("PELIGRO",

“ADVERTENCIA” y “PRECAUCIÓN”), seguidos de

instrucciones específicas, que sirven para proteger la

seguridad personal del operador, usuario, técnico de

servicio y aquellas personas responsables del

mantenimiento de la máquina.

Instrucciones de seguridad

importantes

Guarde estas instrucciones

ADVERTENCIA

Para reducir el riesgo de incendios,

electrocución y lesiones graves o

mortales cuando use la lavadora, tome

estas precauciones básicas:

W023SR1

1. Lea todas las instrucciones antes de usar la

lavadora.

2. Consulte las INSTRUCCIONES DE PUESTA A

TIERRA en el manual de INSTALACIÓN para

conectar bien a tierra la lavadora.

3. No lave artículos que previamente se hayan

limpiado, lavado, puesto en remojo o manchado

de gasolina, disolventes de tintorería u otras

sustancias explosivas o inflamables, ya que éstas

desprenden vapores que pueden inflamarse o

estallar.

Otros avisos de precaución, tales como

“IMPORTANTE” y “NOTA”, van seguidos de

instrucciones específicas.

IMPORTANTE: La palabra “IMPORTANTE” se

utiliza para informar al lector sobre

procedimientos específicos donde se producirán

daños menores a la máquina en caso de que no se

siga el procedimiento.

NOTA: La palabra “NOTA” se utiliza para

comunicar información de instalación, operación,

mantenimiento o servicio técnico que sea

importante pero que no se relacione con un riesgo.

4. No añada gasolina, disolventes de tintorería ni

otras sustancias inflamables o explosivas al agua

de lavado. Estas sustancias desprenden vapores

que pueden inflamarse o estallar.

5. En ciertas condiciones, se puede desprender

hidrógeno en un sistema de agua caliente que no

se haya usado durante dos semanas o más. EL

HIDRÓGENO ES UN GAS EXPLOSIVO. Si no

se ha usado el sistema de agua caliente durante el

período mencionado, abra todas las llaves de

agua caliente y deje correr el agua por cada una

de ellas durante varios minutos antes de usar una

lavadora o combinación de lavadora y secadora.

Esto liberará el hidrógeno que pueda estar

acumulado. ESTE GAS ES INFLAMABLE,

POR LO QUE NO SE DEBE FUMAR NI USAR

UNA LLAMA ABIERTA DURANTE ESTE

TIEMPO.

6. No permita que niños jueguen en la lavadora ni

en sus alrededores. No debe permitir que niños ni

personas enfermas utilicen este aparato sin

supervisión. Deberá asegurarse de que los niños

no jueguen con el aparato.

38970 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

51

Page 54

Información de seguridad

7. Antes de poner la lavadora fuera de servicio o

desecharla, quite la tapa del compartimento de

lavado.