Page 1

设计人员: QQ:

Http:www.yattool.com

张妹珍 99739279

制作日期: 运用软件:

2018-1-26 Adobe Acrobat 7 Pro

名 称:

客 户:

料 号:

尺 寸:

材 质:

说明书

CH171

8458-4348042-011

A5(148.5x210mm)

80G双胶纸

颜 色:

页 数:

备注:

彩色印刷(PT 282U)

5 张A4纸

Page 2

INSTRUCTION

750W

ELECTRIC

POLE SAW S75EC

YT4348

MANUAL

Important - Please read these instructions

fully before starting assembly

These instructions contain important information that will help

you get the best from your pole saw, ensuring it is assembled correctly

and safely. If you need help or have damaged or missing parts,

call the Customer Helpline on 0345 605 2070

AFTER SALES SUPPORT

0345 605 2070

Page 3

SPEAR & JACKSON SINCE 1760

For more than 250 years gardeners have enjoyed high quality performance

and great results using Spear & Jackson tools.

Our garden power tools combine continuous innovation and the latest in

manufacturing technologies with a proud heritage.

Each product is carefully designed with performance,comfort and

durability rmly in mind,which has earned Spear & Jackson an enviable

reputation as a maker of tools to trust.

3 YEARS GUARANTEE

As a testament to the quality of our products, we offer a 3 year

manufacturers warranty and a comprehensive after sales service.

The warranty covers manufacturing faults, however in the event that the

item has been deliberately damaged, used in a commercial environment or

disassembled then the warranty will be null and void.

Please retain proof of purchase.

TECHNICAL SUPPORT

We want you to get the best out of your products. Our easy-to-read

instruction manual guides you with best practice use and maintenance

tips. Please call 0345 605 2070 for technical support, we can solve around

80% of questions directly over the phone.

We hope you enjoy your product and we look forward to any feedback, as

this allows us to develop even better products for the future.

2 AFTER SALES SUPPORT 0345 605 2070

Page 4

CONTENTS

SAFETY INFORMATION........................................................................................................04

Description of symbols...................................................................................04

General power tool safety warnings ..............................................................05

Work area safety.............................................................................................05

Electrical safety...............................................................................................05

Personal safety................................................................................................06

Power tool use and care.................................................................................07

Residual risks..................................................................................................08

Intended use/Not intended use ......................................................................08

IN THE BOX .....................................................................................................................09

Parts List ........................................................................................................09

ASSEMBLE .........................................................................................................................10

PREPARE.....................................................................................................................09

Oil filling...........................................................................................................10

Remove the bar sheath...................................................................................10

Check the chain tension..................................................................................10

Install the shoulder strap.................................................................................10

Adjust the pole length .....................................................................................11

Adjust the blade head.....................................................................................11

Settle power cord............................................................................................12

Connect to the power source.........................................................................12

Check the oil passes.......................................................................................12

OPERATE.........................................................................................................................13

Hold the machine............................................................................................13

Switch on/off...................................................................................................13

Start cutting.....................................................................................................13

Disconnect power source................................................................................14

MAINTENANCE....................................................................................................................15

Motor Cooling.................................................................................................14

Adjust the chain Tension.................................................................................14

Nuts and Screws.............................................................................................14

Chain sharpening............................................................................................14

Guide Bar Maintenance..................................................................................16

Chain Sprocket...............................................................................................16

Storage ...........................................................................................................16

Transportation.................................................................................................17

Recycle and disposal......................................................................................17

TECHNICAL DATA...............................................................................................................18

TROUBLESHOOTING............................................................................................................19

GUARANTEE........................................................................................................................20

