Page 1

Table of Contents

1. Description & Equipment Adjustments p.2

2. Components, Features & Functions p.3

3. Valve User Interface p.4

4. Installation Instructions p.5

5. Valve Initial Set-up p.6

6. Valve Operation p.7

7. End User Instructions p.8

8. Troubleshooting p.9

9. Cautions p.11

10. Technical Information p.12

Spectrum

TM

Installation, Service &

Operation Manual

SoftH2O FLO

Water Softener

Page 2

Spectrum

TM

2

Regeneration Mode

Regeneration Type

Electrical Supply

Installation Number Nominal Capacity

m3 °tH

Valve Serial Number Inlet Water Hardness

°tH

Resin Volume

litres

Treated Water Volume

litres

Outlet Water Hardness

°tH

Volumetric

m

3

1) Backwash

min

2) Brining & Rinse

min

3) Rapid Rinse

min

4) Brine Tank Rell

min

Low Voltage DC Transformer or Battery 2 x 1.5V A

1. Description &

Equipment Adjustments

Page 3

3

Spectrum

TM

2. Components, Features

& Functions

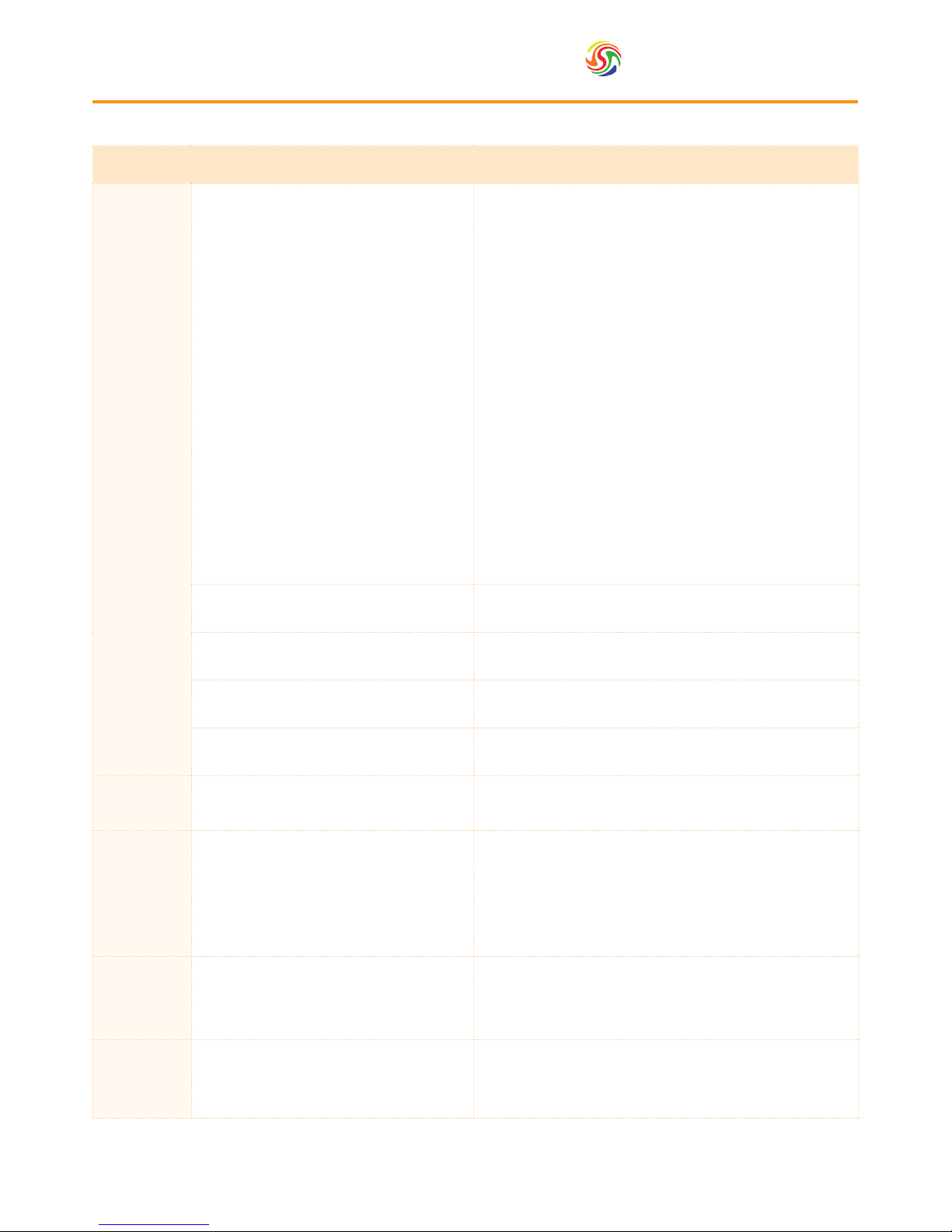

Component Features Functions

Automatic

Control Valve

• FDA approved Noryl plastic

• Strong corrosion resistance

• Innovative design

• 24 hours control and monitoring with a timer; automatically

regenerates the media bed at the system’s set time of

regeneration according to the set regeneration frequency.

• Cycle Process:

In service: Once the water is supplied with correct pressure

and ow, the cations contained in hard water will be replaced

by Na+ in regenerants, then the softening system will supply

softened water through its outlet.

Backwash: When the ion exchange resin has been

exhausted, the resin bed needs to be regenerated. Before

the regeneration of the resin bed, a backwash step is

necessary for two main purposes; removing the residue

in the resin bed and loosening the impacted resin bed for

better regeneration efciency.

Rinse: Rinse the resin bed to remove the residual regenerant

(salt) after the brining step until the water from outlet

contains no regenerant; rinse could also compact the resin

bed for a better softening effect.

Rell: Rell the brine tank with water to dissolve salt for the

next regeneration.

Valve Operation Mode Softener: Standard water softener operation

Regeneration Mode Volumetric

Water Hardness can be adjusted User can adjust the mixing valve to get desired water hardness

Display Format Metric format

Media

High-grade Anion exchange resin

(food grade 2 resin)

