Page 1

设计人员: QQ:

TEL:0573-83225888-503 Http:www.yattool.com

张妹珍 99739279 2018-1-26 Adobe Acrobat 7 Pro

制作日期: 运用软件:

名 称:

客 户:

料 号:

成品尺寸:

材 质:

说明书

CH171

8458-4353017-011

A5(148.5x210mm)

80g双胶纸

颜 色:

页 数:

备注:

一个专色(PT282U)

8张A4纸

Page 2

INSTRUCTION

MANUAL

2000W 40cm

Electric

Chainsaw S2040EC

YT4353-01

Important - Please read these instructions

fully before starting assembly

The instruction contain important information that will help you

get the best from your chain saw,ensuring it is assembled

correctly and safely.If you need help or have damaged or

missing parts, call the customer helpline on 0345 605 2070

AFTER SALES SUPPORT

0345 605 2070

Page 3

SPEAR & JACKSON SINCE 1760

For more than 250 years gardeners have enjoyed high quality performance

and great results using Spear & Jackson tools. Our garden power

tools combine continuous innovation and the latest in manufacturing

technologies with a proud heritage. Each product is carefully designed

with performance,comfort and durability rmly in mind,which has earned

Spear & Jackson an enviable reputation as a maker of tools to trust.

3 YEARS GUARANTEE

As a testament to the quality of our products, we offer a 3 year

manufacturers warranty and a comprehensive after sales service.

The warranty covers manufacturing faults, however in the event that the

item has been deliberately damaged, used in a commercial environment or

disassembled then the warranty will be null and void.

Please retain proof of purchase.

TECHNICAL SUPPORT

We want you to get the best out of your products. Our easy-to-read

instruction manu-al guides you with best practice use and maintenance

tips. Please call 0345 605 2070 for technical support, we can solve around

80% of questions directly over the phone.

We hope you enjoy your product and we look forward to any feedback, as

this allows us to develop even better products for the future.

2 AFTER SALES SUPPORT 0345 605 2070

Page 4

CONTENTS

SAFETY INFORMATION.........................................................................................................4

Description of symbols.....................................................................................4

General Power Tool Safety Warning..................................................................5

Work Safety.......................................................................................................5

Electrical Safety.................................................................................................5

Personal Safety.................................................................................................6

Power Tool Use and Care.................................................................................8

Intended use.....................................................................................................9

Residual risks...................................................................................................9

IN THE BOX.....................................................................................................................11

Parts list...........................................................................................................11

ASSEMBLE & PREPARE...............................................................................................12

PREPARE.............................................................................................................................12

Oil filling..........................................................................................................12

Remove the bar sheath...................................................................................12

Check the chain tension..................................................................................12

Settle the power cord......................................................................................13

Connect to the power source..........................................................................13

Locate the chain brake . ................................................................................13

Check the oil passes.......................................................................................14

OPERATE.........................................................................................................................14

Hold the machine............................................................................................15

Switch On/Off...................................................................................................16

Start cutting ...................................................................................................16

Disconnect the power source.........................................................................18

Limbing...........................................................................................................20

Bucking...........................................................................................................20

Bucking using a sawhorse..............................................................................21

Maintenance ....................................................................................................................23

Adjust the chain tension.................................................................................23

Cleaning saw body ........................................................................................24

Care of the chain.............................................................................................24

Care of guide bar.............................................................................................25

Flip the bar......................................................................................................25

Storing............................................................................................................26

TECHNICAL DATA................................................................................................................27

Environmental protection..................................................................................................27

TROUBLESHOOTING............................................................................................................28

WARRANTY..........................................................................................................................29

