Spectrum SoftH2O DUO 30, SoftH2O DUO 50, SoftH2O DUO 75, SoftH2O DUO 150, SoftH2O DUO 100 Installation, Service & Operation Manual

...Page 1

Table of Contents

1. General Notes p.2

2. Description & Equipment Adjustments p.3

3. Components, Features & Functions p.4

4. Valve User Interface p.5

5. Installation Instructions p.6

6. Assembly & Start-Up p.7

7. Programming & Operation p.9

8. Master Programming Mode p.11

9. User Programming Mode p.16

10. Diagnostic Programming Mode p.17

11. Programming Charts p.18

12. Troubleshooting p.19

13. Cautions p.21

14. Technical Information p.22

Installation, Service &

Operation Manual

SoftH2O DUO

Spectrum

TM

Water Softener

Page 2

Spectrum

TM

2

1. General Notes

The SoftH2O-DUO water softeners are a range that utilise two resin pressure vessels. Compared to standard single

pressure vessel water softeners, this setup guarantees 24/7 access to soft water. Whilst one pressure vessel is in service,

the other one is either in standby or in regeneration. The automatic valve monitors the amount of water going through

the softener and triggers regeneration when the softening capacity of one pressure vessel expires. This manual is for a

range of softeners based on the eck 9000/9100/9500 with various volumes of resin going from 30 to 350 litres.

Please take a look at the model supplied as this will have an inuence on various parameters for starting up your

softener, especially during programming. Once installed softeners are low in maintenance and only require a top up of

salt in order to operate properly. Please ensure that the brine tank has got a minimum level of salt at all times. Although

the original valve manual is included, it is preferable to use this O.E.M. manual as all settings and information will be

adapted to the conguration of your specic system.

Page 3

3

Spectrum

TM

Regeneration Mode

Regeneration Type

Electrical Supply

Installation Number Nominal Capacity

m3 °tH

Valve Serial Number Inlet Water Hardness

°tH

Tank Size Treated Water Volume

litres

Resin Type Outlet Water Hardness

°tH

Resin Volume

litres

Salt Quantity per Regeneration

kg

Chronometric

days

Down Flow Brining

1) Backwash

min

2) Brining & Rinse

min

3) Rapid Rinse

min

4) Brine Tank Rell

min

Low Voltage DC Transformer

2. Description &

Equipment Adjustments

Page 4

Spectrum

TM

4

3. Components, Features

& Functions

Component Features Functions

Automatic

Control Valve

• FDA approved Noryl plastic

• Strong corrosion resistance

• Innovative design

• 24 hours control and monitoring with a timer; automatically

regenerates the media bed at the system’s set time of

regeneration according to the set regeneration frequency.

• Automatically calculates a cycle plan according to the quality

of supply water and the user’s actual water use.

• Cycle Process:

In service: Once the water is supplied with correct pressure

and ow, the cations contained in hard water will be replaced

by Na

+

in regenerants, then the softening system will supply

softened water through its outlet.

Backwash: When the ion exchange resin has been

exhausted, the resin bed needs to be regenerated. Before

the regeneration of the resin bed, a backwash step is

necessary for two main purposes; removing the residue

in the resin bed and loosening the impacted resin bed for

better regeneration efciency.

Rinse: Rinse the resin bed to remove the residual regenerant

(salt) after the brining step until the water from outlet

contains no regenerant; rinse could also compact the resin

bed for a better softening effect.

Rell: Rell the brine tank with water to dissolve salt for the

next regeneration.

