Page 1

Owner’s Manual

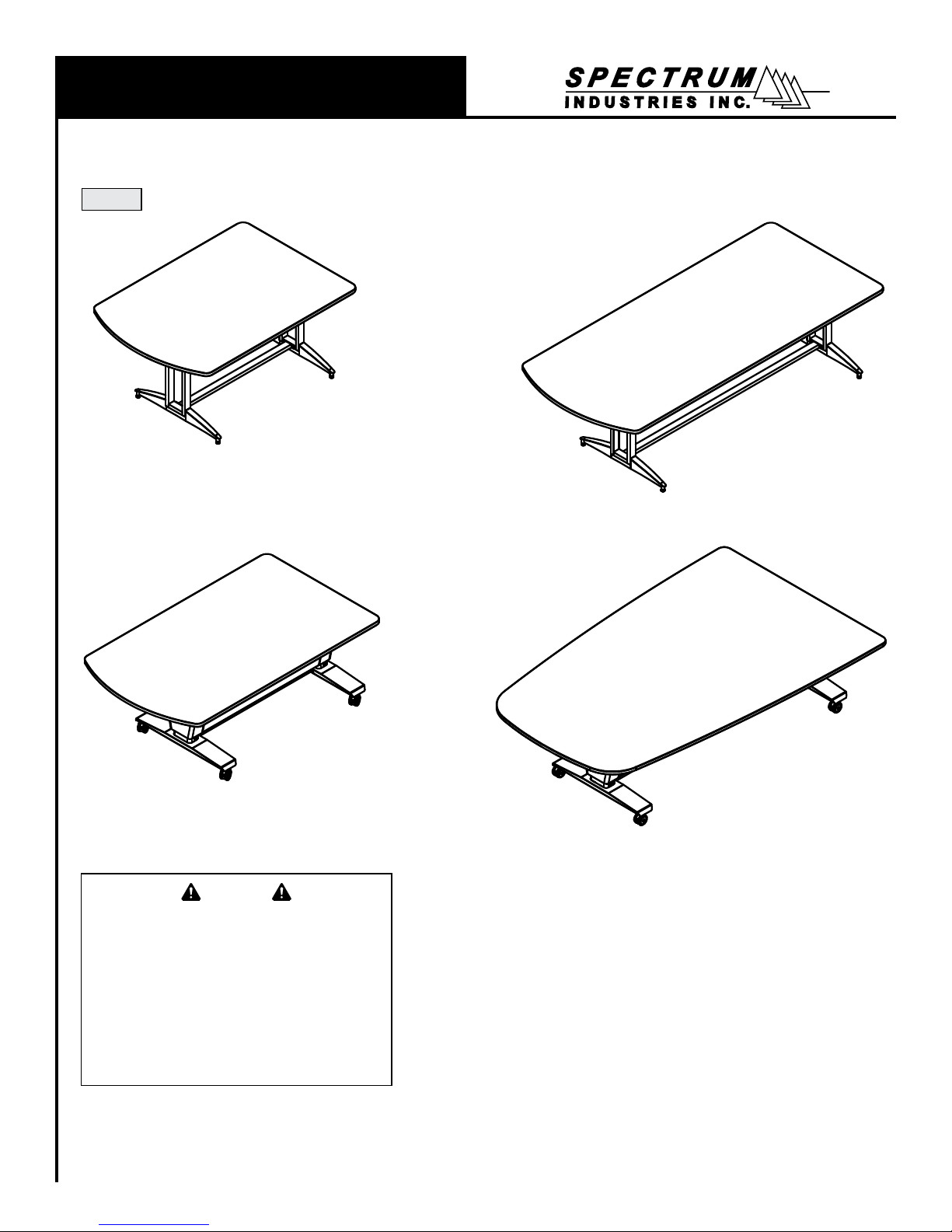

Optio Collaboration Table

37132

Optio 60”L Table

Shown with T-legs

™

Optio 96”L Table

Shown with T-legs, and

cord channel

Optio 72”L Table

Shown with eLift legs, casters,

and AV technology channel

Important

Before using this product:

• Read this manual

• Comply with all safety and operating instructions

• Ensure all parts and correct quantities are included

Any parts damaged during shipment must be reported

within 5 days of receipt. To report information regarding

missing parts or damage, to purchase parts or accessories, or if you have any questions, please contact us.

