Page 1

28 TON VERTICAL/HORIZONT AL

15 TON HORIZONT AL

LOG SPLITTER

LOG SPLITTER

MODEL NO. LS401105 (40110500)

MODEL NO. LS401105H (401105H0)

ASSEMBL Y & OPERA TING INSTRUCTIONS

Owner’s Manual

THIS SAFETY ALERT SYMBOL IDENTIFIES IMPORTANT SAFETY MESSAGES IN THIS MANUAL.

LS79-726-0210

Rev 5

Page 2

Table of Contents

Page(s)

Important Safety Information................................................................................................................. 1-6

Intended Use ......................................................................................................................... 1

Personal Protective Equipment ............................................................................................... 1

Safety Decals ....................................................................................................................... 1-2

General Safety ...................................................................................................................... 3

Preparation of the Log ........................................................................................................... 3

Work Area ........................................................................................................................... 3

Operation of the Log Splitter .................................................................................................. 3-4

Repair and Maintenance Safety ............................................................................................. 4

Hydraulic Safety .................................................................................................................. 5

Fire Prevention ..................................................................................................................... 5-6

Towing Safety ...................................................................................................................... 6

Assembly Instructions ...................................................................................................................... 7

Operating Instructions ....................................................................................................................... 7-9

Engine Oil Recommendations ................................................................................................ 8

Starting Instructions ............................................................................................................... 8

Towing .................................................................................................................................. 9

Operation .............................................................................................................................. 9

Maintenance ...................................................................................................................................... 9

Parts List ........................................................................................................................................ 10-11

Parts Breakdown Illustration ............................................................................................................... 12

Notes ................................................................................................................................................ 13

Specifications .................................................................................................................................. Back Cover

Page 3

WARNING: Read and thoroughly understand all instructions and safety information before assembling

or operating this log splitter. Failure to do so may cause serious injury or death. Do not allow anyone

to operate this log splitter who has not read this manual. As with all power equipment, a log splitter

can be dangerous if assembled or used improperly. Do not operate this log splitter if you have doubts

or questions concerning safe operation. Call our customer service department at 1-800-525-8322 to

address these concerns.

Si no entiende ingles, se prefiere que busque alguien que interprete las instrucciones para usted.

INTENDED USE

NEVER use this log splitter for any other purposes than splitting wood. It is designed for this use only. Any other use can

cause serious injury or death.

PEPER

PERSONAL PROTECTIVE EQUIPMENT

PERPERSONALSONAL PROTECTIVE EQUIPMENT

BEFORE operating this log splitter make sure that you wear safety gear such as goggles or safey glasses, steel toed shoes

and tight fitting gloves (without loose cuffs or draw strings). Always wear a protective hearing device when operating this log

splitter.

NEVER wear loose clothing or jewelry that can be caught by moving parts of the log splitter . Keep clothing and hair away

from all moving parts when operating this log splitter .