Valve Operation Mode Softener: Duplex water softener operation

Regeneration Mode Volumetric immediate with electronic timer

Outlet water hardness can be adjusted

User can adjust the mixing valve to get desired outlet water

hardness

Display Format Metric

Media High-grade Anion exchange resin Food grade softening resin

Pressure

Vessel

• NSF 44 tested and certied

• Polyethene material manufactured for the

Food & Beverage industries

• Light, high pressure resistance

• Strong corrosion resistance

Pressure vessel holds the resin and a distribution system

Riser Tube &

Distribution

System

A riser tube and distribution system disperse water evenly

through the resin bed

Brine Valve

& Tank

• High pressure resistance

• Brine valve prevents the brine tank from overowing

• Water and salt mix in the brine tank. Salt will dissolve

continuously until the water is saturated by salts

Page 5

5

Spectrum

TM

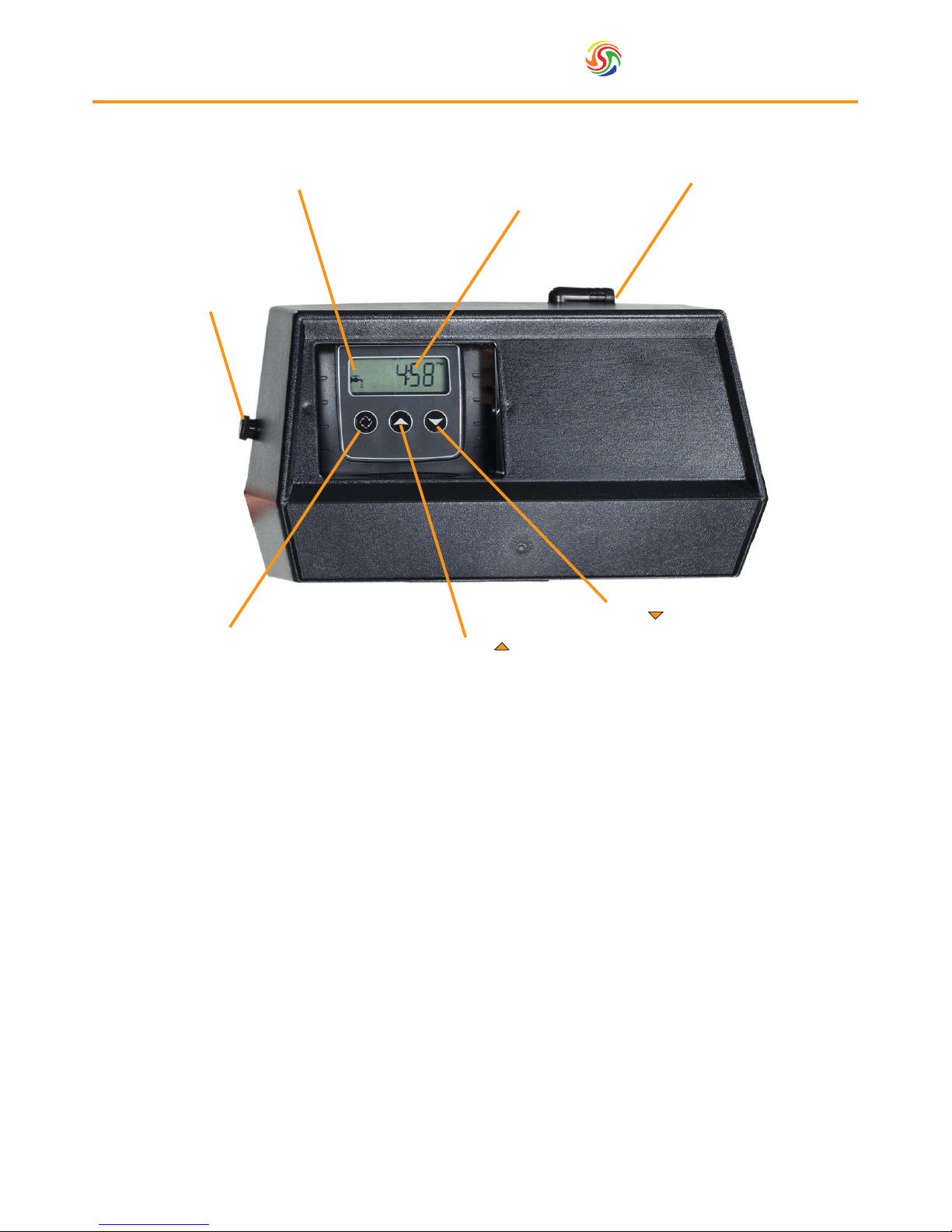

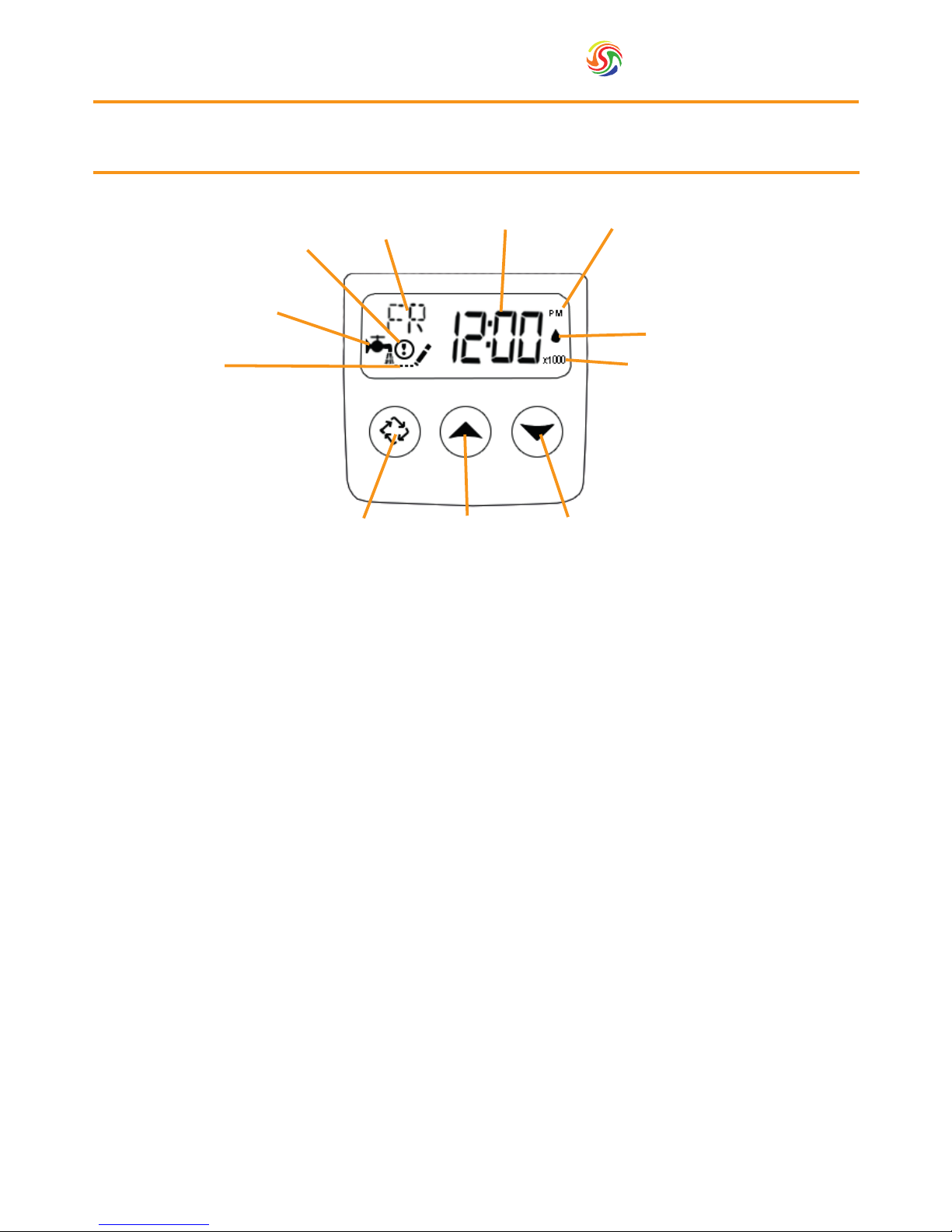

4. Valve User Interface

Down Button ( )

Up Button ( )

Extra Cycle Button

Cover Unlocking Nut

Service Icon

Time/Data Display

Drain Line

Page 6

Spectrum

TM

6

5. Installation Instructions

Water Pressure 2 - 8 bar

Electrical Supply Uninterrupted AC

Existing Plumbing Free of any deposits or build-ups inside pipes

Softener Location Locate close to drain & connect according to plumbing codes

Bypass Valves Always provide external bypass valve

The DUO water softener should be

installed and prepared by a qualied

person.

The system should be ready to use

after the complete installation and a

regeneration test. Any other operations

are not necessary unless power supply is

cut off accidentally.

• The softener needs to be installed onto the mains water supply. Piping has to comply with the regulations of the

country where it is installed.

• The softener will require space for maintenance and operation. Please allow enough room on the top to remove the

valve should it be needed. Also ensure access to the valve is clear in order to be able to visualise or adjust settings

on the electronic board.

• The softener should be installed on a dry at surface.

• The softener uses mains power 230-240V AC 50Hz which is transformed into 24V DC. Please ensure that the electrical

supply is protected from water or extreme conditions. All electrical installations have to comply with laws of the

country in which it is installed.

• The water needs to have a pressure between 2-8 bar and 4-42 degrees Celsius.

• For residential purposes, it is essential to ensure that at least one drinking water tap is not connected to the softener.

Softened water has a high Sodium content which is to be avoided for people on low sodium or salt diets, babies on

infant formulas.

