SpeeCo 597476 Owner's Manual

3-POINT HITCH LOG SPLITTER

MODEL NUMBER

Owner’s Manual P/N 597468

ASSEMBLY & OPERATING INSTRUCTIONS

WARNING: All operators must read this manual before operating this log

splitter. Follow the safety instructions in the manual and in decals attached to

the product. Failure to do so could result in serious injury or death.

(Rev. AA 11/6/2017)

597476

Record the information below for future reference.

WARNING: Read and thoroughly understand all instructions in this manual and on safety decals

before assembling or operating this log splitter. Failure to do so may cause serious injury or

death. Do not allow anyone to operate this log splitter who has not read this manual. As with all

power equipment, a log splitter can be dangerous if assembled or used improperly. Do not

operate this log splitter if you have any questions concerning safe operation. To get answers to

any questions, call our technical support department at 1-800-525-8322.

Model No. _________________________

Date of Purchase ___________________

Serial Number Label Location

Page 2

Tank Plate Below Beam

Serial No. __________________________

Place of Purchase ___________________

___________________

___________________

___________________

TABLE OF CONTENTS

IMPORTANT SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2, 5 - 6

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INTENDED USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PERSONAL PROTECTIVE EQUIPMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PREPARATION OF THE LOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

OPERATION OF THE LOG SPLITTER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

GENERAL REPAIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

MAINTENANCE & SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

FIRE PREVENTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3-POINT HITCH & TRANSPORT SAFETY. . . . . . . . . . . . . . . . . . . . . . . . . . 6

SAFETY DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ASSEMBLY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 9

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 11

CONNECTION TO TRACTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 11

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

WARRANTY SERVICE INFORMATION . . . . . . . . . . . . . . . . . INSIDE BACK COVER

GENERAL INFORMATION

The purpose of this manual is to assist you in operating

and maintaining your log splitter. Read it carefully. It

furnishes information and instructions that will help you

achieve years of dependable performance. These

instructions have been compiled from extensive field

experience and engineering data. Some information

may be general in nature due to unknown and varying

operating conditions. However, through experience

and these instructions, you should be able to develop

procedures suitable to your particular situation.

The illustrations and data used in this manual were current at the time of printing but, due to possible inline

production changes, your machine may vary slightly in

detail. We reserve the right to redesign and change the

machines as may be necessary without notification.

Throughout this manual, references are made to right

and left direction These are determined by standing

behind the equipment facing the direction of forward

travel.