AFTER SALES SUPPORT 0345 605 2070 3

Page 5

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

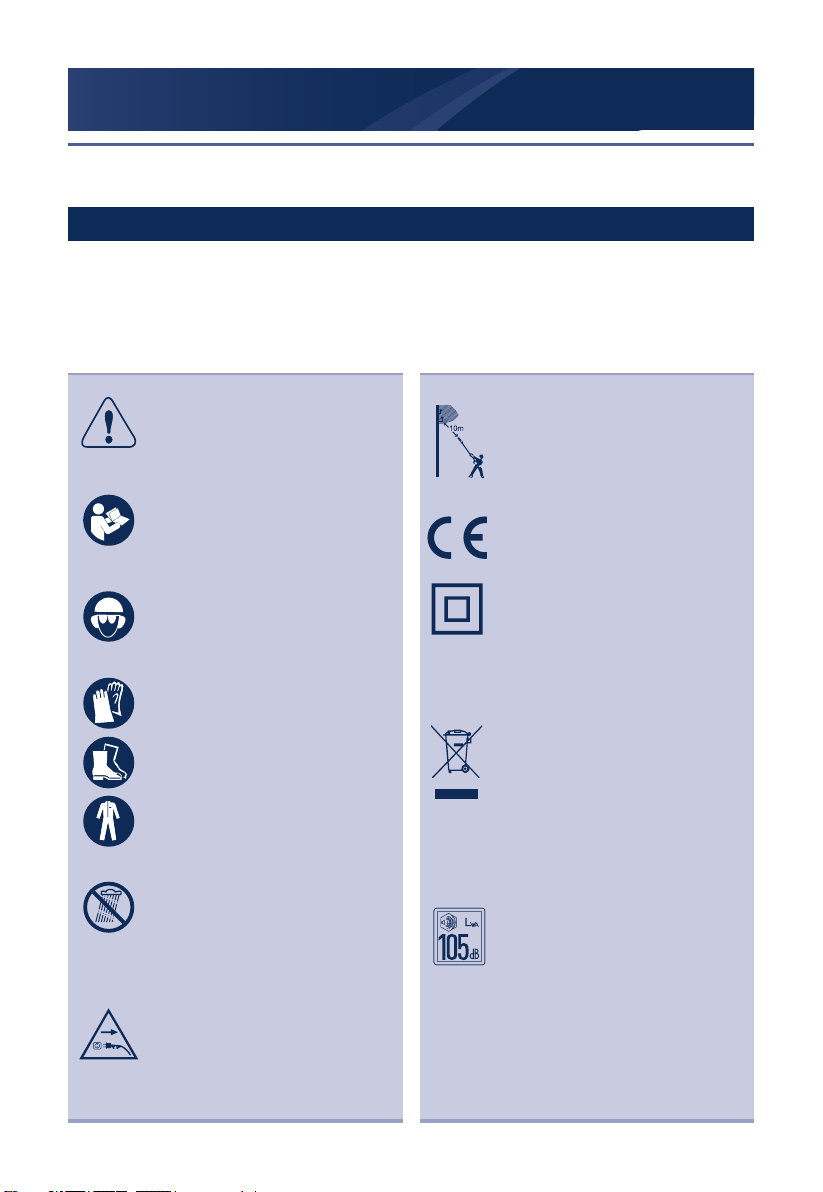

Description of symbols

Some of the following symbols may be used on your tool.Be sure to study

them and learn their meaning. Proper interpretation of these symbols will

allow you to use the machine more effectively and reduce the risk of accident.

Indicates danger, warning or

caution.

WARNING – To reduce the

risk of injury, user must read

instruction manual.

Wear ear protection, eye

protection and helmet when

using the product.

Wear gloves and safety boots

to protect against electric

shock Clothing must be

sturdy and snug-tting, but

allow complete freedom of

movement.

Protect the machine from the

damp and never expose it to

rain.

SWITCH OFF: Remove plug

from mains before cleaning or

maintenance.

SWITCH OFF: Remove plug

from the mains immediately if

the cable is damaged or cut.

Maintain a minimum clearance

of 10 m from current-carrying

lines. Life-threatening danger

from electric shock.

Conforms to relevant safety

standards.

This product is double

insulated electrically.

WEEE symbol. Tools that

are no longer usable should

not be disposed of with

household waste but in an

environmentally friendly way.

Please recycle where facilities

exist. Check with your local

council authority for recycling

advice.

Guaranteed sound power level

(tested according to Directive

2000/14/EC as amended by

2005/88/EC).

4 AFTER SALES SUPPORT 0345 605 2070

Page 6

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

General power tool safety warnings

WARNING Read all

safety warnings and all

instructions.

Failure to follow the

warnings and instructions

may result in electric shock,

re and/or serious injury.

Work area safety

a) Keep work area clean

and well lit. Cluttered

or dark areas invite

accidents.

b) Do not operate power

tools in explosive

atmospheres, such

as in the presence of

ammable liquids, gases

or dust. Power tools

create sparks which may

ignite the dust or fumes.

c) Keep children and

bystanders away while

operating a power tool.

