Page 1

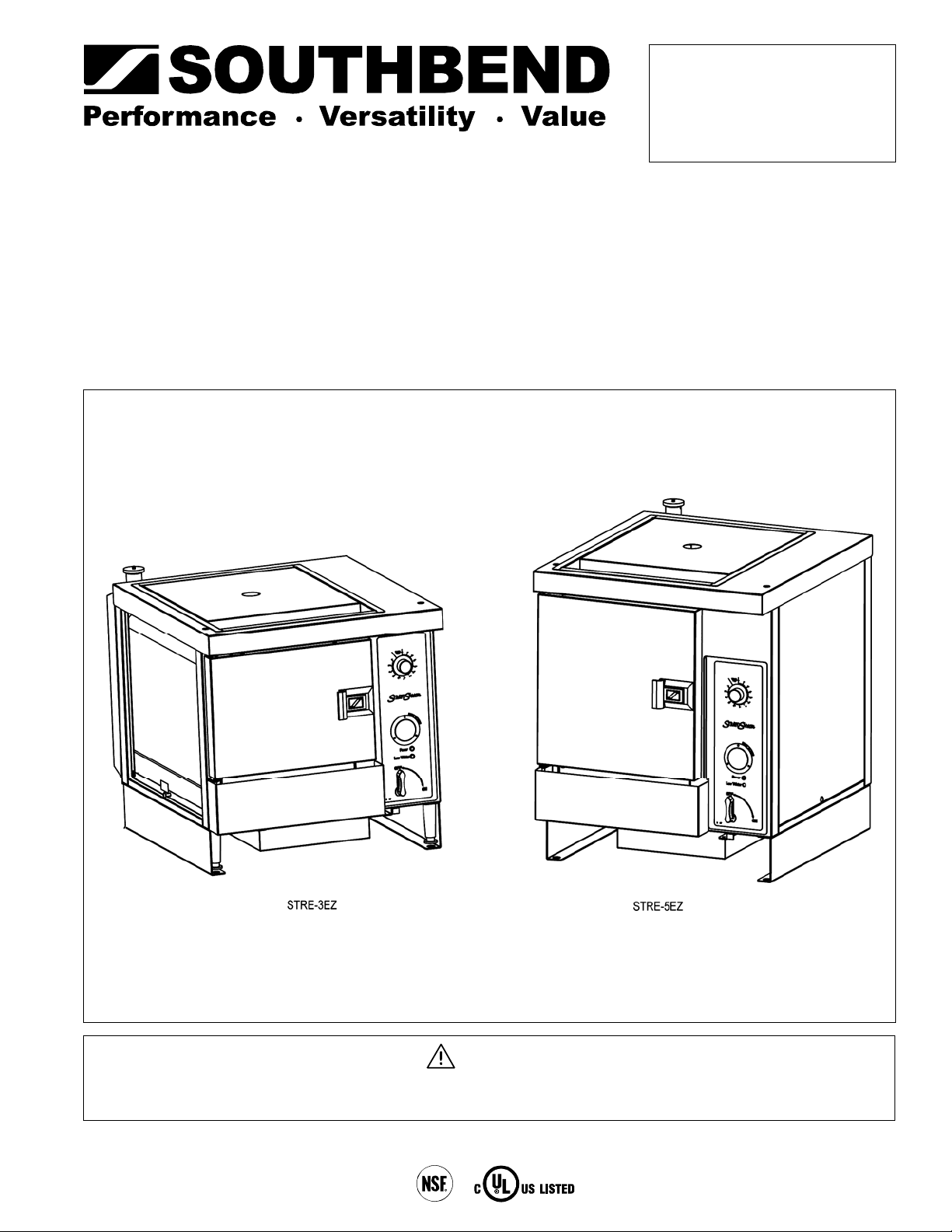

Owner’s Manual

Countertop Steamer

Models STRE-3EZ and STRE-5EZ

StratoSteam

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain

this manual for the life of the equipment:

Model #: __________________________

Serial #: __________________________

Date Purchased: ___________________

WARNING

Improper installation, adjustment, alteration, service, or maintenance can cause property damage, injury, or death.

Read installation, operation, and maintenance instructions thoroughly before installing or servicing this equipment.

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526 USA • www.southbendnc.com

MANUAL 1185184

$18.00

STRATOSTEAM COUNTERTOP STEAMER

MANUAL SECTION STRATOSTEAM

Page 2

SAFETY PRECAUTIONS STRATOSTEAM COUNTERTOP STEAMER

SAFETY PRECAUTIONS

Before installing and operating this equipment, be sure everyone involved in its operation is fully trained and aware of

precautions. Accidents and problems can be caused by failure to follow fundamental rules and precautions.

The following symbols, found throughout this manual, alert you to potentially dangerous conditions to the operator,

service personnel, or to the equipment.

DANGER

WARNING

CAUTION

NOTICE

This symbol warns of immediate hazards that will result in severe injury or death.

This symbol refers to a potential hazard or unsafe practice that could result in injury or

death.

This symbol refers to a potential hazard or unsafe practice that could result in injury,

product damage, or property damage.

This symbol refers to information that needs special attention or must be fully understood,

even though not dangerous.

WARNING

FIRE HAZARD

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of cooking appliances.

Keep area around cooking appliances free and clear of combustibles.

WARNING

BURN HAZARD

Contact with hot surfaces will cause severe burns. Always use caution when operating cooking appliances.

Stand back when opening the steamer door as hot steam or hot water may escape from the door opening.

Hot steam may escape from the pressure relief valve located at the top left rear corner of the steamer.

WARNING

ELECTRIC SHOCK HAZARD

Disconnect the power to the appliance before cleaning. Do not remove panels that require tools to remove.

NOTICE

Southbend appliances are intended for commercial use only. Not for household use.

Warranty will be void if service work is performed by other than a qualified technician, or if other than genuine

Southbend replacement parts are installed.

Give this Owner’s Manual and important papers to the proper authority to retain for future reference.

Copyright © 2004 by Southbend. All rights reserved. Published in the United States of America.

PAGE 2 OF 44 OWNER’S MANUAL 1185184

Page 3

STRATOSTEAM COUNTERTOP STEAMER INTRODUCTION

INTRODUCTION

Congratulations! You have purchased one of the finest pieces of heavy-duty commercial cooking equipment on the

market.

You will find that your new equipment, like all Southbend equipment, has been designed and manufactured to meet

the toughest standards in the industry. Each piece of Southbend equipment is carefully engineered and designs are

verified through laboratory tests and field installations. With proper care and field maintenance, you will experience

years of reliable, trouble-free operation. For best results, read this manual carefully.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

This manual is for Southbend StratoSteam Countertop Steamer models STRE-3EZ and STRE-5EZ. The manual is

divided into six sections:

Introduction ............................................ 3

Specifications ......................................... 4

Operation ............................................... 7

Cleaning & Maintenance ........................ 11

Installation .............................................. 13

Service ................................................... 18

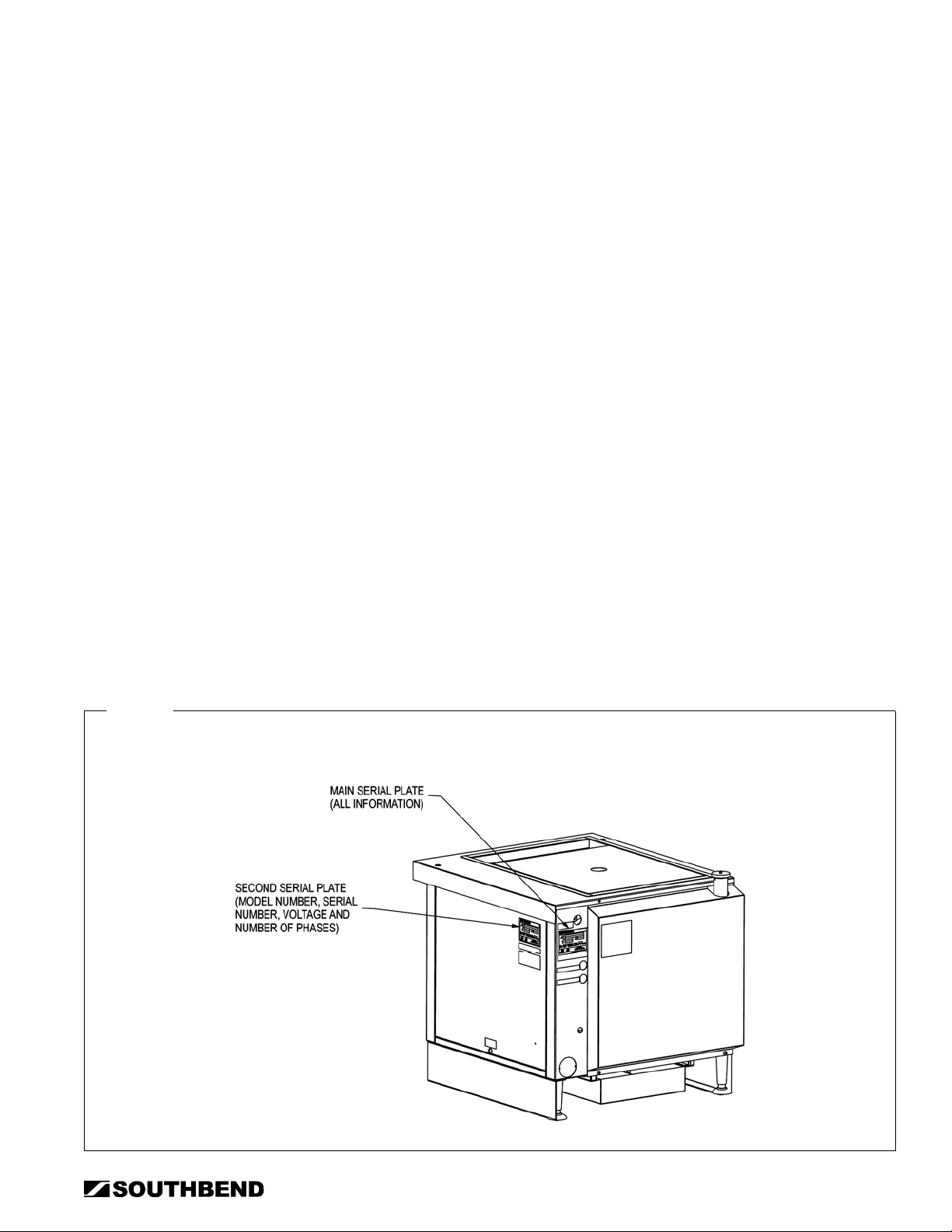

Each steamer has two serial plates located on the exterior of the steamer (see Figure 1 below).