Thank you for purchasing Spectrum products!

Spectrum Industries, Inc

925 First Avenue, Chippewa Falls, WI 54729 USA

800 235 1262

715 723 6750

www.spectrumfurniture.com

Optio 96”L Table

Shown with tapered worksurface,

eLift legs, casters,

and AV technology channel

0190236 Page 1 of 10

Page 2

Important Safety and Care Instructions

• Read this owner’s manual before assembly or operation.

• Do not allow children to move the table.

• For indoor use only. Do not install or store the table where it will be

exposed to moisture.

• Do not block the ventilation openings.

• Do not allow anyone to sit, stand, or climb on the table.

• Use a damp, soft-cloth, or sponge, with mild soap or detergent solution

to clean dirty surfaces. Do not use harsh solvents or abrasives.

• This table is intended for institutional use. It does not have any userserviceable parts or user-maintenance requirements. If servicing is

necessary, please contact Spectrum Industries for assistance.

Warning - Relocating audio and/or video equipment to furniture not speci cally

designed to support audio and/or video equipment may result in death or

serious injury due to the furnishing collapsing or over turning onto a child.

Warning - Death or serious injury may occur when children climb

on audio and/or video equipment furniture. A remote control or toys

placed on the furnishing may encourage a child to climb on the

furnishing and as a result the furnishing may tip over on to the child.