Distractions can cause

you to lose control.

Electrical safety

a) Power tool plugs must

match the outlet. Never

modify the plug in any

way. Do not use any

adapter plugs with

earthed (grounded)

power tools. Unmodied

plugs and matching

outlets will reduce risk of

electric shock.

b) Avoid body contact with

earthed or grounded

surfaces, such as pipes,

radiators, ranges and

refrigerators. There is an

increased risk of electric

shock if your body is

earthed or grounded.

c) Do not expose power

tools to rain or wet

conditions. Water

entering a power tool

will increase the risk of

electric shock.

d) Do not abuse the cord.

Never use the cord

for carrying, pulling or

unplugging the power

tool. Keep cord away

from heat, oil, sharp

edges or moving parts.

Damaged or entangled

cords increase the risk of

electric shock.

e) When operating a power

AFTER SALES SUPPORT 0345 605 2070 5

Page 7

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

tool outdoors, use an

extension cord suitable

for outdoor use. Use of a

cord suitable for outdoor

use reduces the risk of

electric shock.

f) The use of a residual

current device (RCD)

when using this tool is

recommended. Use of an

RCD reduces the risk of

electric shock.

Personal safety

a) Stay alert, watch what

you are doing and use

common sense when

operating a power tool.

Do not use a power

tool while you are tired

or under the inuence

of drugs, alcohol or

medication. A moment

of inattention while

operating power tools

may result in serious

personal injury.

b) Use personal protective

equipment. Always wear

eye protection. Protective

equipment such as dust

mask, non-skid safety

shoes, hard hat, or

hearing protection used

for appropriate conditions

will reduce personal

injuries.

c) Prevent unintentional

starting. Ensure the

switch is in the offposition before

connecting to power

source and/or battery

pack, picking up or

carrying the tool. Carrying

power tools with your

nger on the switch or

energising power tools

that have the switch on

invites accidents.

d) Remove any adjusting

key or wrench before

turning the power tool

on. A wrench or a key

left attached to a rotating

part of the power tool

may result in personal

injury.

e) Do not overreach. Keep

proper footing and

balance at all times. This

enables better control

of the power tool in

unexpected situations.

6 AFTER SALES SUPPORT 0345 605 2070

Page 8

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

f) Dress properly. Do not

wear loose clothing or

jewellery. Keep your hair,

clothing and gloves away

from moving parts. Loose

clothes,jewellery or long

hair can be caught in

moving parts.

g) If devices are provided

for the connection of dust

extraction and collection

facilities, ensure these are

connected and properly

used. Use of dust

collection can reduce

dust-related hazards.

Power tool use and care

a) Do not force the power

tool. Use the correct

power tool for your

application.The correct

power tool will do the

job better and safer at

the rate for which it was

designed.

b) Do not use the

power tool if the switch

does not turn it on and

off.Any power tool that

cannot be controlled with

the switch is dangerous

and must be repaired.

c) Disconnect the plug from

the power source and/

or the battery pack from

the power tool before

making any adjustments,

changing accessories,

or storing power tools.

Such preventive safety

measures reduce the risk

of starting the power tool

accidentally.

d) Store idle power tools out

of the reach of children

and do not allow persons

unfamiliar with the power

tool or these instructions

to operate the power

tool.Power tools are

dangerous in the hands

of untrained users.

e) Maintain power tools.

Check for misalignment

or binding of moving

parts, breakage of parts

and any other condition

that may affect the

power tool’s operation. If

damaged,have the power

tool repaired before

use. Many accidents

are caused by poorly

AFTER SALES SUPPORT 0345 605 2070 7

Page 9

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

maintained power tools.

f) Keep cutting tools sharp

and clean. Properly

maintained cutting tools

with sharp cutting edges

are less likely to bind and

are easier to control.

g) Use the power tool,

accessories and tool bits

etc. in accordance with

these instructions, taking

into account the working

conditions and the work

to be performed. Use

of the power tool for

operations different from

those intended could

result in a hazardous

situation.

Residual risks

Even if you use this electric

power tool in accordance to

instructions, certain residual

risks cannot be eliminated.