Pressure

Vessel

• NSF 44 tested and certied

• Polyethene material manufactured for the

Food & Beverage industries

• Light, high pressure resistance

• Strong corrosion resistance

Pressure vessel holds the resin and a distribution system

Riser Tube &

Distribution

System

A riser tube and distribution system disperse water evenly

through the resin bed

Brine Valve

& Tank

• High pressure resistance

• Prevents the brine tank from overowing

• Water and salt mix in the brine tank. Salt will dissolve

continuously until the water is saturated by salts

Page 4

Spectrum

TM

4

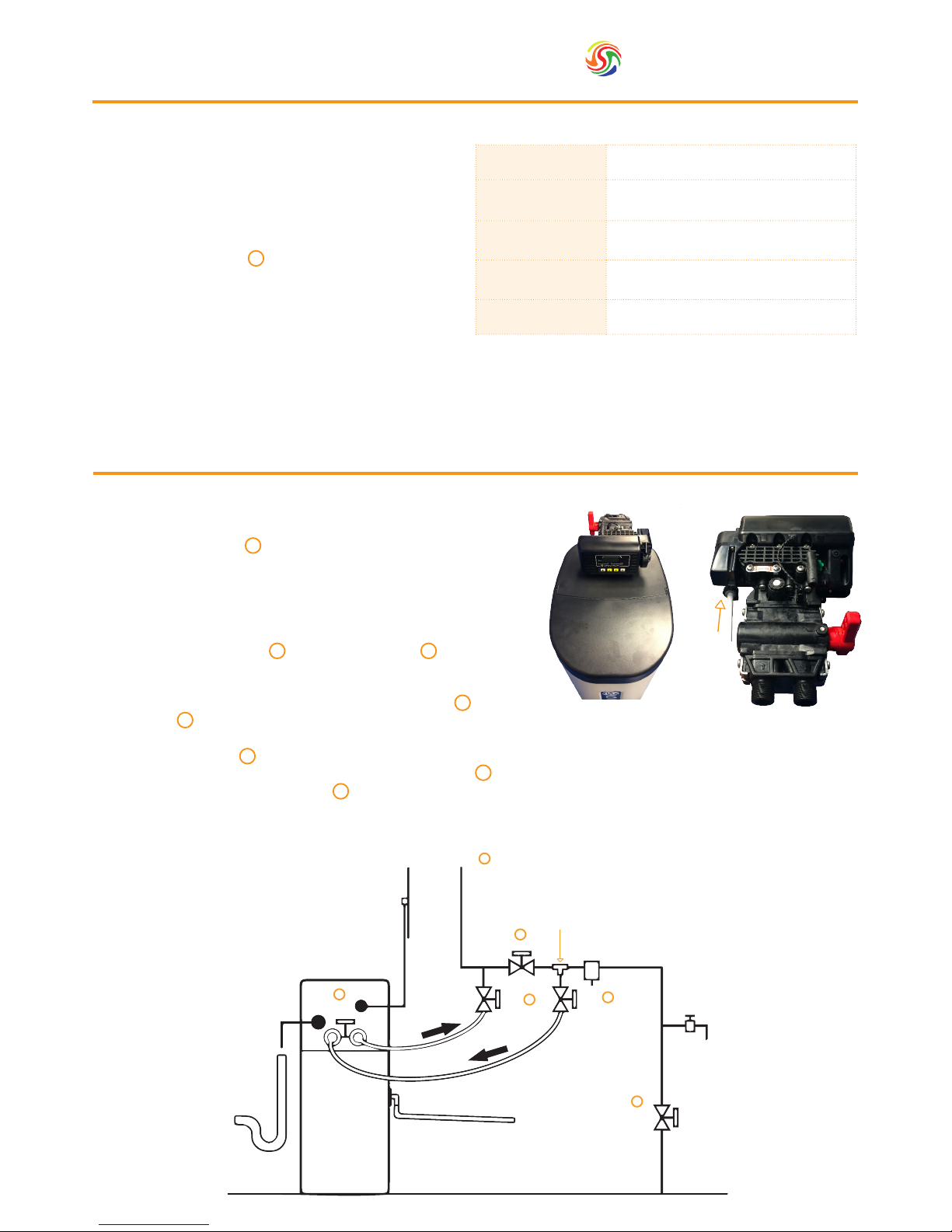

3. Valve User Interface

Brine Line

Drain Line

Blending Valve

Inlet

Outlet

Regeneration Indicator

Parameter Display

Flow Rate Indicator

Regeneration Button ( R )

Next Button ( )

Up Button ( )

Down Button ( )

Time Display

Cycle Nº

Bypass

Page 5

5

Spectrum

TM

4. Installation Instructions

The softener needs to be installed on the mains

water. It has an integrated bypass. Piping has to

comply with the regulations of the country where it

is installed.

• Do not plug in the electrical feed before the

installation.

• Ensure the stopcock is closed.

• The piping of the inlet and outlet are ¾” BSP.

• The water needs to have a pressure between 2-8

bar and 4-42 degrees.

• The softener has to be installed on a at dry surface.

• Electrical mains powered 220-240V AC 50Hz for plug model.

• The soldering on the pipework has to be done before connecting the water softener as heating could damage the

water softener.

• For residential purposes, it is essential to ensure that at least one drinking water tap is not connected to the

softener. Softened water has a high Sodium content which is to be avoided for people on low sodium or salt diets,

babies on infant formulas.