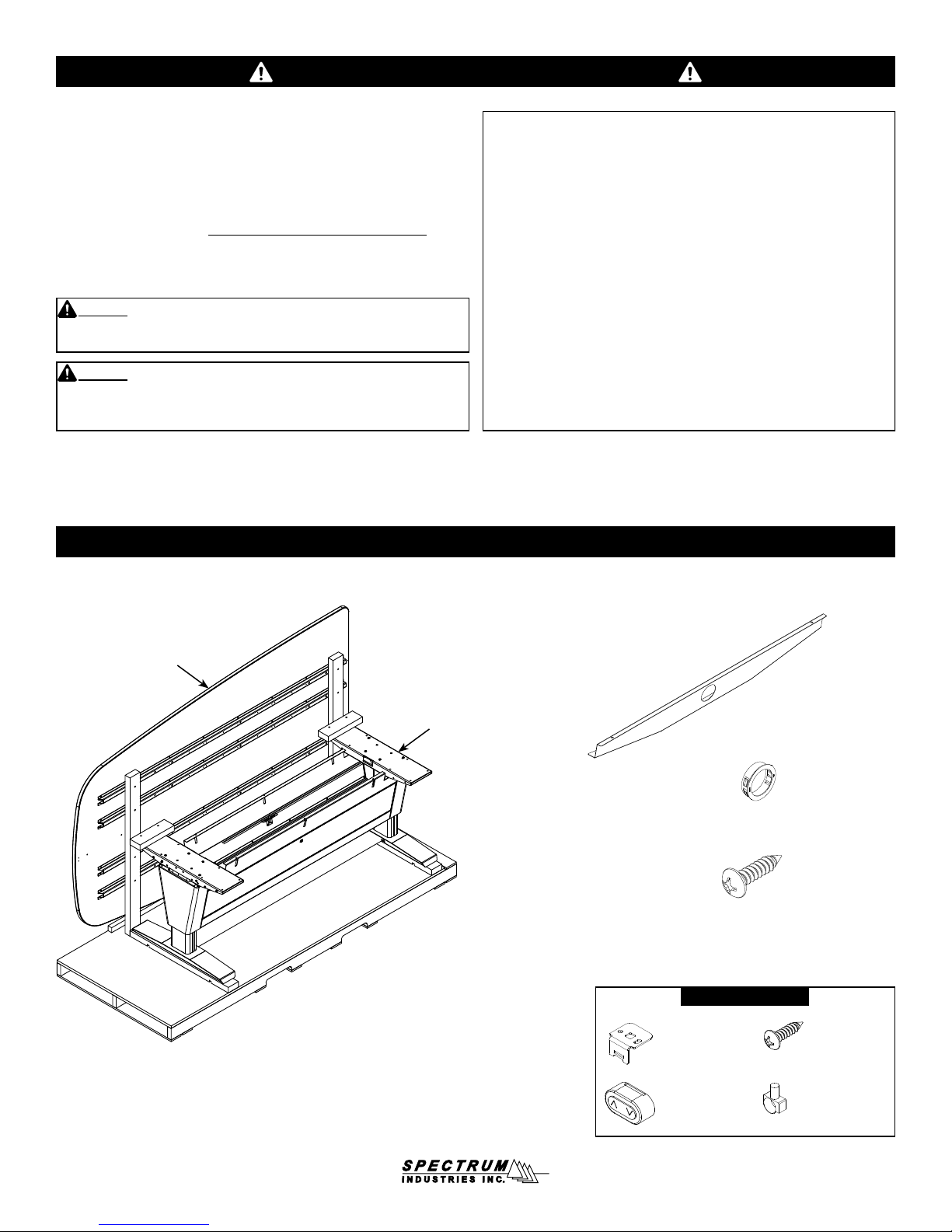

Components

General Electrical Safety:

• Keep power switches in the OFF position before plugging or

unplugging from the wall outlet.

• Be sure total device / equipment load does not exceed 12-amps.

• Do not plug power cords into an extension cord.

• Inspect power cords for damage before each use. Do not use cords

that are damaged.

• Unplug power cord from electrical outlet by gripping the cord-do not

unplug by pulling only on the cord.

• Do not step on, drive over, drag, or place objects on power cords.

• For added safety, plug into a grounded outlet controlled by a GFI

(Ground Fault Interrupter) circuit breaker.

• Damaged electrical components can create signi cant hazards to

users and is not covered by the warranty. Repairs should always be

performed by a quali ed electrician.

• Electrical devices are not toys. Children are often unaware of the

hazards associated with electrical devices. This table must always

be used by adults or with adult supervision.

Worksurface

Pallet

Base

Hardware for eLift

(1) 0109398

Control button

bracket

(1) 0109397

Control button

(1) 0131664

Filler panel

(1) 059984

Grommet

(2) 026057

#10 x 3/4” PHSM

(2) 037542

#8 x 5/8”

PHSM

(2) 0107023

Snap-in pine

tree clip

0190236 Page 2 of 10

Page 3

Assembly / Setup

1. Remove worksurface from pallet

Note: The worksurface must be removed rst from the

pallet before the table base or tipping may occur.

1. Remove the screws securing the worksurface to the pallet blocking.

2. Carefully lift off the worksurface and set aside. Be sure the

worksurface is fully-supported by a second person during removal.

Figure 1.

1

Worksurface

Tools Required

Pallet blocking

2

Base

Phillips

screwdriver

or

Cordless drill with

Phillips driver

(best)

Side cutter

2. Remove base from pallet

Note: If the table has casters, they should be installed while the

base is on the pallet to avoid damage to the oor from the stems.

1. Remove the banding, screws, and wood blocking securing the

base to the pallet. Figure 1.

2. Before moving base, determine if the table has glides or

requires casters to be installed.

3. To install casters: Lift each end of the base and snap-each

caster onto each stem. This may take 2-3 people. Figure 2.

4. Carefully lift the table base off the pallet.

Glide

Pallet

Figure 1

Stem

Caster

Figure 2

0190236 Page 3 of 10

Page 4

3. Install worksurface

1. Set the worksurface onto the base. Figure 3.

2. Align the mounting holes and secure with 1/4-20 x 5/8” PHM screws.

(The screws will attach to the worksurface reinforcement bars).

Tools Required

Worksurface

Phillips

screwdriver

or

Cordless drill with

Phillips driver

(best)

Base

4. Install ller panel

1. Place the grommet panel under the worksurface at the at edge.

Figure 4.

2. Align the mounting holes and secure with (2) #10 x 3/4” PHSM screws.

3. Install in grommet.

Tools

Required

Grommet

Figure 3

Phillips

screwdriver

Filler panel

(2) #10 x 3/4” PHSM

0190236 Page 4 of 10

Figure 4

Page 5

5. Display Stand

1. If you have the optional display stand, proceed with the assembly

instructions included with stand. Figure 5.

Note: Requires mounting holes and

cutout on at end of worksurface.

Note: The assembled Display Stand

accommodates most 37”-70” monitors

up to 125 lb.