AFTER SALES SUPPORT 0345 605 2070 3

Page 5

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

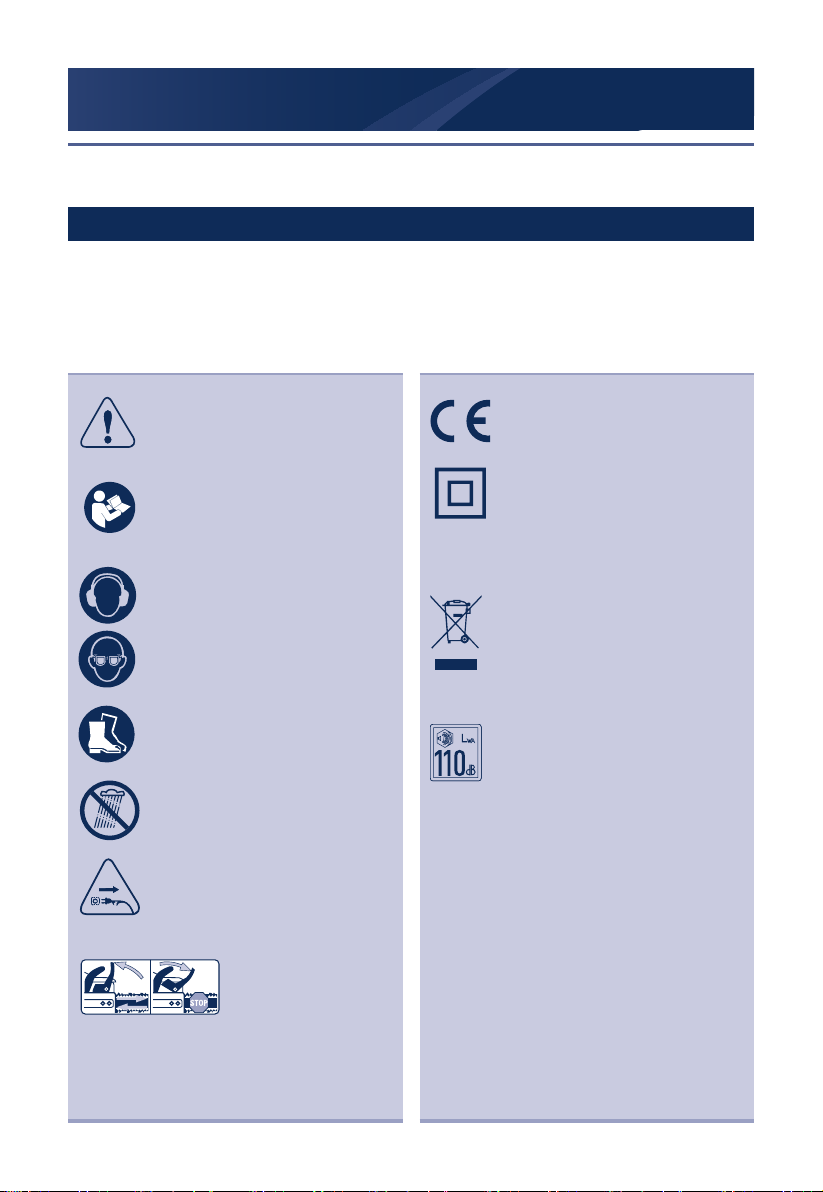

DESCRIPTION OF SYMBOLS

The following warning symbols appear throughout this manual and indicate

the appropriate safety measures you should take when operating and

maintaining the electric chain saw.

Indicates danger, warning, or

caution.

WARNING – To reduce the

risk of injury, user must read

instruction manual.

Wear ear protection, eye

protection, respirator and

gloves when using the

product.

Wear safety boots to protect

against electric shock

Do not expose to rain

Remove plug from the

mains immediately if cable is

damaged or cut

Make sure the

“chain brake” is

disengaged.

Conforms to relevant safety

standards.

This class II symbol indicates

that the product is correctly

insulated. Grounding

this machine is therefore

unnecessary.

onmentally friendly way. Please

recycle where facilities exist.

Check with your

local council authority for

recycling advice.

Guaranteed sound power level

(tested according to Directive

2000/14/EC as amended

by 2005/88/EC)

4 AFTER SALES SUPPORT 0345 605 2070

Page 6

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

GENERAL POWER TOOLS SAFETY WARNINGS

WARNING Read all

safety warnings and

all instructions.

Failure to follow the

warnings and instructions

may result in electric shock,

re and/or serious injury.

WARNING! Read all

safety warnings

designated by the symbol

and all instructions.

Save all warnings and

instructions for future

reference.

The term "power tool" in

the warnings refers to your

mains-operated (corded)

power tool or batteryoperated (cordless) power

tool.

Work Area Safety

a) Keep work area clean

and well lit.

Cluttered or dark areas

invite accidents.

b) Do not operate power

tools in explosive

atmospheres, such

as in the presence of

ammable liquids, gases

or dust.

Power tools create

sparks which may ignite

the dust or fumes.

c) Keep children and

bystanders away while

operating a power tool.

Distractions can cause

you to lose control.

Electrical Safety

a) Power tool plugs must

match the outlet. Never

modify the plug in any

way. Do not use any

adapter plugs with

earthed (grounded)

power tools.

Unmodied plugs and

matching outlets will

reduce risk of electric

shock.

AFTER SALES SUPPORT 0345 605 2070 5

Page 7

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

b) Avoid body contact with

earthed or grounded

surfaces, such as pipes,

radiators, ranges and

refrigerators.

There is an increased

risk of electric shock if

your body is earthed or

grounded.

c) Do not expose power

tools to rain or wet

conditions. Water

entering a power tool

will increase the risk of

electric shock.

d) Do not abuse the cord.

Never use the cord

for carrying, pulling or

unplugging the power

tool. Keep cord away

from heat, oil, sharp

edges or moving parts.

Damaged or entangled

cords increase the risk of

electric shock.

e) When operating a power

tool outdoors, use an

extension cord suitable

for outdoor use.

Use of a cord suitable for

outdoor use reduces the

risk of electric shock.

f) The use of a residual

current device (RCD)

when using this tool is

recommended. Use of

an RCD reduces the risk

of electric shock.

Personal Safety

a) Stay alert, watch what

you are doing and use

common sense when

operating a power tool.

Do not use a power

tool while you are tired

or under the inuence

of drugs, alcohol or

medication.