Read these instructions carefully before attempting installation. Installation and initial startup should be performed by

a qualified installer. Unless the installation instructions for this product are followed by a qualified service technician (a

person experienced in and knowledgeable with the installation of commercial gas and/or electric cooking equipment)

then the terms and conditions on the Manufacturer’s Limited Warranty will be rendered void and no warranty of any

kind shall apply.

In the event you have questions concerning the installation, use, care, or service of the product, write to:

Southbend

1100 Old Honeycutt Road

Fuquay-Varina, North Carolina 27526 USA

Figure 1

Location of Serial Plates

OWNER’S MANUAL 1185184 PAGE 3 OF 44

Page 4

OPERATION STRATOSTEAM COUNTERTOP STEAMER

SPECIFICATIONS

NOTICE

Local codes regarding installation vary greatly from one area to another. The National Fire Protection Association,

Inc., states in its NFPA 96 latest edition that local codes are the “authority having jurisdiction” when it comes to

installation requirements for equipment. Therefore, installations should comply with all local codes.

The steamer, when installed, must be electrically grounded and comply with local codes, or in the absence of local

codes with the National Electrical Code ANSI/NFPA 70-latest edition.

Canadian installations must comply with CSA-Standard (C22.2 No. 109-M1981 General Requirements-Canadian

Electrical Code, Part II. 109-M1981) Commercial Cooking Appliances.

Southbend reserves the right to change specifications and product design without notice. Such revisions do not

entitle the buyer to corresponding changes, additions, or replacements for previously purchased equipment.

This product is intended for commercial use only, not for household use.

CLEARANCES

WARNING

MINIMUM CLEARANCES FROM COMBUSTIBLE CONSTRUCTION

Minimum clearance from combustible and non-combustible surfaces is 0" on the sides, bottom, and top; and 4" on

the rear. Adequate clearance must be provided in the aisle in front of the steamer to permit operation (including

pulling out of pans).

Steam may escape from the pressure relief valve at the top left rear corner of each steamer, and from the door

opening when the door is opened. Installation under a vented hood is recomme nded.

A steamer may be installed on combustible and non-combustible countertops.

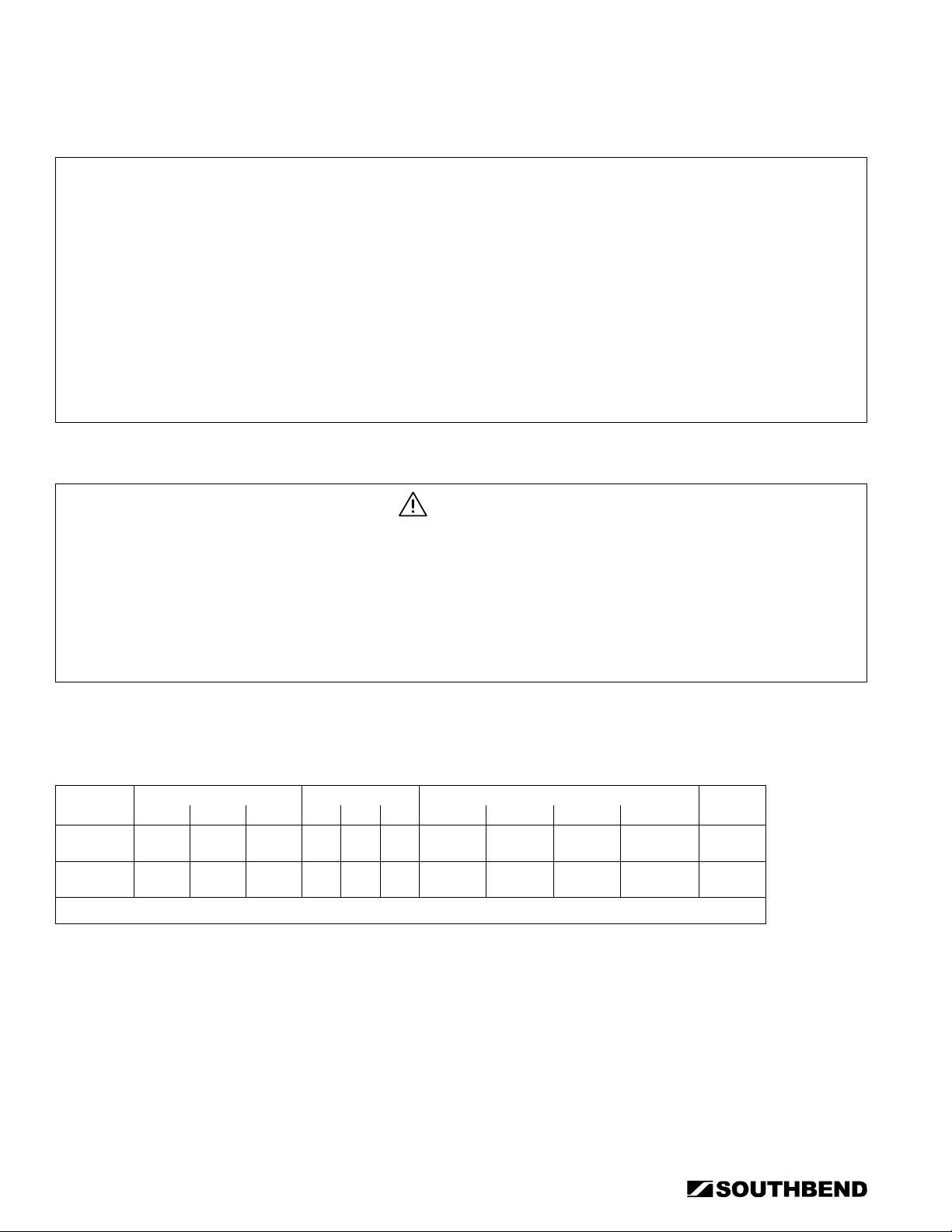

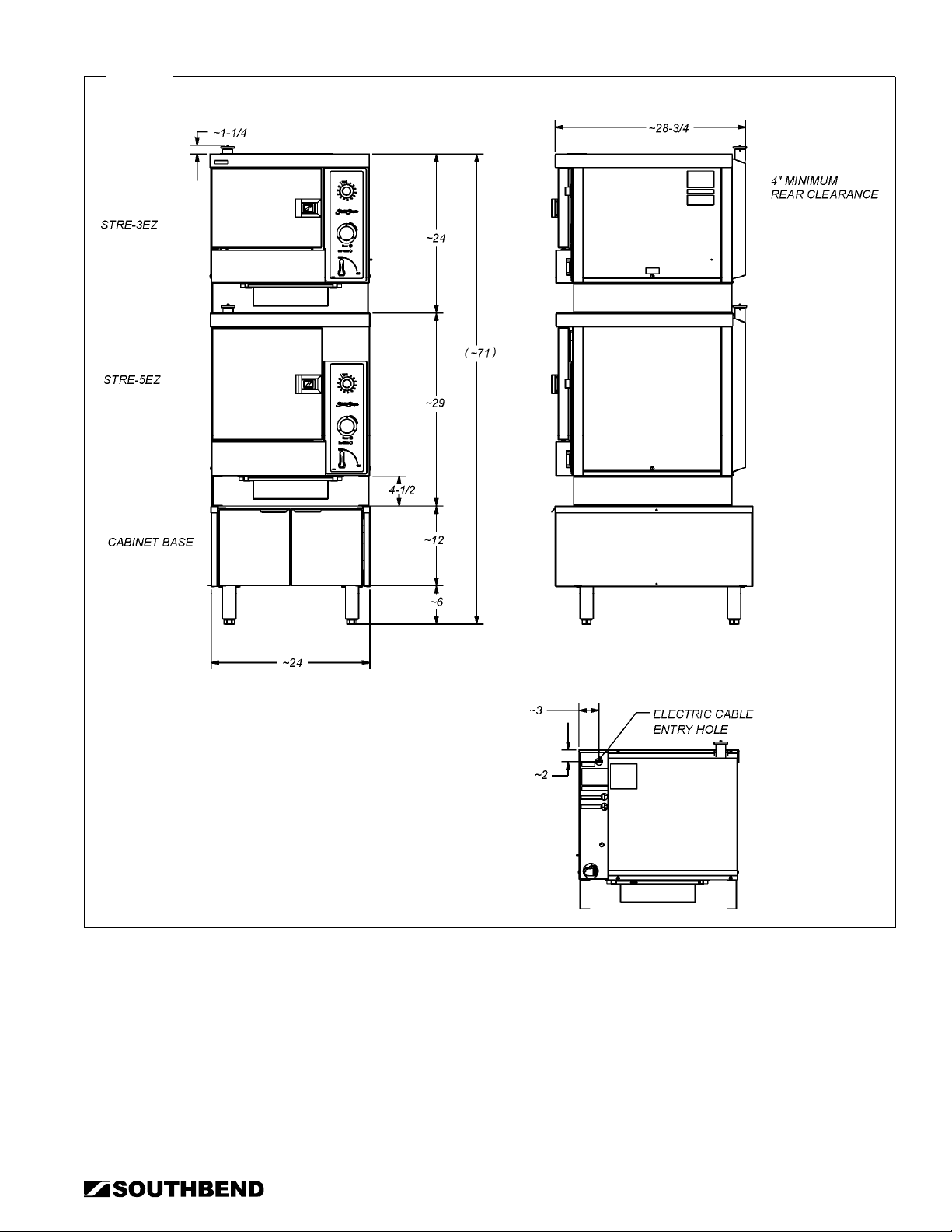

DIMENSIONS

The dimensions of the steamer are shown in Figure 2 on the next page. The following table lists the interior

dimensions and the crate dimensions and weight.