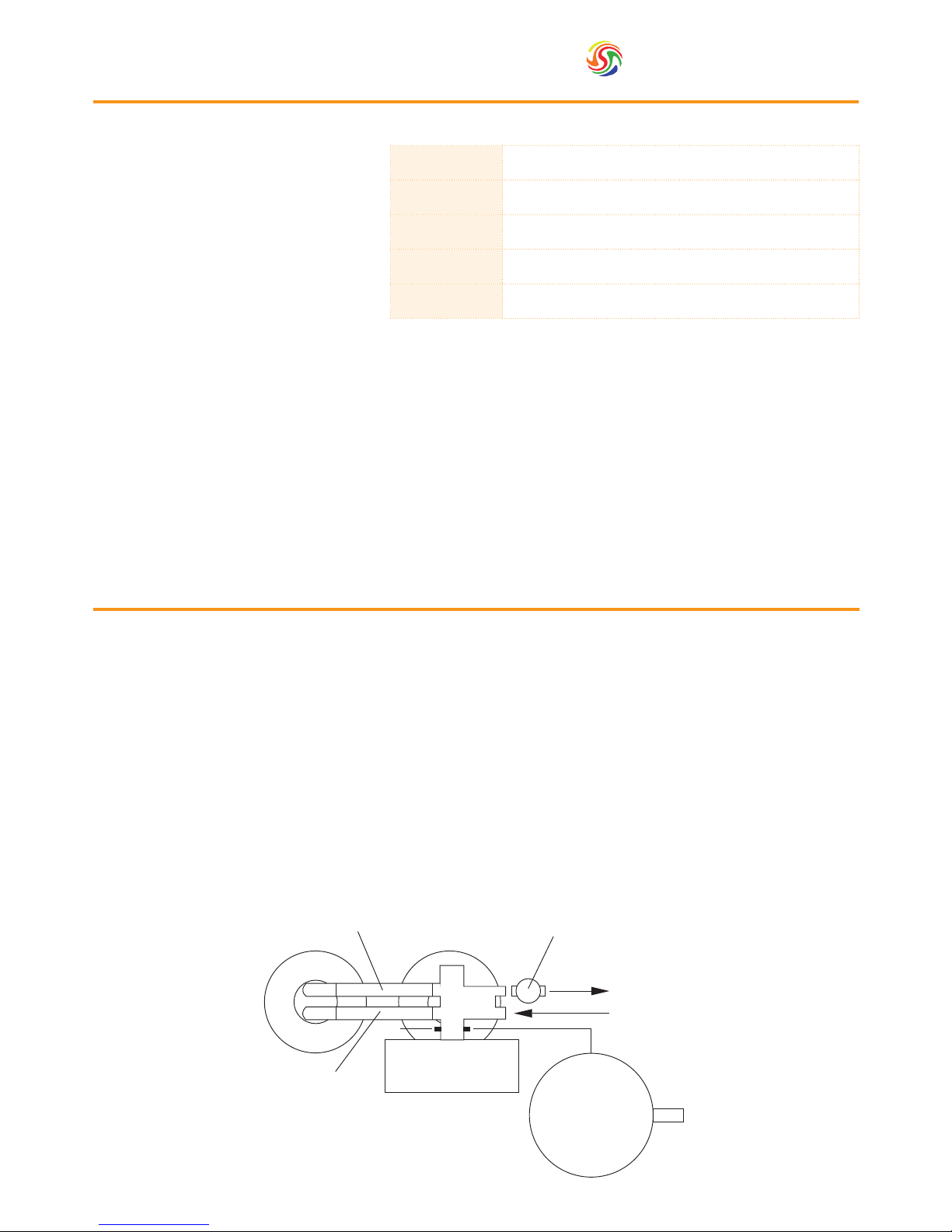

5.1. Connecting

1. Two drain connections will be required. The rst drain should be connected directly to the valve. (For

the 9000/9100 a ½”hose, for 9500 a ¾” BSP). The diameter of the exible drain hose should be able to

accommodate the ow of water to the drain.

N.B. if the water cannot ow to the drain properly, the performance of the softening system will be affected.

The drain should never be connected at a point higher than the softener as the back pressure will again affect

ow.

2. The second drain should be connected to the brine tank over ow elbow. This is in place to ensure that if for

any reason the brine tank should overll the excess is sent to the drain. The diameter of the exible hose should

be able to accommodate the ow and the outlet should not be connected above the height of the system.

N.B. the softening system should be connected with an external bypass in order to allow the system to be

taken ofine without affecting water supply elsewhere.

N.B. any joint work or metal work should be completed prior to installation of the softening system.

Flexible hose

Control Valve

Inlet

Outlet

Watermeter

Drain

Flexible hose

Copper pipe

Control Valve

Salt suction lling

Inlet

Outlet

Watermeter

Copper pipe

Drain

Pressure

Vessel 1

Pressure

Vessel 2

Pressure

Vessel 1

Pressure

Vessel 2

Brine Tank

Salt suction lling

Brine Tank

Water Softener Plumbing Overview

Drain

Connection

Page 7

7

Spectrum

TM

6. Assembly & Start-Up

6.1. Assembly

1. Place the riser tube inside the rst pressure vessel. Depending on the size of the vessel, the system will either be

supplied in a classic cone shape con guration or, for larger vessels, a star-type distribution system. Assemble the

star type distribution system if applicable.

2. Centre the distribution system inside the vessel and seal the top of the riser tube to ensure that no resin enters

the distribution system.

3. Fill the vessel (up to 85%) with the softening resin, ensuring that the distribution system remains upright and

central.

N.B. a funnel is recommended to aid the lling process and prevent excess resin from being spilt.

CAUTION: Resin can present a serious slip hazard if excessive amounts are spilt.

4. Lubricate the internal valve O-ring with 100% silicon lubricant and screw the valve onto the top of the pressure

vessel, again making sure that the distribution system locates securely into the valve body.

5. Repeat steps 1-4 for the secondary (slave) vessel.

6. Connect one end of the brine tube to the valve and the other end of the brine tube to the safety brine valve

located inside the brine tank. (The tubing should be secure to ensure that no air enters the system).