The following hazards may

arise in connection with the

equipment’s construction

and layout:

a) Cut injuries if no safety

clothing is used.

b) Lung damage if no

suitable protective dust

mask is applied.

c) Damage to hearing if no

suitable ear protection is

applied.

d) Health damage caused

by hand-arm vibrations

if the equipment is used

over a longer period or is

not properly guided and

maintained.

intended use/Not intended

use

The chainsaw with

telescoping arm is intended

for removing branches

from trees. It is not suitable

for extensive sawing work

and felling trees or for

the sawing of materials

other than wood. Please

observe that our machine

was not designed for use

in commercial, technical

or industrial applications.

We assume no liability if

the machine is used in

commercial, technical or

industrial applications or for

equivalent activities.

8 AFTER SALES SUPPORT 0345 605 2070

Page 10

IN THE BOX

1.Guide bar

2.Saw chain

3.Adjusting knob for saw chain

tension

4.Adjusting knob (red) for guide bar

tension

5.Cap of oil tank

6.Cover of guide bar and saw chain

7.Adjusting knob for head angle (30

degrees)

8.Pole (tube)

14

12

18

13

19

11

9.Quick clip of telescopic pole

10.Sponge sleeve

11.Seat for shoulder strap

12.Rear handle

13.Switch on/off

14. Lock-off button (at the other side

of machine)

15. Shoulder strap

16. Sheath of guide bar and chain

17. Oil bottle

18. Power cord/cable

19.Cable clip

45

8910

67

123

15

16

17

AFTER SALES SUPPORT 0345 605 2070 9

Page 11

ASSEMBLE

The pole saw has been assembled in the standard

deliveryso no need for extra assembling steps.

PREPARE

1. Oil lling

Open the oil bottle (press the cap on the oil bottle and

turn counterclockwise to open it ),then open oil tank

cap to ll in the oil.

2.Remove the bar sheath

3.Check the chain tension

Always check the chain tension before use, after the

rst cuts and regularly during use, approx. every 10

minutes.

The lowest cutters should be underneath the bar

solidly and contact the bar,if not,adjust the chain with

protection gloves ( Please refer to the detailed info in

later chapter "Adjust the chain tension" ).

4.Install the shoulder strap

Shoulder strap is necessary for your cutting work,and

efcient,comfortable and safe to work with this

machine.

10 AFTER SALES SUPPORT 0345 605 2070

Page 12

PREPARE

5.Adjust the pole length

Adjust the length of the pole saw according to

working situation.

Pull the lever of the quick clip to release the pole

Extend the pole to the desired length.

Lock the pole in position by locking the quick clip lever and

ensure that the pole is secure. If the pole telescopes when

the quick clip lever is locked, the nuts need tightening.

6.Adjust the blade head

The pole chain saw head can be rotated for different

cutting angles from 0ºto 30º.

Turn the adjusting knob for head angle

counterclockwise to loosen the head.

Adjust the head to the desired position.

AFTER SALES SUPPORT 0345 605 2070 11

Page 13

PREPARE

Chain oil

Cable clip

Then turn the knob clockwise to tighten and x the

head in the position.

7.Settle power cord

The power cord should be wrapped around the

cable clip to avoid long lines stumbling pedestrians or

causing electric shock.

8.Connect to the power source

Insert the power cord/plug to the power source

before starting to work.

9.Check the oil passes

Start the machine and check whether the chain can

give off a spray of oil within a few seconds. If an oil

trace can be seen, the pole saw is lubricating.

NOTE! Never saw when a sufcient chain lubrication

is not guaranteed. Before starting work check the oil

level in the tank and the oil feeding.

12 AFTER SALES SUPPORT 0345 605 2070

Page 14

1.Safety lock button

2.Trigger

switch

OPERATE

Load

Second Cut

First Cut

1/3 Diameter

Finishing Cut

60º MAXIMUM

1. Hold the machine

Balance your weight with both feet on solid ground.

Your body should always be to the left of the chain

line.Grip handle tightly.The most typical cutting

application is to position the unit at an angle of 60°or

less depending on the specic situation. As the angle

of the pole chain saw shaft to the ground increases,

the difculty of making the rst cut (from the underside

of limb) increases.

2. Switch on/off

To turn the tool ON, push and hold the safety lock

button with your thumb and then squeeze the trigger

with your ngers. Once the tool is running.

you release the safety lock button.

Release the trigger switch to stop the chain.

