S&P MD Installation, Operation And Maintenance Manual

INSTALLATION, OPERATION &

MAINTENANCE INSTRUCTIONS

MD DEHUMIDIFIERS

QA/IOM/46 Issue 11 - MD Dehumidifier

Contents: page

1. General description 3

1.1. General 5

1.2. Refrigeration system 5

1.3. Fan and ventilation system 6

1.4. Safety features 6

1.5. Performance 7

2. Preparation of dehumidifier from delivery 8

3. General operating instructions 9

3.1. Siting of the dehumidifier 9

3.2. Changing from pump to gravity condensate discharge 10

3.3. Fan only / dehumidifying (modes of operation) 10

3.4. Fan speed operation 11

4. Installation wiring 11

5. Control panel 15

6. Maintenance and fault finding 15

6.1. Maintenance 15

6.2. Faults 16

6.3. Technical support 17

7. Spares list 17

7.1. Electrical 17

7.2. Refrigeration/ mechanical 17

8. Contact Information 18

QA/IOM/46 Issue 11 - MD Dehumidifier

1. GENERAL DESCRIPTION

The dehumidifier is based around a closed refrigeration system comprising evaporator coil,

condenser coil, expansion valve and compressor. It uses heat pipes to increase the cooling

efficiency, allowing more moisture to be extracted, compared to conventional dehumidifiers. A fan is

used to draw air inthrough a filter and across the evaporatorand discharge it through the condenser.

Moisture is removed from the entering humid air at the evaporator coil and it is collected in a drain

pan mounted below the coil. The collected condensate is then removed by an integral condensate

pump.