5

4

5

5

4

6

6

Water Pressure 2 - 8 bar

Electrical Supply Uninterrupted AC

Existing Plumbing

Free of any deposits or build-ups

inside pipes

Softener Location

Locate close to drain & connect

according to plumbing codes

Bypass Valves Always provide external bypass valve

4.1. Connecting

1. Rotate the valve so that the electronic display faces the ip top

lid on the softening system. (Fig.A)

2. Insert white brine tube inside the push t valve connector. (Fig.B)

3. Close the stop cock.

4. Connect the drain Line to the the outside drain of the premises.

It is necessary to t an air gap device.The drain piping should be

as short as possible avoiding height of over 1.5 metres higher

than the softener as well as lengths of over 5 metres.

5. Connect the inlet and outlets to the tted plumbing.

6. Close the bypass valves. Open the stopcock and open the

water at the feed tap. This will allow any particles to be removed

from the system before operation. Let water run out of the tap

until it is clear. Once done, close both the outlet tap and the

stopcock to pursue further steps of the installation.

7. Manually ll the brine tank with water between 5 and 10 cm.

8. Open the bypasses as well as the stop cock . You will hear the water owing into the resin pressure vessel. When

there is no more water owing in, open a cold water tap so that the excess air will purge out of the system. Once

the air is removed, close the tap.

9. You can now switch on the valve electrical power.

10. Press the R button for 5 seconds twice to allow a regeneration. It will last between 30 minutes and 1 hour.

6

5

Mains Out

Power

Supply

Drain

Hose

To Drain

Water Softener

In Out

Overow To Outside

Main Water

Supply

Mains

Stopcock

Main Water

Tap For

Drinking

Pressure Reducing

Valve (if required)