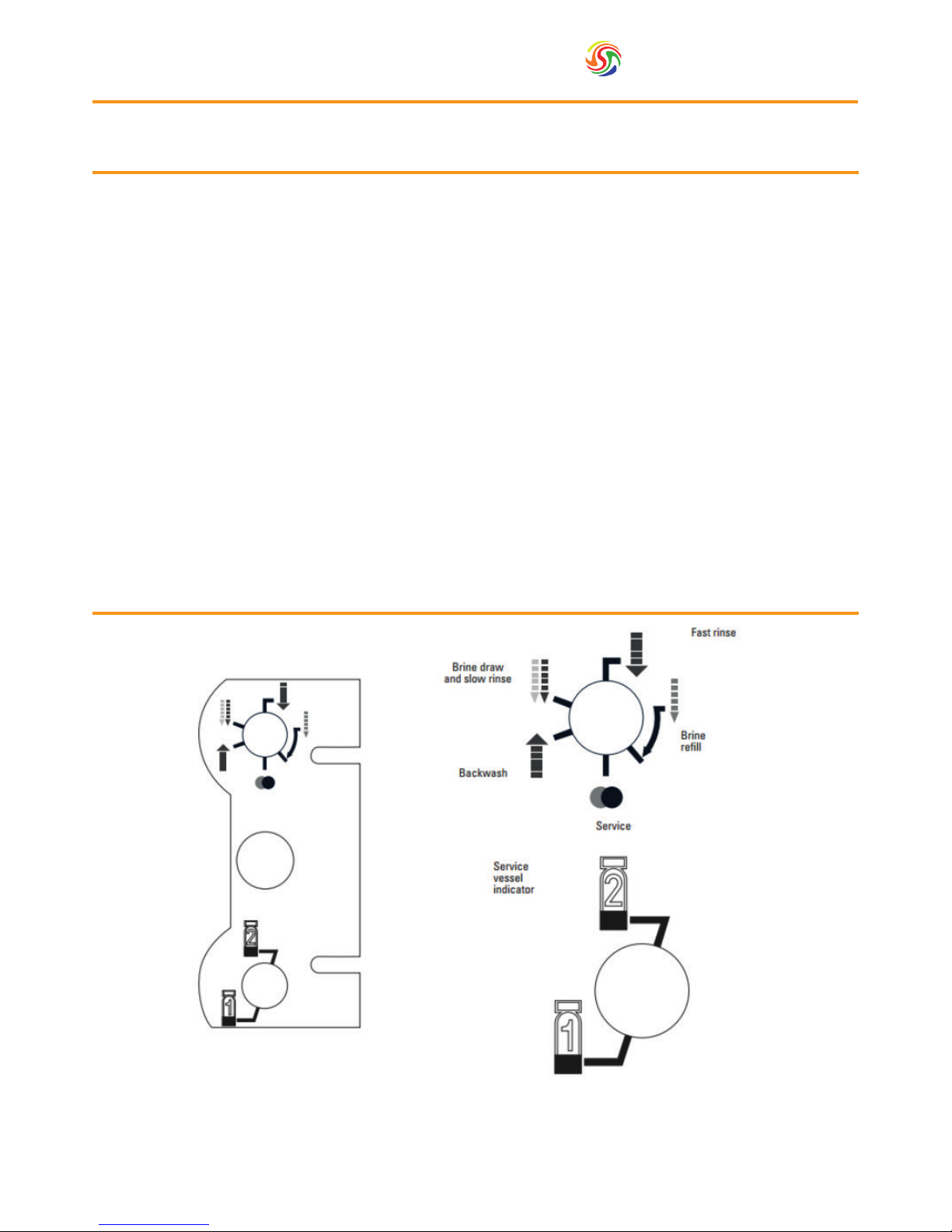

On the side of the motor there is a diagram which illustrates various information regarding the valve’s

regeneration cycle. The top arrow indicates the regeneration cycle. The bottom arrow indicates which tank is in

service. This information will have to be entered during the valve programming.

6.2. Valve’s Regeneration Cycle

Page 8

Spectrum

TM

8

6. Assembly & Start-Up

6.3. Start-Up

1. Fill the brine tank until the water reaches approximately half way up the tank.

2. Add salt until the tank in total is approximately ¾ full.

3. Switch on the electrical power .

N.B. If the valve has a bypass function, place the system in the bypass position.

4. Turn on the mains water supply.

5. Open a cold soft water tap nearby and allow to run until all foreign material has been removed from the system.

6. Once clean, close the soft water tap.

7. Move the bypass in service position and allow water to ow into the pressure vessels.

8. Open a cold soft water tap nearby and allow to run until the system has been purged of air.

9. Plug the valve into a power source. Once the valve has been connected to a power source, it may cycle on its

own in order to return to the service position.

10. Start regeneration by pressing the button on the controller and to bring the 2nd (slave) vessel into service.

Run through the cycle programmes in order to empty residual air in the rst vessel.

11. Repeat step 10 for the second vessel.

12. Once complete, press and allow the valve to go through a full cycle independently.

Page 9

9

Spectrum

TM

7. Programming &

Operation

In green are the options to select to ensure the proper operation of your system

In yellow are values to input based on your individual installation.

Abbreviation Parameter Option Abbreviation Options Functions

DF Display format

GAL Gallons

Ltr Litres

VT Valve type

dF1b Standard downow/Upow single backwash

dF2b Standard downow/Upow double backwash

Fltr Filter

Ufbd Upow brine rst

UFtr Upow lter

Othr Other

CT Control type

Fd Meter (ow) delayed

Fl Meter (ow) immediate

tc Time clock

dAY Day of week

NT Number of tanks

1 Single tank system

2 Two tank system

TS Tank in service

U1 Tank 1 in Service

U2 Tank 2 in Service

C Unit capacity Unit capacity (litres) for capacity, please view chart A

H Feedwater hardness Hardness of inlet water

RS Reserve selection

SF Percentage safety factor

rc Fixed reserve capacity

SF Safety factor Percentage of the system capacity to be used

RC Fixed reserve Fixed volume to be used as a reserve

DO Day override The systems day override setting

RT Regen time The time of day the system will regenerate

BW, BD, RR, BF

Regen cycle step

times

The time duration for each regeneration step.

Adjustable from OFF and 0-199 mins.

Note if “other” is chosen under “Valve Type” then R1,

R2, R3 etc will be displayed instead

D1, D2, D3, D4,

D5, D6 & D7

Day of week settings

Regeneration setting (ON or OFF) for each day of the

week on day-of-week systems

CD Current day The current day of the week

FM Flow meter type

t0.7 3/4” Turbine meter

P0.7 3/4” Paddle wheel meter

t1.0 1” Turbine meter

P1.0 1” Paddle wheel meter

t1.5 1.5” Turbine meter

P1.5 1.5” Paddle wheel meter

P2.0 2” Paddle wheel meter

GEN Generic or other meter

Page 10

Spectrum

TM

10

7. Programming &

Operation

7.1. Timer Operation

Features of the SXT:

• Power backup that continues to keep time and the passage of days for a minimum of 48 hours in the event of

power failure. During a power outage, the control goes into a power-saving mode. It does not monitor water

usage during a power failure, but it does store the volume remaining at the time of power failure.

• Settings for both valve (basic system) and control type (method used to trigger regeneration).

• Day-of-the-Week controls.

• While in service, the display alternates between time of day, volume remaining or days to regeneration, and tank

in service (twin tank systems only).

• The Flow Indicator ashes when outlet ow is detected.

• The Service Icon ashes if a regeneration cycle has been queued.

• Regeneration can be triggered immediately by pressing the Extra Cycle button for ve seconds.

• The Parameter Display shows the current Cycle Step (BW, BF, RR, etc) during regeneration, and the data display

counts down the time remaining for that cycle step. While the valve is transferring to a new cycle step, the

display will ash. The parameter display will identify the destination cycle step (BW, BF, RR, etc) and the data

display will read “----”. Once the valve reaches the cycle step, the display will stop ashing and the data display

will change to the time remaining. During regeneration, the user can force the control to advance to the next

cycle step immediately by pressing the extra cycle button.