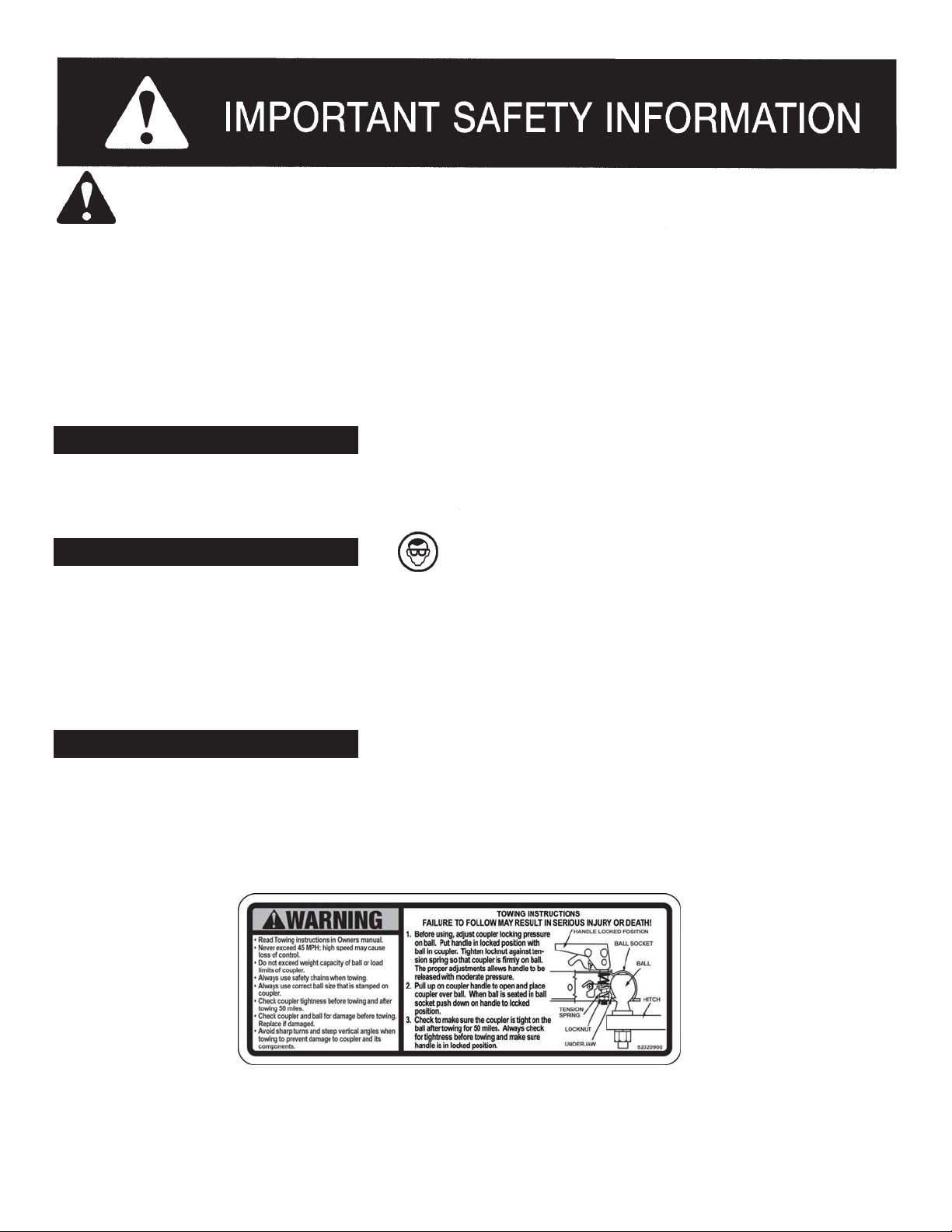

SAFETY DECALS

Make sure that all safety warning decals are in good condition and readable. Always replace missing or defaced decals.

Write us or call 1-800-525-8322 and they will be sent to you at no charge.

