Page 1

MODEL 65

POST HOLE DIGGER

MODEL NO. 24440 (24044000)

OWNER’S MANUAL

ASSEMBL Y & OPERA TING INSTRUCTIONS

THIS SAFETY ALER T SYMBOL IDENTIFIES IMPORT ANT SAFETY MESSAGES IN THIS MANUAL.

FAILURE T O FOLLOW THIS IMPORT ANT SAFETY INFORMA TION MA Y RESULT IN SERIOUS

INJURY OR DEA TH.

PD21-536-0608

Rev 2

Page 2

Table of Contents

Page(s)

Important Safety Information ................................................................................................ 1-4

Intended Use .............................................................................................................. 1

Personal Protective Equipment ................................................................................. 1

Safety Decals ............................................................................................................. 1-3

General Safety and Preparation ................................................................................. 3

Operating Safety ......................................................................................................... 3-4

Repair and Maintenance Safety .................................................................................. 4

Assembly Instructions ............................................................................................................ 5

General Maintenance ............................................................................................................. 6

Operating Instructions ............................................................................................................ 6

..

Parts List ................................................................................................................................. 7

Parts Breakdown Illustration ................................................................................................... 8

Cutting Edges and Point Parts List ......................................................................................... 9

Gear Box Parts List ................................................................................................................. 10

Notes ........................................................................................................................................ 1 1

Specifications ................................................................................................................ ...... Back Cover

Ordering Information ........................................................................................................... Back Cover

Page 3

WARNING: Read and thoroughly understand all instructions and safety information before assembling or

operating this post hole digger Failure to do so may cause serious injury or death. Do not allow anyone

to operate this post hole digger who has not read this manual. As with all power equipment a post hole

digger can be dangerous if assembled or used improperly. Do not operate this post hole digger if you

have doubts or questions concerning safe operation. Call our customer service department at 1-800-5258322 to address these concerns.

Si no entiende ingles, se prefiere que busque alguien que interprete las instrucciones para usted.

INTENDED USE

This product is designed to dig holes in the soil when attached to the 3-point linkage system and power-take-off of a tractor .

It is not intended for any other use. Using the product for anything other than digging holes could result in serious injury or

death.

PERSONAL PROTECTIVE EQUIPMENT

ALWAYS use appropriate personal protective equipment such as protective eyewear, earware, gloves, safety shoes and hard

hat when operating this post hole digger.

NEVER wear loose clothing or jewelry that could become entangled in the auger or driveline.