Parameter

Display

Data

Display

PM

Indicator

Flow Indicator

x1000 Indicator

Error/

Information

Icon

Service Icon

Programming

Icon

Extra Cycle

Button

Up

Button

Down

Button

Page 11

11

Spectrum

TM

8. Master Programming

Mode

When the Master Programming Mode is entered, all available option setting displays may be viewed and set as

needed. Depending on current option settings, some parameters cannot be viewed or set.

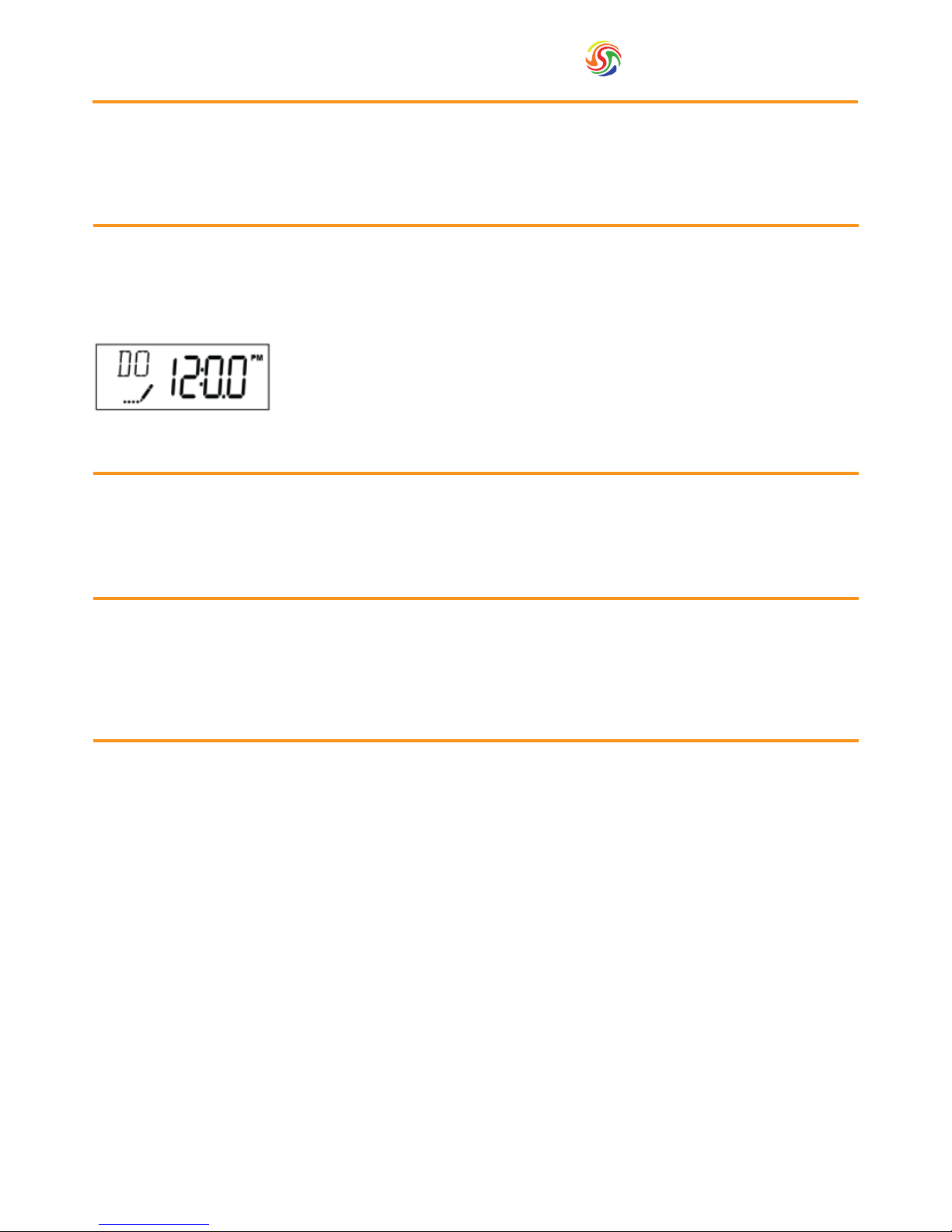

8.1. Setting the Time of Day

1. Press and hold either the ‘Up’ or ‘Down’ buttons until the programming icon replaces the service icon and the

parameter display reads ‘DO’.

2. Adjust the displayed time with the ‘Up’ and ‘Down’ buttons.

3. When the desired time is set, press the ‘Extra Cycle’ button to resume normal operation. The unit will also return

to normal operation after 5 seconds if no buttons are pressed.

8.2. Entering Master Programming Mode

Set the Time of Day display to 12:01 P.M. Press the ‘Extra Cycle’ button (to exit Setting Time of Day mode). Then

press and hold the ‘Up’ and ‘Down’ buttons together until the programming icon replaces the service icon and the

Display Format screen appears.

8.3. Exiting Master Programming Mode

Press the ‘Extra Cycle’ button to accept the displayed settings and cycle to the next parameter. Press the ‘Extra

Cycle’ button at the last parameter to save all settings and return to normal operation. The control will automatically

disregard any programming changes and return to normal operation if it is left in Master Programming mode for 5

minutes without any keypad input.

8.4. Resets

Soft Reset: Press and hold the ‘Extra Cycle’ and ‘Down’ buttons for 25 seconds while in normal Service mode. This

resets all parameters to the system default values, except the volume remaining in meter immediate or meter delayed systems and days since regeneration in the time clock system.

Master Reset: Hold the ‘Extra Cycle’ button while powering up the unit. This resets all of the parameters in the unit.

Check and verify the choices selected in Master Programming Mode.

Page 12

Spectrum

TM

12

Parameter Value Description Parameter Image

1. Display format DF Ltr

This is the rst screen that appears when

entering Master Programming Mode.

The Display Format setting speci es

the unit of measure that will be used for

volume and how the control will display

the Time of Day. This option setting is

identi ed by “DF” in the upper left hand

corner of the screen.

2. Valve type VT dF1b

Press the Extra Cycle button. Use

this display to set the Valve Type. The

Valve Type setting speci es the type

of cycle that the valve follows during

regeneration. Note that some valve

types require that the valve be built

with speci c subcomponents. Ensure

the valve is con gured properly before

changing the Valve Type setting. This

option setting is identi ed by “VT” in

the upper left hand corner of the screen.

3. Control type CT Fl

Press the Extra Cycle button. Use this

display to set the Control Type. This

speci es how the control determines when

to trigger regeneration. For details on how

the various options function, refer to the

“Timer Operation” section of this service

manual. This option setting is identi ed by

“CT” in the upper left hand corner of the

screen.

4. Number of tanks NT 2

Press the Extra Cycle button. Use this

display to set the Number of Tanks

in your system. This option setting is

identi ed by “NT” in the upper left

hand corner of the screen.

5. Tank in service TS U1

Press the Extra Cycle button. Use this

display to set whether tank one or tank

two is in service. This option setting is

identi ed by “TS” in the upper left hand

corner of the screen.