Bypass Valve

Inlet Tee

Incorporating

Check Valve

Outlet

Valve

Inlet

Valve

Internal

Bypass

1

2

3

4

5

6

Fig. A

Fig.B

Page 6

Spectrum

TM

6

5. Valve Initial Set-Up

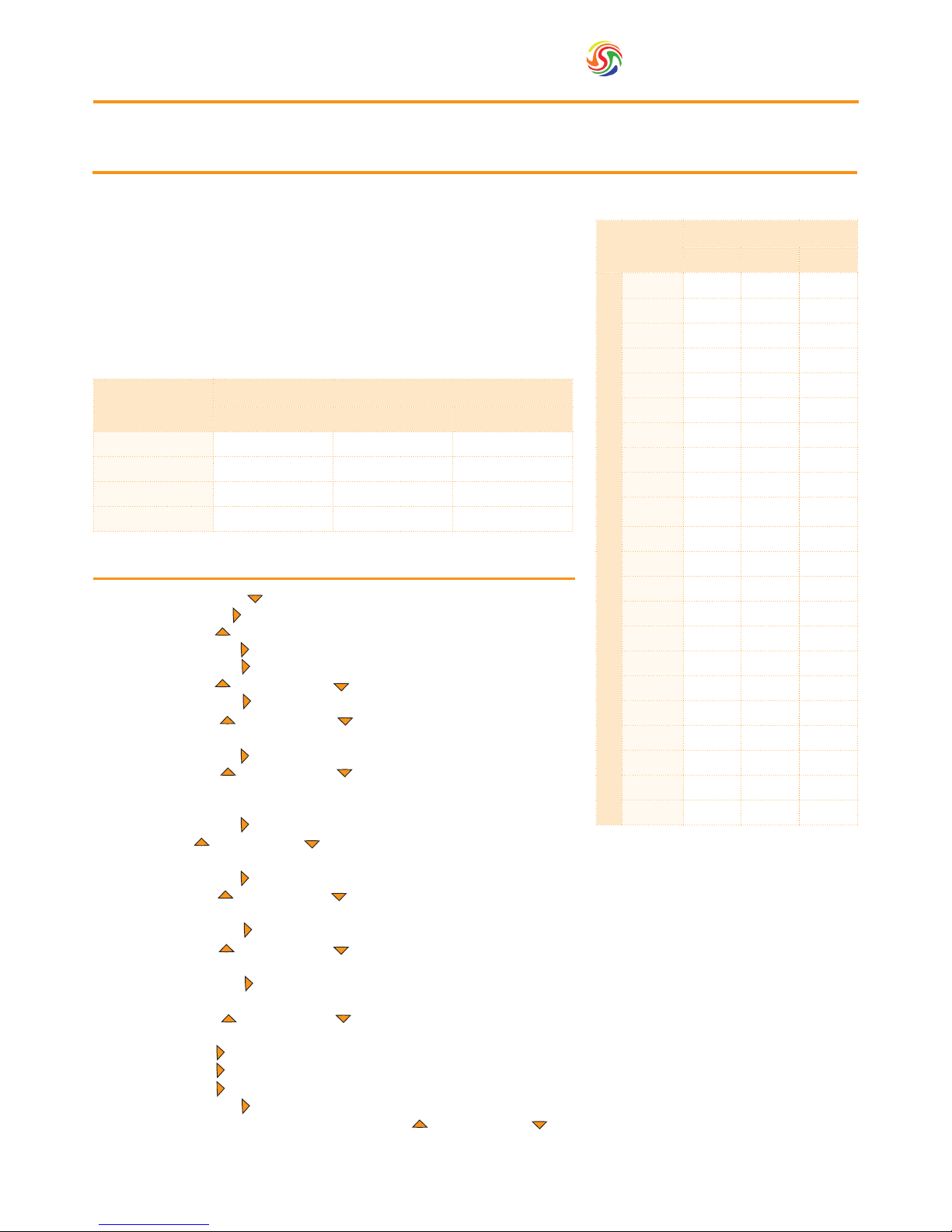

5.2. Setting up the regeneration program

1. Push the “DOWN / ” button until the time displayed is 23:45.

2. Push the “NEXT / ” button for 8 seconds until r_ _ (VALUE) is displayed.

3. Push the “UP / ” button until r-3 is displayed.

4. Press the “NEXT / ” button until t-df is displayed.

5. Press the “NEXT / ” button until F-(VALUE) is displayed.

6. Press the “UP/ ” or “DOWN / ” button until F-05 is displayed.

7. Press the “NEXT / “ button until 1F-(VALUE) is displayed.

8. Press the “UP / ” or “DOWN / “ until reaching the value

determined in chart 1. (i.e. an 18l softener with 200ppm = 4.5)

9. Press the “NEXT / ” button until 1-(VALUE) is displayed.

10. Press the “UP / ” or “DOWN / ” button until you reach the value

determined in the regeneration cycle setting chart for cycle 1 for your

specic softener.

11. Press the “NEXT / ” button until 2-(VALUE) is displayed.

12. Press “UP / ” or “DOWN / “ until you reach the valued determined

in the cycle setting chart for cycle 2 for your specic softener.

13. Press the “NEXT / ” button until 3-(VALUE) is displayed.

14. Press the “UP / ” or “DOWN / ” button until you reach the value

determined in the cycle setting chart for cycle 3

15. Press the “NEXT / ” button until 4-(VALUE) is displayed

16. Press the “UP / ” or “DOWN / ” button until you reach the value

determined in the cycle setting chart for cycle 4

17. Press the “NEXT / ” button until the regeneration time is displayed

(VALUE).H1

18. Using the “UP / ” or “DOWN / ” buttons set the time to a

convenient one, when you are less likely to use water i.e. 3.H1 = 3AM

19. Press “NEXT / ” button oF:H2 will be displayed

20. Press “NEXT / ” button oF:H3 will be displayed

21. Press “NEXT / ” button oF:H4 will be displayed

22. Press the “NEXT / ” button so that a time will be displayed.

23. Adjust to the correct rime of day using “UP / ” or “DOWN / ”

then your softener is ready to work.