P ART NUMBER: 52020000

LOCA TION: TOP, FRONT END OF TONGUE

Page 1

Page 4

PA RT NUMBER: 51018900

LOCA TION: TOP OF HYDRAULIC CYLINDER

P ART NUMBER: 52055200

LOCA TION:TOP , FRONT END OF

HYDRAULIC CYLINDER

P ART NUMBER: 52023200

LOCA TION: HYDRAULIC T ANK

LOWER T ANK, RIGHT CORNER

Page 2

Page 5

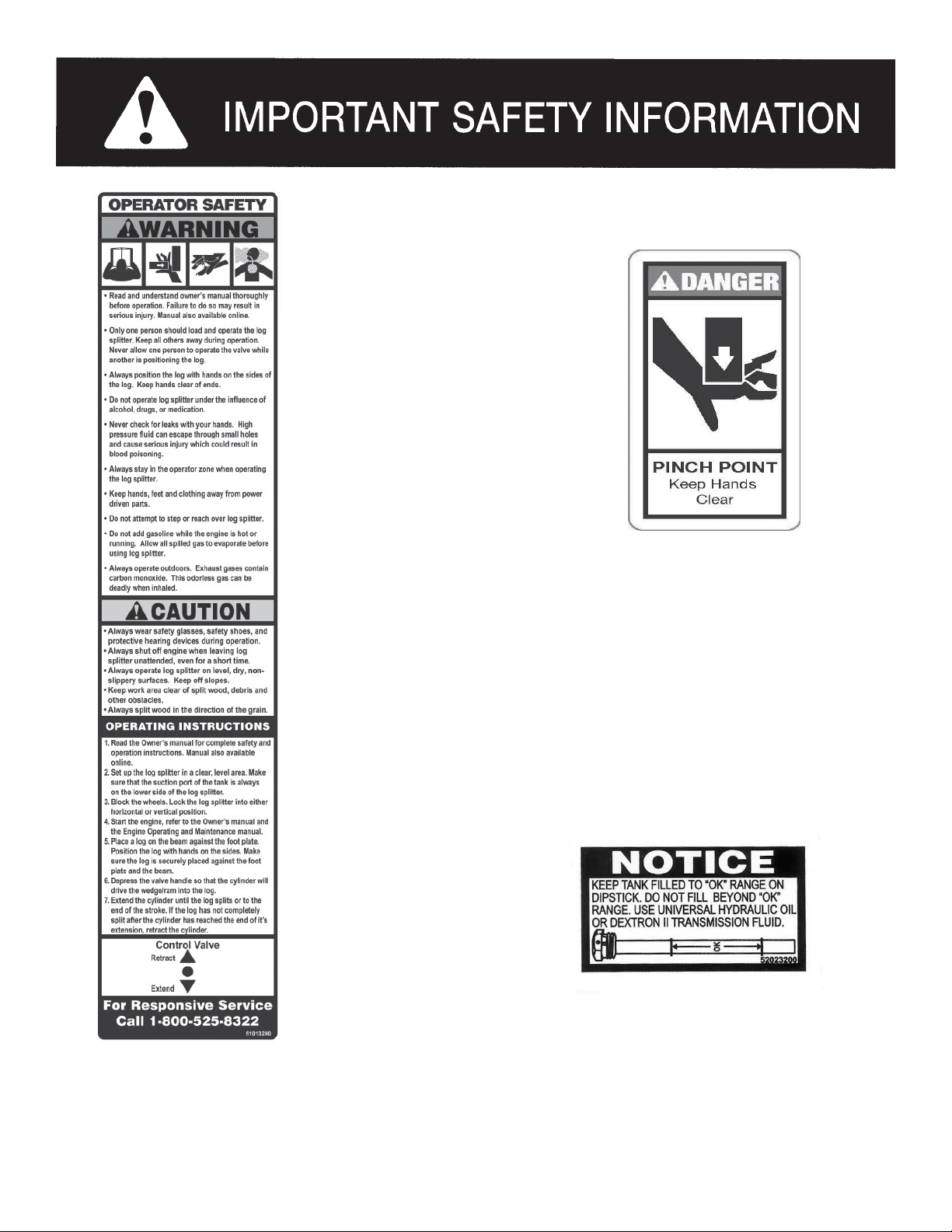

GENERAL SAFETY

Failure to follow these instructions may result in serious injury or death.

EVER

NEVER allow children to operate this log splitter. NEVER allow adult s lacking proper instructions and understanding to

operate this log splitter.

KEEP all people and pets a minimum of 10 feet away from your work area when operating this log splitter. Only the operator

is to be near the log splitter during use.

If a helper is assisting in loading logs, NEVER actuate the control until the helper is clear of the work area.

NEVER operate the log splitter when under the influence of alcohol, drugs or medication.

NEVER allow a person who is tired or otherwise not alert to use your log splitter.

PREP ARA TION OF THE LOG

Both ends of the log should be cut as square as possible to help prevent the log from riding out of the splitter during

operation. Do not split logs greater than 26 in. in length.

WORK AREA

NEVER operate the log splitter on slippery , wet, muddy or icy ground.

ONLY operate your log splitter on level ground. Operating on a slope could cause the log splitter to roll over or logs to fall of f.

NEVER operate your log splitter in an enclosed area. Exhaust fumes contain carbon monoxide which can be deadly when

inhaled.

NEVER attempt to move your log splitter over hilly or uneven terrain without a tow vehicle or adequate help.

ALWAYS block the wheels to prevent movement of the log splitter while in operation.

ONLY operate your log splitter in daylight or under good artificial light.

ALWAYS keep the work area clean. Remove split wood around your log splitter immediately so that you don’t stumble

over it.

