Page 1

November 2015_JS

DG813 & DG613

Pipe Laser

How to use the pipe lasers – step by step

Page 2

DG813/DG613 Components

DG813

DG613

SF803

RC803 Recharge kit

Page 3

Powering the Laser

1 – DG’s are shipped with a rechargeable

NiMH battery pack (Q104667).

Only the original rechargeable battery

pack allows charging with the

provided charger.

2 – An optional external charger Cable,

12V Battery w/Cigarette Lighter Plug

(P25) is also available

3 – Alkaline batteries can be used as a

backup

4 – Plus and minus symbols indicate

how to put the alkaline batteries into

the battery compartment

Page 4

Installing Batteries

- Open the battery door by pulling out

the battery door latches.

- Push down the battery door and lift up

the locking lever that has the

two pins

- Insert batteries (or a rechargeable

battery pack) into the housing so

that the negative poles are on the

bigger battery spiral springs.

- Close the battery door and lock it by

pushing the door latches back to the

housing.

Page 5

Powering the Remote Control RC803

1. Open the battery door using a coin or similar

pry device to release the battery door tab on

the RC803.

RC803 will be shipped with alkaline batteries

Rechargeable batteries can be used optional

but need to be charged externally.

2. Insert two AA batteries noting the plus (+)

and minus (-) diagrams inside the battery

housing.

3. Close the battery door. Push down until it

“clicks” into the locked position.

Page 6

Using the Remote Control RC803

1. Press the button to turn on the Radio/IR

remote control.

If the RC803 is outside the radio operating range

the remote switches automatically into the IR

connection capability.

Note: When the remote control is initially turned

on, the standard display (model number and

software version) appear for the first 3 seconds,

then the grade value and line direction

indications briefly appear in the LCD.

With every button press, the LCD backlight is

activated and turns off automatically if no button

is pressed for 8 seconds.

To turn off the radio remote control, press and

hold the button for two seconds.

Note: 5 minutes after the last button press, the

remote control turns off automatically.

Page 7

Powering the Spot Finder SF803

1. Open the battery door pulling the battery

door latch.

The SF803 will be shipped with 4 AA

alkaline batteries.

Rechargeable batteries can be used

optional but need to be charged externally.

2. Insert four AA batteries noting the plus (+)

and minus (-) diagrams inside on the

battery door.

3. Close the battery door. Push down until it

“clicks” into the locked position.

Page 8

Components Spot Finder SF803

13 12

5

9

7 3

6

5

8

1

10

11

1 - SF803

2 - Target Plate

for Spot Finder

3 - Center Hole

4 - Power Button

5 - Bubble Vial

4

6 - Battery LED

10

7 - Mode LED

8 - Red Direction LEDs

9 - IR transmitters/receivers

10 - Marking notches (front and back)

11 - M6 Clamp Mount

12 - Battery door

13 - Latch for Battery Door

14 - Release Tab Target Plate

15 - SF Pole Adapter

2

14

15

Page 9

DG813/DG613 Components

1. Battery Compartment – holds the

NiMH battery pack. (D-Cell alkaline

batteries can be used as a backup.)

2. Battery Door Latches – locks/unlocks

and holds the battery compartment in

place.

3. LCD Graphic Display - shows the power,

grade, battery, out-of-level, beam position,

menu information and status of the laser.

4. Grade Axis Pivot Marker - identifies the

pivot point for the grade system

5. Line-Axis Pivot Marker and LED - used

to align a transit over the top of the laser;

lights for 15 minutes after turning on the

laser or pressing one of the buttons.

6. Handle - to carry the laser easily

5

4

3

2

6

1

and to attach a safety rope in manholes

with water.

Page 10

DG813/DG613 Components

7. Axis Alignment Markers - used to align

7

the laser when the line system is centered.

8. Mounts for scope adapter – to

attach the optional scope adapter for the

„Over the Top“ application

9. 5/8”-11 Threaded Mount – to attach the

laser to various setup accessories

10. Remote Receiver Window – receives

signals from the RC803 and SF803

11. Beam-Exit Window – provides a

clear window for the laser beam to exit

the pipe laser.

8

9

10

11

Page 11

DG813/DG613 Controls

12. Power Button - turns the laser On/Off

(To turn off the laser, press and hold the button

for 2 seconds).

13. M – Menu Button - Quickly press and release

starts the menu entry. Use the +/- and Left/Right

buttons to toggle through the menu.

14. E - Enter Button - Quickly press and release

to activate a selected menu function and show

the actual laser and remote control battery

status.

15. Escape/Lock (ESC) Button - If pressed

simultaneously with one of the left/right or +/-

buttons, it locks/unlocks the +/- or the left/right

buttons, so that the unit can’t be unintentionally

changed.

If pressed for 5 seconds, the unit switches

to the manual mode (steep grade).

13

15

14

12

Page 12

DG813/DG613 Controls

16. Left Line Control Button - moves the laser

beam to the left.

(Simultaneously pressed with the Right Line

Button, centers the line.)

17. Plus Button - increases the grade.

(Press and hold this button simultaneously with

the Minus button to zero the grade when in

Step & Go mode.)