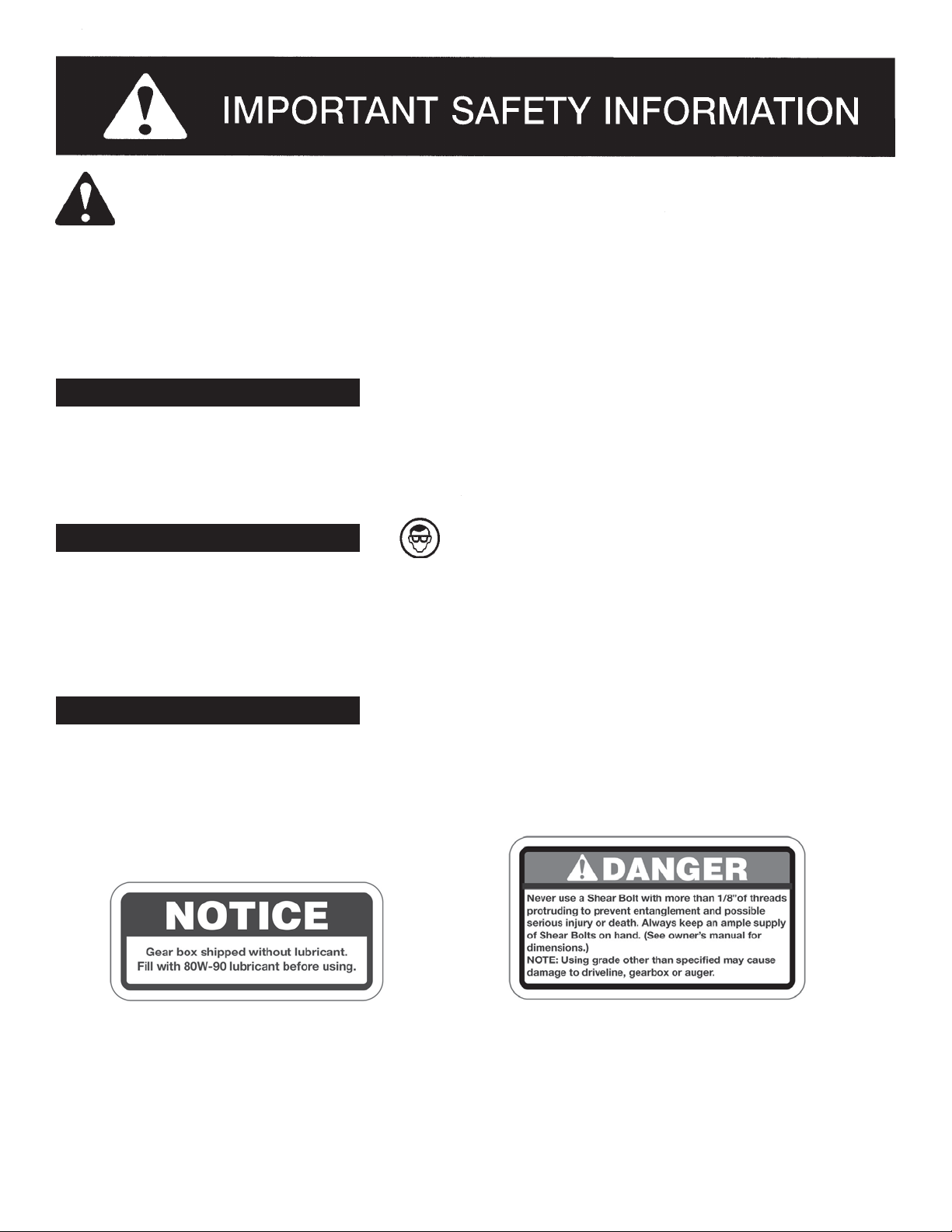

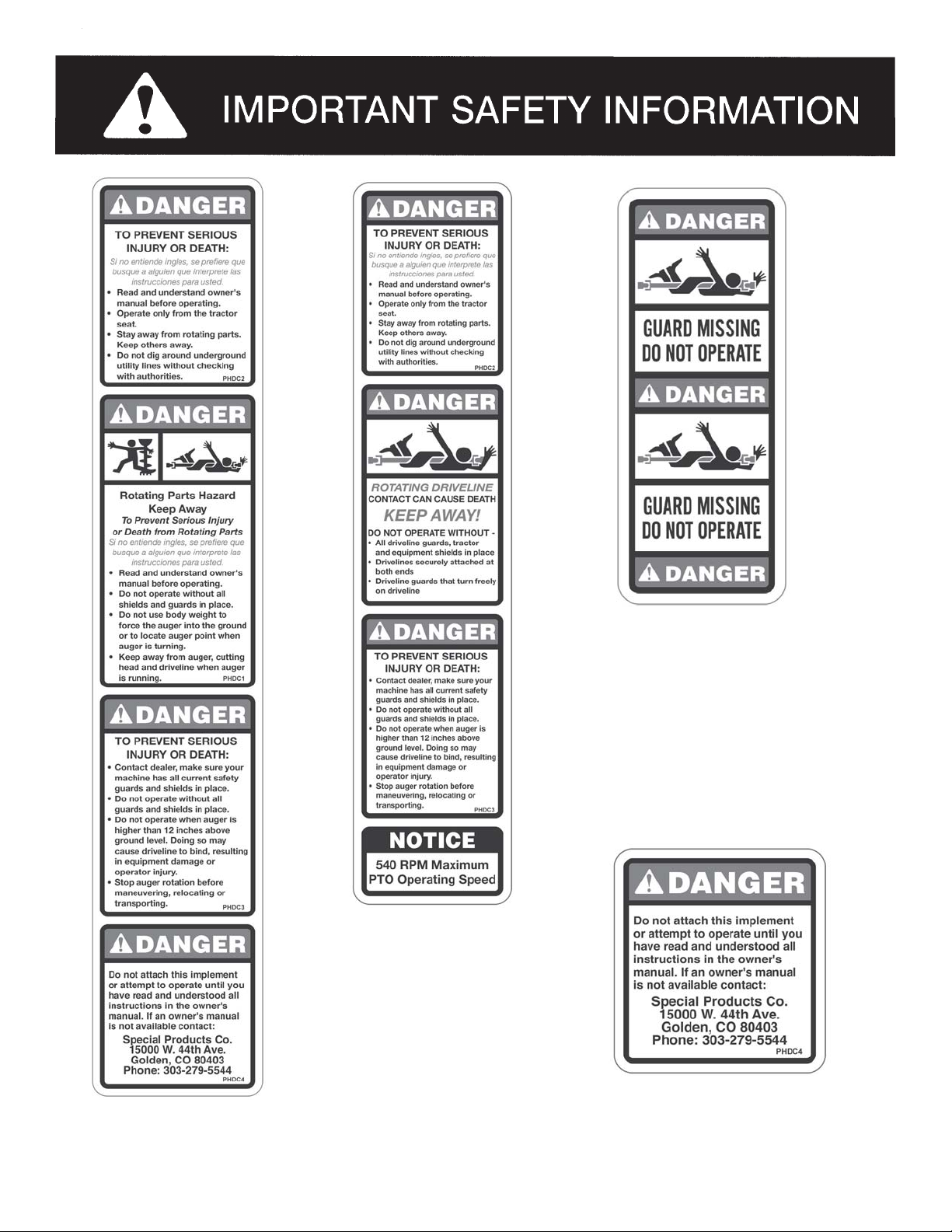

SAFETY DECALS

ALWAYS replace missing or defaced decals. Reorder from S peeCo, Inc., 15000 W. 44th A ve., Golden, CO 80403 or call

1-800-525-8322.

LOCA TION: FRONT OF GEAR BOX

P ART NUMBER: 52022000

LOCA TION: SIDE OF GEAR BOX

PA RT NUMBER: 52045600

Page 1

Page 4

LOCA TION: PTO DRIVE SHAFT SHIELD

PA RT NUMBER: 52046100

LOCA TION: PTO DRIVE SHAFT

UNDER SHIELD

ORDER DECAL KIT : 52044100

NOTE: IF THE DRIVE SHAFT GUARD

MENTIONED IN THE ABOVE DECAL IS

MISSING ,YOU MUST ORDER A

REPLACEMENT BY CALLING US

A T 1-800-525-8322.

Page 2

LOCA TION: BOOM

P ART NUMBER: 52033300

LOCA TION: TOP END OF BOOM ON

GEAR BOX END

ORDER DECAL KIT : 52050500

Page 5

LOCA TION: TOP END OF AUGER TUBE

P ART NUMBER: DL52020500

NOTE: IF THE OUTPUT SHAFT GUARD MENTIONED IN THE ABOVE DECAL IS MISSING ,YOU

MA Y ORDER A REPLACEMENT BY CALLING US AT 1-800-525-8322.

GENERAL SAFETY AND PREPARA TION

ALWAYS make sure that anyone else who operates this post hole digger has read and understood the contents of the

owner’s manual and all safety decals on the product.

ALWAYS be certain that all members of the work party are familiar with the operation of the digger and the hazards

associated with it.

ALWAYS check with authorities for underground utilities before digging a hole. Serious injury or death could result from

contact with gas or electric lines.

ALWAYS check the tractor owner’s manual for instructions on operation, attachment of 3-point equipment and safety .

ALWAYS make sure that all safety shields are in place and tightened down. Do not operate this post hole digger if any

shields are missing. Contact SpeeCo, Inc. at 1-800-525-8322 for replacement p art(s).

ALWAYS make sure that the auger point and cutting edges are intact and in good working order before using this digger.

NEVER allow children or other persons to ride on the Tractor or Implement. Falling off can result in serious injury or death.

NEVER allow children to play on or around Tractor or Implement. Children can slip or fall off the Equipment and be injured

or killed. Children can cuase the Implement to shift or fall crushing themselves or others.

NEVER allow others within 20 feet while operating the post hole digger.

NEVER operate post hole digger without all guards in place.

ALWAYS ensure the driveline is securely locked onto the PTO.

Page 3

Page 6

OPERA TING SAFETY

ALWAYS operate this post hole digger from the tractor seat.Only one person should operate the digger .

NEVER attach the post hole digger with the tractor engine running.

NEVER operate the post hole digger with anyone near or in contact with any part of the implement, PTO driveline or auger .

Serious injury or death could result from entanglement with moving parts.