This parameter is only available if the

number of tanks has been set to 2.

There are two possible settings:

Look on the side label next to the

motor, the bottom arrow indicates

which tank is in service. If the arrow

indicates tank 1, then select U1. If the

arrow indicates tank 2 then choose U2–.

8. Master Programming

Mode

Page 13

13

Spectrum

TM

8. Master Programming

Mode

Parameter Value Description Parameter Image

6. Unit capacity C

Press the Extra Cycle button. Use this

display to set the Unit Capacity. This

setting speci es the treatment capacity

of the system media. Enter the capacity

of the media bed in grains of hardness

when con guring a softener system, and

in the desired volume capacity when

con guring a lter system. This option

setting is identi ed by “C” in the upper

left hand corner of the screen.

The Unit Capacity parameter is only

available if the control type has been set

to one of the metered options. Use the

Up and Down buttons to adjust the value

as needed. Input the value indicated in

the programming chart corresponding

to your model.

7. Feed water

hardness

H

Press the Extra Cycle button. Use this

display to set the Feed water Hardness.

Enter the feed water hardness in the

same unit chosen for determining the

capacity .volume for softener systems,

This option setting is identi ed by “H”

in the upper left hand corner of the

screen. Use the Up and Down buttons

to adjust the value as needed.

8. Reserve selection RS rc

Press the Extra Cycle button. Use this

display to set the Safety Factor. Use this

display to select the type of reserve to

be used in your system. This setting is

identi ed by “RS” in the upper left-hand

corner of the screen

9. Safety factor SF 0-50%

Press the Extra Cycle button. Use this

display to set the Safety Factor. This

setting speci es what percentage of

the system capacity will be held as a

reserve. Since this value is expressed

as a percentage, any change to the unit

capacity or feed water hardness that

changes the calculated system capacity

will result in a corresponding change to

the reserve volume. This option setting

is identi ed by “SF” in the upper left

hand corner of the screen. Use the Up

and Down buttons to adjust the value

from 0 to 50% as needed.

Page 14

Spectrum

TM

14

Parameter Value Description Parameter Image

10. Fixed reserve

capacity

RC

Press the Extra Cycle button. Use this

display to set the Reserve Capacity. This

setting speci es a xed volume that

will be held as a reserve. The reserve

capacity cannot be set to a value

greater than one-half of the calculated

system capacity. The reserve capacity is

a xed volume and does not change if

the unit capacity or feed water hardness

are changed. This option setting is

identi ed by “RC” in the upper left-

hand corner of the screen. Use the Up

and Down buttons to adjust the value as

needed.

11. Day override DO

This setting speci es the maximum

number of days between regeneration

cycles. The system will regenerate

regardless of usage if the days since

last regeneration cycle equal the

day override setting. Setting the day

override value to “OFF” disables this

function. This option setting is identi ed

by “DO” in the upper left hand corner

of the screen. Use the Up and Down

buttons to adjust the value as needed.

This parameter is dependant by your

individual needs.

12. Regeneration

time

RT

Press the Extra Cycle button. Use this

display to set the Regeneration Time.

This setting speci es the time of day the

control will initiate a manually queued,

or day override triggered regeneration.

This option setting is identi ed by “RT”

in the upper left hand corner of the

screen. Use the Up and Down buttons

to adjust the value as needed.

13. Regeneration

cycle step times

BD

BF

BW

RR

SV

0-199

Press the Extra Cycle button. Use this

display to set the Regeneration Cycle

Step Times. The different regeneration

cycles are listed in sequence based on

the valve type selected for the system,

and are identi ed by an abbreviation in

the upper left-hand corner of the screen.

The abbreviations used are listed below

although not necessarily in that order.

The values to input are dependent on

your own model and can be found in

the table in Section 11. Use the Up and

Down buttons to adjust the value as

needed. Press the Extra Cycle button to

accept the current setting and move to

the next parameter.