Model

STRE-3EZ

STRE-5EZ

* “Pan Capacity” is the number of 1", 2.5", or 4" high standard pans (12" wide x 20" front-to-back) that the steamer will hold.

Interior Dimensions Pan Capacity* Crate Dimensions

Width Depth Height 1" 2.5" 4" Width Depth Height Volume

13-1/2"

(343)

13-1/2"

(343)

24"

(610)

24"

(610)

10-5/8"

(270)

15-5/8"

(397)

6 3 2

11 5 3

52"

(1321)

52"

(1321)

43"

(1092)

43"

(1092)

40"

(1016)

40"

(1016)

51.8 cu. ft.

1.47 cu. m.

51.8 cu. ft.

1.47 cu. m.

Crated

Weight

216 lbs.

98 kg.

238 lbs.

108 kg.

PAGE 4 OF 44 OWNER’S MANUAL 1185184

Page 5

STRATOSTEAM COUNTERTOP STEAMER OPERATION

Figure 2

Dimensions

OWNER’S MANUAL 1185184 PAGE 5 OF 44

Page 6

OPERATION STRATOSTEAM COUNTERTOP STEAMER

ELECTRICAL REQUIREMENTS

One fused electrical connection is required to the contactor of each steamer. All steamers are shipped per customer

order, three phase or single phase. (A kit is available for field conversion to three phase or single phase.) The fused

connection must be wired for the required voltage and maximum amperage as listed in the chart below:

Total Connected Amps

Voltage

208 V 60 Hz 44 26 53 31

220 V 50/60 Hz 41 24 51 29

240 V 60 Hz 38 22 46 27

Model STRE-3EZ Model STRE-5EZ

1 Phase 3 Phase 1 Phase 3 Phase

WATER REQUIREMENTS

To meet warranty requirements, the water supply must be as follows:

Total Dissolved Solids (TDS) 60 PPM or less

Hardness 2 grains (35 PPM) or less

pH 7.0 to 7.5

Maximum Reservoir Capacity 3.0 gallons

Typical usage is 3.0 gallons in 4 hours.

In order to minimize service problems and to meet the warranty requirements, a water treatment system (softener) is

recommended when water quality does not meet the limits stated above.

DRAIN REQUIREMENTS

Water drains into a pan attached to the bottom of the steamer. Pan pulls out for periodic dumping.

PAGE 6 OF 44 OWNER’S MANUAL 1185184

Page 7

STRATOSTEAM COUNTERTOP STEAMER OPERATION

OPERATION

NOTICE: WATER SPECIFICATION

To meet warranty requirements, supply water must meet the following specification:

Total Dissolved Solids (TDS) ............ 60 PPM or less

Hardness ........................................... 2 Grains (35 PPM) or less

pH Factor .......................................... 7.0 to 7.5

STARTUP

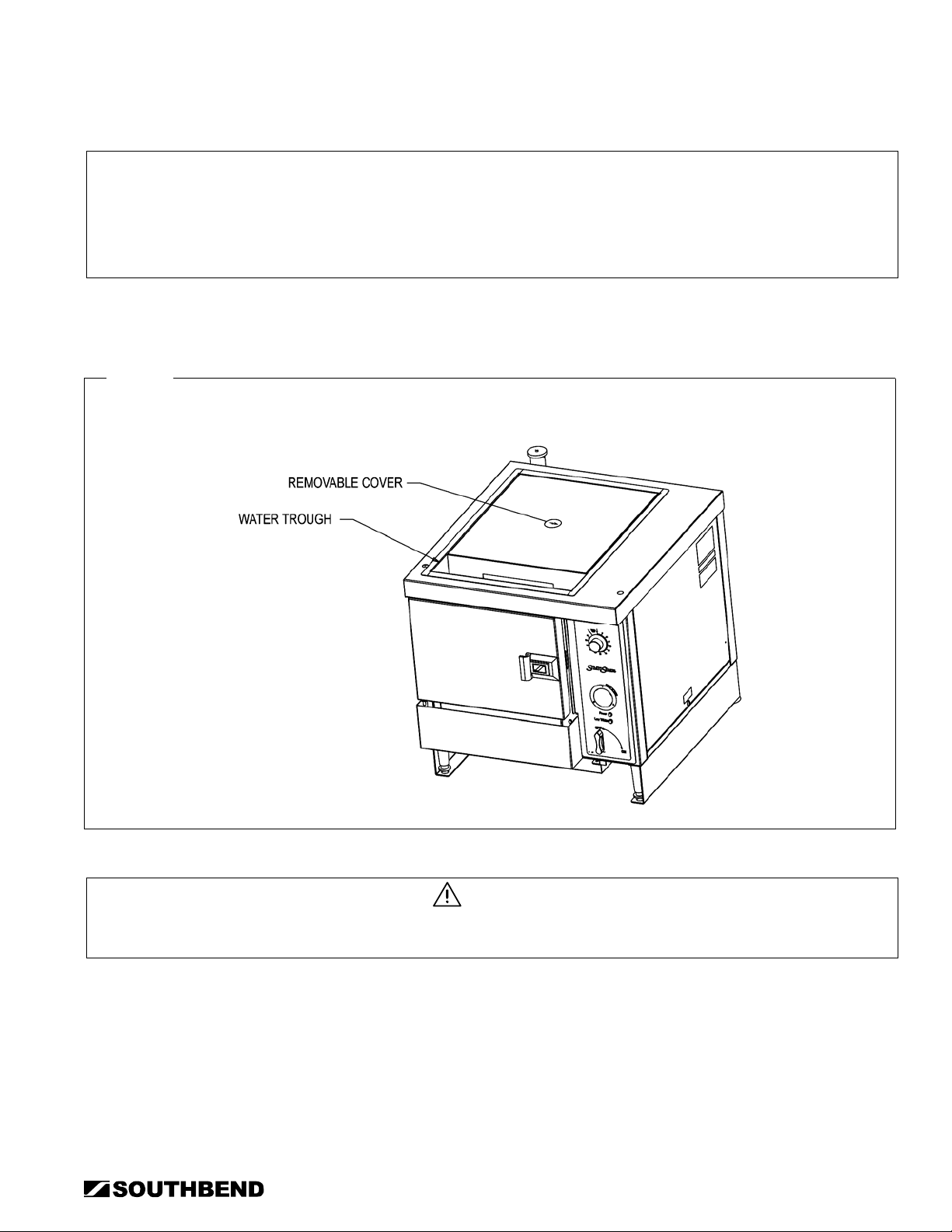

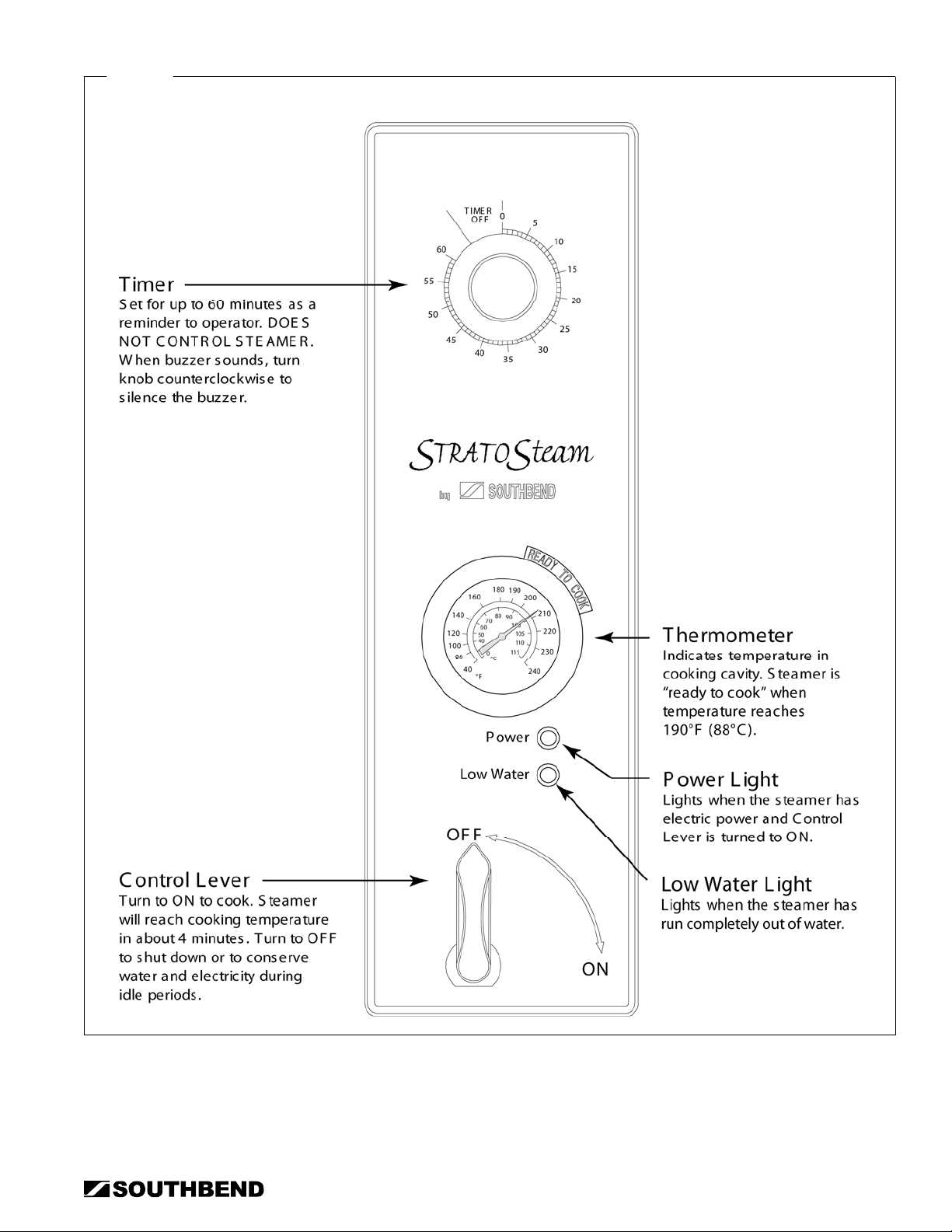

Fill steamer with 3.0 gallons of water through upper trough as shown in Figure 3. Turn control lever to “ON” position

(see Figure 4). The steamer will fill automatically and be ready for cooking in about four minutes.

Figure 3

Location of Water Trough

OPERATION

CAUTION

HOT STEAM WILL ESCAPE WHEN DOOR IS BEING OPENED. TO PREVENT BURNS KEEP HANDS AND

FACE AWAY FROM STEAM.

When turned ON, the steamer operates continuously. To save water and electricity, turn the control lever to OFF

when the steamer is not in use.

Suggested cooking times for various foods are shown in the table in the following section.

Pan specifications are shown on page 4.

The door may be opened or closed at any time. The steamer temporarily shuts off while the door is open.

Timer can be used as a reminder to the operator. The timer does NOT turn the steamer on or off!

When low water indicator light turns ON, fill steamer with water.

Periodically check drain pan for water accumulation, empty drain pan if necessary.

OWNER’S MANUAL 1185184 PAGE 7 OF 44

Page 8

OPERATION STRATOSTEAM COUNTERTOP STEAMER

SHUTDOWN

Turn lever to the “OFF” position. The water in the bottom of the cavity will automatically drain.

TROUBLESHOOTING BY OPERATOR

The following table lists the possible causes and solutions of problems that may occur during operation.

Problem Possible Causes and Solutions

Steamer does not heat up at all. – Electric power is shut off. Turn on power.

– Not enough water is in steamer. Add water.

– Lime build-up. De-lime steamer cavity (see page 11).

– If water is OK and there is little lime build-up, call repair service.

Steamer does heat up, but does not produce enough steam. – Door is open or ajar. Close steamer door completely.

– Lime build-up. De-lime steamer cavity (see page 11).

– Not enough water. Add water.

Steamer does not drain correctly. – Clogged drain on inside of steamer cavity. Check and clear.

– Clogged drain outside of steamer. Check and clear.

PAGE 8 OF 44 OWNER’S MANUAL 1185184

Page 9

STRATOSTEAM COUNTERTOP STEAMER OPERATION

Figure 4

Controls

COOKING TIPS

• Schedule cooking of fresh vegetables so that they will be served soon after they are cooked. If it is necessary to

prepare them in advance, they can be plunged into cold water, drained thoroughly and held under refrigeration

until needed for service. Five pounds of cold cooked vegetables can be reheated in the steamer in 5 to 10

minutes, depending upon the variety.

OWNER’S MANUAL 1185184 PAGE 9 OF 44

Page 10

OPERATION STRATOSTEAM COUNTERTOP STEAMER

• To avoid green yolk (which is a deposit of iron sulfide) chill the eggs immediately after removing from the

steamer by plunging them into a cold water bath (preferably containing ice).

• A quick and easy way to cook eggs for a salad mixture is to crack them directly into a solid steam table pan

which has been lightly coated with salad oil. Do not mix. Steam until they are hard cooked. Remove and chop as

you would for egg salad. The job of peeling is eliminated.

• Chicken, sausage, and/or fish may be browned in an infra-red or radiant broiler after steaming by brushing with

melted margarine mixed with salad oil to give a golden brown color.

• Save juices from steamed meat and poultry to make soups, sauces, or casserole dishes.

• Chicken may be steamed in advance and then refrigerated. Bring food back to 180°F before serving.

• Steaming brisket is a definite time saver. Boiling in water takes 40 to 50 minutes per pound. Using the steamer

can save 50% in cooking time.

• Steamed cabbage retains its color and wedge identity. It will not break apart as it does when boiled.

• When removing items prepared in a perforated pan, place a solid pan underneath the perforated pan with the

cooked food in order to prevent dripping on the floor.

• The steamer is designed to accept standard 12" x 20" pans. Fractional size pans and dishes can be used as

well with a perforated shelf.

• For stirring, the pan does not have to be removed from the steamer. Pull pan 1/3 way out of the cavity and the

entire surface is accessible.

• The door may be opened at any time during operation to remove or add food. While the door is open, the

steamer will stop producing steam.

SUGGESTED COOKING TIMES

These cooking times are for general guidance only. Differences in food quality, size, shape, thickness, freshness, load

size, and desired degree of doneness must be taken into consideration and adjustments made in time, if necessary.

Product Quantity

Eggs

Potatoes, Red

Rice

Shrimp, Frozen

Corn, Frozen

Peas, Frozen

Mixed Vegetables, Frozen

Salmon Filets, Frozen, 4.5 oz.

Salmon Filets, Frozen, 6 oz.

Lasagna, 6 lb., Frozen

Cake, White, 5 lb. Mix 1 pan 30 25

18 pieces (3 full pans)

30 pieces (5 full pans)

18

48

4 lbs.

8 lbs.

2 lbs.

3 lbs.

2.5 lbs.

8 lbs.

2.5 lbs.

7.5 lbs.

5 lbs.

12 lbs.

2.5 lbs.

8 lbs.

15 lbs. (3 full pans)

25 lbs. (5 full pans)

1 piece

8 pieces

8 pieces

1

3

5

STRE-3EZ Cooking

Time (minutes)

5

6

18

18

15

15

4.5

8

3

5

5.5

10

4

6.5

14

-

7

7

12

17

-

65

65

-

STRE-5EZ Cooking

Time (minutes)

6

7

18

18

16

17

4

7

2.5

4.5

4

8

3.25

5.5

-

17

7

7

10

-

15

60

-

60

PAGE 10 OF 44 OWNER’S MANUAL 1185184

Page 11

STRATOSTEAM COUNTERTOP STEAMER CLEANING & MAINTENANCE

CLEANING & MAINTENANCE

WARNING

Shut off the steamer before cleaning or performing maintenance.

Southbend appliances are sturdily constructed of the best materials and are designed to provide durable service when

treated with ordinary care. To expect the best performance, your equipment must be maintained in good condition and

cleaned daily. Naturally, the periods for this care and cleaning depend on the amount and degree of usage.

Following daily and periodic maintenance procedures will enhance long life for your equipment. Climatic conditions

(such as salt air) may require more thorough and frequent cleaning or the life of the equipment could be adversely

affected.

Keep exposed, cleanable areas clean at all times.

DAILY CLEANING AND MAINTENANCE

NOTICE

DO NOT USE high-chlorine or bleach solution for cleaning the door gasket.

DO NOT USE steel wool or other metallic pads in the steamer.

1. Turn control lever to “OFF” and allow time for the steamer to drain and cool.

2. Remove and clean pans.

3. Remove and clean pan supports and cavity bottom cover. Wash separately in a sink with a mild detergent and

warm water. Dry thoroughly with a clean cloth. Non-metallic scouring pads may be used to remove cooked-on

deposits.

4. Clean all interior surfaces with mild detergent, warm water, and a non-metallic pad. If discoloration of surfaces

starts due to buildup of seasonings or food products, remove them using a non-metallic scouring pad. RI NSE

THOROUGHLY WITH CLEAN WATER. Dry thoroughly with a clean cloth.

5. Ensure drain opening inside of cavity is clear.

6. Clean drain opening.

7. Place cleaned cavity bottom cover, pan supports, and pans back into their correct positions.

8. Leave the door open at night after cleaning to allow complete drying and to prolong the life of the door gasket.

PERIODIC DE-LIMING (AS NEEDED)

If lime or mineral deposits start to buildup on the cavity interior, they should be removed with a non-caustic de-liming

solution such as Lime-A-Way

®

. Follow the manufacturer’s instructions for use of the de-liming solution.

STAINLESS-STEEL SURFACES

To remove normal dirt, grease and product residue from stainless steel surfaces that operate at LOW temperature,

use ordinary soap and water (with or without detergent) applied with a sponge or cloth. Dry thoroughly with a clean

cloth.