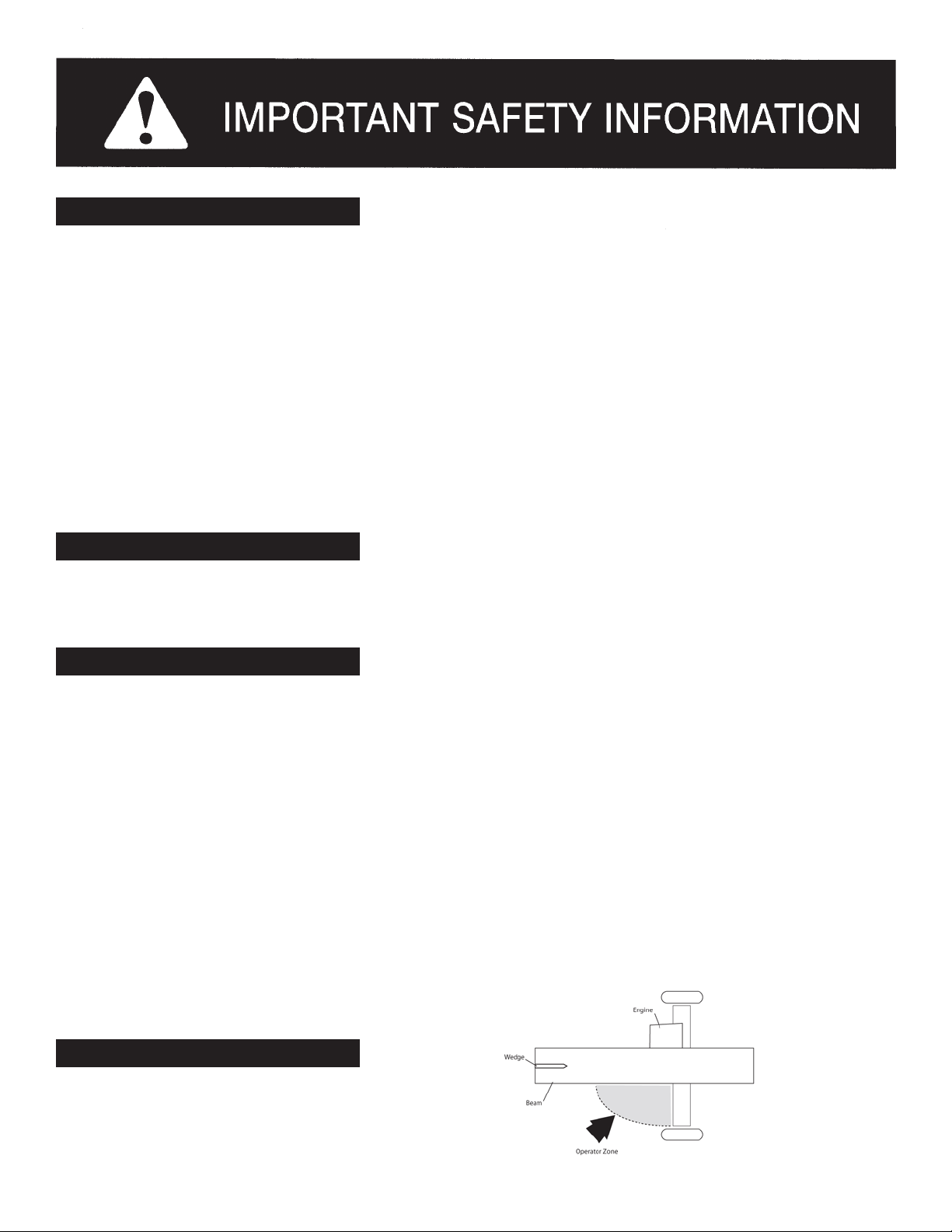

OPERATION OF THE LOG SPLITTER

ONLY operate the log splitter from the operator zone.

Page 3

Page 6

KNOW how to stop the log splitter and disengage the controls before operating it.

NEVER place hands or feet between the log and splitting wedge or ram during forward or reverse stroke. Serious injury or

death could result.

NEVER straddle or step over the log splitter during operation.

NEVER reach or bend over the log splitter to pick up a log.

NEVER try to split two logs on top of each other.

NEVER try to cross split a second log.

NEVER allow one person to operate the valve while another is positioning the log.

NEVER attempt to load your log splitter when the ram is in motion.

ALWAYS use your hand to operate the control lever on the valve. NEVER use your foot, a rope or any extension device.

NEVER move the log splitter while the engine is running. Shut off the engine even if you are leaving the log splitter for a short

period of time.