ALWAYS make sure that the tractor brake is set before digging a hole.

ALWAYS keep hands, feet and clothing away from power-driven parts during operation.

NEVER manually position the auger or manually force the auger into the ground.

ALWAYS make sure that the tractor engine is shut off and the PT O drive is disengaged before leaving the tractor seat.

NEVER move the tractor with the power-take-off in the ON position.

NEVER exceed 540 RPM PTO operating speed.

NEVER operate the post hole digger when the auger point is more than 6 in. above ground level. Operating the digger in

elevated positions may cause the PTO driveline “U” joints to bind resulting in equipment damage and operator injury .

ALWAYS turn of f the digger immediately if an immovable object is encountered to prevent damage to the gear box or

driveshaft and possible injury . A shear bolt is provided but may become welded to the input shaft if the driveshaft is left

running after being sheared.

.

TRANSPORT ATION SAFETY

NEVER allow anyone to ride on Implement.

Make certain the slow moving (SMV) sign and other reflectors are clearly visible. Follow local traffic codes for slow moving

vehicles when transpotting on public roads.

REP AIR AND MAINTENANCE SAFETY

ALWAYS perform maintenance operations such as lubrication, adjustments or repairs on the post hole digger with the

tractor engine off, the PTO drive disengaged and the auger point resting on the ground.

ALWAYS use the correct shear bolt (Grade 5). NEVER use or replace the shear bolt with one that is longer than the one

specified in the manual (5/16” x 2-1/2”).

Periodically inspect all moving parts for wear and replace when necessary with authorized service parts. Look for loose

fasteners, worn or broken parts, and leaky or loose fittings. Serious injury may occur from not maintaining this machine in

good working order.

Do not modify or alter this Implement. Do not permit another to modify or alter this Implement, any of its

components or any Implement function. Any modification will void the warranty.

Page 4

Page 7

ASSEMBLY INSTRUCTIONS

IMPORT ANT: The gear box is shipped without lubricant. Fill the top hole with 80W-90 lubricant or the equivalent.

Fill until the lube appears at the side level check hole. Approximately two pint s or two pounds of

the lubricant is enough to lubricate the gears and bearings. A greater amount will not harm the

gear box. Do not fill to overflow point as this may damage the seals.

STEP 1: Be certain that the gear box has adequate lubrication. Check the oil level after every fifty hours

of use.

STEP 2: Attach the boom (1) to the top link mounting bracket on the tractor using a top link pin and a

lynch pin (not provided) through the hole at the bottom of the boom.

STEP 3: Connect the “A” frame (5) to the tractor’s 3-point lift arms using the 7/8 in. pull pins with nut and

lockwasher (5A) as shown in the drawing. Att ach the “A” frame (5) to the boom (1) after selecting

the desired hole (for angle adjustment) using the “A” frame pin (6) and lynch pin (4).

STEP 4: Attach the gear box (10) to the boom (1) using the boom pin (2). When in place secure with

cotter pins (3). NOTE: Input shaft shield (9) and output shaft shield (12) are already attached

to the gear box.

STEP 5: Attach the auger (20, 21 or 22) to the output shaft on the bottom of the gear box (10) using the

1/2 in. hex cap screws (17), 1/2 in. lockwashers (18) and 1/2 in. hex nuts (19). Tighten the nuts.

STEP 6: Attach the driveline (13) to the gear box input shaft using the 5/16 in. grade 5 hex cap screw (14),

the 5/16 in. lockwasher (15) and the 5/16 in. NC hex nut (16). Tighten the hex nut. Insert the 1/4

in. x 3/8 in. set screw from the hardware kit in the hole on the yoke that aligns with the 3/16 in.

groove on the gear box input shaft. Tighten.

ATTENTION: THE 5/16 IN. HEX CAP SCREW PROVIDES SHEAR PROTECTION. USE A GRADE 5

2-1/2” BOL T ONL Y TO A VOID DAMAGE TO THE GEAR BOX OR AUGER.

IMPORT ANT: The universal joint should be greased with a good grade chassis lube every week. At the

beginning of each season grease the sliding driveshaft members with a moly grease. All

diggers are equipped with quick-detach universal joints on the power-take-off end for a

1-3/8 in. splined shaft.