WARNING

The monitor should always be lifted

off the stand before moving the table.

Display stand

Figure 5

Wiring

1. If your worksurface has cutouts for optional power modules or other

components, install the devices then route and secure the cords

using the wiring tray or AV channel underneath. Figure 6.

Optional power

module(s)

Optional Display

Stand

Wiring tray /

AV channel

Figure 6

0190236 Page 5 of 10

Page 6

eLift operating instructions - eLift equipped tables only

1. Attach the control button bracket under the radiused portion of the

worksurface with (2) #8 x 5/8” PHSM screws and pre-drilled pilot holes

in the center of the worksurface.

2. Push the control button onto the bracket.

3. Use the included pine tree clips to secure the cord to the worksurface.

Control button

Curved or rectangular

end worksurface

Pine tree clip

Tools

Required

Phillips

screwdriver

Up

Figure 7.1

Note: Additional sets of predrilled mounting holes are available under the straight sections

of the worksurface to mount the

control button if preferred.

1. Plug the 11-foot, 15-amp power cord into a wall outlet.

2. Locate the “Up” and “Down” buttons on the control pad.

3. To raise or lower the worksurface, press and hold the “up” or “down”

arrow keys on the control pad until the worksurface reaches the desired

height. The worksurface maximum height is 42”, minimum height is 29”.

Keep clear of pinch points during worksurface movement.

Down

Control

button

Operation:

Reset Procedure:

#8 x 5/8” PHSM

Cord

Figure 7.2

CAUTION

Keep clear of pinch points during worksurface movement.

Note: The lift actuators are rated at a maximum capacity of 180 lb each.

Pine tree clip

To control box

in AV channel

1. Unplug, then re-plug the power cord into a wall outlet.

2. Make sure all lift mechanism wire connections are in place and secure.

3. Remove anything located under the worksurface.

4. Press and hold the “Down” button to lower the worksurface to the

lowest “work” position until it stops moving.

5. Release the “Down” button.

6. Press and hold the “Down” button again until the worksurface

bottoms-out, slightly rises, and stops moving. The worksurface must

be completely lowered before resuming operation.

Note: If the worksurface does not lower when doing this step,

release the “Down” button, and retry step 6.

7. Release the “Down” button. The lift mechanism has now been

reset and the worksurface can be adjusted normally.

CAUTION

Always unplug the eLift before working under the worksurface.

Although this table utilizes an anti-collision feature that briey stops

and reverses the motion of the table in the event of an obstruction, Use

caution when raising or lowering the worksurface! Do not sit at,

under, or on the worksurface when operating the lift mechanism and be

sure table movement does not interfere with objects or people.

CAUTION

USE CAUTION WHEN RAISING OR LOWERING TABLE!

0190236 Page 6 of 10

Page 7

Display Stand - 37130

Accessories

(Available separately after initial congured purchase)

• Bolts directly to worksurface

• Integrated wiring channel routes and hides wires

• Slim VESA mount (non-tilting)

• Adjustable (VESA-compatible) mount

• Requires worksurface mounting holes and cutout

Monitor size range: 37”-70” [94-178 cm] diagonal

Monitor weight capacity: 125 lb [75 kg]

Vertical adjustment

(worksurface-to-center)

Shipping weight: 35 lb [15.9 kg]

• 23.5”H [59.7 cm]

• 21.5”H [54.6 cm]

• 19.5”H [49.5 cm]

• 17.5”H [44.5 cm]

• 15.5”H [39.4 cm]

(5 vertical positions

in 2” increments)

Slim VESA mount

Display stand

Wiring

channel

Cord Chase - 38999

• Cleanly routes wires and cords from cord channel or AV channel to the oor

• Compatible with eLift leg tables, and T-leg tables with laminate leg

insert panel

• Two cord chases included

• 3"W [7.6 cm] x 1.425"D [3.6 cm] x 17"L [43.2]

• Shipping weight: 2 lb

Cove™ Power Module - 99044

• Two power receptacles

• Two USB charge ports

(not data-compatible)

• Thumbscrew clamps

Cutout required: 5.25” [13.3 cm] x 2” [5.1 cm]

Power cord: 9’ [274 cm] with 90° at plug with 45° rotation

Power receptacles: 12A, 120 VAC spill-resistant

USB charging ports: 2.1A (10.5W)

Dimensions:

Unit weight: 2.29 lb [1 kg]

• Requires worksurface cutout

• ETL listed

• Available in Black or Silver

(mounts to surface thicknesses up to 1.5”)

6”W [15.2 cm] x 2.5”D [6.35 cm] x 3.18”H

[8.1 cm]

Mounting holes and

cutout needed on at

end of worksurface

See spectrumfurniture.com for the latest

accessories and detailed warranty information.