18. Minus Button - decreases the grade.

(Press and hold this button simultaneously with

the Plus button to zero the grade when in

Step & Go mode.)

19. Right Line Control Button - moves the laser

beam to the right.

(Simultaneously pressed with the Left Line

Button, centers the line.)

16

17

18

19

Page 13

SF803 – Controls, Features and Functions

1. Power Button:

Press and release the button to turn ON the SF803.

All display LED’s will light for 1.0 sec.

Press and hold button for >2 sec. to turn OFF the

Spot Finder.

2. Battery LED:

solid green when SF803 is on and batteries are OK

blinking red if battery voltage is 3,8V<V bat <4V

solid red if battery voltage is <3,8V; SF803 turns off

automatically after 5 min.

3. Mode LED:

4

3

2

1

yellow solid: paired and radio connection OK

yellow flashing: none or lost radio signal

4. Red Direction LEDs:

Spot Search mode: pointing towards the center of the

beam.

All 4 LEDs are solid red when the SF803 is centered

at the beam.

Automatic SpotLok mode: solid for 5 min.,

then the LED’s flash every 5 seconds.

Page 14

Pairing DG813/DG613 with RC803

First, make sure the transmitter and the remote control are turned off. Then press and hold

the button and turn on the transmitter. During the next 6 seconds (the red LED

flashes fast while the display shows Pairing repeat the same steps on the

remote control.

The remote’s display show Pairing OK for one second and then the same

function as the laser is actually working to indicate the transmitter has been matched with

the remote control.

1

2

O

O

+

+

I

I

Page 15

Pairing DG813 with SF803

First, make sure the transmitter and the Spot Finder are turned off.

Then press and hold the button and turn on the transmitter.

During the next 6 seconds (the red LED flashes fast while the display shows Pairing.

Turn On the Spot Finder; the SF803 pairs now automatically with the transmitter.

After a successful pairing, the Laser shows the standard display while the yellow SF803

LED is solid.

1

2

O

O

+

I

I

Page 16

DG813/DG613 Setup

Position the laser at the manhole invert or on bottom of the trench at the desired elevation.

Press the power button to turn On the laser.

The LCD shows Initialization for one second, then the model number (red and green LEDs are on

for one second - diagnostic mode).

The standard display appears and the temperature/reference check

will start while the thermometer symbol is flashing.

Don‘t start automatic functions at the menu before the reference check has been finished.

If an automatic function will be selected and then confirmed with the button during the

reference check, the display shows the reference check is still running.

Page 17

DG813/DG613 Setup

The unit starts the self-leveling when the temperature check has been completed indicated by

the flashing beam and flashing vial symbol at the display.

The unit is leveled when the laser beam is no longer flashing

(once every second).

If the laser is positioned beyond its self-leveling range of -12% to + 40%,

the laser beam remains flashing.

Note: If the laser can’t level during two minutes, the error message 141 “Time Out” appears.

Reposition the laser within its self-leveling range.

The laser’s cross axis is completely compensated over the entire roll range.

Page 18

DG813/DG613 Setup

Line Alert

Once leveled, the unit constantly monitors its level condition by checking if the setup will be

disturbed caused by vibrations or bumps. Depending on the selection at settings, the setup

control (Line alert) is activated 5 minutes or 30 seconds after self-leveling was performed.

If Line Alert condition comes Off, the beam flashes two times,

pauses for 2 seconds and flashes again two times.

In addition, both LEDs flash at the same rate and the display shows the error message.

2 seconds

break

Delete the Line Alert by pressing the button, then check the correct beam position using

the pipe target at the last pipe which was laid before the Line alert came off.

To turn Off the laser, press and hold the button for two seconds.

