S&P SWF-100, SWF-100X, SWF-150, SWF-150X, SWF-200 Installation Instructions Manual

SIDEWALL (SWF)

CENTRIFUGAL SIDEWALL FANS

VENTILADORES CENRIFUGOS DE MONTAJE EN PAREDES

VENTILATEUR DE PAROI CENTRIFUGE EN LIGNE

Models SWF-100, 100X, 150, 150X, 200

U

R

C U

L

S

INSTALLATION AND WIRING INSTRUCTIONS

INSTRUCCIONES DE MONTAJE

INSTRUCTIONS DE MONTAGE ET DE CÂBLAGE

(English / Español / Français)

READ AND SAVE THESE INSTRUCTIONS

LEER Y GUARDAR ESTAS INSTRUCCIONES

LIRE ET CONSERVER CES INSTRUCTIONS

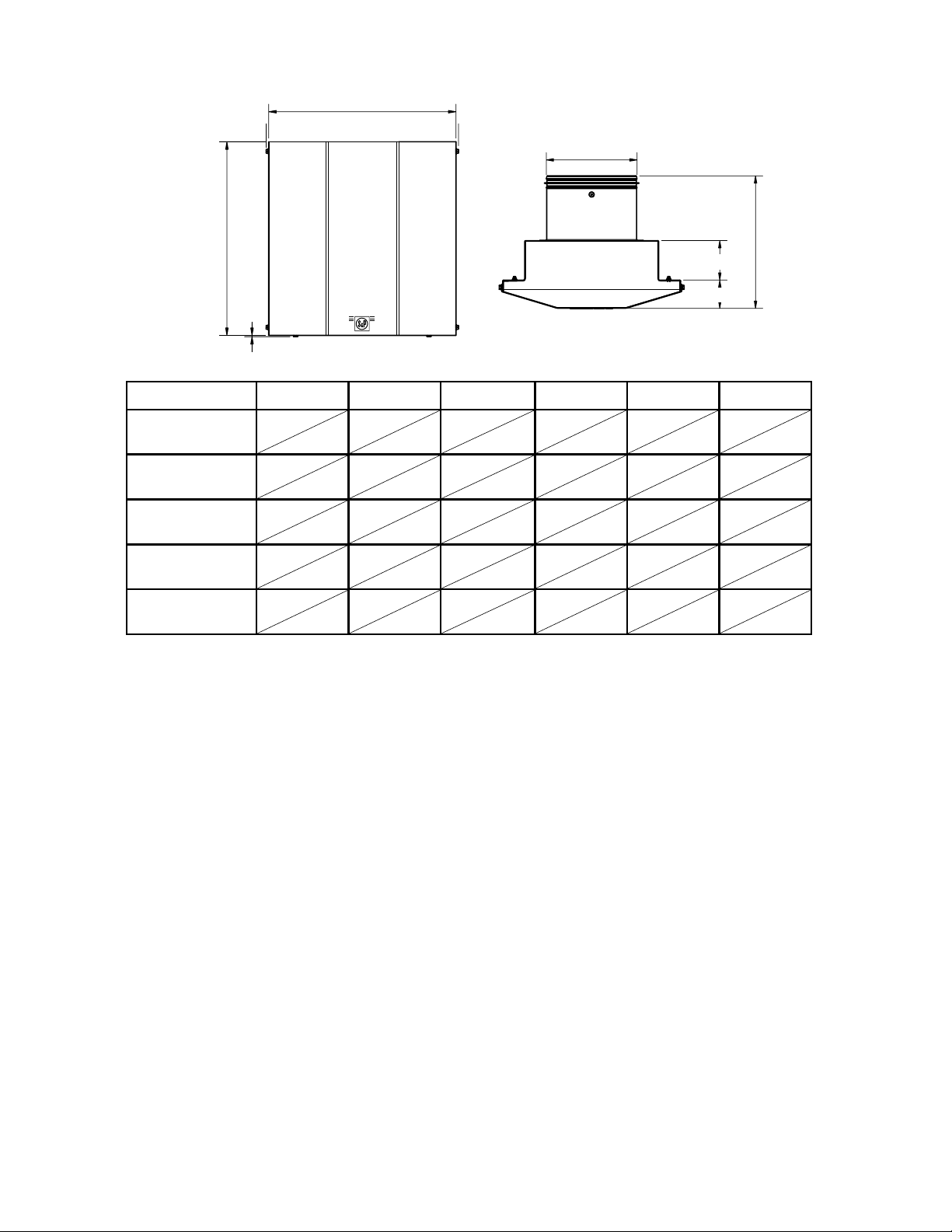

Dimensional Data

A

D

B

2 mm

C

C1

C2

Model A B C C1 C2 D

SWF-100

SWF-100x

SWF-150

SWF-150x

SWF-200

13 ¼

13 ¼

15 ½

15 ½

15 ½

337

337

394

394

394

13 ¼

13 ¼

13 ¼

16 1/16

16 1/16

337

337

337

408

408

9

9

10 3/16

10

11 7/16

228

228

256

254

290

3

3

3

3 3/16

3 3/8

76

76

76

81

87

2 7/16

2 7/16

2 7/16

2 7/16

2 7/16

62

62

62

62

62

4

100

4

100

6

150

6

150

8

200

WARNING

Soler and Palau designs the highest quality products available in the industry and meets stringent

manufacturing requirements. These units are not designed however to be utilized as the primary

devices used in a life support ventilation systems where failure could result in loss or injury, the user

should provide adequate backup ventilation, supplementary natural ventilation, failure alarm system, or acknowledge willingness to accept the risk of such loss or injury