0190236 Page 7 of 10

Page 8

Electric actuator information

Warning!

Failure to comply with these instructions may result in accidents involving serious personal injury. Failing to follow these instructions can result in the product being damaged or

being destroyed.

Safety Information

General

Safe use of the system is possible only when the operating instructions are read

completely and the instructions contained are strictly observed. Failure to comply with

instructions marked with the ”NOTE” symbol may result in serious damage to the system

or one of its components.

• It is important for everyone who is to connect, install, or use the systems to have the

necessary information and access to this User Manual. Follow the instructions for

mounting – risk of injury if these instructions are not followed.

• The appliance is not intended for use by young children or infi rm persons without supervision.

• If there is visible damage on the product it must not be installed.

• Note that during construction of applications, in which the actuator is to be fi tted, there

must be no possibility of personal injury, for example the squeezing of fi ngers or arms.

Assure free space for movement of application in both directions

to avoid blockade.

Before installation, re-installation, or troubleshooting:

• Stop the DL5/DL6

• Pull out the mains plug.

• Relieve the DL5/DL6 of any loads, which may be released during the work.

Before start-up:

• Make sure that the system has been installed as instructed in this User Manual.

• Make sure that the voltage of the control box is correct before the system is connected

to the mains.

• System connection. The individual parts must be connected before the control box is

connected to the mains. See the User Manual for LINAK actuators, if necessary.

During operation

• If the control box makes unusual noise or smells, switch off the mains voltage

immediately.

• Take care that the cables are not damaged.

• Unplug the mains cable on mobile equipment before it is moved.

• The products must only be used in an environment, that corresponds to their IP

protection.

Misc.

The actuator system has a sound level below 55dB(A) in typical applications.

Updated manuals and declarations can always be found here:

www.linak.com/deskline

Only for EU markets

• This appliance can be used by children aged from 8 years and above and persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge if

they have given supervision or instruction concerning use of the appliance in a safe way

and understand the hazards involved.

• Children shall not play with the appliance. Cleaning and user maintenance shall not be

made by children without supervision.

Only for Non-EU markets

• Persons who do not have the necessary experience or knowledge of the product/

products must not use the product/products. Besides, persons with reduced physical,

sensory or mental abilities must not use the product/products, unless they are under

surveillance or they have been thoroughly instructed in the use of the apparatus by a

person who is responsible for the safety of these persons.

• Moreover, children must be under surveillance to ensure that they do not play with the

product.

Misuse

• Do not overload the actuators – this can cause danger of personal injury and damage

to the system.

• Do not use the actuator system for lifting persons. Do not sit or stand on a table while

operating – risk of personal injury.

• Do not use the system in environments other than the intended indoor use.

Repairs

In order to avoid the risk of malfunction, all DESKLINE® repairs must only be carried out

by authorised LINAK workshops or repairers, as special tools must be used and special

gaskets must be fi tted. Lifting units under warranty must also be returned to authorised

LINAK workshops.

Warning! If any of the DESKLINE® products are opened, there will be a risk of

subsequent malfunction.

Warning! The DESKLINE® systems do not withstand cutting oil.

C/N 120690

C/N 9901916

C/N 4008003

C/N 4008004

C/N 4008005

C/N 4008671

C/N 4009507

Note: Use the included control box only-do not

connect other control boxes to this product.

Label for CBD6S 200W (SMPS)

Label for DL6

0190236 Page 8 of 10

Page 9

Misc. on the DESKLINE® DL5/DL6 system

This system is a DESKLINE system developed for desks and for indoor use in offi ces. Do

not use it in industrial kitchens or in other enviroments that have to be cleaned with ag-

gressive detergents. Do not bolt the legs to the fl oor so that free movement is prevented.

This could cause serious damage to the legs in fault situations.