Page 3

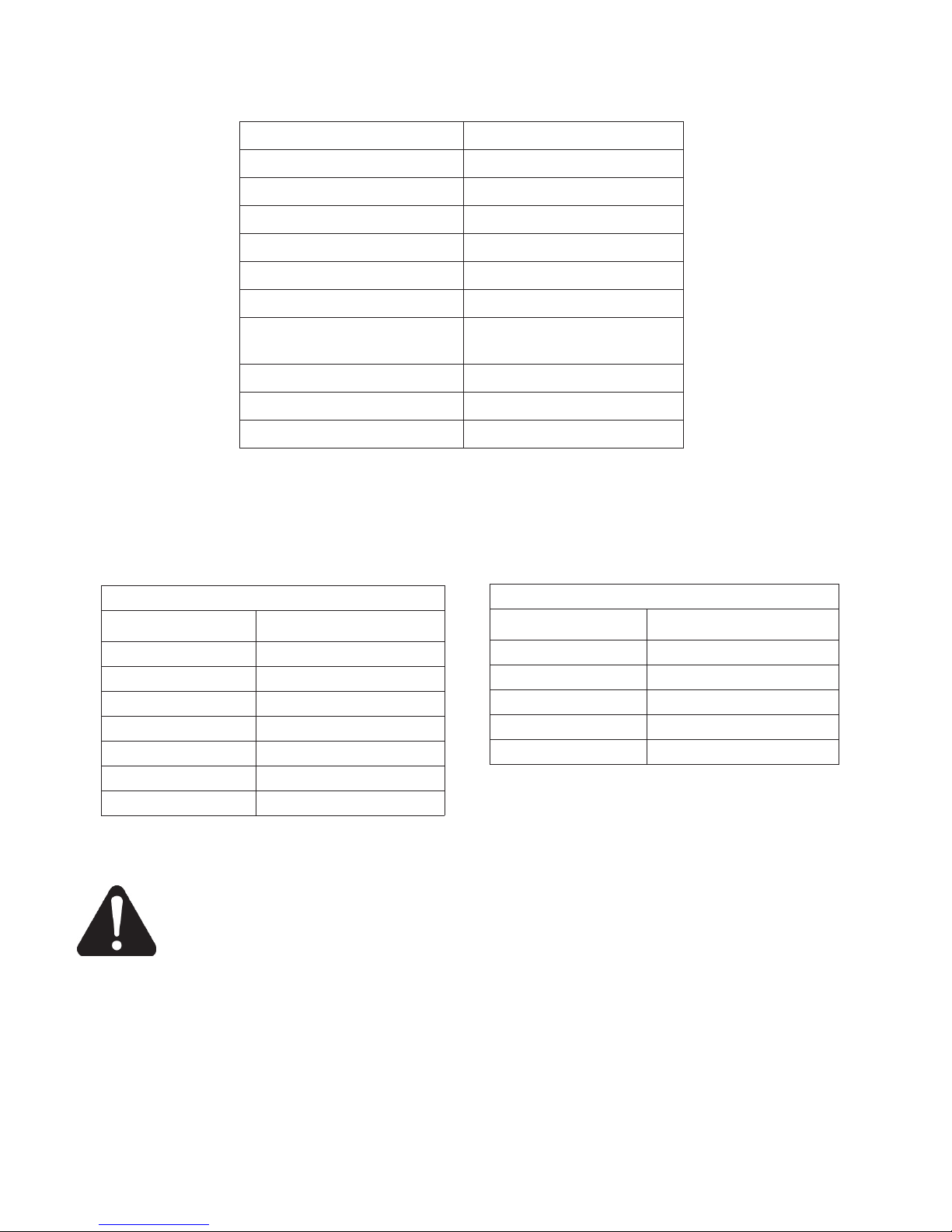

SPECIFICATIONS

Model No. 579806

Cylinder 4" Diam. x 24" Stroke

Valve Auto-Return

Maximum Splitting Force* 20 Tons

Maximum Log Length 24.5 in.

Cycle Time* 13 Seconds

Wedge 8" High

Height 70.9" in Vertical Position

41.5" in Horizontal Position

Length 82.5"

Width 48.2"

Shipping Weight

*

Tonnage and cycle times vary dependent upon tractor PSI and GPM.

DO NOT EXCEED 3200 PSI OR 20 GPM

Splitting Force

Pressure Force

(PSI) (Tons)

1,000 6.3

1,500 9.5

2,000 12.6

2,500 15.7

3,000 18.8

3,200 20.0

400 lbs.

Cycle Time

Flow Rate Time

(GPM) (Secs)

528.3

10 14.2

15 9.4

20 7.1

WARNING: This log splitter is designed for tractors with a pressure rating of 3200 PSI

and under, and flow of 20 GPM and under. Warranty will be voided if used on tractors

that exceed pressure ratings of 3200 PSI or flow over 20 GPM. Do not exceed the pressure or flow rating of the cylinder and valve manufacturers.