Page 19

Standard Display Laser and RC803

The remote control mirrors the functionality of the pipe laser keypad

Automatic mode Beam line position related to the housing

+/- buttons locked actual grade value

Line buttons locked

Beam position at SF803

1 - Escape/Lock Button

2 - Left Line Control Button

3 - Plus Button

9

4 - Minus Button

5 - Right Line Control Button

6 - Power Button

M - Menu Button

E - Enter Button

Hole for hand loop

Page 20

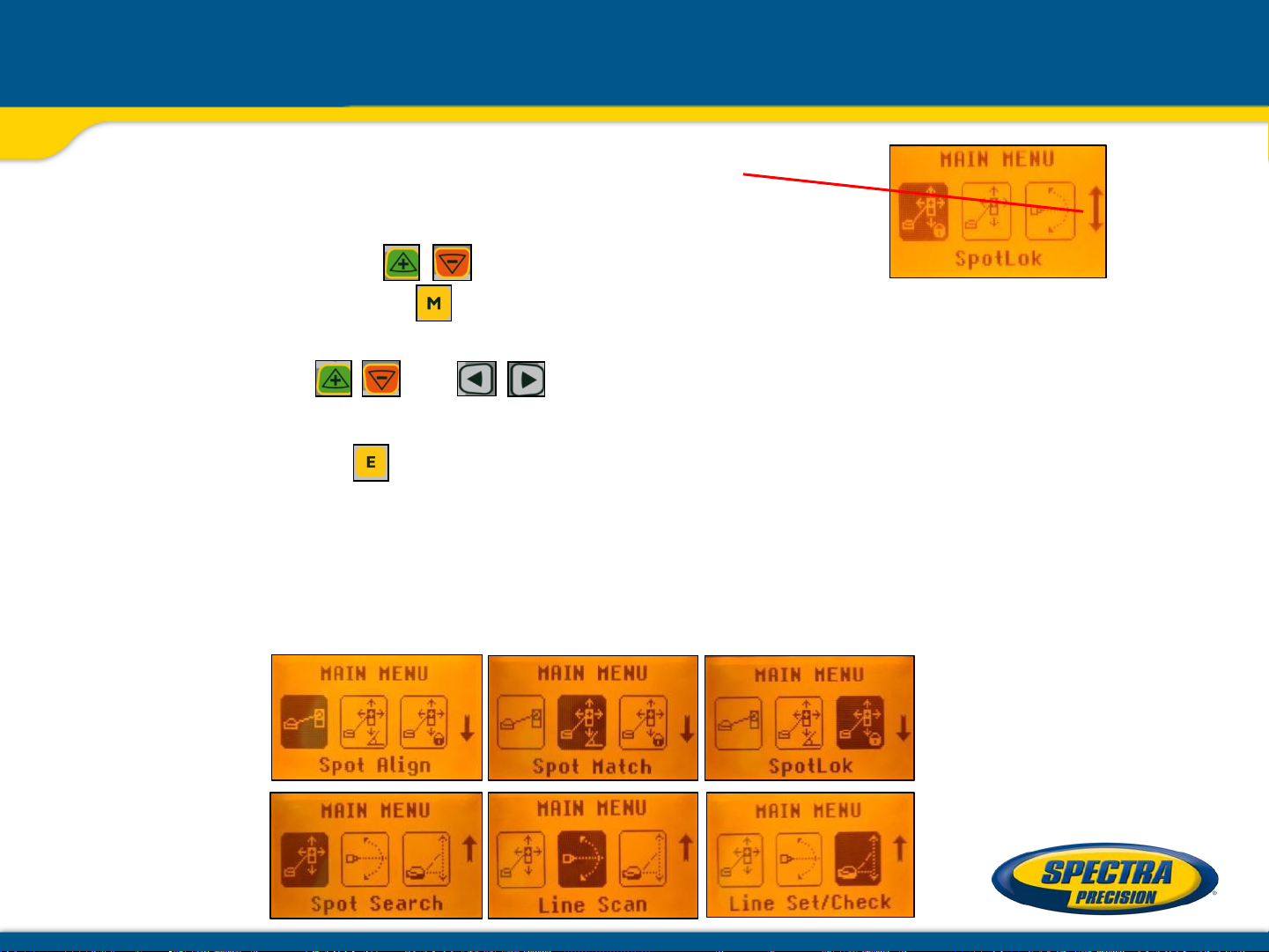

Menu functions – Radio controlled

Press and release button at the Standard Display to enter the MENU.

The menu offers always only the available features depending which pipe laser (DG813

or DG613) is used.

Menu functions available at the DG813

Menu functions available at the DG613

The icon of the selected function will be highlighted.

A down arrow at the the right site

indicates that the user can scroll

down through the menu using

the (-) button.

Page 21

Menu functions – Radio and IR controlled

After going to the next menu row, an up/down arrow

at the the right site indicates that the user can scroll up/down

through the menu using the buttons.

Pressing and releasing button changes the unit always back to the standard or

previous display.

Press and release the and buttons until the desired function at the selected menu

row is marked with a dark background.

Press and release button to open the submenu OR start the selected function.

Menu Functions (IR controlled)

If the RC803 is paired with a transmitter and the radio connection gets lost, e.g., when used

through a pipe, the IR connection offers the following functions.

IR-menu functions available at the DG813

Page 22

Menu functions

IR-menu functions available at the DG613

Note: If a remote is paired with a transmitter the IR signals of the remote (in case of an

interrupted radio connection) will be transmitted in a private mode so that only the paired

transmitter can receive these IR commands.

Don‘t start automatic functions at the menu before the reference check has been finished.

If an automatic function will be selected and then confirmed with the button during the

reference check, the display shows the reference check is still running.

Page 23

Menu functions – Entering Grade

Entering Grade – changing the grade value in Step + Go or Digit Select (Default) mode.

Press and release the button; icon Grade Edit will be highlighted.

Digit Select Mode (Default):

Press/release button A cursor at the sign of the

grade value is flashing.

Press/release or button change the sign of the grade value.

Press and hold the button quick set to 0%.

Pressing and releasing or button moves the cursor

to the right/left.

Press and release buttons to change the selected digit.

The laser will self-level to the required grade position

after confirming the grade change with button.

Grade Entering can be exited any time by

pressing and releasing button.

Page 24

Menu functions – Entering Grade

Step + Go Mode:

Press and hold or button for changing the grade value after the comma.

Press/release button or change the sign of the grade value.

The Plus sign won’t be displayed.