5.1. Programming

Hardness

Settings

Resin Volume (L)

13 18 25

100 6.5 9.0 12.5

120 5.4 7.5 10.4

140 4.6 6.4 8.9

160 4.1 5.6 7.8

180 3.6 5.0 6.9

200 3.3 4.5 6.3

220 3.0 4.1 5.7

240 2.7 3.8 5.2

260 2.5 3.5 4.8

280 2.3 3.2 4.5

300 2.2 3.0 4.2

320 2.0 2.8 3.9

340 1.9 2.6 3.7

360 1.8 2.5 3.5

380 1.7 2.4 3.3

400 1.6 2.3 3.1

420 1.5 2.1 3.0

440 1.5 2.0 2.8

460 1.4 2.0 2.7

480 1.4 1.9 2.6

500 1.3 1.8 2.5

600 1.1 1.5 2.1

Hardnes Level in ppm CaCO

3

The capacity of your softener will depend on the hardness of your water.

First of all, check Chart 1 to the right, depending on your softener model

13, 18 or 25 L

The volume given in Chart 1 will be the volume of soft water produced

between 2 regenerations in m3.

As an example, if you have a 18L softener with a hardness of 360ppm, your

capacity will be 2.5m3. This is the value you should set in the program.

Cycle

Settings

Softener Model

13 18 25

Cycle 1 5 6 7

Cycle 2 21 25 30

Cycle 3 4 4 5

Cycle 4 4 6 8.5

Chart 1: Softener Water Capacity Chart

Chart 2: Regeneration Cycle Chart

Page 7

7

Spectrum

TM

6.1. Operation in service mode

• Once your softener is running, you can view the time of day. By pressing “NEXT / ” for a few seconds, you will be

able to see the remaining capacity of soft water left.

• Once the capacity is expired, a ashing (CIRCLE) will be displayed on the screen, indicating a regeneration will be

programmed at the time determined in the program.

• Regeneration will cause the machine motor to run, creating a mechanical noise, this is normal.

6. Valve Operation

6.2. Adjust the Time of Day

• Push the “UP / ” and “DOWN / ” buttons to set the correct time.

NB. The display of a valve using a low voltage transformer will blink during power failure. This blinking will end once

the programming has been restored.

6.3. Displaying the Remaining Volume of Water to be Treated (Metered System Only)

• Push the “NEXT / ” button to switch between the time of day and the remaining volume display.

6.4. Initiate a Regeneration

• Push the “regeneration / R” button for one second to initiate regeneration (the system will regenerate immediately for

a valve in “immediate regeneration mode” or at the next pre-set time for a valve in “delayed regeneration mode”).

• Push the “REGENERATION / R” button for 5 seconds to initiate regeneration immediately for a valve that is

programmed in “chronometric” or “volumetric” mode. This is to be used to ush the system after a long time such

as returning from holidays.

6.5. In Service

• The display will show the time of day during normal operation and will turn off after 3 minutes to conserve battery

life for battery operated models. The remaining volume of water to be treated can be displayed by pushing the

“NEXT ” button.

Page 8

Spectrum

TM

8

7. End User Instructions

Once the softener has been installed and setup by a professional, there are some useful functions to be aware of.

Salt replenishment: when the softener runs out of salt, it will not produce any more soft water. It is therefore impor-

tant to keep it topped-up, this is done via the lid of the top of the softener. Salt should always be visible over the line

of water in the cabinet but the total volume of salt and water should not exceed the overow level.

NOTE: ONLY USE GRANULATED OR TABLET SALT DEDICATED TO

WATER SOFTENERS

Bypass: The Bypass is a function which makes the water softener ofine.

This is useful when soft water is not required (e.g. using a hosepipe)

In the service position, the softener will produce soft water.

In the Bypass position, the water will not go through the resin tank and

remain as hard water.

Blending Valve: This can be used optionally when some

applications require a certain level of hardness. When

the blending valve is closed (Fully turned clockwise), you

will get 100% soft water. The more you open it (turning

anticlockwise), the harder the water will get.

Display: In service, the valve will go in power saving mode and will not

display information.