To remove BAKED-ON grease and food splatter, or condensed vapors; apply cleanser to a damp cloth or sponge and

rub cleanser on the metal in the direction of the polishing lines on the metal. Rubbing cleanser, as gently as possible,

in the direction of the polished lines will not mar the finish of the stainless steel. NEVER RUB WITH A CIRCULAR

MOTION. Soil and burnt deposits which do not respond to the above procedure can usually be removed by rubbing

the surface with SCOTCH-BRITE scouring pads or STAINLESS scouring pads. DO NOT USE ORDINARY STEEL

WOOL as any particles left on the surface will rust and further spoil the appearance of the finish. NEVER USE A

WIRE BRUSH, STEEL SCOURING PADS (EXCEPT STAINLESS), SCRAPER, FILE OR OTHER STEEL TOOLS.

OWNER’S MANUAL 1185184 PAGE 11 OF 44

Page 12

CLEANING & MAINTENANCE STRATOSTEAM COUNTERTOP STEAMER

Surfaces which are marred collect dirt more rapidly and become more difficult to clean. Marring also increases the

possibility of corrosive attack. Refinishing may then be required.

“Heat tint” is darkened areas that sometimes appear on stainless steel surface s where the area has been subjected to

excessive heat. These darkened areas are caused by thickening of the protectiv e surface of the stainless steel and

are not harmful. Heat tint can normally be removed by the foregoing, but tint which does not respond to this procedure

calls for a vigorous scouring in the direction of the polish lines using SCOTCH-BRITE scouring pads or a STAINLESS

scouring pad in combination with a powered cleanser.

PAGE 12 OF 44 OWNER’S MANUAL 1185184

Page 13

STRATOSTEAM COUNTERTOP STEAMER INSTALLATION

INSTALLATION

CAUTION

Do not locate steamer adjacent to any high heat or grease producing piece of equipment, such as a range top,

griddle, fryer, etc., that could allow radiant heat to raise the exterior temperature of the steamer body above

130°F (54°C). DO NOT MOUNT ABOVE OTHER COOKING EQUIPMENT.

NOTICE

These installation procedures must be followed by qualified personnel or warranty will be void.

Local codes regarding installation vary greatly from one area to another. The National Fire Protection Association,

Inc., states in its NFPA 96 latest edition that local codes are the “authority having jurisdiction” when it comes to

installation requirements for equipment. Therefore, installations should comply with all local codes.

The steamer, when installed, must be electrically grounded and comply with local codes, or in the absence of local

codes with the National Electrical Code ANSI/NFPA 70-latest edition.

Canadian installations must comply with CSA-Standard (C22.2 No. 109-M1981 General Requirements-Canadian

Electrical Code, Part II. 109-M1981) Commercial Cooking Appliances.

NOTICE

EXHAUST FANS AND CANOPIES: It is recommended that the steamer be installed under a ventilation hood.

Consult local codes for proper installation of hoods. Proper ventilation is the owner’s responsibility. Any problem

due to improper ventilation will not be covered by warranty.

LEVELING: Steamer must be level for proper operation. Improper leveling may void the warranty.

STEP 1: UNPACKING

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has assumed

responsibility for its safe transit and delivery. If damaged equipment is received, either apparent or concealed, a

claim must be made with the delivering carrier.

Apparent damage or loss must be noted on the freight bill at the time of delivery. The freight bill must then be

signed by the carrier representative (Driver). If the bill is not signed, the carrier may refuse the claim. The carrier

can supply the necessary forms.

A request for inspection must be made to the carrier within 15 days if there is concealed damage or loss that is not

apparent until after the equipment is uncrated. The carrier should arrange an inspection. Be certain to hold all

contents plus all packing material.

Do the following:

1. Cut the banding straps and remove the corrugated cardboard surrounding the steamer. If legs were shipped in

the same container, set them aside for installation in later steps of this procedure. Do not remove any tags or

labels attached to the steamer until the steamer is installed and working properly.

2. If the steamer was shipped on a wooden skid, cut the banding strap holding the steamer to the wooden skid,

unbolt the shipping hold-down brackets from the skid, then remove the brackets from the steamer.

3. If the steamer is to be installed on legs, go to Step 2a.

If the steamer is to be mounted on the optional cabinet base, go to Step 2b.

If two steamers are to be stacked, go to Step 2c.

OWNER’S MANUAL 1185184 PAGE 13 OF 44

Page 14

INSTALLATION STRATOSTEAM COUNTERTOP STEAMER

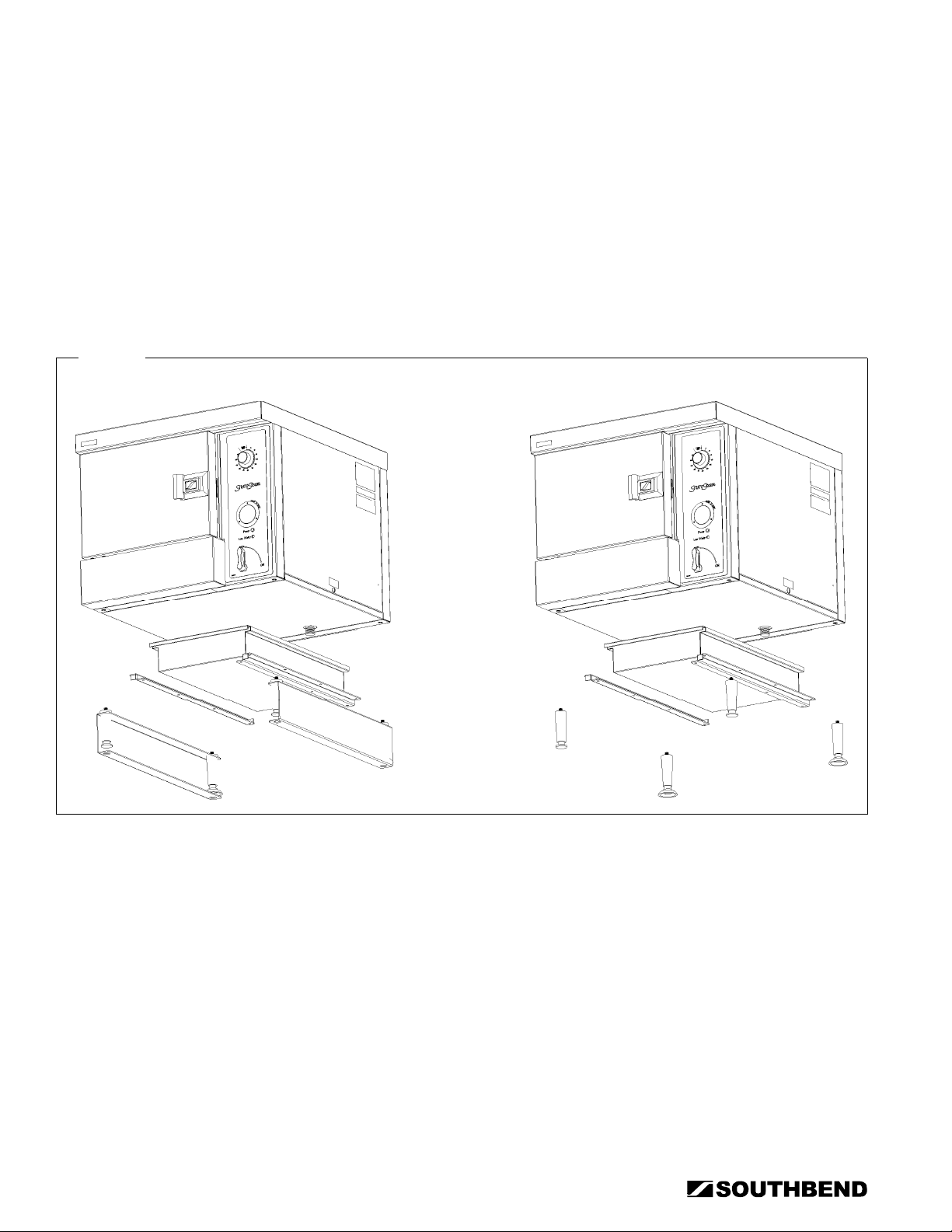

STEP 2A: ATTACH LEGS AND BRACKETS

A set of four legs is packed with steamers ordered with legs.

A threaded hole is located at each corner. Each leg has a corresponding mating thread. The legs can be adjusted to

overcome a slightly uneven surface.

1. Raise the steamer sufficiently to allow the legs to be attached. For safety, “shore up” and support the steamer

with an adequate blocking arrangement strong enoug h to support the load.

2. Screw the legs into the holes (see Figure 5). Note that the front legs are different than the rear legs.

3. Lower the steamer gently onto a level surface. Never drop or allow the steamer to fall.

4. Make sure that the steamer is level (both side-to-side and front-to-back). If necessary, adjust the height of each

leg by turning the foot-pad of the leg.

5. Go on to Installation Step 3.

Figure 5

Attach Legs and Brackets

STEP 2B: MOUNTING ON CABINET BASE

If the steamer is to be mounted on the optional cabinet base, first attached the legs to the cabinet base (if not already

attached). Then place the steamer on top of the cabinet base and line up the threaded holes on the bottom of the

steamer with the holes in the cabinet-base top. Secure the steamer to the base with four 3/8-16 bolts. Go on to

Installation Step 3.

STEP 2C: STACKING TWO STEAMERS

If two steamers are to be stacked, mount the lower steamer first on either legs (Step 2a) or the optional cabinet base

(Step 2b). Remove (if present) the four chrome-plated plugs from the holes in the top panel of the lower steamer.

Place the upper steamer on top of the lower steamer and line up the threaded holes on the bottom of the upper

steamer with the holes in the top of the lower steamer. Secure the upper steamer to the lower steamer with four 3/816 bolts. The remaining steps of the installation must be performed for both steamers (they do not share an y

connections internally).