Warranty - 60 months on DESKLINE® (NEW)

This will be valid for all DESKLINE products produced after the 1st of May 2015.

Products produced before 1st of May 2015 will still be covered by 36 months.

Products used in DESKLINE application: If these products are used in another application, they will be covered by 18 months warranty.

If there is any doubt that returned products are within the warranty period it is to be

treated as if they are covered by the warranty. We recommend that you use the date of

the control box or actuator as reference if possible. We will have our purchase number

printed on the label.

Maintenance

Clean dust and dirt on the outside of the system at appropriate intervals and inspect them

for damage and breaks. Inspect the connections, cables, and plugs and check for correct

functioning as well as fi xing points.

Service of double-insulated products:

Class II

A Class II or double insulated electrical appliance is one which has been designed in

such a way that it does not require a safety connection to electrical earth (US: ground).

The basic requirement is that no single failure can result in dangerous voltage becoming

exposed so that it might cause an electric shock and that this is achieved without relying

on an earthed metal casing. This is usually achieved at least in part by having two layers

of insulating material surrounding live parts or by using reinforced insulation.

There is no earthing / grounding means provided on the product, and no earthing/grounding means is to be added to the product.

In Europe, a double insulated appliance must be labelled “Class II”, “double insulated” or

bear the double insulation symbol (a square inside another square).

Servicing a double-insulated product requires extreme care and knowledge of the system,

and is to be done only by qualifi ed service personnel. Replacement parts for a double-in-

sulated product must be identical to the parts they replace.

The cleaners and disinfectants must not be highly alkaline or

acidic (pH value 6-8).

Description of the DESKLINE® DL5/DL6 system

Each DESKLINE® DL5/DL6 lifting units is equipped with a motor and parallel / memory

drive is ensured by means of software in the CBD6S (SMPS) that also takes account of

oblique load on the desk. Soft start and stop are also part of this software, which ensures

a soft start and stop when adjusting the desk.

Application of the DESKLINE® DL5/DL6 system:

Irrespective of the load the duty cycle 10% ~ 6 min./ hour or max. 2 min. at

continuous use stated in the data sheets, must NOT be exceeded as this will result

in a superheating of the motor, the brake and the spindle nut. Exceeding the duty cycle

will result in a dramatic reduction of the life of the system.

The DESKLINE® DL5/DL6 system range contains the following products:

• 1 control box CBD6S 200W or CBD6S 300W (SMPS - Switch Mode Power Supply)

• 1 single DL5/DL6 or 2 in parallel

• 1 exchangeable mains cable

• 1 or 2 motor cables

• 1 DP1U/DPF1M (if memory function is required) DP1C/DPT/DPF1C (if memory

function and display is required) or DPF1D (if display is required).

Electrical connection of the DL5/DL6 system

The DESKLINE® DL5/DL6 system is to be connected as shown in Figure 4. Each DL5/

DL6 is to be connected to the sockets on the control box by means of the motor cables,

which have a 6-pin plug on each end. Finally, the main power cable is to be mounted and

power switched on.

Please note that the control box must only be connected to the voltage stated on

the label.

DL5/DL6

Figure 4

Hook for

cable relief

DL5/DL6

DP

Main power cable

Anti-Collision™

The function (anti-collision) is an option for the standard CBD6S (SMPS) control box. A

system with anti-collision can limit material damages on a desk if a collision with a solid

object should occur.

Enabling the anti-collision

To enable the anti-collision function a little plug called a dongle must be mounted in one

of the 2 control ports. The function is only active when the dongle is mounted. - If you

remove the dongle again you disable the function.

Method of operation

When the DL/DB’s are running, the CBD6S (SMPS) monitors the current consumption

on each channel using a special algorithm. If the current consumption on one channel

is increased more than a predefi ned slope, a collision is assumed and all channels are

stopped immediately and all DL/DB’s will start to run in the opposite direction (approx. 50

mm). This return drive is done automatically and continues with or without any control key

pressed (for max. 2.5 sec.).

The anti-collision sensitivity is different in upward and downward direction. Upwards the

force is approx. 20 kg. Downwards the load will be approx. 40 kg + the load on the DL/DB

(the desk + what is on top of the desk). The 40 kg are needed to activate the anti-collision

function.