• Press “regeneration / R ” button and the display will be active again,

displaying the time of day.

• By pressing “NEXT / “ you will display the amount of water left

before the next regeneration is planned.

• If the symbol (Little circle with an arrow) is ashing, it indicates that

your softener will regenerate at the programmed time.

Regeneration is a standard process required to recharge the resin

contained inside the softener. The regeneration will happen at the time

set in the program. A motor noise can be heard when the softener is in

regeneration mode, this is normal.

The screen will display the various cycles of the regeneration and will then

go back to service mode.

• Backwashing

• Brining

• Rinse

• Rell

Power Cuts: Your softener will keep its parameters in memory for up to 48 hours. After that, reprogramming may be

necessary. Please refer to the programming sheet in the installer part of the manual.

Downtime: After holidays, or a long period without using water over a week, it is recommended to initiate a manual

regeneration in order to ush the resin tank.

Press the “regeneration / R ” button to bring up the display, press “regeneration / R ” again for 5 seconds in order to

program a delayed display (little circle ashing) and press a third time 5 seconds to start immediately. The cycle will

nish after approximatively one hour.

‘Service position’

shown.

Moving the red

lever upwards to

a vertical position

will put the valve

into the ‘Bypass

position’.

Front view shows

display/controls.

13 Litre Flo

System.

Lid

Overow

!

Page 9

9

Spectrum

TM

Problem Possible Cause Possible Solution

A. Controller does not work

1. Power off

2. Transformer is not plugged in

3. Defective power cord

4. Defective transformer

1. Switch on power

2. Connect to constant power source

3. Replace cord

4. Replace the transformer

B. Incorrect time of regeneration 1. Power outage causes inaccurate timing 1. Reset the timer

C. Leaking 1. Loose connections 1. Tighten joints

D. Noisy 1. Air pressure in the system 1. Re-backwash the system to vent air

E. Milk-white water 1. Air exists in the system 1. Turn on the tap to vent air

F. Unsatised water hardness

1. Poor raw water quality

2. Time of regeneration is too long

3. Resin disabled

1. Contact your supplier for assistance

2. Reset time of regeneration

3. Re-regeneration or use new resin

G. Softener fails to use salt

1. Water pressure is too low

2. Brine line blocked

3. Injector is blocked

4. Internal control leak

1. Line pressure must be at least 20 psi

2. Clean brine line

3. Clean or replace injector & screen

4. Check piston, seals and spacers

H. Brine container overow 1. Rell time too long 1. Contact your supplier for assistance

I. Water hardness remains

1. Fail to regenerate automatically

2. Brine concentration is poor

3. Injector is plugged

1. Check power of controller

2. Keep brine tank full of salt

3. Disassemble the injector and clear it

by washing with water

K. Untreated water leakage

during service

1. Improper regeneration

2. Leaking of bypass valve

3. O-ring around riser tube damaged

4. Incorrect regeneration cycle setting

1. Repeat regeneration making certain

that the correct salt dosage is set

2. & 3. Replace O-ring

4. Reset regeneration cycle

8. Troubleshooting

8.1. FLO System

Page 10

Spectrum

TM

10

8. Troubleshooting

8.2. FLO Valve

Problem Possible Cause Possible Solution

A. The system will not regenerate

1. Used or defective batteries

2. Disrupted electric supply

3. Damaged meter cable

4. Water meter turbine blocked

5. Defective drive motor

6. Defective electronic board

1. Replace old batteries

2. Recover the power supply

3. Verify the connection & inspect cable

4. Clean or replace the turbine

5. Replace the drive motor

6. Replace the electronic board

B. There is hard water coming

from the outlet

1. No salt in the brine tank

2. System in bypass position

3. Internal leak in valve

4. Dirty breech

5. Low brine tank rell

6. See symptoms in “A”

1. Rell the brine tank

2. Return the system to service position

3. Change the internal seals

4. Clean the breech

5. Change the two breech seals

6. See resolution in “A”

C. Decrease in pressure and ow

1. Iron build up in the water supply

2. Iron build up in the system

3. Levels of iron too high in the feed water

1. Clean or replace the supply line to

the system

2. Clean the valve and the resin bed.

3. Increase backwash time to prevent

fouling. Specically install an additional lter to remove iron.