Page 4

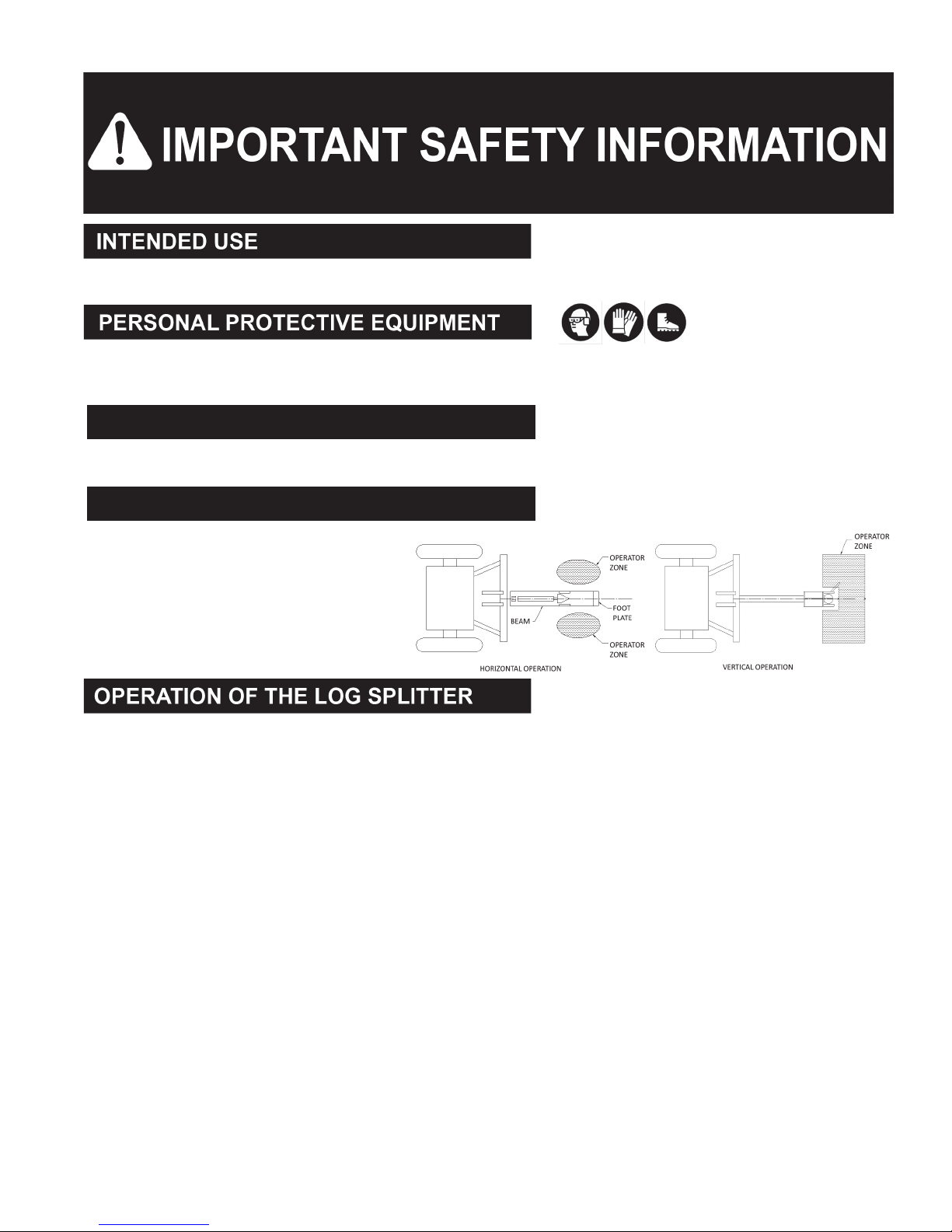

NEVER use this log splitter for any other purposes than splitting wood. It is designed for this use only. Any other use