ADVERTENCIA

Soler y Palau diseña productos de la más alta calidad en la industria, los cuales han sido fabricados

siguiendo las más rigurosas normas de producción. Sin embargo, estas unidades no son diseñadas

para ser utilizadas como dispositivos primarios que se emplean en un sistema de ventilación vital

donde una falla podría tener como resultado perdidas o lesiones. El usuario debe también adoptar

un sistema de ventilación de reserva; ventilación natural de suplemento o un sistema de alarma de

fallas, o reconocer que está dispuesto a asimilar el riesgo de tales pérdidas o lesiones

AVERTISSEMENT

Soler and Palau conçoit les produits de la plus haute qualité disponibles dans l’industrie et rencontre les exigences de fabrication rigoureuses. Toutefois, ces unités ne sont pas conçues pour être

utilisées comme dispositifs principaux dans les systèmes de ventilation critiques pour préserver la

vie et dont la défaillance pourrait entraîner une perte ou un préjudice ; l’usager doit assurer une

ventilation de secours adéquate, une ventilation naturelle supplémentaire, un système d’alarme de

protection contre les pannes, ou signier sa disposition d’accepter le risque de telle perte ou de tel

préjudice.

3

ENGLISH

Fan Installation

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY, OBSERVE THE

FOLLOWING:

(a) Use this unit only in the manner intended by the manufacturer. If you have any questions

contact the manufacturer.

(b) Before servicing or cleaning the unit, switch the power off at the service panel and lock the

service disconnecting means to prevent power from being switched on accidentally. When the

service disconnecting means cannot be locked; securely fasten a prominent warning device such

as a tag to the service panel.

(c) Installation work and electrical wiring must be done by qualied person(s) in accordance with

all applicable codes & standards including related construction.

(d) When cutting or drilling into wall or roof, do not damage electrical wiring and other hidden

utilities.

(e) CAUTION: For General Ventilating Use Only. Do Not Use To Exhaust Hazardous Or Explosive

Materials And Vapors.

(f) DO NOT USE with heated air in excess 140˚F (60˚C).

Select Fan Location

When selecting a location to install the SWF fan that has been chosen, take into consideration the

application of the product, the locations of fresh air intakes, and sound generated by the SWF unit.

The fan should be located a minimum of 6 feet horizontally and 8 feet vertically from any fresh air

intakes for HVAC systems, heat recovery systems, etc. to prevent exhaust air streams from being

re-introduced into the occupied space. Doors or windows that are frequently opened during pleasant seasons may also be considered fresh air intakes so keep this in mind when selecting the

location of the SWF.

Mark and Introduce Required Holes

Once the location on the exterior wall where the fan is to be mounted has been selected, mark

all screw and hole locations utilizing the included template. Cut the holes through the wall for the

duct connection and for the electrical conduit. Measure the thickness of the wall and the length of

the duct connection that is supplied on the SWF fan. Cut a length of duct so that once connected

to the fan, will extend 2” through the wall.

If mounting the fan on a masonry wall, drill four holes and insert wall anchors. If mounting to

wooden structure, you will utilize wood screws to secure the SWF to the wall.

If the fan is to be mounted on a wall surface which is not ush such as lapped siding, a mounting

plate to provide for a ush t needs to be made.

Mount the Fan

Insert electrical supply through the wall. Attach the duct extension to the SWF making sure that

the connection is secure. Apply a generous amount of exterior silicone caulk to backplate of

the fan to ensure an airtight/waterproof connection between the fan and the wall surface. If a

mounting frame is used in conjunction with lapped siding, be certain to apply a generous amount

of caulk between the frame and the wall as well as the fan backplate and the frame. Mount the fan

to the wall.

4

Note: Be certain to make an airtight seal around all interior wall penetrations before

attaching duct work.

Electrical Connection

All SWF series fans operate from a standard 120V 60Hz A.C electrical supply. All wiring must be

carried out in accordance with National Electrical Code, and all applicable state and local buildings

codes.

WIRING INSTRUCTIONS

WARNING! Make sure that power supply is disconnected and locked to prevent accidental

activation.

1. Remove the screws securing the terminal box cover plate located on the fan motor mounting

bracket. All fan motor and capacitor connections are pre-wired to the electrical terminal strip. A

3/8” romex type cable restraint connector will be needed to secure the wiring through the knockout

provided on the side of the terminal box.

2. Bring incoming electrical service through the romex connector and the fan electrical service

opening. Using a small regular screwdriver, tighten the neutral (white) wire of the incoming 115V

power supply under the open terminal strip port opposing the motor Blue wire. Tighten the line

(black) wire of the incoming supply under the open terminal opposing the motor Black wire. Now,

secure the source ground to the open terminal strip opposing the Green/Yellow Wire.

3. Secure the romex connector. Secure the incoming supply with the romex connector. Replace

the fan terminal box cover.

4. Apply a generous bead of silicone caulk around the electrical provision hole in the backplate of

the fan to provide for a secure seal.

MAINTENANCE INSTRUCTIONS

1. Since fan bearings are sealed and provided with an internal lubricating material, no additional

lubrication is necessary.

2. It is recommended that the cover is screen is checked on a regular basis to check for any obstructions and the cover is removed and the motor and wheel are inspected and cleaned as necessary.

No other maintenance is necessary.

5

Loading...

Loading...