ALWAYS avoid cont act with the muffler and other hot areas of the engine during operation to prevent burns.

REP AIR AND MAINTENANCE SAFETY

NEVER operate your log splitter when it is in poor mechanical condition or in need of repair.

Periodically check that all nuts, bolts, screws, hydraulic fittings and hose clamps are tightened.

NEVER alter your log splitter in any manner such as adding a rope or extenstion to the control lever or adding to the width or

height of the wedge. Such alterations may cause your log splitter to be unsafe and will void the warranty .

Perform all recommended maintenance procedures before using your log splitter.

Replace all damaged or worn parts immediately .

NEVER tamper with the engine to run it at excessive speeds. The maximum engine speed is preset by the manufacturer and

is within safety limits.

ALWAYS remove the spark plug wire before performing any service or repair on your log splitter .

ALW AYS check the level of hydraulic oil and engine oil before operation.

ALL replacement parts must meet manufacturer’s specifications.

Page 4

Page 7

HYDRAULIC SAFETY

The hydraulic system of your log splitter requires careful inspection along with the mechanical parts. Be sure to

replace frayed, kinked, cracked or otherwise damaged hydraulic hose and components.

NEVER check for leaks of hydraulic fluid with your hand. Fluid escaping from a small hole can be almost invisible.

Escaping fluid under pressure can have sufficient force to penetrate skin causing serious personal injury or even death.

Leaks can be detected by passing a piece of cardboard over the suspected leak and looking for discoloration.

ALWAYS seek professional medical attention immediately if injured by escaping hydraulic fluid. Serious infection or reaction

can develop if proper medical treatment is not administered immediately .

ALWAYS be sure to relieve all pressure by shutting of f the engine and moving the valve control handle back and forth

should it become necessary to loosen or remove any hydraulic fitting.

NEVER remove the cap from the hydraulic tank or reservoir while the log splitter is running. Hot oil under pressure

could result in serious injury .

NEVER adjust the hydraulic valve. The pressure relief valve on your log splitter is preset at the factory . Only a qualified

service technician should perform this adjustment.

FIRE PREVENTION

NEVER operate your log splitter near a flame or spark. Hydraulic oil and gasoline are flammable and can explode.

NEVER fill the gas t ank while the engine is hot or running. Allow the engine to cool before refueling.

NEVER smoke while operating or refueling your log splitter. Gas fumes can easily explode.

ONLY refuel your log splitter in a clear area with no gas fumes or spilled gas.

ALWAYS use an approved fuel container .

ALWAYS replace the gas cap securely .

If gasoline has spilled, move the log splitter away from the area of the spill and avoid creating any source of ignition until the

spilled gas has evaporated.

ALWAYS take a Class B fire extinguisher with you when operating this log splitter in dry areas as a precautionary

measure against possible flying sparks.

ALWAYS drain the fuel tank prior to storage to avoid the potential fire hazard.

ALWAYS store gasoline in an approved, tightly sealed container . S tore the container in a cool, dry place.

NEVER store gasoline in the house or near a heating appliance.

Page 5

Page 8

IMPORTANT NOTE:

This log splitter is equipped with an internal combustion engine and should not be used on or near any unimproved forestcovered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in efffective working order by the

operator. In the state of California a sp ark arrester is required by law . Other states have similar laws. Federal laws apply on

federal lands. A spark arrester muf fler (optional by manufacturer) is available as an accessory at your nearest engine dealer

Always check the legal requirements in your area.

TOWING SAFETY

ALWAYS check all local and state regulations regarding towing, licensing, and lights before towing your log splitter.

ALWAYS check before towing to make sure that the log splitter is correctly and securely attached to the towing vehicle

and that the safety chains are secured to the hitch or bumper of the vehicle with enough slack to allow turning. Always

use a Class I, 2” ball with this log splitter.

NEVER carry any cargo or wood on your log splitter.

NEVER allow anyone to sit or ride on your log splitter .

ALWAYS disconnect your log splitter from the towing vehicle before operating it.

ALWAYS be careful when backing up with your log splitter in tow . It could jackknife.

ALWAYS allow for added length of your log splitter when turning, parking, crossing interesections and in all driving

situations.