A moment of inattention

while operating power

tools may result in

serious personal injury.

b) Use personal protective

6 AFTER SALES SUPPORT 0345 605 2070

Page 8

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

equipment. Always wear

eye protection.

Protective equipment

such as dust mask, nonskid safety shoes, hard

hat, or hearing protection

used for appropriate

conditions will reduce

personal injuries.

c) Prevent unintentional

starting. Ensure the

switch is in the offposition before

connecting to power

source and/or battery

pack, picking up or

carrying the tool.

Carrying power tools with

your nger on the switch

or energising power tools

that have the switch on

invites accidents.

d) Remove any adjusting

key or wrench before

turning the power tool

on.

A wrench or a key left

attached to a rotating

part of the power tool

may result in personal

injury.

e) Do not overreach. Keep

proper footing and

balance at all times.

This enables better

control of the power tool

in unexpected situations.

f) Dress properly. Do not

wear loose clothing or

jewellery. Keep your hair,

clothing and gloves away

from moving parts.

Loose clothes, jewellery

or long hair can be

caught in moving parts.

g) If devices are provided

for the connection of dust

extraction and collection

facilities, ensure these

are connected and

properly used.

Use of dust collection

can reduce dust-related

hazards.

AFTER SALES SUPPORT 0345 605 2070 7

Page 9

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

Power Tool Use and Care

a) Do not force the power

tool. Use the correct

power tool for your

application.

The correct power tool

will do the job better

and safer at the rate for

which it was designed.

b) Do not use the power

tool if the switch does

not turn it on and off.

Any power tool that

cannot be controlled with

the switch is dangerous

and must be repaired.

c) Disconnect the plug from

the power source and/

or the battery pack from

the power tool before

making any adjustments,

changing accessories, or

storing power tools.

Such preventive safety

measures reduce the risk

of starting the power tool

accidentally.

d) Store idle power tools

out of the reach of

children and do not allow

persons unfamiliar with

the power tool or these

instructions to operate

the power tool. Power

tools are dangerous in

the hands of untrained

users.

e) Maintain power tools.

Check for misalignment

or binding of moving

parts, breakage of parts

and any other condition

that may affect the

power tool’s operation.

If damaged, have the

power tool repaired

before use.

Many accidents are

caused by poorly

maintained power tools.

f) Keep cutting tools sharp

and clean.

Properly maintained

cutting tools with sharp

8 AFTER SALES SUPPORT 0345 605 2070

Page 10

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

cutting edges are less

likely to bind and are

easier to control.

g) Use the power tool,

accessories and tool bits

etc. in accordance with

these instructions, taking

into account the working

conditions and the work

to be performed.

Use of the power tool for

operations different from

those intended could

result in a hazardous

situation.

Intended use

The chain saw is intended

for sawing of trees, tree

trunks, branches, wooden

beams, planks, etc. Cuts

can be sawed with or

across the grain. This

product is not suitable for

sawing mineral materials.

Furthermore a professional

use for tree services is

strictly forbidden.

The user and not the

manufacturer is liable

for every accident which

results from a combination

of not intended use or a

not allowed change of

the construction on the

machine.

The chain saw is only

intended to use outdoor.

Residual risks

Even with the intended

use of the appliance there

is always a residual risk,

which can not prevented.

According to the type

and construction of the

appliance the following

potential hazards might

apply:

- Contact with exposed

saw teeth of the saw

chain (cutting hazards)

AFTER SALES SUPPORT 0345 605 2070 9

Page 11

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

- Access to the rotating

saw chain (cutting

hazards)

- Unforeseen, abrupt

movement of the guide

bar (cutting hazards)

- Flung out of parts from

the saw chain (Cutting /

injection hazards)

- Flung out of parts of the

work piece

- Inhalation of work peace

particles,

- Skin contact with the oil,

- Loss of hearing, if no

required ear protection

used during work.