Press and hold buttons simultaneously starts the

Quick change mode where the grade value will be set to 0% and

then starts in front of the comma changing in 1% increments.

Note: When the grade value reaches its highest amount, the grade value switches to

the lowest value. For example, the value switches from +40% to -12%.

The laser will self-level to the required grade position after confirming

the grade change with button.

Note: The bubble symbol at the laser’s and remote’s LCD and the

laser beam will flash until the laser has been self-leveled to the

requested grade position.

Page 25

Menu functions – Spot Align (only DG813)

Automatic Spot Align

The Spot Finder SF803 guides the beam to the target point, while

the grade value will be maintained.

Don’t start Spot Align while the Reference Check is running.

Press and release the button at the standard display and

select icon Spot Align

using the and buttons.

Press/release button escape/return to the standard display.

Pressing and releasing button activates the Spot Alignment function while the beam

moves to the 0% position. A bubble vial appears while the beam and a

Spot Finder symbol will flash.

To make sure the beam moves plumb, roll the unit at the invert or use the screws of the

invert plate until the vial is centered and the beam and SF symbol stop

flashing.

Page 26

Menu functions – Spot Align (only DG813)

Spot Align (cont.)

Pressing and releasing button again starts the automatic Spot Alignment

while the beam becomes a rotating fan beam which will search automatically

for the SF803‘s center position in a range up to +45°/ 100%.

Note: The left SF symbol flashes while an additional SF symbol at the right site of the

display indicates the beam movement until the beam is centered at the SF803.

Note: The SF803 needs to be tilted into the direction of the DG813

using the pole adapter when placed at a steep slope position.

When the alignment is finished, the beam moves plumb down to the dialed in grade value.

Automatic Spot Align can be exited any time by pressing and releasing button.

Page 27

Spot Align at the jobsite - First day setup

Place the Spot Finder at the correct position using the direction pole

Automatic Spot Align

is the most accurate

choice to align the

laser beam quickly

and correctly to the

next manhole

Page 28

Spot Align at the jobsite

Place the Spot Finder at the direction stake or correct line position

Roll the unit at the invert or use the screws of the invert plate

until the vial is centered and the left SF symbol and the beam stop flashing

Select Spot Align at

the menu and press E

Page 29

Spot Align at the jobsite

Press E again to

start Spot Align

All LEDs On confirm

alignment completed

Rotating Fan beam searches for the Spot Finder‘s center;