NEVER exceed 45 mph when towing your log splitter. T owing the log splitter at speeds higher than 45 mph could result

in loss of control, damage to the equipment , serious injury or death. Adjust towing speed for terrain and conditions.

Be extra cautious when towing over rough terrain especially railroad crossings.

Page 6

Page 9

ASSEMBLY INSTRUCTIONS

NOTE: This log splitter was partially assembled at the factory. Refer to the drawing and parts list should it become necessary to disassemble the

unit for repair or replacement of parts.

STEP 1: Remove all the components from the crate. Inspect each piece for shipping damage. If any part is damaged, contact your dealer or

delivering carrier.

NOTE: Refer to the exploded view drawing on pages 11 and 12 when assembling this log splitter

STEP 2: Remove the tank/engine assembly (2) from the crate and set it on the ground. Make sure that it is stable.

STEP 3: Remove the rubber covering from the two spindles on the tank/axle (2). The wheel bearing cups, bearing cones, grease seals and hub

caps are already assembled. Bearing cones have been greased at the factory. Remove the hub cap (53) by prying it loose with a

common tip screwdriver. Mount the wheels (45) to the spindles on the tank/axle (2) using the 3/4 in. light flatwasher (50) and 3/4 in.

slotted nut (51) from the hardware kit.Tighten the nut until bearing play is removed and the wheel will still rotate freely . Install the cotter

pin (52) and hub cap (53). Repeat step 4 for the other wheel.

STEP 4: Check to make sure that the tank/axle assembly (2) is stable and will not roll. Blocking the wheels will help to prevent any movement. Position the

beam assembly (1) over the plate with the four holes on the tank/engine assembly (2). When the holes are aligned, insert the four 1/2 in. UNC x

1 in. GR 5 bolts (26), the four 1/2 in. lock washers (25) and the four 1/2 in. UNC nuts (24). Tighten the nuts and bolts.

STEP 5: Connect the 3/4 in. x 7-1/2 in. return hose (22) to the 3/4 in. 45° fitting on the valve (4). Secure with a hose clamp (19). Tighten clamp.

STEP 6: Connect the 1/2 in. x 21 in. pressure hose (21) to the swivel fitting (40) on the valve (4). Tighten.

OPERATING INSTRUCTIONS

STEP 1: STARTING

WARNING: Read and thoroughly understand all instructions and safety information before operating

this log splitter. Failure to do so may cause serious injury or death. Do not allow anyone to operate this

log splitter who has not read this manual. As with all power equipment, a log splitter can be dangerous

if assembled or used improperly. Do not operate this log splitter if you have doubts or questions

concerning safe operation. Call our customer service department at 1-800-525-8322 to address these

concerns.

Si no entiende ingles, se prefiere que busque alguien que interprete las instrucciones para usted.

IMPORTANT: The engine and hydraulic tank are shipped without oil. See the engine operating and maintenance instructions manual packed

with the log splitter for the type of crankcase oil, fuel, etc. The engine manufacturer recommends lead-free gasoline only .

Please note that this log splitter is available with either a SpeeCo 6.5 HP or a Honda GC 190 engine. Please follow the appropriate

instructions for your engine.

CAUTION: DO NOT START OR RUN THE ENGINE WITHOUT OIL IN THE HYDRAULIC RESERVOIR AND IN

THE ENGINE.

STEP 2: The hydraulic reservoir should be filled with an AW46 hydraulic oil. If hydraulic oil is difficult to obtain, automatic transmission fluid can

be substituted and should be used instead of hydraulic oil when temperatures are below 32 degrees. Use only clean oil and take care to

prevent dirt from entering the hydraulic reservoir.

CAUTION: WHEN TIGHTENING THE BREATHER CAP ON THE TANK, POINT THE HOLE AWAY FROM THE ENGINE

AND THE OPERATOR ZONE.

Page 7

Page 10

ENGINE OIL RECOMMENDA TIONS

SpeeCo 6.5 HP

Use 4-stroke automotive detergent oil. SAE 10W-30 is recommended for general use. Refer to the SAE Viscosity Grades chart on page 17 of your engine

owner’s manual for average temperature ranges. The engine manufacturer recommends using API SERVICE Category SE or SF oil.

The engine oil capacity is 0.63 US qt (0.6 L).

Always check oil level before starting the engine. Keep oil level at full.