8. Master Programming

Mode

Page 15

15

Spectrum

TM

8. Master Programming

Mode

Parameter Value Description Parameter Image

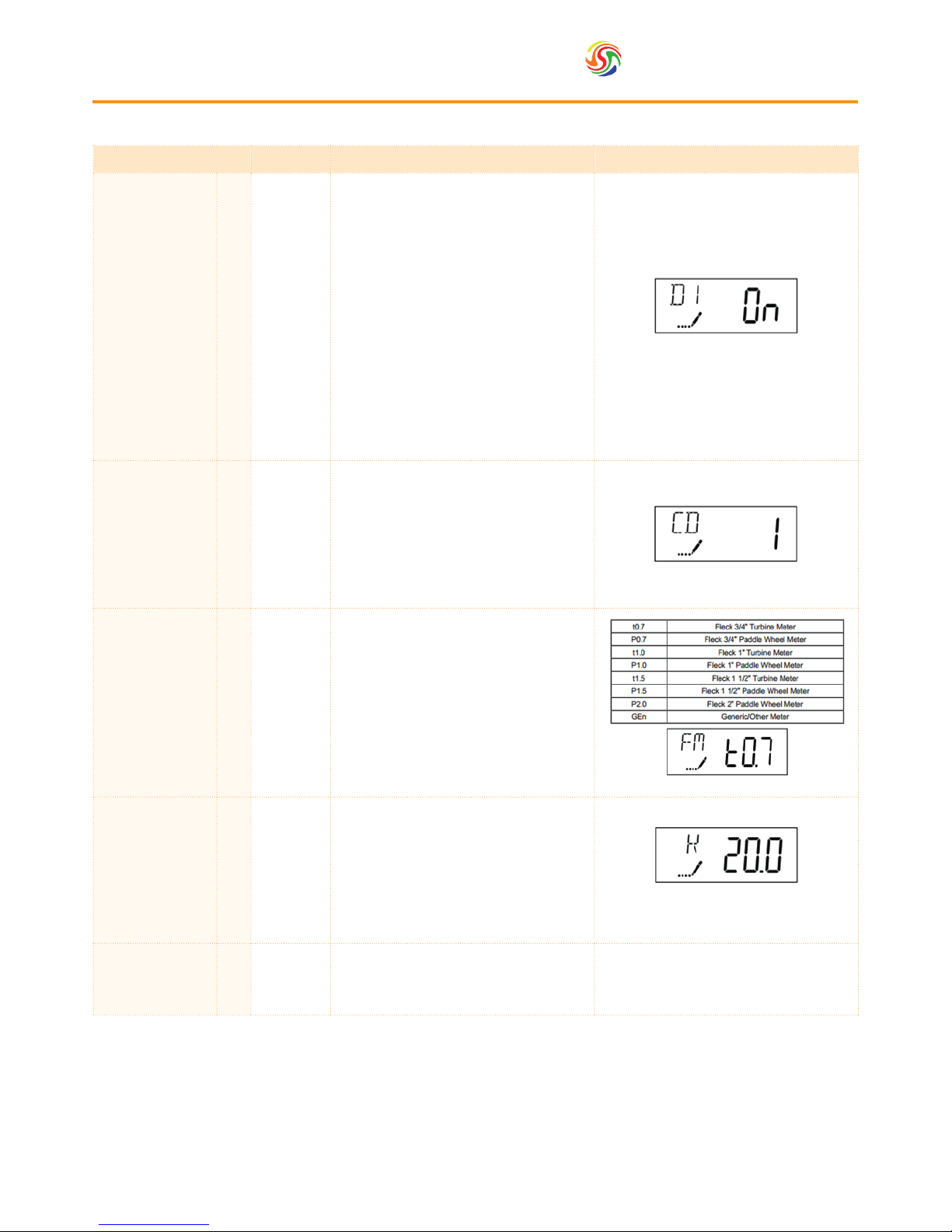

14. Day of week

D1

D2

D3

D4

D5

D6

D7

ON or OFF

Press the Extra Cycle button. Use this

display to set the regeneration schedule

for a system con gured as a Day of

Week control. The different days of the

week are identi ed as D1, D2, D3, D4,

D5, D6, and D7 in the upper left-hand

corner of the display. Set the value to

“ON” to schedule a regeneration or

“OFF” to skip regeneration for each

day. Use the Up and Down buttons to

adjust the setting as needed. Press the

Extra Cycle button to accept the setting

and move to the next day. Note that

the control requires at least one day to

be set to “ON.” If all 7 days are set to

“OFF”, the unit will return to Day One

until one or more days are set to “ON.”

15. Current day CD 1-7

Press the Extra Cycle button. Use this

display to set the current day on systems

that have been con gured as Day of

Week controls. This setting is identi ed

by “CD” in the upper left-hand corner

of the screen. Use the Up and Down

buttons to select from Day 1 through

Day 7.

16. Flow meter type FM

Press the Extra Cycle button. Use this

display to set the type of ow meter

connected to the control. This option

setting is identi ed by “FM” in the

upper left-hand corner of the screen.

Use the Up and Down buttons to select

one of the 7 available settings.

The values to input are dependent on

your own model and can be found in the

table in Section 11.

17. Meter pulse

setting

K

Press the Extra Cycle button. Use this

display to specify the meter pulse

setting for a non-standard ow meter.

This option setting is identi ed by “K”

in the upper left-hand corner of the

screen. Use the Up and Down buttons

to enter the meter constant in pulses

per unit volume.

18. End of master

programming

mode

Press the Extra Cycle button to save all

settings and exit Master Programming

Mode.

Page 16

Spectrum

TM

16

9. User Programming Mode

Abbreviation Parameter Description

DO Day override The time’s day override setting

RT Regeneration time

The time of day that the system will regenerate

(meter delayed timeclock, and day-of-week systems)

H Feed water hardness

The hardness of the inlet water - used to calculate system capacity for

metered systems

RC or SF Reserve capacity The xed reserve capacity

CD Current day The current day of week

N.B. Press the Up and Down buttons for ve seconds while in service, and the time of day is NOT set to 12:01 PM.

9.1. Timer Operation

Parameter Description Parameter Image

1. Day override DO

Use this display to adjust the Day Override.

This option setting is identi ed by “DO” in

the upper left hand corner of the screen.

2. Regeneration time RT

Press the Extra Cycle button. Use this display

to adjust the Regeneration Time. This option

setting is identi ed by “RT” in the upper left

hand corner of the screen.

3. Feed water hardness H

Press the Extra Cycle button. Use this display

to adjust the Feed Water Hardness. This

option setting is identi ed by “H” in the

upper left hand corner of the screen.

4. Reserve capacity RC

Press the Extra Cycle button. Use this display

to adjust the Fixed Reserve Capacity. This

option setting is identi ed by “RC” or “SF”

in the upper left-hand Corner of the screen.

Page 17

17

Spectrum

TM

10. Diagnostic Programming

Mode

Abbreviation Parameter Description

FR Flow rate Displays the current outlet ow rate

PF Peak ow rate Displays the highest ow rate measured since the last regeneration

HR Hours in service Displays the total hours that the unit has been in service

VU Volume used Displays the total volume of water treated by the unit

RC Reserve capacity

Displays the system’s reserve capacity calculated from the system capacity, feed

water hardness, and safety factor

SV Software version Displays the software version installed on the controller

N.B. Some items may not be shown depending on timer con guration. The timer will exit Diagnostic Mode after 60

seconds if no buttons are pressed. Press the Extra Cycle button to exit Diagnostic Mode at any time.

Press the Up and Extra Cycle buttons for ve seconds while in service.

10.1. Diagnostic Programming Mode Steps

Parameter Description Parameter Image

1. Flow rate FR

Use this display to view the current Flow Rate.

This option setting is identi ed by “FR” in

the upper left hand corner of the screen. It is

expressed in m3/hr.

2. Peak ow rate PF

Press the Up button. Use this display to view

the Peak Flow Rate since the last regeneration

cycle. This option setting is identi ed by “PF”

in the upper left hand corner of the screen. Its

expressed in m3/hr.

3. Hours in service HR

Press the Up button. Use this display to

view the Hours in Service since the last

regeneration cycle. This option setting is

identi ed by “HR” in the upper left hand

corner of the screen.

4. Volume used VU

Press the Up button. Use this display to view

the Volume Used since the last regeneration

cycle. This option setting is identi ed by “VU”

in the upper left hand corner of the screen.

5. Reserve capacity RC

Press the Up button. Use this display to view

the Reserve Capacity. This option setting is

identi ed by “RC” in the upper left hand

corner of the screen.

6. Software version SV

Press the Up button. Use this display to view

the Software Version. This option setting

is identi ed by “SV” in the upper left hand

corner of the screen.

7. End diagnostic

programming mode

Press the Extra Cycle button to end Diagnostic

Programming mode.

Page 18

Spectrum

TM

18

11. Programming Charts

The chart below can be used to help programme steps 13 and 16 in the Master Programming Mode.