LEDs indicate the beam movement

If the beam stops

flashing,

start laying pipes using

the target plate

Beam moves down plumb to the dialed in grade value

Page 30

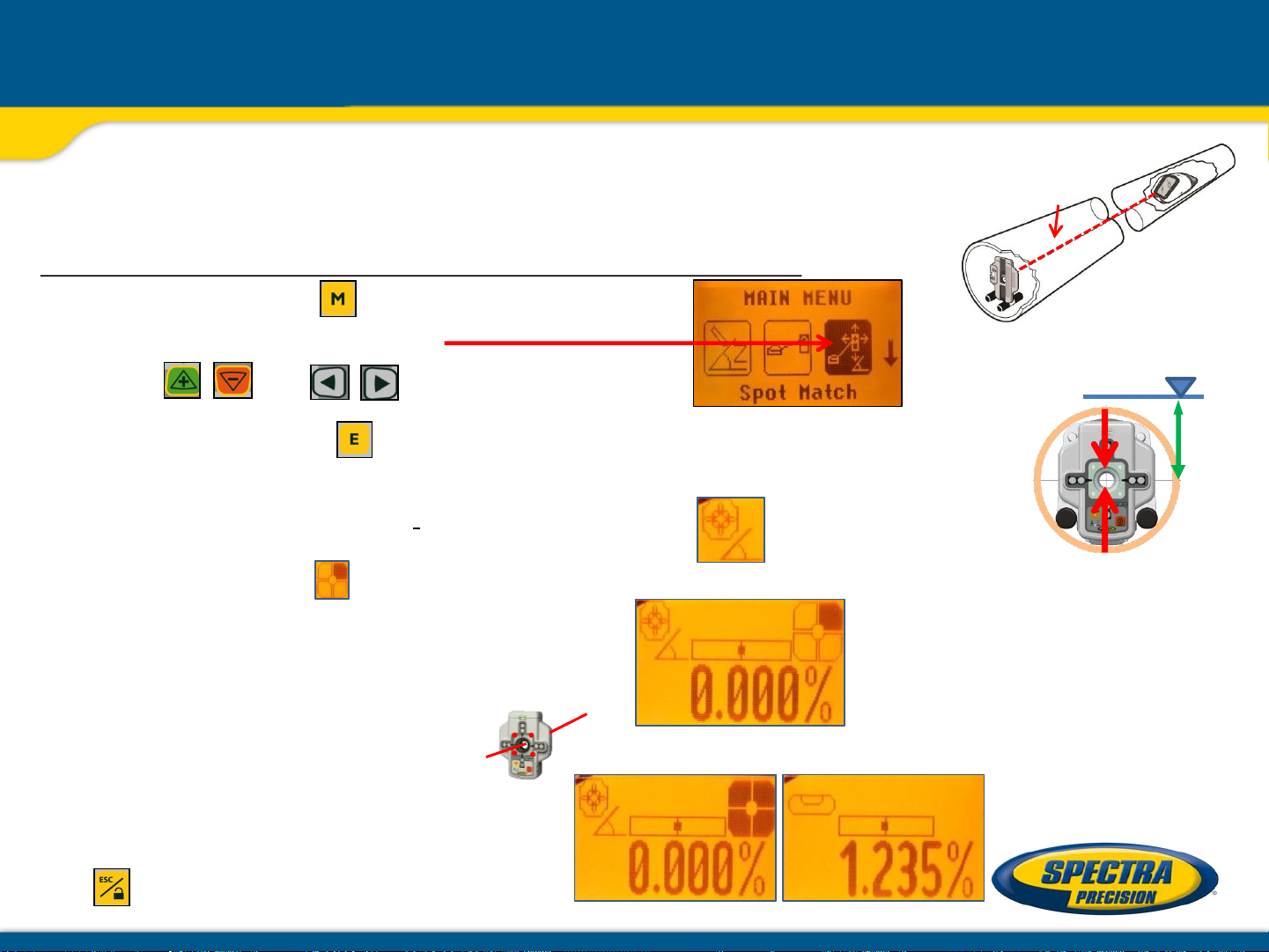

Menu functions – Spot Match (only DG813)

Automatic-Spot-Match can be used for measuring an unknown

grade value in an existing pipe or open trench.

Don’t start Spot Match while the Reference Check is running.

Press and release the button at the standard

display and select Spot Match

using the and buttons.

Pressing and releasing button starts the automatic Spot Match while

the beam becomes a rotating fan beam which will be automatically aligned

to the SF803‘s center position.

Note: The left SF symbol along with a grade symbol flashes while an

additional SF symbol at the right site of the display indicates the beam movement until the

beam is centered.

%?

Z%

When Spot Match has finished,

the beam goes through the SF hole and the measured grade value will be displayed.

Automatic Spot Match can be exited

any time by pressing and releasing

the button.

Page 31

Spot Match at the jobsite

Adjust the Spot Finder‘s center hole to the center of the laser beam

then set up the laser at the manhole or at the first pipe

Automatic Spot Match can be

used to measure the grade value

of an existing pipe which needs

to be replaced but also

to check if the pipes

have laid correctly the day before

%?

Place the Spot Finder at the last pipe

Select Spot Match at

the menu and press E

Page 32

Spot Match at the jobsite

Rotating Fan beam searches for the Spot Finder‘s center;

LEDs indicate the beam movement

All LEDs On confirm Spot Match completed; beam goes through

the SF center hole; display shows the measured grade value

Replace the Spot Finder with the target plate

and proceed laying pipes

Page 33

Menu functions – SpotLok (only DG813)

Automatic SpotLok (like PlaneLok) can be used to align and hold

the beam automatically to the SF803’s center point in automatic

or manual mode. It can also be used in manual mode for establishing an

automatic steep slope reference in mountain areas.

Don’t start SpotLok while the Reference Check is running.

Press and release the button at the standard display and select SpotLok

using the and buttons.

Pressing and releasing button starts automatic SpotLok while the beam

becomes a rotating fan beam which will be automatically aligned to

the SF803‘s center position.

Note: The left SF symbol together with a lock symbol flashes while

an additional SF symbol at the right site of the display indicates

the beam movement until the beam is centered.

Automatic SpotLok complete: LEDs solid for 5 min.,

then flashing every 5 seconds to confirm SpotLok is OK.

Automatic SpotLok can be exited any

time by pressing and releasing button

where the unit switches back to

automatic or manual mode.