PAGE 14 OF 44 OWNER’S MANUAL 1185184

Page 15

STRATOSTEAM COUNTERTOP STEAMER INSTALLATION

Figure 6

Location of Connections and Vents

STEP 3: WATER CONNECTION

NOTICE

To meet warranty requirements, the supply water must meet the following specifications:

Pressure 30 to 60 PSI (205 to 410 kPa)

Total Dissolved Solids (TDS) 60 PPM or less

Hardness 2 grains (35 PPM) or less

pH 7.0 to 7.5

STEP 4: ELECTRICAL CONNECTION

The electric connection is made to the contactor, which is located inside the service compartment on the right side of

the steamer. The right side panel must be removed to gain access to the contactor. A hole on the rear of each

steamer is provided for a 3/4" conduit fitting (solid or flex). An electric cable support bracket and clamp are located

inside of the service compartment, to the right and above the contactor (see Figure 7).

Be sure that the input voltage and number of phases matches the requirement stated on the serial plate. The steamer

is factory wired per customer order. A wiring diagram is attached to the inside of the right side panel of the steamer.

WARNING

A POSITIVE GROUND CONNECTION IS ESSENTIAL. DO NOT ALLOW ANY TAMPERING OR

ADJUSTMENT OF ANY CONTROL OR WIRING. THE STEAMER IS FACTORY SET. ADJUSTING ANY

INTERNAL COMPONENT CAN VOID THE WARRANTY.

THIS STEAMER REQUIRES A KIT TO BE FIELD CONVERTED FROM THREE-PHASE TO SINGLE-PHASE

OR VICE-VERSA. CONSULT FACTORY FOR PHASE CHANGES.

OWNER’S MANUAL 1185184 PAGE 15 OF 44

Page 16

INSTALLATION STRATOSTEAM COUNTERTOP STEAMER

For 3-wire 3-phase installations, connect wires L1, L2, and L3 to the three terminals on the upper end of the contactor.

For 2-wire 1-phase installations, connect wires L1 and L2 to the two outer terminals on the upper end of the contactor.

Make the electrical ground connection to the ground lug located at the top right-hand corner of the contactor bracket.

Figure 7

Electrical Connection

PAGE 16 OF 44 OWNER’S MANUAL 1185184

Page 17

STRATOSTEAM COUNTERTOP STEAMER INSTALLATION

STEP 5: CHECK THE INSTALLATION

Check the installation of each steamer, as follows:

1. Check that all screws and bolts are tightened.

2. Check that the electrical connection has been made correctly.

3. Check that the steamer is level. If not, adjust the legs (or level the countertop surface).

4. Check that the appropriate minimum clearances are satisfied (see page 4).

5. Check the door for proper alignment, and that it opens and closes properly.

6. Check that there is sufficient clearance in front of the steamer to open the door and to pull out the pans.

7. Wipe clean all surfaces.

STEP 6: CHECK STEAMER OPERATION

Check the operation of each steamer, as follows:

1. Fill tank with water.

2. Turn on the electric power supply.

3. Move the ON/OFF lever to the “ON” position and check that the Power light comes on.

4. Check that the timer and buzzer operate correctly.

5. Open the door and check that water is entering the cavity (NOTE: The fill rate is slow).

6. Wait four minutes, then check that some water has covered the bottom of the cavity.

7. Depress the door-switch actuator rod and listen for an audible “click.” Release the door-switch actuator rod

and listen for another audible “click.” (The clicks indicate that the contactor is functioning properly.)

8. Check that steam is escaping from the vent at the top left rear corner of the steamer.

9. Move the ON/OFF lever to the “OFF” position and check that the Power light goes out. Also check that the

water is draining correctly into the drain, and that the steamer completely drains.

STEP 7: SHUT-DOWN AND WIPE-CLEAN STEAMER

Complete the installation by leaving the steamer ready for customer use:

1. Allow the steamer to cool.

2. Wipe clean all surfaces.

3. Unless the steamer is to be placed in service immediately, turn off the electric power supply.

4. Make sure that a copy of this manual will be available to the people who will operate and maintain the

steamer.

OWNER’S MANUAL 1185184 PAGE 17 OF 44

Page 18

SERVICE STRATOSTEAM COUNTERTOP STEAMER

SERVICE

WARNING

ADJUSTMENTS AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUALIFIED TECHNICIAN WHO IS

EXPERIENCED IN, AND KNOWLEDGEABLE WITH, THE OPERATION OF COMMERCIAL COOKING

EQUIPMENT. TO ASSURE YOUR CONFIDENCE, CONTACT YOUR AUTHORIZED SERVICE AGENCY FOR

RELIABLE SERVICE, DEPENDABLE ADVICE OR OTHER ASSISTANCE, AND FOR GENUINE FACTORY

PARTS.

NOTICE

INSTALLATION OF OTHER THAN GENUINE SOUTHBEND PARTS WILL VOID THE WARRANTY ON THIS

EQUIPMENT.

A serial plate is located on the right side of the steamer, near the top right corner. A second serial plate is located on

the rear of the steamer near the top left corner (see Figure 1).

Replacement parts (including parts not listed in this manual) may be ordered either through a Southbend Authorized

Parts Distributor or a Southbend Authorized Service Agency.

When ordering parts, please supply the Model Number, Serial Number, Part Number, and Part Description.

This section contains troubleshooting flowcharts, procedures, and electric schematics to assist a qualified service

technician in the servicing of a StratoSteam countertop steamer.

A description of how the steamer operates appears on the next page.

To remove a side panel (for access to the interior), remove the securing screw near the center of the bottom edge of

the panel. To remove the top panel, remove the two securing screws on the rear face, then slide the top panel forward

and off.

The door is field-reversible (contact Southbend for instructions).

TROUBLESHOOTING FLOWCHARTS, PROCEDURES, AND WIRING DIAGRAMS

Find the symptom below that corresponds to the malfunction, then turn to the corresponding page. Follow the

flowchart on that page until the problem is solved.

Troubleshooting Flowchart, Procedure, or Wiring Diagram Page

Troubleshooting Flowchart: Steamer Not Heating Up, “Power” Light Is Not Lit 21

Troubleshooting Flowchart: Steamer Not Heating Up Properly or Not Cooking Properly, “Power” Light is Lit 22

Troubleshooting Flowchart: Buzzer Does Not Come On When Timer Runs Out 23

Troubleshooting Procedure: Heating Cartridge Check (at Contactor) 24

Troubleshooting Procedure: Power Switch Check 25

Troubleshooting Procedure: Contactor Check 26

Troubleshooting Procedure: Timer and Buzzer Check 27

Troubleshooting Procedure: Door Switch Check 28

Troubleshooting Procedure: High Limit Thermostats Check 29

Troubleshooting Procedure: Water-Level-Control Sensor Check 30

Troubleshooting Procedure: Water Solenoid Check 31

Wiring Diagram for 208/220/240 Volt Models 32

PAGE 18 OF 44 OWNER’S MANUAL 1185184

Page 19

STRATOSTEAM COUNTERTOP STEAMER SERVICE

HOW THE STEAMER OPERATES

The steamer is a manual fill, “connectionless” steamer. The internal components of the steamer are shown in

Figure 8.

The only utility required for operation is electrical power. The unit is available in 208, 220, and 240V single or

three phase.

To fill the unit approximately 3.0 gallons of water should be poured into the trough just above the door. Water can also

be poured directly into the cavity, if desired.

Water poured into the upper trough will fill the reservoir tank at the top of the steamer. This water is gravity fed

through a solenoid valve that is controlled by a time delay relay that is controlled by a capacitive discharge water level

sensor on the side of the tank. As the water level in the interior of the steamer drops below the midpoint of the sensor

the level switch will close. After 30 seconds of continuous close the time delay relay will trip closing the circuit to the

water solenoid. The water solenoid will be energized opening the valve to allow water to flow from the tank into the

cavity. Water will continue to fill the cavity until the water level sensor has opened and remained open for 30 seconds.

A pressure switch is located on the right side toward the rear of the control compartment. The high pressure side of

the switch is open to the interior of the cavity, the low pressure side is open to atmosphere. When the cavity pressure

rises, because the product is absorbing energy from the steam the interior pressure will rise. When the interio r

pressure reaches approximately 3″ W.C. the switch shuts off power to the contactor coil, which shuts off power to the

heating elements. This is intended to reduce consumption of water. When the reservoir is full (3.0 gallons) the

steamer will operate for 4 hours in an empty cavity.

Any excess steam is vented out the pressure-relief valve located at the top left rear corner of the steamer. The dial

thermometer on the control panel is connected by a capillary tube to the sensor bulb located in the pre ssure-relief

vent. The thermometer does not affect the operation of the steamer.

A mechanical timer activates when the timer times out. The timer does not affect anything else! When the control

valve is turned to OFF, power to the electronic circuitry is turned off, which de-energizes the contactor and shuts off

the heating cartridges. Turning the control lever to OFF also de-energizes the water solenoid (turning off the water)

and mechanically opens the drain valve, permitting all water to drain from the bottom of the cooking cavity into the

drain pan.

OWNER’S MANUAL 1185184 PAGE 19 OF 44

Page 20

SERVICE STRATOSTEAM COUNTERTOP STEAMER

Figure 8

How the Steamer Operates

PAGE 20 OF 44 OWNER’S MANUAL 1185184

Page 21

STRATOSTEAM COUNTERTOP STEAMER SERVICE

Figure 9

Steamer Not Heating Up, “Power” Light Is Not Lit

Steamer not heating up, “Power” light not lit.

DISCONNECT POWER AT CIRCUIT BREAKER

Remove right side panel for access.

Reconnect power at circuit breaker.