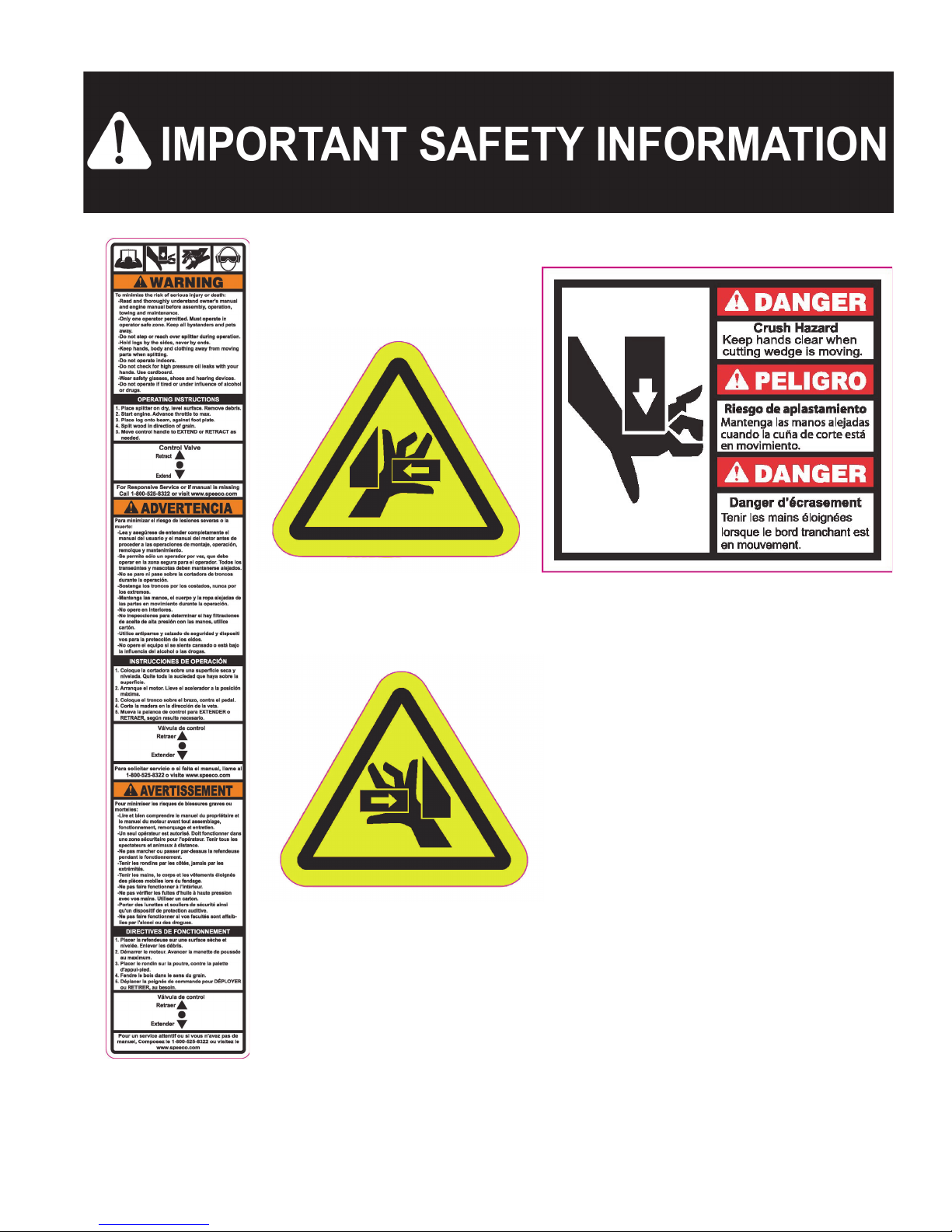

SAFETY DECALS

PREPARATION OF THE LOG

can cause serious injury or death.

BEFORE operating this log splitter, make sure that you wear safety gear such as goggles or safety glasses, steel toed

shoes and tight fitting gloves (without loose cuffs or draw strings). Always wear a protective hearing device when operating this log splitter.

Make sure that all safety warning decals are in good condition and readable. Always replace missing or defaced

decals. Contact SpeeCo at 1-800-525-8322 for replacement decals.

Both ends of the log should be cut as square as

possible to prevent the log from riding out of

the splitter during operation. Do not split logs

greater than 24-1/2” in length.

ONLY operate the log splitter from the operator zone as shown in the diagram. The operator has the safest and most

efficient access to the control valve and the beam in this location. Operating the log splitter in another location can

result in serious injury or death.

•

ALWAYS block the wheels to prevent movement of the log splitter while in operation.

•

KNOW how to stop the log splitter and disengage the controls before operating it.

•

NEVER place hands or feet between the log and splitting wedge during forward or reverse strokes as this could

result in serious injury or death.

•

NEVER straddle or step over the log splitter during operation.

•

NEVER reach or bend over the log splitter to pick up a log.

•

NEVER try to split two logs on top of each other.

•

NEVER try to cross split a log.

•

NEVER attempt to load the log splitter when the ram or wedge is in motion.

•

NEVER use your foot, a rope, or any extension device to operate the control lever on the valve. Only use hand.

•

NEVER move the log splitter while the engine is running. Shut off the engine if you are leaving the log splitter, even

for a short period of time.

•

NEVER touch the muffler and hot areas of the engine during operation. Wait until the engine cools down.