Page 34

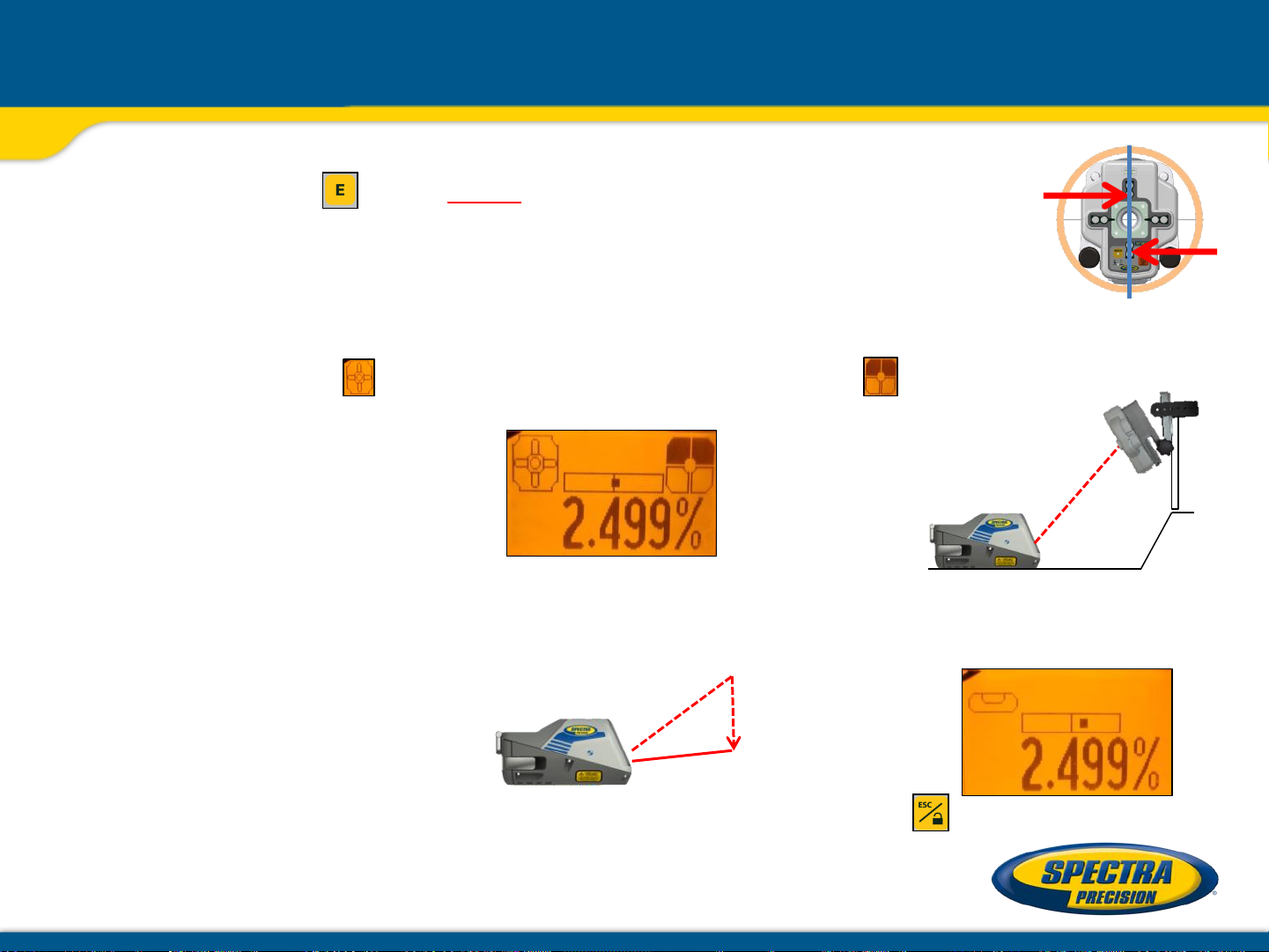

Menu functions – Manual Spot Search (only DG813)

Spot Search mode is used for pipe laying by detecting the beam manually using the

Spot Finder SF803 and can be activated in automatic and manual mode.

Using the “Over the Top” application, the Spot Finder detects the fan beam while the remote

control’s display provides the information for positioning the pipe correctly at the required

direction and elevation.

Press and release the button at the standard display and select Spot Search

using the and buttons.

Pressing and releasing button starts the manual Spot Search mode while the

beam becomes a rotating fan beam.

The empty SF symbol indicates the Spot Search mode has been activated.

A black block at the SF symbol indicates the beam position at the Spot Finder and gives the

direction for finding the center of the beam. Two black blocks on top or the bottom of the

SF symbol confirm the correct direction.

4 black blocks at the SF symbol confirm the Spot Finder has been adjusted to the center of

the beam which means the pipe has been placed correctly.

Manual Spot Search can be exited any

time by pressing and releasing button.

Page 35

Menu functions – Line Scan / Line Set Check

Line Scan - For a faster second day setup, line scan enables complete

automatically movement of the laser beam to the left and right limits.

Press and release the button at the standard display and select Line Scan

using the and buttons.

Pressing and releasing button activates the Line Scan mode while the laser

beam moves horizontally to the right/left limits and stops at the center position.

When the beam crosses the target press the button to stop the automatic

beam movement.

Corrections for centering the beam at the target’s bulls-eye can be done using

the buttons.

Line Set/Check - Moves the laser beam vertically to its maximum limit

for setting line in a first day setup without a SF803.

Press and release the button and select Line Set/Check

using the and buttons.

Pressing and releasing button activates the Line Set/Check mode.

The beam moves to the 0% position while the flashing Line Set/Check symbol

appears together with a bubble vial.

Page 36

Menu functions – Line Set Check (cont.)

Roll the unit at the invert or use the screws of the invert plate until the vial is

centered and the Line Set/Check symbol stops flashing.

Pressing and releasing the button again starts the beam moving vertical

automatically up to 45°/ 100%.

Using the or button at the RC803 remote control or at the laser stops the

automatic upwards beam movement.

Adjust the beam using buttons until the beam is centered at the line stake.

After aligning the beam to the required direction position, pressing and releasing

the button starts the beam plumb down movement to the previous dialed in

grade value.

Page 37

Menu functions – Reference Check / Standby mode

Start Reference Check – Before starting some sensitive pipe work, an

additional Reference Check can be started manually.

Press and release the button at the standard display and select Reference

Check

using the and buttons.

Pressing and releasing button starts the Reference Check considering the

current temperature inside the housing. While the unit checks the correct 0%

reference the beam flashes once a second simultaneously with a

thermometer symbol at the display.