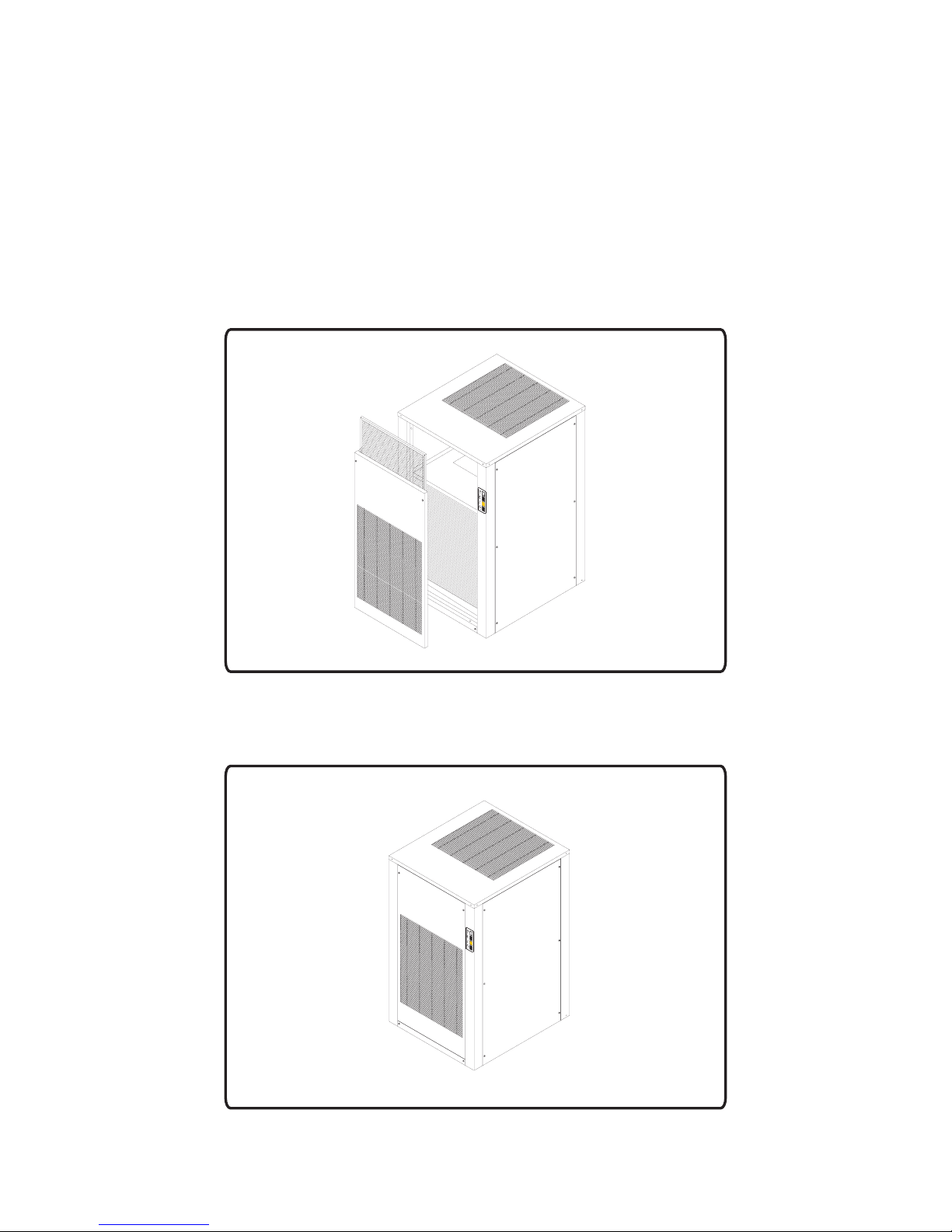

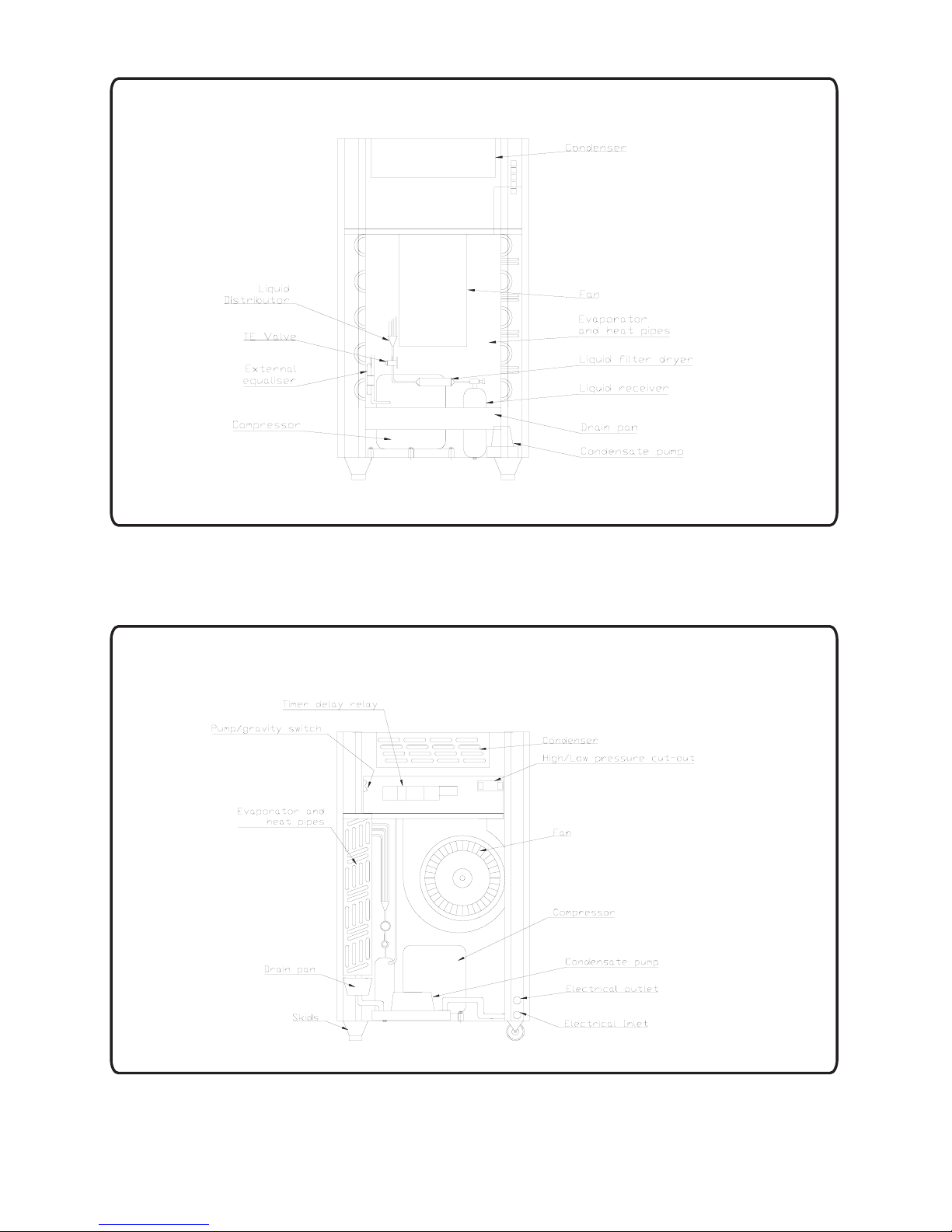

Figures 1. to 4. Showthe general layout of the dehumidifiers externallyand internally.

Figure 1. General layout of MD units with front grille removed

Figure 2. General layout of MD units

QA/IOM/46 Issue 11 - MD Dehumidifier

Page 3

Figure 3. Front view with front panel removed

QA/IOM/46 Issue 11 - MD Dehumidifier

Figure 4. Side view with side panel removed

Page 4

1.1. General

The dehumidifiers are mounted on 2 skids at the front and 2 fixed wheels at the back. These allow

secure siting of the units and make provision for local manoeuvring. All units are designed to allow