Honda GC190

For temperatures above 50 degrees F , use an SAE 30W oil. Using multigrade oil may increase oil consumption. For temperatures below 50 degrees F use

and SAE 10W-30 oil. Using SAE 30W oil below 40 degrees F will result in hard starting and possible engine bore damage due to inadequate lubrication. SAE

10W-30 is recommended for general use. Refer to Honda engine owner’s manual. Oil capacity is 0.56 quart

(18 ounces; 0.53 liter).

Always check oil level before starting the engine. Keep oil level at full.

DIRECTIONS FOR FILLING HYDRAULIC SYSTEM

Fill the hydraulic reservoir with at least two gallons of hydraulic fluid. After the hydraulic reservoir and the engine crankcase are filled with oil, start the

engine. The hydraulic pump should prime itself. With the engine running, move the hydraulic valve lever toward the wedge. This will cause the cylinder to

extend and expel air. When the cylinder is fully extended, retract it. Repeat this procedure several times. An erratic movement of the cylinder indicates that

there is still air in the system. More oil should then be added to bring the fluid level up to the “OK” range on the dipstick. T otal hydraulic capacity is 2.5

gallons.

NOTE: If the tank is overfilled, it will tend to expel oil from the breather cap when the cylinder is retracted. After adding more oil to the tank, cycle the

cylinder again until it has a constant speed indicating that all oil has been expelled. Check the oil level in the reservoir again to make sure it is in the “OK”

range.

STARTING INSTRUCTIONS

SpeeCo 6.5 HP

NOTE: REFER TO THE ENGINE OWNER’S MANUAL FOR COMPLETE INFORMATION ON STARTING, MAINTENANCE AND TROUBLE SHOOTING.

1) Move the fuel valve lever to the ON position.

2) T o start a cold engine, move the choke lever to the CLOSE position.

T o restart a warm engine, leave the choke lever in the OPEN position.

3) Move the throttle lever away from the SLOW position, about 1/3 of the way toward the FAST position.

4) Turn the engine switch to the ON position.

5) Pull the starter grip until you feel resistance, then pull briskly. Return the starter grip gently .

6) If the choke lever has been moved to the CLOSE position to start the engine, gradually move it to the OPEN position as the engine

warms up.

7) T o stop the engine in an emergency , simply turn the engine switch to the OFF position. Under normal conditions, move the throttle lever to the

SLOW position and then turn the engine switch to the OFF position. Then turn the fuel valve lever to the OFF position.

For further information on starting and stopping the engine, refer to your engine owner’s manual.

Honda GC 190

NOTE: REFER TO HONDA ENGINE OWNER’S MANUAL FOR COMPLETE INFORMATION ON STARTING, MAINTENANCE AND TROUBLE SHOOTING.

To Start a Cold Engine

1) Turn the fuel valve to the ON position.

2) Move the choke to the ON position.

3) Move the throttle control to the FAST position.

4) Pull the starter grip lightly until resistance is felt. Then pull rapidly to start engine.

5) Move the choke lever to the OFF position if it was used to start the engine as soon as it warms up enough and is running smoothly.

6) When engine starts, move the throttle to the FAST position. It is recommmended that the engine be operated in the F AST position for

maximum performance.

Page 8

Page 11

To Start a Warm Engine

1) Move the throttle lever to the FAS T position.

2) Leave the choke lever in the OFF position.

3) Pull the starter grip until the engine starts.

To Stop the Engine

1) Move the throttle lever to the SLOW position.

2) Move the throttle lever to the STOP position.

3) Turn the fuel valve to the OFF position.

NOTE: The engine maximum governed speed is preset at the factory at 3600 RPM no load speed. When splitting wood, the throttle should be

set at the maximum setting to develop the horsepower required for the pump.

TOWING

The log splitter is equipped with pneumatic tires, a Class I coupler (2 in. diameter ball required) and safety chains. Before towing, the safety chains must be

secured to the hitch or bumper of the vehicle. Local regulations should be checked regarding licensing, lights, towing, etc. See also towing safetyin the safety

information section of this manual. Do not exceed 45 mph when towing this log splitter.

OPERATION

WARNING: ALWAYS WEAR SAFETY GLASSES WHEN OPERA TING THIS LOG SPLITTER.

DANGER: KEEP HANDS AND FEET CLEAR OF RAM, STRIPPER PLATES AND BASE PLA TE AT ALL TIMES.