STEP 7: Attach the tractor end of the driveline (13) to the tractor PTO shaft. Push in the spring-loaded pin

in the splined yoke (13C) and slip it on the splined PTO shaft of the tractor . Release the pin and

push until it locks securely in place. It will be necessary to obtain a 1-1/8 in. to 1-3/8 in. sleeve

spline adapter if your tractor PTO shaft has a 1-1/8 in. spline.

STEP 8: Attach and secure both chains on the driveline to the boom (1). See illustration A.

STEP 9: Attach the handle (8) to the gear box (10) and secure with the 5/16 in. set screw (1 1). T ighten.

STEP 10: Check all nuts and bolts for tightness. S tabilizers should be kept tight to avoid side sway of the

digger.

NOTE: See illustration A for reference in assembling the digger and mounting it to the tractor .

Note that the boom angle can be adjusted on your tractor for proper digging and ground

clearance by moving the “A” frame to a different mounting hole as shown in illustration B.

NOTE: When the 7/8 in. diameter pull pins in the “A” frame are too small for the holes in the lift

arms, bushings should be used to obtain a proper fit.

Page 5

Page 8

Angle

Adjustment

ILLUSTRATION A

ILLUSTRATION B

OPERATING INSTRUCTIONS

WARNING: Read and thoroughly understand all instructions and safety information before operating

this post hole digger Failure to do so may cause serious injury or death. Do not allow anyone to

operate this post hole digger who has not read this manual.

STEP 1: Af ter mounting the digger to the tractor , lower the auger point slowly to the ground at the desired digging

angle before engaging power.

STEP 2: Engage the power-take-off and start digging at a slow speed, lowering the auger slowly as it begins to dig.

STEP 3: Increase speed as the auger goes deeper . The type of soil will determine the proper auger speed. If the

soil is extremely hard, it will generally improve operation to vary the speed of the auger at times.

STEP 4: When the auger has reached the desired depth, spin it momentarily at a high speed to clear the hole of

dirt. Reduce speed before withdrawing the auger from the hole.

STEP 5: Disengage the power-take-off after withdrawing from the hole and move the tractor to the next hole location.

GENERAL MAINTENANCE

REFER TO ILLUSTRATION C

WARNING: Always perform maintenance operations with the tractor engine off, the PTO drive disengaged

and the auger point resting on the ground.

1. To remove the auger from the gear box output shaft, take out the two 1/2 in. x 3 in. hex cap screws (17).

2. To remove the driveshaft from the gear box input shaft, take out the shear pin bolt (14) and 1/4 in. set screw

(13E).

3. T o remove the auger control handle (8), loosen the 5/16 in. set screw (11) in the side of the gear box (10).

4. Check the oil level after every fifty hours of use. Use 80W-90 lubricant and fill to oil level plug. All replacement

lubricant should be of this type.

5. The universal joints should be greased with a good grade chassis lube every week. At the beginning of each

season, grease the sliding driveshaft members with a moly grease.