•

IMPORTANT: Holding the valve in the “actuate” position at the end of the stroke may damage the log splitter.

•

ALWAYS use extra care when splitting logs with unsquare ends.

•

NEVER operate the log splitter with the incorrect valve spool. Please contact 1-800-525-8322 if you need assis-

tance determining spool.

Page 5

• NEVER operate your log splitter when it is in poor mechanical condition or in need of repair.

3 POINT CONNECTION AND TRANSPORT SAFETY

• NEVER alter your log splitter in any manner. Such alterations may cause your log splitter to be unsafe and will void

the warranty.

• ALWAYS perform all recommended maintenance procedures before using your log splitter.

• ALWAYS periodically check that all nuts, bolts, screws, hydraulic fittings and hose clamps are tight.

• ALWAYS replace all damaged or worn parts immediately.

• ALWAYS be sure that all replacement parts meet manufacturer’s specifications.

The hydraulic system of your log splitter requires careful inspection along with the mechanical parts. Be sure to replace

frayed, kinked, cracked or otherwise damaged hydraulic hoses or hydraulic components.

•

NEVER check for leaks of hydraulic fluid with your hand. Fluid escaping from a small hole can be almost invisible.

Escaping fluid under pressure can have sufficient force to penetrate skin causing SERIOUS INJURY or DEATH.

Leaks can be safely detected by passing a piece of cardboard over the suspected leak and looking for discoloration.

•

ALWAYS seek professional medical attention immediately if injured by escaping hydraulic fluid. Serious infection

or reaction can develop if proper medical treatment is not administered immediately.

•

NEVER adjust the hydraulic valve. The pressure relief valve on your log splitter is preset at the factory. Only a

qualified service technician should perform this adjustment.

•

ALWAYS be sure to relieve all pressure by shutting off the engine and moving the valve control handle back and

forth should it become necessary to loosen or remove any hydraulic fitting.

•

NEVER operate your log splitter near a flame or spark, or smoke during operation. Hydraulic oil is flammable and

can explode.

•

NEVER move your log splitter without tractor or adequate help.

•

NEVER carry cargo or wood on your log splitter.

•

NEVER allow anyone to sit or ride on your tractor.

•

NEVER exceed weight capacity of tractor.

•

ALWAYS confirm 3 point pins are secure with lynch pins in place before lifting or transporting log splitter.

•

ALWAYS have your log splitter attached to 3-point hitch before operating it.

•

ALWAYS allow for added length of your log splitter when turning, crossing intersections and in all transporting situ-

ations.

•

ALWAYS attach to Category I or II 3-point hitch only.

•

ALWAYS replace attachment pins or 3-point hitch components if damaged or excessively worn.

•

ALWAYS have beam pinned down for transport.