10 AFTER SALES SUPPORT 0345 605 2070

Page 12

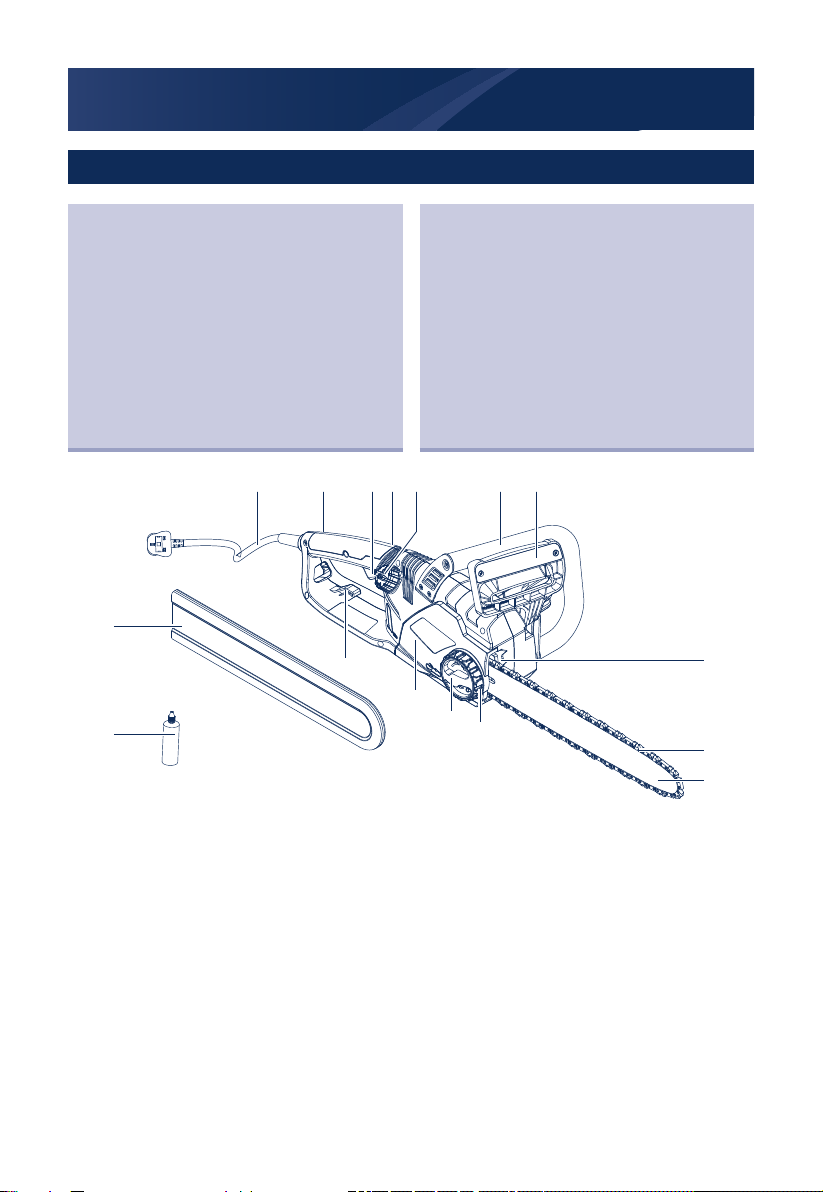

IN THE BOX

Parts List

1.REAR HANDLE

2.SWITCH ON/OFF

3.LOCK-OFF BUTTON

4.OIL TANK CAP

5.FRONT HANDLE

6.BRAKE (HAND GUARD)

7.GUIDE BAR

8.CHAIN

9.BAR COVER

14

13

15

10.BAR LOCKING KNOB

11.CHAIN TENSIONING KNOB

12.SPIKED BUMPER

13.CHAIN SHEATH

14.POWER CORD/CABLE

15.OIL BOTTLE.

16.CABLE CLIP

1

2 3 5 64

16

9

10

11

12

8

7

AFTER SALES SUPPORT 0345 605 2070 11

Page 13

ASSEMBLE

The chain saw has been assembled in

the standard delivery so no need for extra

assembling steps.