3. Start cutting

Cut lower branches rst to allow the top branches

·

more room to fall.

When pruning trees, it is important not to make

·

the nishing cut next to the main limb or trunk until

you have cut off the farthest lying limb. This will

reduce the weight and prevent stripping the bark

from the main member.

Under cut the branch 1/3 through for your rst cut.

·

Your second cut should over cut to drop the

branch off

Be prepared to balance the weight of the pole

·

chain saw when the limb falls.

AFTER SALES SUPPORT 0345 605 2070 13

Page 15

OPERATE

4. Disconnect power source

When nished working,switch off the machine and

disconnect power source.

14 AFTER SALES SUPPORT 0345 605 2070

Page 16

MAINTENANCE

Max.2mm

9N

Motor Cooling

To avoid overheating and damage to the motor,

always keep the cooling air vents clean and free of

sawdust and debris.

Adjust the chain tension

Always check the chain tension before use, after

the rst cuts and regularly during use, approx.

every 10 minutes.

Loosen the bar locking knob(the inner circle) slightly,

but do not remove the side cover.

Hold up the nose of the guide bar and turn the chain

btensioning knob(the out circle) clockwise.

When the saw chain is tensioned with 9N (approx.1kg),

the gap between the saw chain and the guide rail

should never be more that 2mm.

Do not over tension the chain as this will reduce life of

chain bar and motor. With a correctly tensioned chain

you will get good cutting performance and a longer

life.

Tighten the bar locking knob(the inner circle) by

turning it counter-clockwise.

Nuts and Screws

Periodically check that all the nuts and screws are

tightened securely. Check that the cam-lock that

controls the telecoping pole is intact and in proper

working order.

Chain sharpening

Secure the bar rmly, with the chain mounted, in a

·

suitable vice.

Tighten the chain if it is loose.

·

Mount the le in the guide and then insert it in the

·

tooth at a constant angle from the cutting edge.

Sharpen in a forward motion a few times and

·

repeat this on all the cutting edges facing the

same way (right or left).

AFTER SALES SUPPORT 0345 605 2070 15

Page 17

MAINTENANCE

< 0.5 mm

Inspection tool

Depth limiter tooth

Cutting edge

Depth

limiter

tooth

To move the chain forward, use a screwdriver.

·

Turn the bar over in the vice and repeat on all the

·

other cutting edges.

Check that the depth limiter tooth does not stick

·

out farther than the inspection tool and le any

projecting parts with a at le, rounding off the

edges.

After sharpening, remove all traces of ling and

·

dust and lubricate the chain in an oil bath. Replace

the chain whenever:

– the length of the cutting edges decreases to 5

mm or less

– there is too much play between the links and the

rivets.

Guide Bar Maintenance

When the guide bar shows signs of wear, turn it over

on the saw to distribute the wear for maximum bar

life. Feathering or burring of the bar rails is a normal

process of bar wear. You should smooth such faults

with a le as soon as they occur.

Replace a bar with any of the following faults:

wear inside the bar rails permitting the chain to lay

·

over sideways

bent guide bar

·

cracked or broken rails

·

spread rails

·

Turn the saw over, check the underside of the guide

bar, and make sure that the lubrication holes and

chain groove are free from impurities.

Chain Sprocket

Regularly check the condition of the sprocket and

replace it when wear exceeds 0.5 mm.Do not mount

a new chain with a worn sprocket or vice-versa.

Storage

Clean the product as described above.

Store the product and its accessories in a dry, frost-

16 AFTER SALES SUPPORT 0345 605 2070

Page 18

MAINTENANCE

free place.

Always store the product in a place that is inaccessible

to children. The ideal storage temperature is between

10 to 30°C.

We recommend using the original package for

storage or covering the product with a suitable cloth

to protect it against dust. Clean the product as

described above.

Store the product and its accessories in a dry, frostfree place.

Always store the product in a place that is inaccessible

to children. The ideal storage temperature is between

10 to 30°C.

We recommend using the original package for

storage or covering the product with a suitable cloth

to protect it against dust.

Transportation

Switch the product off and disconnect it from power

supply before transporting it anywhere. Attach

transportation guards, if applicable.

Always carry the product by its handle.

Protect the product from any heavy impact or strong

vibrations which may occur during transportation in

vehicles.