SoftH20-DUO Programming Chart

Parameter

Softener

CapacityCBackwashBWBrine drawBDRapid rinseRRBrine rell

BR

Total

Flow meter

FM

WTP-SOFT30D 150 6 60 4 12 82 0.75

WTP-SOFT50D 250 6 70 4 10 90 0.75

WTP-SOFT75D 375 6 70 4 13 93 0.75

WTP-SOFT100D 500 6 70 6 10 92 0.75

WTP-SOFT150D 750 8 80 8 16 112 1.5

WTP-SOFT250D 1250 10 90 10 14 124 1.5

WTP-SOFT350D 1750 10 90 10 18 128 1.5

Page 19

19

Spectrum

TM

Problem Possible Cause Possible Solution

A. Controller does not work

1. Power off

2. Transformer is not plugged in

3. Defective power cord

4. Defective transformer

1. Switch on power

2. Connect to constant power source

3. Replace cord

4. Replace the transformer

B. Incorrect time of regeneration 1. Power outage causes inaccurate timing 1. Reset the timer

C. Leaking 1. Loose connections 1. Tighten joints

D. Noisy 1. Air pressure in the system 1. Re-backwash the system to vent air

E. Milk-white water 1. Air exists in the system 1. Turn on the tap to vent air

F. Unsatised water hardness

1. Poor raw water quality

2. Time of regeneration is too long

3. Resin disabled

1. Contact your supplier for assistance

2. Reset time of regeneration

3. Re-regeneration or use new resin

G. Softener fails to use salt

1. Water pressure is too low

2. Brine line blocked

3. Injector is blocked

4. Internal control leak

1. Line pressure must be at least 20 psi

2. Clean brine line

3. Clean or replace injector & screen

4. Check piston, seals and spacers

H. Brine container overow 1. Rell time too long 1. Contact your supplier for assistance

I. Water hardness remains

1. Fail to regenerate automatically

2. Brine concentration is poor

3. Injector is plugged

1. Check power of controller

2. Keep brine tank full of salt

3. Disassemble the injector and clear it

by washing with water

K. Untreated water leakage

during service

1. Improper regeneration

2. Leaking of bypass valve

3. O-ring around riser tube damaged

4. Incorrect regeneration cycle setting

1. Repeat regeneration making certain

that the correct salt dosage is set

2. & 3. Replace O-ring

4. Reset regeneration cycle

12. Troubleshooting

Important Notice

The controlling components are driven by an electric circuit. Some programmed parameters will be lost if a

power outage lasts over 8 hours and the water softener will carry out the regeneration process at the incorrect

time. We strongly recommend that after a power outage, users should check the time and adjust accordingly.

12.1. DUO System

Page 20

Spectrum

TM

20

12. Troubleshooting

12.2. DUO Valve

Problem Possible Cause Possible Solution

A. Unit fails to initiate a

regeneration cycle

1. No power supply Check electrical service, fuse, etc

2. Power Failure Reset time of day

B. Water is hard

1. By-pass valve open Close by-pass valve

2. Out of salt Add salt to tank

3. Plugged injector / screen Clean parts

4. Flow of water blocked to brine tank Check brine tank rell rate

5. Leak between valve and central tube

Check if riser tube is cracked or o-ring is damaged.

Replace faulty parts

6. Internal valve leak Replace valve seals, spacer and piston assembly

C. Salt use is high 1. Rell time is too long Check rell time setting

D. Low water pressure

1. Iron or scale builds up in line feeding unit Clean pipes

2. Iron build up inside valve or tank

Clean control and add resin cleaner to clean the

bed. Increase regeneration frequency

3. Inlet of control blocked due to foreign matter Remove piston and clean control valve

F. Too much water in

brine tank

1. Blocked injector or screen Clean parts

2. Foreign material in brine tank Clean parts

G. Unit fails to draw

brine

1. Drain line ow control is blocked Clean parts

2. Injector or screen is blocked Clean parts

3. Inlet pressure too low Increase pressure to 25 PSI

4. Internal valve leak Replace seals, spacers and piston assembly

H. Valve continuously

cycles

1. Broken Gear Replace faulty parts

I. Flows to drain

continuously

1. Valve settings incorrect Check valve settings

2. Foreign material in control valve Clean control

3. Internal leak Replace seals, spacers and piston assembly

Page 21

21

Spectrum

TM

13. Cautions

1. Without reading and understanding the contents of this user manual, DO NOT perform any operations on the

control valve.

2. Strictly prohibit a leaning position when shipping, installing and using this product as this could cause damage.

3. During the regeneration, water from the tap will NOT be softened. It is NOT recommended to use water during

regeneration; otherwise a negative effect on the regeneration result will occur.

4. Initiate a regeneration cycle when the softener has been inactive for a long period of time and then turn on the

tap for several minutes before resuming normal use.

5. Do not disconnect power during service to prevent timer distribution.

6. If water usage or hardness of raw water dramatically increases (compared to the normal usage), then the frequency

of regeneration should increase.

7. Hot water could cause severe damage to the softener system, for water boiler and water heaters users, ensure the

total-run of the piping between the softener and the boiler is not less than 3 meters. It is recommended to install

a check valve between the lter and the boiler if unable to meet the required piping length.

8. The input water pressure must be between 2 - 8 bar.

9. No chemicals should be present at the inlet and outlet connecting sectors.

10. Besides the system, spare part connection materials are not included in the scope of the manufacturer’s warranty.

11. The required environmental temperature for a softener is 1 - 42°C. Below this will cause the softener to malfunction.

12. Do not apply pressure to the softener.

13. Indoor installation is preferred. Avoid exposure to direct sunlight, radiation from other heating sources and avoid

extreme weather conditions including rain and snow.

14. Use salt granules or tablets designed for softeners.

15. No tools should be used for connecting the plastic parts as over tightening or excessive force could result in

damage.

16. If necessary use food grade silica sealant for lubricating rubber O-rings.

17. Only qualied personnel should adjust or remove the adaptor locking clips on the reverse of the valve, as this can

tamper with the valve settings. Should this be required pressure must rstly be discharged from inside the water

softener.

Page 22

Spectrum

TM

22

14. Technical Information

Model (litres of resin)

30 50 75 100 150 250 350

Maximum Operating Temperature (ºC)

42

Minimum Operating Temperature (ºC)

2

Maximum Operating Pressure (bar)

8

Minimum Operating Pressure (bar)

2

Optimal Flow Rate (m3/hr)

1 2 3 3 6 8.4 8.4

Max Flow Rate (m3/hr)

4.5 4.5 4.5 4.5 8.6 8.6 8.6

Inlet / Outlet (")

¾ ¾ ¾ ¾ 1½ 1½ 1½

Valve

FLECK

9000/9100

FLECK

9000/9100

FLECK

9000/9100

FLECK

9000/9100

FLECK

9500

FLECK

9500

FLECK

9500

Drain (")

1 1 1 1 1 1 1

Brine Line (")

⅜ ⅜ ⅜ ⅜

½ ½ ½

Power Requirements (V)

240V

50Hz

240V

50Hz

240V

50Hz

240V

50Hz

240V

50Hz

240V

50Hz

240V

50Hz

Resin Volume (l)

30 50 75 100 150 250 350

Salt Consumption Per Regeneration (kg)

4.5 7 11 14 21 35 50

Pressure Tank Thread (")

2½ 2½ 2½ 4 4

Vessel Size

09x35 10x54 13x54 14x65 16x65 21x62 24x72

Brine Tank Volume (l)

140 140 140 350 350 350 500

Brine Tank Dimensions (mm)

582x362

x904

582x362

x904

582x362

x904

ø 740 x

1275

ø 740 x

1275

ø 740 x

1275

ø 840 x

1335

Total Height (mm)

1100 1600 1600 1860 1960 1960 1960

Total Weight (kg)

70 100 180 250 350 580 750

Loading...

Loading...