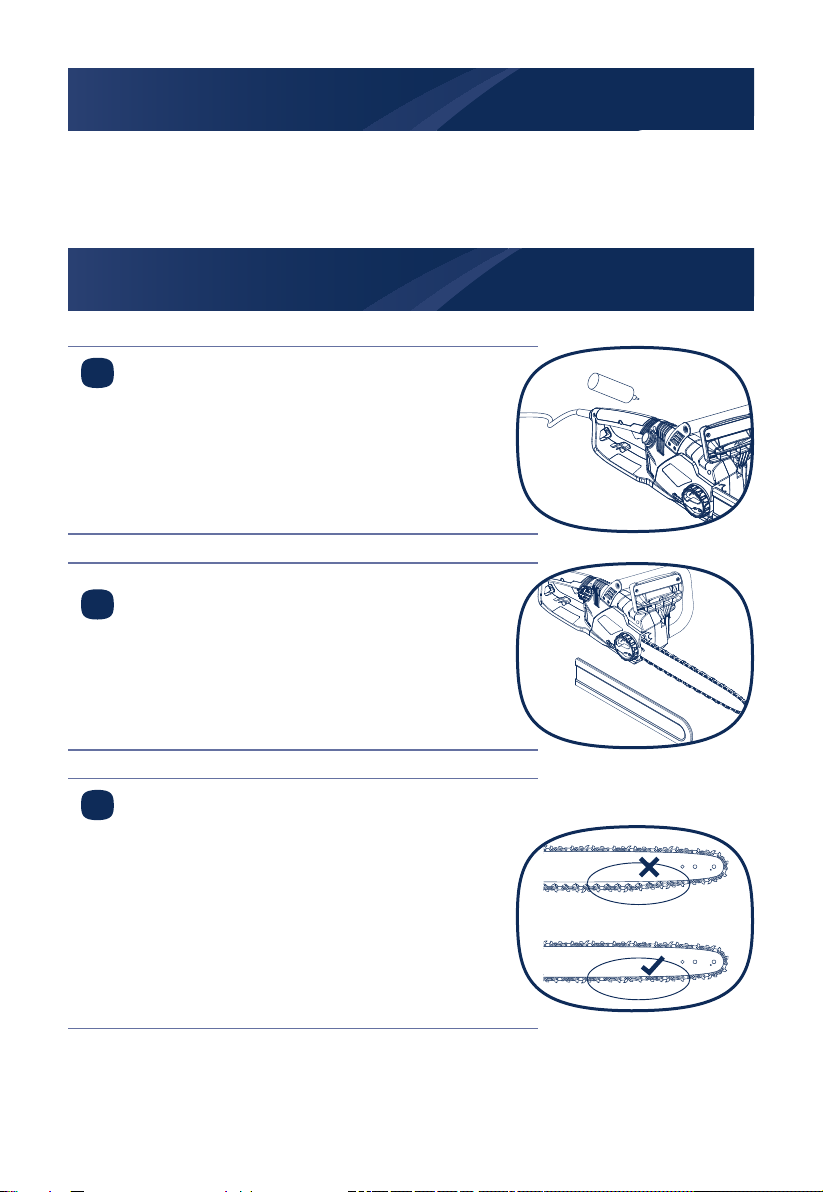

PREPARE

1

Oil lling

Open the oil bottle (press the cap on the oil

bottle and turn counterclockwise to open it ),

then open oil tank cap to ll in the oil.

Remove the bar sheath

2

Check the chain tension

3

Always check the chain tension before use, after

the rst cuts and regularly during use, approx.

every 10 minutes.

The lowest cutters should be underneath the

bar solidly and contact the bar,if not,adjust the

chain with protection gloves ( Please refer to the

detailed info in later chapter "Adjust the chain

tension" ).

12 AFTER SALES SUPPORT 0345 605 2070

Page 14

PREPARE

brake disengage

brake engage

4

Settle the power cord.

The power cord should be wrapped around

the cable clip to avoid long lines stumbling

pedestrians or causing electric shock.

5

Connect to the power source

Insert the power cord/plug to the power source

before starting to work.

6

Locate the chain brake

The motor will not start if the chain brake is in

the engaged position.

Disengage the chain brake level by pulling

backward toward the front handle. Keep brake

setting is in correct position before use,and

ensure chain saw operate normally.

AFTER SALES SUPPORT 0345 605 2070 13

Page 15

PREPARE

Chain oil

Make sure the chain brake is working before

using the chain saw. To check brake operation:

• Place the saw on a rm, at surface.

• Start the saw briey. Please refer to later

chapter "switch on/off" for how to start the

machine

• Keep the left hand on the front handle and

roll the left wrist to move the front hand guard

forward to manually activate the chain brake.

If the chain brake works normally the machine

will stop after brake engage.Otherwise there is

malfunction to the machine and seek help from

service center before using.

Check the oil passes

7

Start the machine and check whether the chain

can give off a spray of oil within a few seconds.

If an oil trace can be seen, the chainsaw is

lubricating.

NOTE! Never saw when a sufcient chain

lubrication is not guaranteed. Before starting

work check the oil level in the tank and the oil

feeding.

14 AFTER SALES SUPPORT 0345 605 2070

Page 16

PREPARE

Caution! Never starve the bar and chain of

lubrication oil. Running the saw dry or with too little

oil will decrease cutting efciency, shorten chain

saw life, and cause rapid during of the chain and

excessive wear of the bar from overheating. Too little

is evidenced by smoke or bar discoloration.

> Kickback.

Kickback is the sudden backward/upward motion

of the chain saw, occurring when the chain (at the

tip of the chain bar) comes in contact with a log or

wood, or when the chain becomes jammed. When

kickback occurs the chain saw reacts unpredictably

and can cause severe injuries to the operator or

bystanders. Particular attention must be given when

sawing sideward, slanted or during length cuts, as

the spiked bumper usually can not be applied.

To avoid kickback:

> Saw with guide bar at a at angle:

> Never work with a loose, widely stretched or the

heavily worn out chain:

> Ensure chain is sharpened correctly:

> Never saw above shoulder height:

> Never work with the tip of the guide bar:

> Always hold the chain saw rmly with both hands:

> Always use a low kickback chain:

> Apply the metal gripping teeth for leverage:

> Ensure correct chain tension:

Hold the machine

Always hold the chain saw rmly with both hands.

Front grip with the left hand and rear grip with the

right hand. Fully grip both handles at all times during

operation. Never operate chain saw using only one

hand. Ensure power cord is located to the rear, away

from the chain and wood and so positioned that it will

AFTER SALES SUPPORT 0345 605 2070 15

Page 17

OPERATE

brake

disengaged

1

2

not be caught on branches or the like during cutting.

Use the chain saw only with secure footing. Hold the

chain saw at the right-hand side of your body

Switch on / off

Switch on the machine: press the lock-off button 1

, then fully press the on/off switch 2 and hold in this

position to start the cutting work.

The lock-off button 1 can now be released.

Release the Trigger switch On / Off 2 to stop the

machine,the chain stops completely after a few

seconds.