Turn lever to “ON” position and close door (to actuate door switch).

Check voltage between terminals L1 and L3 on contactor

No Yes

DISCONNECT POWER AT CIRCUIT BREAKER

Check resistance between heating-cartridge contactor terminals

as described on page 24.

(see page 26).

Is measured

voltage 208, 220, or 240

volts?

Test operation of power switch (see page 25). Replace if

necessary. If power switch is OK, replace “Power” light and follow

procedure on page 22.

No Yes

Disconnect all the heating

cartridges from the contactor.

Measure the resistance across

the leads each cartridge.

Replace any cartridge that

shows either an open or short

circuit.

Is measured resistance

in the range specified on

page 24?

Cartridges are OK

OWNER’S MANUAL 1185184 PAGE 21 OF 44

Page 22

SERVICE STRATOSTEAM COUNTERTOP STEAMER

que)

Figure 10

Steamer Not Heating Up Properly or Not Cooking Properly, “Power” Light is Lit

Steamer not heating properly or not cooking properly,

Turn off steamer and check that it drains completely. If steamer

does not drain, check drain path for obstructions. Fill steamer

reservoir. Turn steamer back on and wait 10 minutes.

No Yes

DISCONNECT POWER AT CIRCUIT BREAKER

Check door switch (see page 28).

No Yes

Replace door switch.

Reconnect door switch lead wires.

Check water solenoid (see page 31).

Door switch OK?

“Power” light is lit.

Is water level at

normal level in cavity?

No

Replace high-limit

thermostats as necessary.

Check resistance between heating-cartridge contactor terminals

and replace heating cartridges as necessary (see page 24).

DISCONNECT POWER AT CIRCUIT BREAKER

Check high-limit thermostats (see page 29).

High-limit thermostats OK?

Yes

No Yes

Replace water solenoid.

Water solenoid OK?

Check for loose or broken

wires (see wiring diagram).

If wiring is OK, remove screen

from strainer and clean or

replace as necessary.

Reassemble, reconnect, and

recheck the steamer. If water

still does not enter the

steamer, examine the water

solenoid and inline Y strainer

for obstructions or deposits.

Clean or replace as

necessary.

Check water-level control sensor (see page 30).

No

Replace water-level

control sensor.

No Yes

Replace contactor.

Water-level control

sensor OK?

Check contactor (see page 26).

Contactor OK?

Check for loose or broken

wires (see wiring diagram).

If wiring is OK, check that

heating cartridges are secure

(tighten to 75 inch-pounds of

tor

.

Yes

PAGE 22 OF 44 OWNER’S MANUAL 1185184

Page 23

STRATOSTEAM COUNTERTOP STEAMER SERVICE

Figure 11

Buzzer Does Not Come On When Timer Runs Out

Buzzer does not come on when timer runs out.

DISCONNECT POWER AT CIRCUIT BREAKER

Remove right side panel for access.

Set timer for 5 minutes.

No Yes

Replace timer.

Does timer time down?

Disconnect buzzer lead wires from the timer.

Check the timer (see page 27).

No Yes

Replace timer. Replace buzzer.

Timer OK?

OWNER’S MANUAL 1185184 PAGE 23 OF 44

Page 24

SERVICE STRATOSTEAM COUNTERTOP STEAMER

Figure 12

Heating Cartridge Check (at Contactor)

Ohms

L1

L2

L3

Top of

Steamer

A

B

C

1. DISCONNECT POWER AT CIRCUIT BREAKER.

2. Turn Control Lever to OFF.

3. Remove right side panel of steamer.

4. DO NOT DISCONNECT HEATING-CARTRIDGE LEAD WIRES FOR THIS TEST.

5. Using a multimeter, check the resistance across contactor terminals as specified in the following table:

Allowable Resistance (Ohms) Allowable Resistance (Ohms)

Three-Phase Single-Phase Three-Phase Single-Phase

A-B and B-C A-C A-C A-B and B-C A-C A-C

208 10 to 12 14 to 16 5 to 6 8 to 10 11 to 13 4 to 5

220 12 to 13 15 to 18 6 to 7 9 to 11 13 to 15 5 to 6

240 14 to 16 18 to 21 7 to 9 11 to 13 15 to 17 6 to 7

Serial-

Plate

Voltage

Model STRE-3EZ Model STRE-5EZ

6. If the measured resistance at the contactor is not in the specified range, disconnect all the heating cartridges

from the contactor. Measure the resistance across the leads each cartridge. Replace any cart ridge that

shows either an open or short circuit.

PAGE 24 OF 44 OWNER’S MANUAL 1185184

Page 25

STRATOSTEAM COUNTERTOP STEAMER SERVICE

Figure 13

Power Switch Check

Connector

PL1

(socket half)

14

25

36

L1 L2 L3

Contactor

Continuity

Connector

PL1

(socket half)

14

25

36

Continuity

L1 L2 L3

Connector

PL1

(socket half)

14

25

36

No Continuity

Test-Lead Positions

for Steps 5 to 7

Test-Lead Positions

for Step 8

Test-Lead Positions

for Step 9

1. DISCONNECT POWER AT CIRCUIT BREAKER.

2. Remove right side panel.

3. Turn control lever from OFF to ON and then from ON to OFF while looking to see that the power switch is

properly actuating when the lever moves.

4. Disconnect the connector (PL1) that connects the control-panel component wires to the wiring harness.

5. As shown above, place one test lead on terminal L1 of the contactor and the other test lead in position 1 of

connector PL1 (the socket half, which is wired to the control panel).

6. Check for continuity with control lever in OFF position (there should not be continuity).

7. Check for continuity with control lever in ON position (there should be continuity).

8. Repeat steps 5 through 7 with one test lead on terminal L3 of the contactor and the other test lead in position

2 of connector PL1 (as shown above).

9. Place one test lead on PL1 position 1 and the other test lead on PL1 position 2 (as shown above). Check for

continuity with control lever in the ON position (there should not be continuity).

10. If continuity checks are incorrect, replace power switch.

11. Reconnect lead wires.

OWNER’S MANUAL 1185184 PAGE 25 OF 44

Page 26

SERVICE STRATOSTEAM COUNTERTOP STEAMER

Figure 14

Contactor Check

Top of

Steamer

No Continuity

L1

L2

Actuator

Button

L3

Ohms

A

B

C

View Looking Down

Behind Contactor

1. DISCONNECT POWER AT CIRCUIT BREAKER.

2. Remove right side panel.

3. Depress actuator on top of contactor. Actuator should travel freely and spring back when released.

4. Check for continuity between contacts L1 and A as shown above. There should be no continuity.

5. Repeat Step 4 for contacts L2 and B and for contacts L3 and C.

6. Remove wires B3 and B9 from contactor coil.

7. Place test leads on contactor coil terminals as shown in “View Looking Down” shown above and check

resistance

8. If resistance is not in the range 350 to 425 Ω, replace contactor.

9. Reconnect all wires.

PAGE 26 OF 44 OWNER’S MANUAL 1185184

Page 27

STRATOSTEAM COUNTERTOP STEAMER SERVICE

Figure 15

Timer and Buzzer Check

Continuity

1

3

Timer

Ohms

Buzzer

Inside of Control Panel

1. DISCONNECT POWER AT CIRCUIT BREAKER.

2. Remove right side panel.

3. Set timer for one minute and allow to time out. If timer does not run, then replace timer.

4. Disconnect from the timer the wire that leads to the buzzer.

5. Disconnect connector PL1 to separate the other buzzer lead wire from the wiring harness.

6. Place test leads between positions 1 and 3 on the timer (as shown above).

7. Check for continuity when the timer has run down (so the buzzer should be on). If no continuity, replace timer.

8. Disconnect other lead wire from buzzer. Place test leads in terminals of buzzer lead wires (as shown above).

9. Check that resistance is approximately 3400 Ω. If it is not, replace the buzzer.

10. Reconnect wires.

OWNER’S MANUAL 1185184 PAGE 27 OF 44

Page 28

SERVICE STRATOSTEAM COUNTERTOP STEAMER

Figure 16

Door Switch Check

1. DISCONNECT POWER AT CIRCUIT BREAKER.

2. Remove right side panel.

3. Open and close the steamer’s door while looking to see that the door switch actuator rod actuates the door

switch when the rod moves.

4. Disconnect the wiring harness from the switch terminals at the two places shown above (where the test-probe

tips are located).

5. Place the test probes on the switch terminals (as shown above).

6. Check for continuity with the door open (there should NOT be continuity).

7. Check for continuity when the door is closed (there should be continuity).

8. If the continuity checks are not correct, replace the door switch.

9. Reconnect the wiring harness to the switch terminals.

PAGE 28 OF 44 OWNER’S MANUAL 1185184

Page 29

STRATOSTEAM COUNTERTOP STEAMER SERVICE

Figure 17

High-Limit Thermostats Check

1. Allow cavity bottom to cool before performing this test.

2. DISCONNECT POWER AT CIRCUIT BREAKER.

3. Remove left side panel.

4. Disconnect wire B4 from left side of high-limit thermostat.

5. Disconnect wire B5 from right side of high-limit thermostat.

6. Disconnect remaining high-limit thermostat wires B11 and B12.

7. Test each high-limit thermostat for continuity (as shown above). There should be continuity when the

thermostat is cool. Replace as necessary.

8. Reconnect wires.

OWNER’S MANUAL 1185184 PAGE 29 OF 44

Page 30

SERVICE STRATOSTEAM COUNTERTOP STEAMER

Figure 18

Water-Level-Control Sensor Check

1. DISCONNECT POWER AT CIRCUIT BREAKER.

2. Remove the left and right side panels.

3. Remove bottom panel (four screws).

4. Remove insulation cover panel (four nuts).

5. Locate the water-level-control sensor (at the rear edge of the rear element block). Disconnect wires B1 and B2

from the sensor.