D. High levels of brine present in

the brine tank

1. Clogged drain line

2. Defective cycle time

1. Check and clean the drain line

2. Adjust the cycle times

E. The outlet water tastes “salty”

1. Clogged injectors

2. Clogged drain line

3. Clogged brine valve

4. Defective cycle time

5. Damaged drain ow control

1. Clean the injectors

2. Check the drain line and ow control

3. Clean or replace the piston assembly

4. Adjust the cycle time

5. Change the ow control

F. There is a constant leak during

normal operation

1. Defective seal

2. Defective piston

3. Control valve blocked in regeneration

4. Defective power head

1. Change the seals

2. Change the piston

3. Change the piston and the seals and

spacers

4. Change the power head

G. Valve regenerates continuously

1. Defective power head 1. Change the power head

Page 11

11

Spectrum

TM

9. Cautions

1. Without reading and understanding the contents of this user manual, DO NOT perform any operations on the

control valve.

2. Strictly prohibit a leaning position when shipping, installing and using this product as this could cause damage.

3. During the regeneration, water from the tap will NOT be softened. It is NOT recommended to use water during

regeneration; otherwise a negative effect on the regeneration result will occur.

4. Initiate a regeneration cycle when the softener has been inactive for a long period of time and then turn on the

tap for several minutes before resuming normal use.

5. Do not disconnect power during service to prevent timer distribution.

6. If water usage or hardness of raw water dramatically increases (compared to the normal usage), then the frequency

of regeneration should increase.

7. Hot water could cause severe damage to the softener system, for water boiler and water heaters users, ensure the

total-run of the piping between the softener and the boiler is not less than 3 metres. It is recommended to install

a check valve between the lter and the boiler if unable to meet the required piping length.

8. The input water pressure must be between 2-8 bar.

9. No chemicals should be present at the inlet and outlet connecting sectors.

10. Besides the system, spare part connection materials are not included in the scope of the manufacturer’s warranty.

11. The required environmental temperature for a softener is 1-42°C. Outside these parameters may cause the

softener to malfunction.

12. Do not apply pressure to the softener.

13. Indoor installation is preferred. Avoid exposure to direct sunlight, radiation from other heating sources and avoid

extreme weather conditions including rain and snow.

14. Use salt granules or tablets designed for softeners.

15. No tools should be used for connecting the plastic parts as over tightening or excessive force could result in

damage.

16. If necessary use food grade silica sealant for lubricating rubber O-rings.

17. Only qualied personnel should adjust or remove the adaptor locking clips on the reverse of the valve, as this can

tamper with the valve settings. Should this be required pressure must rstly be discharged from inside the water

softener.

Page 12

Spectrum

TM

12

10. Technical Information

Maximum Operating Temperature (ºC)

42

Minimum Operating Temperature (ºC)

1

Maximum Operating Pressure (bar)

8

Minimum Operating Pressure (bar)

2

Hydrostatic Test Pressure (bar)

20

Max Flow Rate (m3/hr)

4.5

Inlet / Outlet (")

¾

Pressure Tank Thread (")

2.5

Valve

SPECTRUM 5

Power Requirements (V)

230

Salt Storage (kg)

10 14 21

Resin Volume (l)

13 18 25

Nominal Flow Rate (m3/hr)

0.5 0.6 1

Salt Consumption Per Regeneration (kg)

1.5 2 3

Water Consumption Per Regeneration (l)

78 90 133

Cabinet Width (mm)

330

Cabinet Depth (mm)

470

Cabinet Height (mm)

660 870 1100

Loading...

Loading...