Page 6

PART NUMBER: S52062100

LOCATION: TOP OF HYDRAULIC

CYLINDER

PART NUMBER: S52062300

LOCATION: STRIPPER PLATE,

OPERATOR SIDE

PART NUMBER: S52062600

LOCATION: STRIPPER PLATE,

NON OPERATOR SIDE

PART NUMBER: S52062200

LOCATION: TOP OF CYLINDER

Page 7

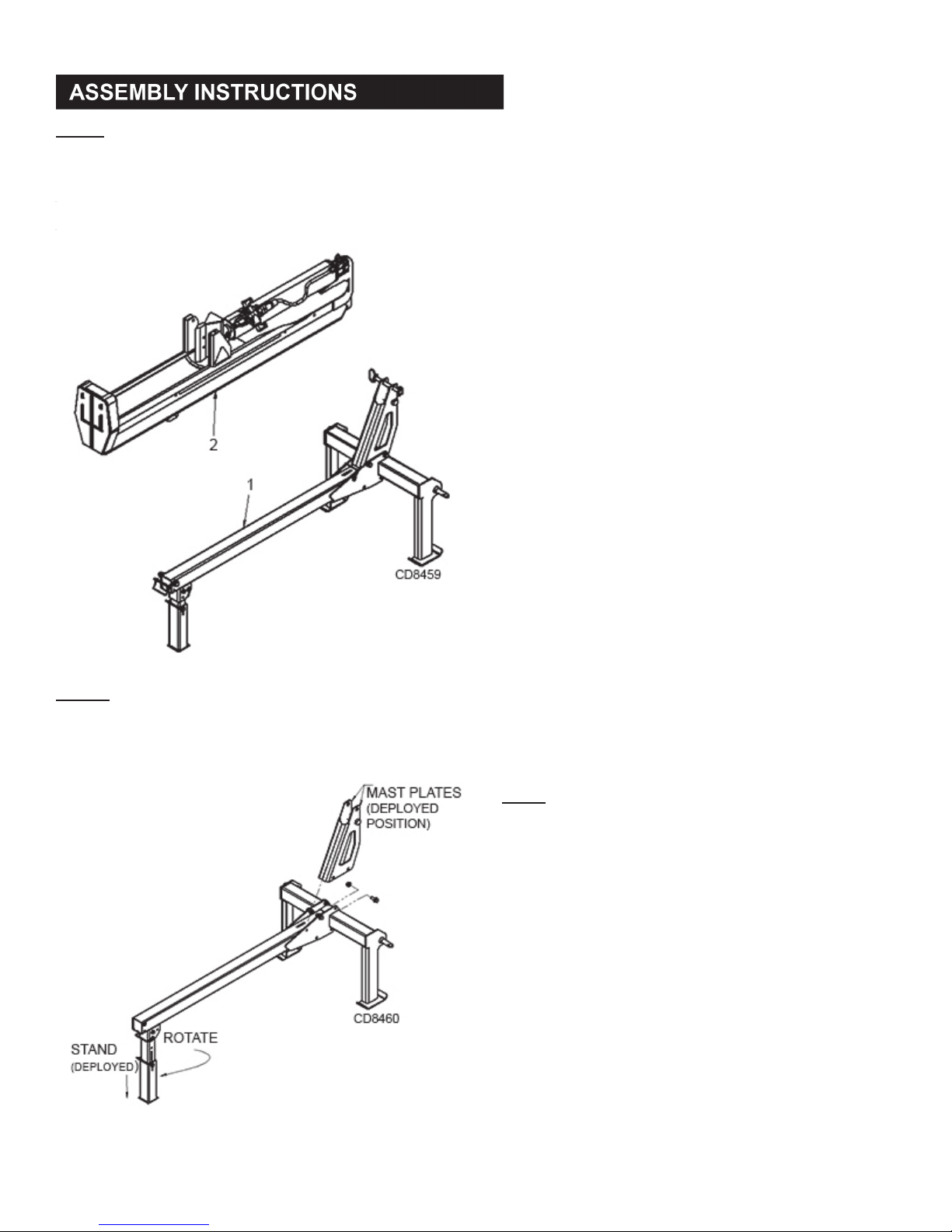

NOTE: This log splitter was partially assembled at the factory. Refer to the drawings and parts list should it become

ITEM DESCRIPTION QTY

1

FRAME ASSEMBLY

1

2

BEAM ASSEMBLY

1

necessary to disassemble the unit for repair or replacement of parts. The drawings in this manual are for reference only. Some of the components on your log splitter may look slightly different.

STEP 1:

Remove all the components from the container. Inspect each piece for shipping damage. If any part is damaged, contact your dealer or delivering carrier.

STEP 2

Remove lock pin and rotate stand to vertical position.

Replace pin to lock in place.

Remove second lock pin to release leg and slide to

deployed position. Replace pin to lock in place.

Remove stowed mast plates by removing 4 screws.

Attach mast plates as shown using same 4 screws.

:

Page 8

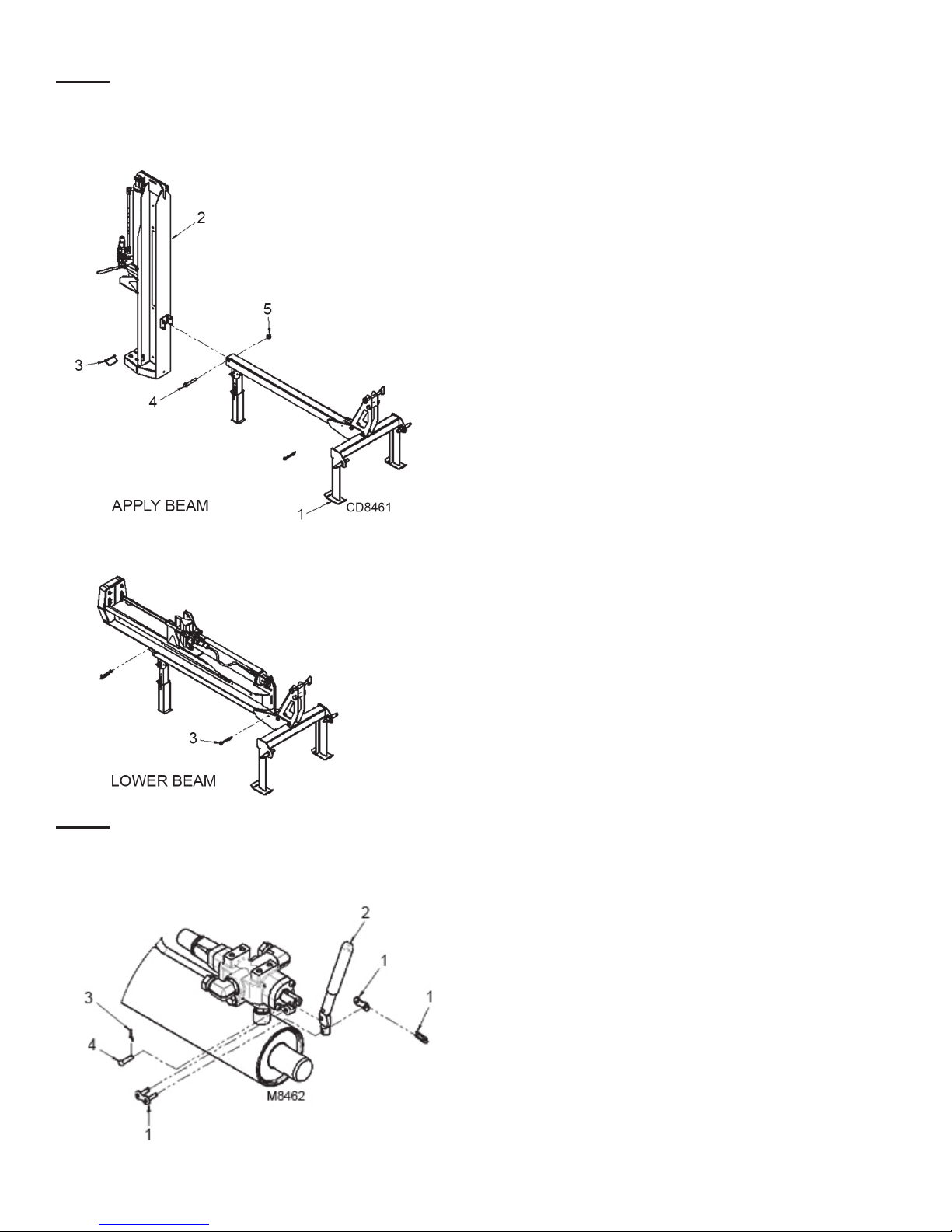

STEP 3:

ITEM DESCRIPTION QTY

1

FRAME ASSEMBLY

1

2

BEAM ASSEMBLY

1

3

5/16 X 3-1/4" SQUARELOCK PIN

2

4

BOLT, HFS 5/8 NC X 4.25 GR5

1

5

NUT, HFN 5/8 NC FLANGE LOCK

2

Stand the beam (2) up on end. Two people may be needed for this step to ensure safety. Make sure that the beam is

stable and on a level surface. Locate frame assembly (1) into position between the two tabs on the beam (2). Install

5/8 bolt (4) through aligned holes and fasten with 5/8 flange lock nut (5). Attach lock pins (3) one through the frame and

beam near mast plates and one near pivot. as shown. Carefully lower the beam (2) to the frame.

STEP 4

Attach the lever control (2) using the link chain (1) and clevis pin (4). Secure with cotter pin (3).

:

ITEM DESCRIPTION QTY

1

CHAIN LINK

2

CONTROL LEVER

3

COTTER PIN

4

CLEVIS PIN

1

1

1

1

Page 9

Loading...

Loading...