Situations where the anti-collision does not work

There are situations where the anti-collision will not be activated. These situations are:

• If the collision happens during the initialisation phase

• If the collision happens within the fi rst 1000 msec or after the control button has been

released

• If the collision happens between the fl oor and the table and the load on the desk + the

weight of the legs are lower than 40 kg

• If the collision happens over too long time, e.g. if the collision is with a soft object.

DL5/DL6

Figure 5

0190236 Page 9 of 10

Page 10

Warranty

DESIGNED AND ASSEMBLED IN

CHIPPEWA FALLS

WISCONSIN.USA

WE WILL MAKE IT RIGHT FOR YOU!

Spectrum is committed to provide complete customer satisfaction. Each of our products is manufactured from the best materials available and each

product is stringently monitored throughout the production process through our P.A.C.E. program (Product Assurance to meet Customer Expectations).

We expressly warrant that Spectrum products will be of good quality and workmanship and free from defect for the period set out in the warranty table below

from the date of delivery. This warranty shall not apply to defects or damage resulting from misuse, abuse, neglect, improper care, modifi cation or repair not

authorized by Spectrum, or any other cause outside the control of Spectrum. Spectrum will, at its sole option, either repair or replace the defective product.

This warranty is exclusive; no other warranty, written or oral, is expressed or implied. This warranty is given by Spectrum to Buyer and to no other per-

son or legal entity. No Spectrum dealer, distributor, agent or employee is authorized to make any modifi cation or addition to this warranty.

NOTWITHSTANDING ANYTHING TO THE CONTRARY, SPECTRUM WILL NOT UNDER ANY CIRCUMSTANCES BE LIABLE FOR INDIRECT OR LIQUIDATED DAMAGES, INCLUDING CONSEQUENTIAL, INCIDENTAL AND SPECIAL DAMAGES. IN NO EVENT SHALL SPECTRUM’S LIABILITY, WHETHER

UNDER CONTRACT OR WARRANTY, IN TORT OR OTHERWISE, EXCEED THE PURCHASE PRICE RECEIVED BY SPECTRUM FOR THE PRODUCT AT

ISSUE AND “RECALL ACTION” EXPENSES. SPECTRUM SHALL NOT BE SUBJECT TO ANY OTHER OBLIGATIONS OR LIABILITIES, WHETHER ARISING OUT OF BREACH OF CONTRACT, WARRANTY, TORT (INCLUDING NEGLIGENCE AND STRICT LIABILITY) OR OTHER THEORIES OF LAW, WITH

RESPECT TO PRODUCTS SOLD OR SERVICES RENDERED BY SPECTRUM, OR ANY UNDERTAKINGS, ACTS OR OMISSIONS RELATING THERETO.

Our Customer Service Department is ready to provide immediate attention to any questions, comments or concerns. They are available to answer your calls

Monday through Friday from 7 am to 5 pm CST. In addition your product comments or concerns are welcome via e-mail at: spectrum@spectrumfurniture.com.

Warranty Table

Item

Adjustable Crank / Electric Desk Legs

Flat Panel Desk Gas Cylinders

Chairs

• Adjustable Height Chair Parts – including frames, gas

cylinders, wood and plastic parts, control handles, casters

• Adjustable Height Chair Upholstery

• In-Stock Upholstery

• Graded-In Fabrics and Customer Owned Material

Height Adjustable Columns and Lifts

General Use Casters

Electrical (including timers and LINAK actuators) • 2 Years

Keyboard / Mouse Trays • 1 Year

Flat Panel Monitor Arms

• Flat Panel Monitor Arm – General Parts

• Flat Panel Monitor Arm – Gas Cylinders

Desks and Lecterns

• Computer Desk Chassis

• Cart Chassis

• Lectern Chassis

Warranty Period

effective 1/1/2015

• 1 Year

• 7 Years

• 2 Years

• 2 Years

• No Warranty

• 1 Year

• 5 Years

• 2 Years

• 10 Years

925 FIRST AVENUE, CHIPPEWA FALLS, WI 54729 / 800-235-1262 / 715-723-6750 / WWW.SPECTRUMFURNITURE.COM

© 2017 Spectrum Industries Inc., All rights reserved.

8

0190236 Page 10 of 10

Loading...

Loading...