1) Set up the log splitter in a clear, level area and block the wheels. Make sure that the suction port on the tank is always on the lower side

of the log splitter.

2) Place a log on the beam against the wedge. Make sure that the log is securely on the wedge and up against the beam. Always use

extra care when splitting logs with unsquare ends.

3) Depress the valve handle so that the cylinder will drive the ram into the log. Extend the cylinder until the log splits or to the end of its

stroke. If the log has not completely split after the cylinder has reached the end of its extension, retract the cylinder.

IMPORTANT: Leaving the valve in the “actuate” position at the end of the stroke may damage the pump.

NOTE: Output tonnage varies with altitude.

MAINTENANCE

1) Consult the operating and maintenance instructions of the engine manufacturer for engine care and maintenance.

2) Always check the oil level of the hydraulic reservoir before operation. Operating the log splitter without an adequate oil supply will

cause severe damage to the pump.

3) Change the oil filter after the first 25 hours of operation. Thereafter change the oil filter every hundred hours or seasonally, whichever

comes first.

5) Clean the breather cap after 25 hours of operation. Clean it more often when operated in dusty conditions. To clean, remove the breather

from the tank and flush with kerosene or liquid detergent to remove the dirt.

6) See also Repair and Maintenance Safety in the Safety Information section of this manual.

7) All replacement parts must meet manufacturer’s specifications.

Page 9

Page 12

PARTS BREAKDOWN FOR MODEL LS401105/LS401105H

LOG SPLITTERS

Page 10

O/L- Obtain locally. Common fasteners available through hardware and farm stores.

Page 13

O/L- Obtain locally . Common fasteners available through hardware and farm stores.

38

Beam Assembly

Page 11

Page 14

MODEL NO LS401 105/LS401105H0

LOG SPLITTERS

T ank and Wheel Assembly

Refer to parts List on Pages 10 and 1 1

Engine Assembly for Honda GC190/S peeCo 6.5 HP

Refer to Parts List Below

Ref. No Part Number Description Quantity

1 17020700 5/16”-18 UNC Nylock Nut 4

MODEL NO. LS401105 LOG SPLITTER

Page 12

2 17030900 5/16” Regular Lock Washer 4

3 17053900 5/16” x 1-1/4” GR 5 Hex Cap Bolt 4

4 17054400 5/16” x 1” UNF GR 5 Bolt 1

5 39054200 Honda GC 190 Engine 1

39053900 SpeeCo 196cc Engine 1

6 39026100 21” Hydraulic Pressure Hose 1

7 390705C 11 GPM Pump 1

8 40034800 3/16” x 1” Square Key 1

9 40081200 Pump Mount 1

10 400835L0 Jaw Coupler with 3/4” Bore 1

11 400833L0 Jaw Coupler with 1/2” Bore 1

12 400834L0 Rubber Spider for Coupler 1

Page 15

IMPORTANT NOTICE

We, the manufacturer , reserve the right to change the product and/or specifications in this manual without notification.

The manual is for information usage only and the pictures and drawings depicted herein are for reference only .

NOTES

Warranty Rep air and Service

Do not return this product to the store for warranty issues or repair . Call 1-800-525-8322 for the location of the

nearest service center.

Record the information below for future reference.

Model No. ____________________ Serial No. _____________________________

Date of Purchase _______________ Place of Purchase _______________________

_______________________

_______________________

_______________________

Page 13

Page 16

SPECIFICATIONS

Engine SpeeCo 6.5 H.P. OHV or Honda GC190

Pump Two-Stage, 11 gpm

Cyli nder 3-1/2 in. Di ameter x 18 i n. Stroke

Valv e Auto-Return

Maximum Spli tting Fo rc e 15 To ns

Maxi mum Log Length 19 in.

Cycle Time 9 Seconds

Wheels 4.80 x 8 i n. Road Tires

Wedge 6 i n. Hi gh

Beam Size 4-1/2 in. x 7 in.

Hydrauli c C apacity 10 Quarts

Filter Replaceable

Height 36 in.

Length 65 in.

Wid th 45 in.

Weight 300 lbs.

*Ideal case cycle time. Actual cycle time will vary depending on temperature, altitude,

engine speed, pump efficiency, etc.

Loading...

Loading...