Do not stop chain saw when sawing through activating

the front hand guard (chain brake)!

Start cutting

The chain must be running at full speed before it

makes contact with the wood. Use the metal gripping

teeth to secure the saw onto the wood before starting

to cut. Use the gripping teeth as a leverage point

while cutting.

> Reset the gripping teeth at a low point when

sawing thicker logs by pulling the chain saw slightly

backwards until the gripping teeth release, and

reposition at lower level to continue sawing. Do not

remove the saw completely from the wood.

> Do not force the chain while cutting, let the chain do

the work, using the gripping teeth to apply minimal

leverage pressure.

16 AFTER SALES SUPPORT 0345 605 2070

Page 18

OPERATE

> Do not operate the chain saw with arms fully

extended or attempt to saw areas which are difcult

to reach, or on a ladder. Never use the chain saw

above shoulder height.

> Sawing is optimized when the chain speed remains

steady during cutting.

> Beware when reaching the end of the cut. The

weight of the saw may change unexpectedly as it

cuts free from the wood. Accidents can occur to

the legs and feet. Always remove the saw from a

wood cut while the saw is running.

> Cutting logs. Observe the following safety

instructions:

> Support logs so that the face sides at the cut do

not close in against each other, which would result

in the chain being jammed or pinched.

> Position and set short logs safety prior to sawing.

Saw only wood or wooden objects. When sawing,

always take care to avoid hitting stones, nails, etc,

as these could be thrown up or cause damage

to the chain or serious injury to the operator or

bystanders.

> Keep a running saw clear or wire fencing or the

ground. Use of the saw to thin out branches or

bushes is not approved.

> Length cuts must be carried out with care, as

leverage with the gripping teeth is not possible.

Saw at a at angle to avoid kickback.

> When working on a slope, operate above or to the

side of the trunk or laying tree.

> Be careful not to trip over tree stumps, branches,

roots, etc.

AFTER SALES SUPPORT 0345 605 2070 17

Page 19

OPERATE

Disconnect the power source

Disconnect the plug source for safety. When the

machine is cooled down for several minutes, it is

advised to put on the blade protection cover for

longer storage.

Tips:

I. Felling.

Felling is the term for cutting down a tree. Small trees

up to 15-18cm in diameter are usually cut in a single

cut. Larger trees require notch cuts. Notch cuts

determine the direction the tree will fall.

Warning! A retreat path (A) should be planned and

cleared as necessary before cuts are started. The

retreat path should extend back and diagonally to the

rear of the expected line.

Warning! If felling a tree on sloping ground, the chain

saw operator should keep on the uphill side of the

terrain, as the tree is likely roll or slide down hill after is

felled.

Note: Direction of fall (B) is controlled by the notching

cut. Before any cuts are made, consider the location

of larger branches and natural leaves of the tree as

well as the wind direction to determine the way the

tree will fall.

Warning! Do not cut down a tree during high or

changing winds or if there is a danger to properly.

Consult a tree professional. Do not cut down a tree

if there is a danger of striking utility wires: notify the

utility company before making any cuts. Remove dirt,

stones, loose bark, nails, staples and wire from the

tree.

18 AFTER SALES SUPPORT 0345 605 2070

Page 20

OPERATE

II. General guidelines for felling trees.

Normally felling consists of 2 main cutting operations,

notching(C) and making the felling cut (D). Start

making the upper notch cut (C) on the side of the

tree facing the felling direction (E). Be sure you don't

make the lower cut too deep into the trunk. The notch

(e) should be deep enough to create a hinge (F) of

sufcient width and strength. The notch should be Fig

23 wide enough to direct the fall of the tree for as long

as possible.

Warning! Never walk in front of a tree that has been

notched. Make the felling cut (D) from the other side

of the tree and 3-5cm above the edge of the notch (C).

Warning! Don’t use the saw above shoulder-height,

because of difcult handling of the chainsaw which

can cause serious injury. Take care of a stable position

so you have good control on the chain saw.

Never saw completely through the trunk. Always

leave a hinge. The hinge guides the tree. If the trunk

is completely cut through, control over the felling

direction is lost. Insert a wedge or felling lever in the

cut well before the tree becomes unstable and starts

to move. This will prevent the guide bar from binding

in the felling cut if you have misjudged the falling

direction. Make sure no bystanders have entered the

range of the falling tree before you push it over.

Warning: As the felling cut (D) gets close to the hinge

(F), the tree should begin to fall. Remove saw from

cut, stop the engine, put the chainsaw down and

leave the area by the retreat path.

III. Felling cut.

Use wooden or plastic wedges (A) to prevent binding

the bar or chain (B) in the cut. Wedges also control

felling.

AFTER SALES SUPPORT 0345 605 2070 19

Page 21

OPERATE

A

When diameter of wood being cut is greater than the

bar length, make 2 cuts as shown.

Limbing

Limbing a tree is the process of removing the

branches from a fallen tree. Do not remove supporting

limbs (A) until after the log is bucked (cut) Into lengths.