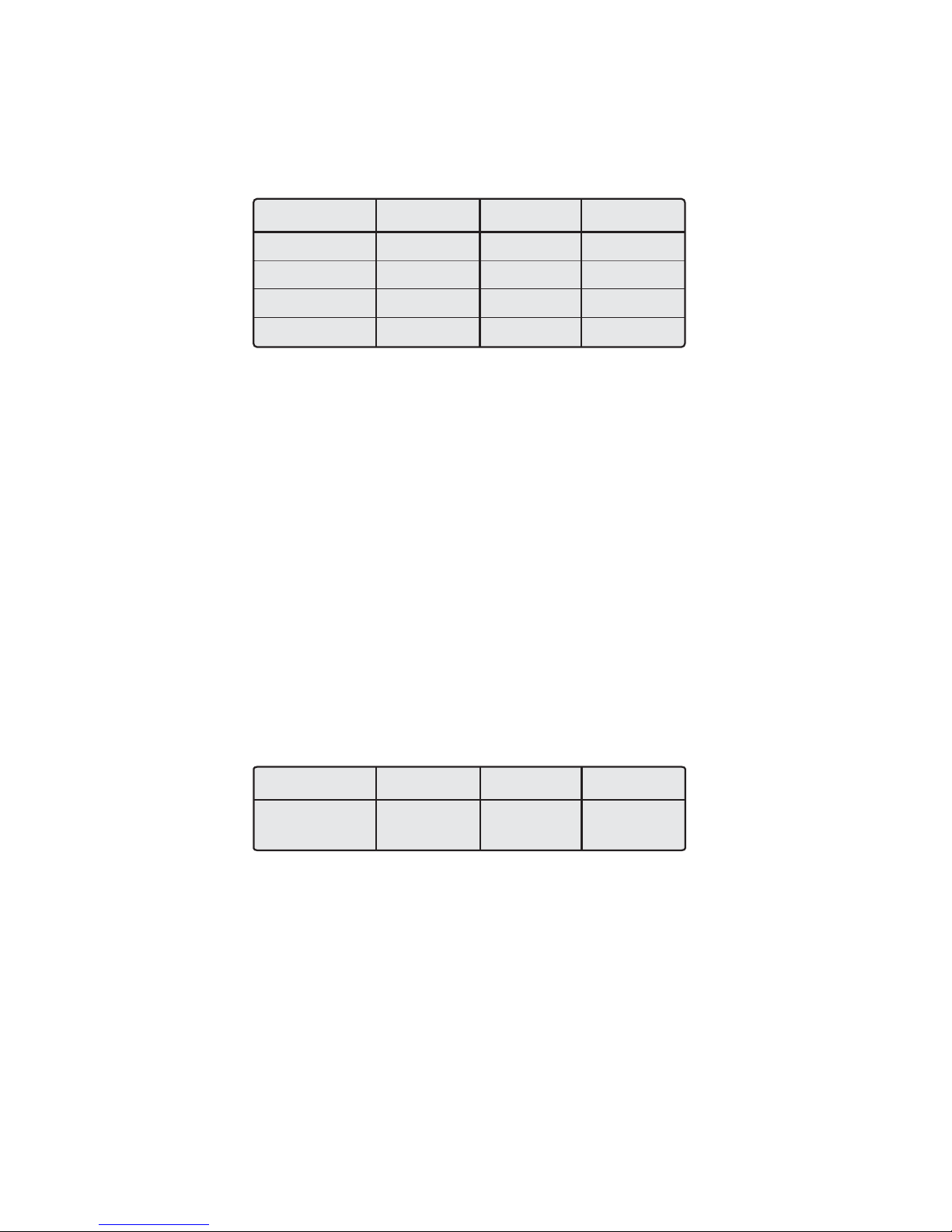

lifting by forklift. Dimension and weights are shown below:

Model

Width (mm)

Depth (mm)

Height (mm)

Weight (mm)

MD100

690

770

920

150

MD160

690

770

1234

169

MD200

690

770

1234

173

VoltageSupply 230V. 4% 50 Hz. Single Phase.

The supply current required byeach model is detailed in Section 4.

The unit is constructedaround 4 'pentapost' type pillars. The panels are screwed into the pillars via a

series of screws and captive nuts fitted inside the pillars. Removal of the side panel allows access to

the control void where the majority of the controls are located. These controls should not be altered

from their factory settings. The upper front panel carries the inlet grille and allows access to the air

filter. This panel sits on the lower front panel supported by studs and is removed by using the keys

provided to unlock the panel,and hinging forward.

The control panel allows switchingbetween different modes, see section 5.

1.2. Refrigeration system

Compressor type: Scroll

Compressor oil type : Mineral

Refrigerant type: R22

Model

Refrigerant

Charge (g)

MD100

1500

MD160

2000

MD200

2200

The evaporator with heat pipesis mounted vertically behind the front grille.

The condenser is mounted horizontallyat the top of the unit belowthe discharge grille.

To prevent the evaporator coil freezing below design range conditions, a low pressure cut-out is

included in the refrigeration system. This detects if the condensateis freezing on the evaporator and

stops the compressor. The coil is allowed to thawpassively before the compressor is restarted.

QA/IOM/46 Issue 11 - MD Dehumidifier

Page 5

1.3. Fan and ventilation system

All dehumidifiers use double inlet low-pressure centrifugal direct drive fans fitted with forward

curved impellers.

Restriction or adjustment of the air flow rate has a significant effect on the performance of the units.

Therefore, the inlet and exhaustmust never be obstructed or attempts made to duct theair to or from

the units.

The filters remove air borne dirt from the air and keep the evaporator clean and this should not be

removed, except for cleaning purposes, as indicated in section 6.1. The filters should not be

replaced by other filters withdifferentpressure drop characteristics.

To ensure that the air is drawn through the evaporator, great care has been taken to seal and

insulate all panels. To ensure proper operation the dehumidifier must never be operated with any of

the panels removed. Great careshould also be taken to avoid damageto the seals on the panels.

1.4. Safety features

Compressor on delay

To protect the compressor from hunting, a start delay has been built into the electrical start-up

circuit. It is important thatthis delay is adjusted as this may result in compressordamage.

not

Hi/low pressure cut outs

To protect the compressor from operating at temperatures too high or too low, pressure cut-outs

have been included in the refrigeration circuit. These are mounted in the control void behind the side

panel. Both pressure cut outs are automatically reset when the pressure has returned within the

design range.

The low pressure cut-out is set to prevent operation against conditions which would encourage the

freezing of the evaporator. The coil is allowed to thaw passively should any ice would have built up,

before the compressor is restarted.

High level condensate

If the level of the condensate in the pump drain pan becomes excessively high, the warning light on

the front panel lights up,Figure 10. If this occurs refer tosection 6.2.

QA/IOM/46 Issue 11 - MD Dehumidifier

Page 6

Loading...

Loading...