Secure the product to prevent it from slipping or

falling over.

AFTER SALES SUPPORT 0345 605 2070 17

Page 19

TECHNICAL DATA

Model number YT4348

Rated voltage 220-240V/50Hz

Rated input power 750W

No-load speed 5600/min

Guide bar length 20cm

Oil tank capacity 60ml

Chain speed 11m/s

The total length(from the end of handle

to top of guide bar)

Protection class ll

Degree of protection IPX0

Net weight(with chain and bar) 3.7kg

Cable length 10m

Max. Vibration value 1.641m/s2 K=1.5m/s

Measured sound pressure level LPA 86.8dB(A) K=2.5dB(A)

Measured sound power level LWA 102.4dB(A) K=2.5dB(A)

Guaranteed sound power level LWA 105dB(A)

PART NUMBER ACCESSORIES

91PJ033X Chain

080SDEA041 Bar

1.92~2.60m

2

Recycling and disposal

The product comes in a package that protects it against damage during

shipping. Keep the package until you are sure that all parts have been

delivered and the product is function properly. Recycle the package

afterwards.

Old products are potentially recyclable under WEEE and do not, therefore,

belong in your household rubbish. You are requested to assist us and our

contribution to saving resources and protecting the environment by handing

in this appliance at an equipped collection centre (if there is one available).

18 AFTER SALES SUPPORT 0345 605 2070

Page 20

TROUBLESHOOTING

Suspected malfunctions are often due to causes that the users can x themselves.

Therefore check the product using this section. In most cases the problem can be

solved quickly.

WARNING! Only perform the steps described within these instructions! All

further inspection, maintenance and repair work must be performed by

an authorized service centre (call the helpline on 0345 605 2070) if you

cannot solve the problem yourself!

Fault Possible Cause Solution

Motor does not run No electricity Check socket, cables and

plugs.Damaged cable: Have

repairedby a service agent. Do

not patchcables with insulation

tape. Damaged switch: Have

repaired by a service agent.See

section on chain brake.

Worn carbon brushes Carbon brushes need replacing

Chain does not move Chain brake Check the chain brake and

release if necessary

Poor cutting

performance

Chain jumps off

guide bar

Chain works with

difculty

Chain becomes hot Chain lubricant Check oil level

Blunt saw chain Sharpen or replace the saw

chain

Chain tension Check chain tension

Saw chain tted incorrectly Check saw chain

Chain tension Check chain tension

Chain tension Check chain tension

Check chain lubrication

AFTER SALES SUPPORT 0345 605 2070 19

Page 21

WARRANTY

If your device develops a fault, please don’t hesitate to contact our customer service

department on 0345 605 2070, we can solve 80% of problems via the phone.

1. These warranty terms cover additional warranty rights and do not affect your

statutory warranty rights. All our products are covered by a 3 year manufacturer

warranty.

2. Claims must be accompanied by proof of purchase. This must be in the form

of a sales receipt or bank statement and must show that the product has been

purchased within the warranty period as described under point 1, from the retailer

that it was originally bought from. Please keep your receipt safe or staple it to the

back of this manual for future reference.

3. Our warranty covers problems caused by material or manufacturing defects, and

will result in the repair of these defects or replacement of the device with a like for

like or similar article.

4. Our devices have not been designed for commercial, trade or industrial

applications, any signs of use of the equipment in these application or equivalent

activities, invalidates the warranty.

5. The following are also excluded from our warranty:

A. Faults due to accidents, customer misuse or unauthorized repairs

B. Consumable Parts such as bar,chain and other accessories that are compatible

with the product.

C. Failure due to lack of routine maintenance.

D. Failure as a result of not using the equipment in accordance with the manual

and safety instructions

Warranty claims should be submitted before the end of the warranty period, see point

1,but a paid service exists for repairs commissioned after this period. The original

warranty period remains applicable to the device even if repairs are carried out or

parts are replaced. In such cases,the work performed or parts tted will not result in

an extension of the warranty period, and no new warranty will become active for the

work performed or parts tted.

If you have any problems or questions concerning your garden power tool, please

contact our after sales service at 0345 605 2070.

This device may be re-conditioned, like for like or upgraded replacement.

20 AFTER SALES SUPPORT 0345 605 2070

Page 22

AFTER SALES SUPPORT 0345 605 2070 21

Loading...

Loading...