Standby Mode – activating/deactivating the Standby Mode.

Press and release the button at the standard display and select Standby

using the and buttons.

Pressing and releasing button activates the Standby mode.

The self-leveling will be stopped and the beam will be turned off while the

Line alert is still active. The display shows the Standby symbol.

To deactivate Standby mode and restore full operation of the laser,

press and release button again.

Page 38

Menu functions – Info

Info - The DG/RC information (software version, ID, etc.), runtime of the DG

or the actual used radio channel will be displayed.

Press and release the button at the standard display and select Info

using the and buttons.

Pressing and releasing button opens the Info’s submenu.

The buttons can be used to toggle between

About Laser, Runtime and Radio.

Press and release to show the Laser Info (Serial number, Software

version, internal temperature), Runtime (endless counter) or Radio (actual

radio channel) information

Page 39

Menu functions – Service / Entering Setting Details

Service – capability to recalibrate the level sensors.

Press and release the button at the standard display and select Service

using the and buttons.

Pressing and releasing button starts the Z-axis calibration process at 0%.

The Service submenu also offers access to special features for technicians only.

Setting Menu Details – offers the different setting features.

Press and release the button at the standard display and select Settings

using the and buttons.

Pressing and releasing button opens the Setting’s menu.

and buttons can be used to select the desired Setting

function then press button to open the selected submenu.

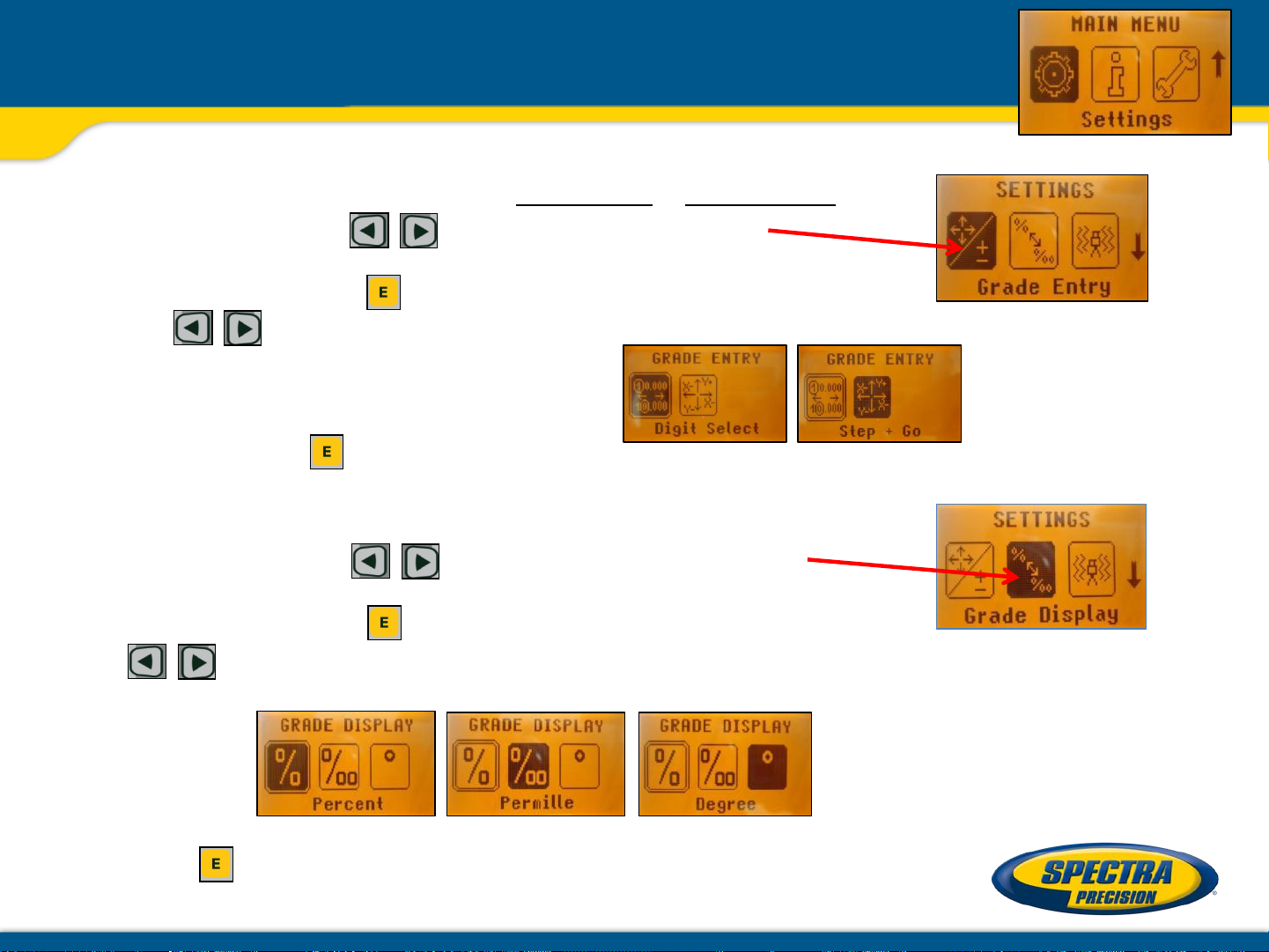

Page 40

Settings – Grade Entry / Grade Display

Grade Entry – offers selection of Step + Go or Digit Select Mode.