Branches under tension should be cut from the

bottom up to avoid binding the chain saw.

Warning: Never cut tree limbs while standing on tree

trunk.

Bucking

Bucking is cutting a fallen log into lengths. Make sure

you have a good footing and stand up hill of the log

when cutting on sloping ground. If possible, the log

should be supported so that the end to be cut off is

not resting on the ground. If the log is supported at

both ends and you must cut in the middle, make a

downward cut halfway through the log and then make

the undercut. This will prevent the log from pinching

the bar and chain.

Be careful that the chain does not cut Into the ground

when bucking as this causes rapid dulling of the

chain. When bucking on a slope, always stand on the

uphill side.

> Log supported along entire length: Cut from top

(over buck), being careful to avoid cutting into the

ground

20 AFTER SALES SUPPORT 0345 605 2070

Page 22

OPERATE

Log supported on 1end: First, cut from bottom (under

buck) 1/3 diameter of log to avoid splintering.

Second, cut from above (over buck) to meet rst cut

and avoid pinching

> Log supported on both ends: First. over buck 1/3

diameter of log to avoid splintering. Second, under

buck to meet rst cut and avoid pinching.

Note: The best way to hold a log while bucking is to

use a sawhorse. When this is not possible, the log

should be raised and supported by the limb stumps

or by using supporting logs. Be sure the log being cut

is securely supported.

Bucking using a sawhorse

For personal safety and ease of cutting, the correct

position for vertical bucking is essential. Vertical

cutting:

> Hold the saw rmly with both hands and keep the

saw to the right of your body while cutting.

> Keep the left arm as straight as possible.

> Keep weight on both feel.

Caution! While the saw is cutting, be sure the chain

and bar are being properly lubricated.

The three golden rules for care

1. Regularly grease the moving parts .

2. Check that ventilation holes , bar rails and oil

passages are always unobstructed and clean.

3. Clean the chain saw with a soft brush and clean

cloth . Do not use water , solvents or polishers.

AFTER SALES SUPPORT 0345 605 2070 21

Page 23

OPERATE

Replacing/changing chain and guide bar

Fit the chain and guide bar as described in “Assembly

and Tensioning Chain”. The circular groove of the

guide bar will wear particularly on the lower edge

with time. When replacing the chain turn the chain

bar 180° to allow even wear, thus extending chain

bar life. Check drive sprocket. If it is worn out or

damaged due to strain, have it exchanged by an

authorized service agent. If the chain bar is worn out

or damaged, have it exchanged by an authorized

service agent

22 AFTER SALES SUPPORT 0345 605 2070

Page 24

MAINTENANCE

Max.2mm

9N

Warning: Disconnect the power source before

servicing, sever injury or death could occur

from electrical shock or body contact with

moving chain.

Warning: Cutting edges or chain are sharp, use

protective gloves when handling chain.

Warning: Do not use water, solvents or polishes

as medium for clearance and maintenance.

Remove all debris, especially from the motor

cooling vents.

Adjust the chain tension

Loosen the bar locking knob(the inner circle) slightly,

but do not remove the side cover.

Hold up the nose of the guide bar and turn the chain

tensioning knob(the out circle) clockwise.

When the saw chain is tensioned with 9N (approx.1kg),

the gap between the saw chain and the guide rail

should never be more that 2mm.

Do not over tension the chain as this will reduce life of

chain bar and motor. With a correctly tensioned chain

you will get good cutting performance and a longer

life.

AFTER SALES SUPPORT 0345 605 2070 23

Page 25

MAINTENANCE

1

5

Tighten the bar locking knob(the inner circle) by

turning it counter-clockwise.

Cleaning saw body

Keep saw body clean, use a soft cloth dampened

with a mild soap and water mixture, wipe saw body to

clean.

clean the area under the cover plate, the drive procket

and chain bar assembly using a soft brush. And oil

outlet with a clean cloth.

Care of the chain

Remove sheath and clean the chain with a clean cloth

after 1 to 3 hours of use.

When working,keep it is with chain oil.

And use tool to sharpen the chain when it become

not sharp.

24 AFTER SALES SUPPORT 0345 605 2070

Page 26

MAINTENANCE

Care of guide bar

Wear gloves.

• Unplug the chain saw.

• Loosen the side cover release knob slightly, but do

not remove the side cover.

• Loosen the chain tensioning ring (turn it counter

clockwise) as far as it will go.

• Loosen the side cover release knob and remove

the side cover.

• Remove the bar and chain and inspect for damage

and wear.

• Remove the screw from the back side of the chain

tensioning gear and remove the chain tensioning

gear from the guide bar.(Fig.9)

Flip the bar

• There is a rubber washer that is important to the

function of the chain lubrication. The rubber washer

must be in place around the pin on the tensioner

before the tensioner is screwed onto the bar

AFTER SALES SUPPORT 0345 605 2070 25

Page 27

MAINTENANCE

BAR PAD

ALIGNMENT FLANGE

MOUNTING STUD

• Place the chain tensioning gear on the side of the

guide bar facing you such that the rectangular

piece does not protrude past the edges of the

guide bar and replace the screw.