Page 6

Page 9

MODEL POST HMRTS BREAKDOWN

MODEL 65 POST HOLE DIGGER

PARTS BREAKDOWN

ECNEREFER

REBMUN

1HC048042mooB1

200328042niPmooB1

3L/OniPrettoC.ni2/1-1x.ni23/52

400109070niPhc

5HC938042emarF"A"1

A500802070rehsawkcoLdnatuNhtiwniPlluP.ni8/72

600517070niPemarF"A"1

700228042pirGeldnaH1

800148042doRlortnoC1

900157042drauGtupnIxoBraeG1

01SA107042ylbmessAxoBraeG1

A0100387042tiKlaeS&gniraeBxoBraeG1

11L/Ower

2100707042drauGtuptuOxoBraeG

31ZH206042dleihScitsalPhtiwenilevirD1

A31ZH011142ylbmessAdrauG1

B31ZH516

C31ZH616042ekoYniPhsuP1

D3100821142ekoYdnEtnemelpmI1

E31L/OwercSteSdetnioP"8/3x"4/11

41L/O)tloB

51L/OrehsawkcoL.ni61/51

61L/OtuNxeHCN.ni61/51

71L/OwercSpaCxeH.ni3xCN.ni

81L/OrehsawkcoL.ni2/12

91L/OtuNxeHCN.ni2/12

020A515042segdEgnittuCdnatnioPwercShtiwreguA.ni61

120A525042segdEgni

220A535042segdEgni

TRAP

REBMUNNOITPIRCSED

00044042reguAsselreggiDeloHtsoP56ledoM1

nyL.ni61/71

cSteS.ni61/51

042tiKgniraeBdnassorC2

raehS5edarG(wercSpaCxeH.ni2/1-2x.ni61/51

2/12

ttuCdnatnioPwercShtiwreguA.ni91

00925042 segdEgnittuCdnatnioPwercShtiwreguAytuDyvaeH.ni91

ttuCdnatnioPwercShtiwreguAni211

00635042 segdEgnittuCdnatnioPwercShtiwreguAytuDyvaeH.ni211

REBMUN

DERIUQER

deriuqersa

deriu

qersa

.serotsmrafdnaerawdrahhguorhtelbaliavasrenetsafnommoC.yllacolniatbO-L/O

Page 7

Page 10

See Illustration D for Cutting Edges

NOTE: Safety shields are shaded on

this diagram. NEVER operate

the digger with any shield missing.

ILLUSTRA TION C

Page 8

POST HOLE DIGGER

MODEL 65

Page 11

CUTTING EDGES AND POINT PARTS BREAKDOWN

ECNEREFER

REBMUN

100765042egdEgnittuC.ni62

A200775042egdEgnittuCretuO.ni91

B200875042egdEgnittuCrennI.ni91

300785042egdEgnittuCretuO

400885042egdEgnittuCrennI.ni211

500295042sdaerhTCN.ni4/1-1htiwtnioPwercS1

6L/OtloBegairraC4/1-1xCN.ni8/34

7L/

8L/OtuNxeHCN.ni8/34

--UBZ765042teSegdEgnittuC.ni61

--UBZ975042teSegdEgnittuC.ni91

--UBZ985042teSegd

TRAP

REBMUNNOITPIRCSED

.ni211

OrehsawkcoL.ni8/34

EgnittuC.ni211

serotsmrafdnaerawdrahhguorhtelbaliavasrenetsafnommoC.yllacolniatbO-L/O

REBMUN

DERIUQER

ILLUSTRA TION D

NOTE: It is important to replace the self-sharpening point on the auger when it shows signs of excessive wear .

Generally , the digging life of the point will be greater than that of the inner cutting edge. The digging life of

the inner cutting edge will be greater than that of the outer cutting edge since it covers fewer inches of

digging circumference.

Page 9

Page 12

NOTES

Model No. ____________________

Date of Purchase _______________ Place of Purchase _______________________

_______________________

_______________________

_______________________

Page 10

Page 13

yrogetaCrotcarT2ro1yrogetaC

xoBraeG raeghcaefosedishtobnosgniraebrellorderepatdnasraegnoinipyollalaicepS

sraeG 040.-030.fohtpedaot04-03CllewkcoRotdetaert-taeH

SPECIFICATIONS

enilevirD )dedleihsyletelpmoc(OTPenilps-6dradnatst

segdegnittuCelbaecalper,leetsnobrachgih,deleveB

sreguA regua-itnA.ni54fohtpedllufaotgidllatahtelbaliavasezis.ni21dna.ni9,.ni6

mooBgnibu

emarf-Agnibuthtgnertshgih.ni8/7-2

sdleihsytefaS tfahstuptuoxobraegdnatnioj"U"xo

nipraehS .elbaecalpeR.sraegdnaregua,enilevirdtcetorpottfahstupninO

braeg,enilevirdnO

ORDERING INFORMA TION

REBMUNTRAPNOITPIRCSED

00044042reguasselreggidelohtsop56ledoM

ifotekoyhcat-kciuqhtiwdeppiuqE

sliostfosotnigniwercsmorftitneverpotsetalp

thtgnertshgih.D.O.ni8/7-2

0A515042 segdegnittucelbaecalperdnatniopwercs

0A525042 segdegnittucelbaecalperdnatniopwercshtiwregua.ni9

00925042 segdegnittucelbaecalper

0A535042 segdegnittucelbaecalperdnatniopwercshtiwregua.ni21

00635042

00295042tniopwercS

UBZ76542tesegdegnittuc.ni6

UBZ97542tesegdegnittuc.ni9

UBZ98542tesegdegnittuc.ni21

htiwregua.ni6

dnatniopwercshtiwreguaytudyvaeh.ni9

segdegnittucelbaecalperdnatniopwercshtiwreguaytudyvaeh.ni21

Page 14

Loading...

Loading...