Press and release the buttons until Grade Entry

is displayed.

Pressing and releasing button opens the submenu.

Use the buttons to toggle between Step + Go and Digits Select. (Default).

Press and release to confirm the selection.

Grade Display – offers the different Grade Display options.

Press and release the buttons until Grade Display

will appear.

Pressing and releasing button opens the submenu.

The buttons can be used to toggle between

Percent, (Default) Per Mille Degree.

Press the button to confirm the selection.

Page 41

Settings – Sensitivity / Line Alert

Sensitivity Selection – offers three different sensitivity options.

Press and release buttons until Sensitivity is displayed.

Pressing and releasing button opens the submenu.

Use the buttons to toggle between Low, Mid (Default) and High.

Press the button to confirm the selection.

Line Alert– offers three different Line Alert options.

Press and release and buttons until Line Alert is displayed.

Pressing and releasing button opens the submenu.

Use the buttons to toggle between LA 5 min (Default), LA 30 sec and LA Off.

Press the button to confirm the selection.

Page 42

Settings – User Name / Set Password

User Name – offers the activation of the user name.

Press and release and buttons until User Name is displayed.

Pressing and releasing button opens the submenu; cursor flashes.

Use the button to toggle between both lines.

Pressing and releasing button moves the cursor to the right/left.

Press and release buttons to change the character (letters and

numbers).

If the button will be hold for a longer time, the speed of changing the

characters is increasing.

Press the button to store the user name.

Set Password – a password can be entered.

Press and release and buttons until Set Password is displayed.

Pressing and releasing button opens the submenu.

Use button 1 to 6 to type in a password at the second row containing

of 4 digits and repeat the password at the third row.

A previous used password needs to be typed in at the row “Old”.

Press and release button to store the selected password; unit falls

back to the standard display.

Page 43

Settings – Password On/Off / RF Channel

Password ON/OFF – activating/deactivating Password function.

Press and release and buttons until Password On/Off

is displayed.

Pressing and releasing button opens the submenu.

Use the buttons to toggle between Password On and Password Off.

Press the button to confirm the selection.

Any time when the DG will be turned on, the password has to be entered after the password

function has been confirmed.

Typing in a wrong password turns off the DG immediately.

Radio RF Channel – offers the selection of a different radio channel.

Press and release and buttons at the laser until RF Channel

is displayed.

Pressing and releasing button opens the submenu.

Use the and buttons to toggle between RF Channel k=1 and Channel k=6

Press the button to confirm the channel.

After changing the radio channel,

the RC803 and SF803 need to be

paired again.

Page 44

Settings – Language / Position Info

Select Language – offers language selection for the main menu text.

Press and release and buttons until Language is displayed.

Pressing and releasing button opens the submenu.

Use the and buttons to toggle between the different language

options.

Press the button to confirm the selection.

Position Info – capability of changing transmitters geographical location

Press and release and buttons until Position Info

is displayed.

Pressing and releasing button opens the submenu; the cursor flashes.

Pressing and releasing button moves the cursor to the right/left.

Use the button to toggle between Latitude and Altitude.

Use the buttons for editing the required numbers, then press

the button to confirm the dialed in numbers.

Page 45

Error

codes

Description

Solution

21

Temporary EEprom problem

Repeat pairing and re-enter the customer

settings

120

LA

changed

Check laser beam

130

Mechanical Limit during

-

o

Re

point; check if existing slope is

below/above

140

Laser beam blocked

nly at DG813

Make sure there are no obstacles

between the transmitter and the

141

Time Out

self

in the allowed

Check radio operating range/ connection;

ensure a stable

Troubleshooting DG813/DG613

Any error message can be deleted with a short press of the button.

The table shows the related description and possible solutions.

The next service center should be contacted if a different error message as shown at the

table will be displayed.

alert - Unit setup has been

Spot Match

nly at DG813

- o

– Automatic alignment or

-leveling could not be completed

time

elevation/direction

-align the closer to the alignment

-12% to +40%

SF803

laser setup

Page 46

Laser setup - Existing accessories

– DG613/DG813 fit into a 6 inch/150 mm pipe

– 1238 1248

– 1230/1237 heavy duty invert plate

10 inch

250 mm

– 1239 vertical pole

8 inch

200 mm

12 inch

300 mm

15 inch

400 mm

Page 47

Laser Setup using 1230/1239

After mounting the pipe laser

to the pole, dial in 0% and

measure the distance from the

invert to the beam’s center

Place the 936 target in front

and adjust the bulls-eye to the

beam – disregard the scale

but check the bubble vial

when laying the pipes.

Page 48

Laser Setup using T-bar/1239

T - bar with 1239 fixed pole for big pipes

Speed release

handle

Vertical

centerline

Vertical

pole

T-bar

T-bar

section

Loading...

Loading...