• Place the guide bar on the bar pad by sliding the

bar slot over the alignment ange.

Remove guide bar from chain saw. remove sawdust

from guide bar groove periodically. use putty knife

or wire. clean oil slots after each day of use. remove

burrs from sides of guide bar. use at le to make side

edges square.

IMPORTANT! Remove and brush clean the cover

plate, chain and chain bar after 1 to 3 hours

of use.

Inspect guide bar before sharpening chain. A worn

or damaged guide bar is unsafe. A worn or damaged

guide bar will damage chain, it will also make cutting

harder. replaces guide bar if this occurs.

Storing

If the chain saw is to be stored for a longer period of

time, clean chain and chain bar.

Store in a secure, dry place out of the reach of

children. do not place other objects on the chain

saw. to prevent leakage ensure machine is left in a

horizontal position (oil tank cap 4 uppermost). when

storing machine in original packaging the oil tank

must be completely emptied.

26 AFTER SALES SUPPORT 0345 605 2070

Page 28

TECHNICAL DATA

Model YT4353-01

Voltage

Rated power 2000W

No-load speed

Bar length 40cm

Chain speed

Oil tank capacity 150ml

Chain pitch

Number of chain links 56

Chain gauge 0.05”

Protection class II

Machine weight (chain & bar included) 6.6kg

Sound pressure level LPA 93.99dB(A)

Sound power level LWA 104.32dB(A)

Guaranteed sound power level LWA 110dB(A)

Vibration a

PART NUMBER ACCESSORIES

91PJ056X Chain

h

220-240V/50Hz

8000/min

13.5 m/s

3/8”

5.084m/s2 K=1.5m/s

2

160SDEA041 Bar

Environmental Protection

Waste electrical products should not be disposed of with household waste.

Please recycle where facilities exist. Check with your Local Authority or retailer for

recycling advice.

AFTER SALES SUPPORT 0345 605 2070 27

Page 29

TROUBLESHOOTING

Never use tools with defective On/Off switches or defective Kickback brake(Hand

Guard).

In the case of all other types of technical faults, please contact helpline 0345 605 2070

or local service center.

Fault Possible Cause Solution

Tool will not start Lock button not pressed. Press the lock button.

"Front guard in the

brake position"

Blown fuse Replace fuse

Tripped RCD Check RCD

TMains loead not connected Check mains supply

Chain does not stop within

2 seconds when the tool is

switched off

"Bar/chain appear hot/

smoking"

Chainsaw does not cut well Chain on backwards "Check/modify chain

Chainsaw not using oil Debris in tank Empty oil from tank and

Chain tension is too slack Check chain tension

Oil tank empty Check oil tank level

Oil hole blocked on chain

bar

Chain tension is too tight Check chain tension

"Guide bar sprocket

nose needs greasing"

Oil hole in cap blocked "Remove debris from

Debris in chain bar "Remove debris and

Debris in oil outlet Remove debris

Reset front guard

Clean oil hole and clear the

groove around the edge of

the chainbar.

"Oil the guide bar

sprocket nose"

direction"

Sharpen

replace

hole"

clean the chain bar"

28 AFTER SALES SUPPORT 0345 605 2070

Page 30

WARRANTY

If your device develops a fault, please don’t hesitate to contact our customer service

department on 0345 605 2070, we can solve 80% of problems via the phone.

1. These warranty terms cover additional warranty rights and do not affect your statutory

warranty rights. All our products are covered by a 3 year manufacturer warranty.

2. Claims must be accompanied by proof of purchase. This must be in the form of a

sales receipt or bank statement and must show that the product has been purchased

within the warranty period as described under point 1, from the retailer that it was

originally bought from. Please keep your receipt safe or staple it to the back of this

manual for future reference.

3. Our warranty covers problems caused by material or manufacturing defects, and will

result in the repair of these defects or replacement of the device with a like for like or

similar article.

4. Our devices have not been designed for commercial, trade or industrial applications,

any signs of use of the equipment in these application or equivalent activities,

invalidates the warranty.

5. The following are also excluded from our warranty:

A. Faults due to accidents, customer misuse or unauthorized repairs

B. Consumable Parts such as chain, bar and other accessories that are compatible

with the product.

C. Failure due to lack of routine maintenance.

D. Failure as a result of not using the equipment in accordance with the manual and

safety instructions

Warranty claims should be submitted before the end of the warranty period, see point 1,

but a paid service exists for repairs commissioned after this period. The original warranty

period remains applicable to the device even if repairs are carried out or parts are

replaced. In such cases, the work performed or parts tted will not result in an extension

of the warranty period, and no new warranty will become active for the work performed

or parts tted.

If you have any problems or questions concerning your garden power tool, please

contact our after sales service at 0345 605 2070.

This device may be re-conditioned, like for like or upgraded replacement.

AFTER SALES SUPPORT 0345 605 2070 29

Page 31

Page 32

Page 33

Loading...

Loading...