6. Place test leads across water-level-control sensor terminals (as shown above) and check for continuity when

the sensor is cool. If no continuity, replace sensor.

7. Reconnect wires and reassemble.

PAGE 30 OF 44 OWNER’S MANUAL 1185184

Page 31

STRATOSTEAM COUNTERTOP STEAMER SERVICE

Figure 19

Water Solenoid Check

1. DISCONNECT POWER AT CIRCUIT BREAKER.

2. Remove right side panel.

3. Disconnect wires B6 and B7 from water solenoid lead wires.

4. Place test probes into water solenoid lead wires as shown above.

5. Resistance should be approximately 800 Ω. Replace if necessary.

6. Apply waterline pressure to water inlet. Water should not leak out of the compression fittings. If necessary,

replace water solenoid. Check to see that water is slowly running into the cooking cavity.

7. Reconnect solenoid lead wires and reconnect power to steamer. When power is turned on with the steamer

cool, the solenoid should “click.” If no click is heard, test for 200 to 240 volts on wires B6 and B7. If 200 to 240

volts is present and the water solenoid does not click, replace water solenoid.

OWNER’S MANUAL 1185184 PAGE 31 OF 44

Page 32

SERVICE STRATOSTEAM COUNTERTOP STEAMER

Figure 20

Wiring Diagram for 208/220/240 Volt Models

PAGE 32 OF 44 OWNER’S MANUAL 1185184

Page 33

STRATOSTEAM COUNTERTOP STEAMER SERVICE

Figure 21

Wiring Diagram for 480 Volt Models

OWNER’S MANUAL 1185184 PAGE 33 OF 44

Page 34

SERVICE STRATOSTEAM COUNTERTOP STEAMER

PARTS

The following parts diagrams list and show serviceable parts. For parts not listed, contact a Southbend Authorized

Parts Distributor or a Southbend Authorized Service Agency.

Parts Diagram Page

Structural Parts 35

Door Assembly Parts 37

Door Switch Parts 39

Control Panel Parts 40

Heating Cartridges, Thermostats, and Contactor Parts 40

Water Train Parts 41

Cabinet Base Parts 42

PAGE 34 OF 44 OWNER’S MANUAL 1185184

Page 35

STRATOSTEAM COUNTERTOP STEAMER SERVICE

Structural Parts

See drawing on following page.

Key Part Number

1 1185026 1 -

1185122 - 1

2 1185016 1 1

3 1185115 1 -

1185135 - 1

4 1185072 1 1

5 1185036 1 1

6 1185103 1 -

1185123 - 1

7 1178668 1 -

1178664 - 1

8 1178663 1 -

1178669 - 1

9 1185019 2 -

1185137 - 2

10 1189315 1 1

11 1-2476 2 2

12 1185042 1 -

1185138 - 1

13 1185075 1 -

1185121 - 1

14 1185189 1 -

1185192 - 1

15 1185078 1 1

16 1185172 1 1

17 1185067 1 1

18 1185185 1 1

19 1178485 2 2

20 1178486 2 2

21 1188948 2 2

22 11889462 2 2

23 1178410 1 1

24 1189032 1 1

Quantity*

3EZ 5EZ

Description

STRE-3 DOOR ASSEMBLY (see page 377 for individual parts)

STRE-5 DOOR ASSEMBLY (see page 377 for individual parts)

DRIP PAN

DOOR GASKET, STRE-3

DOOR GASKET, STRE-5

DOOR SWITCH ASSEMBLY (see page 388 for individual parts)

FLOOR PANEL

SIDEWALL ASSEMBLY STRE-3

SIDEWALL ASSEMBLY STRE-5

PAN GUIDE, LEFT SIDE, STRE-3

PAN GUIDE, LEFT SIDE, STRE-5

PAN GUIDE, RIGHT SIDE, STRE-3

PAN GUIDE, RIGHT SIDE, STRE-5

SIDE PANEL, LEFT OR RIGHT STRE-3

SIDE PANEL, LEFT OR RIGHT STRE-5

TOP PANEL W/A STRE-EZ

PLUG, BUTTON, ZN PLATED, 5/8"

REAR INSULATING COVER STRE-3

REAR INSULATING COVER STRE-5

REAR PANEL ASSEMBLY STRE-3

REAR PANEL ASSEMBLY STRE-5

COVER, SIDE INSULATION STRE-3

COVER, SIDE INSULATION STRE-5

BRACKET, CONT S/A

WIRING SUPPORT BRACKET

BOTTOM PANEL ASSEMBLY

PANEL, COVER BOTTOM INSULATION

FRONT LEG

REAR LEG

BRACKET LEG

PAN GUIDE BRACKETS

PAN ASSEMBLY

PLATE REAR DRAIN BLANK

* Quantity of part used may depend on model (STRE-3EZ or SRTE-5EZ).

OWNER’S MANUAL 1185184 PAGE 35 OF 44

Page 36

SERVICE STRATOSTEAM COUNTERTOP STEAMER

Figure 22

Structural Parts

See parts list on previous page.

PAGE 36 OF 44 OWNER’S MANUAL 1185184

Page 37

STRATOSTEAM COUNTERTOP STEAMER SERVICE

Figure 23

Door Assembly Parts

Note: The entire door, assembled, can be ordered (see page 35).

Key Part Number Qty Description

1 1177317 1

2 1177344 4

3 1146527 6

4 1146526 4

5 1185053 1

1185124 1

6 1185028 2

7 1185115 1

1185135 1

8 1146268 2

9 6600412 2

10 1177086 1

11 1185088 1

12 PH-423 1

13 PH-292 2

14 1185029 1

1181018 1

15 1185023 1

1185128 1

16 1173254 8

17 1185118 1

1185136 1

18 1180460 4

19 1173224 4

LATCH ASSEMBLY

SCREW, #10-24 × 3/4 SLOTTED HEX

WASHER #10 LOCK, SS, 300

WASHER, #10, FLAT

PANEL W/A, STR-3

PANEL W/A, STR-5

HINGE PLATE W/A

GASKET, DOOR STR-3

GASKET, DOOR STR-5

BOLT, 1/4-20 × 5/8 HEX HEAD, SS

LOCK WASHER, SS

RETAINER

DOOR HINGE BRACKET

FLANGE BUSHING, 1/4 ID BRONZE

NYLON WASHER, 1/4 × 1/2 × 1/8

INSULATION, DOOR STR-3

INSULATION, DOOR STR-5

SUPPORT W/A , DOOR GASKET STR-3

SUPPORT, DOOR GASKET STR-5

SCREW, 6-32 × 3/4, SELF TAP

RETAINER, DOOR GASKET STR-3

RETAINER, DOOR GASKET STR-5

WASHER, FLAT #10

SCREW, 1/2-20 × 5/8 S, SLOT TRS

OWNER’S MANUAL 1185184 PAGE 37 OF 44

Page 38

SERVICE STRATOSTEAM COUNTERTOP STEAMER

Figure 24

Door Switch Parts

4

1

5

2

3

6

Note: The entire door switch, assembled, can be ordered (see page 35).

Key Part Number Qty Description

1 1185070 1

2 1185071 1

3 1185195 1

4 1146320 2

5 1177081 1

6 1177082 1

7 PH-292 1

8 6600402 1

ARM, DOOR SW SWING STRATOSTEAM

BRACKET W/A, STRATOSTEAM, DOOR SWITCH

SWITCH, DOOR, SPDT, 15 AMP SUBMINIATURE

SCREW, 6-32 × 1 ROUND HEAD

PIN, .250 DIA, SS, CAST LATCH STEAMER

SPRING, DOOR HANDLE

NYLON WASHER, 1/4 × 1/2 × 1/8

RING, RETAINING S.S. COMBI

8

7

PAGE 38 OF 44 OWNER’S MANUAL 1185184

Page 39

STRATOSTEAM COUNTERTOP STEAMER SERVICE

Figure 25

Control Panel Parts

Key Part Number Qty Description

1-17 1185039 1

1 1170337 1

2 1188947 1

3 1189024 1

4 1185205 1

5 1170350 2

6 1178388 1

7 1177770 1

8 1177865 1

9 1178276 1

10 1178549 1

11 1185056 1

12 1183429 2

13 6600430 2

14 1178535 1

15 1146320 2

16 1175712 1

17 1178341 1

18 1185080 1

19 1185031 1

20 1178393 1

* 1185161 1

CONTROL PANEL ASSEMBLY (assembled)

KNOB

POLYPANEL, CONTROL

PANEL, CONTROL W/A

GAUGE, THERMOMETER 2 IN

LIGHT, AMBER 240V SIGNAL

VALVE LEVER W/A

BUSHING, VALVE LEVER MOUNT

NUT, HEX, 5/8-18, BRASS

CAM ACTUATOR

SCREW, SET

BRACKET, ON/OFF SWITCH

INSERT, KNURLED

LOCKNUT

SWITCH, POWER

SCREW, 6-32 × 1 ROUND HD

BUZZER ASSEMBLY

TIMER, MECHANICAL

GASKET, CONTROL PANEL

VALVE ACTUATION ROD

1/8 × 1 1/4 18-8 COTTER PIN

WIRING HARNESS

* Not shown on drawing.

OWNER’S MANUAL 1185184 PAGE 39 OF 44

Page 40

SERVICE STRATOSTEAM COUNTERTOP STEAMER

Figure 26

Heating Cartridges, Thermostats, and Contactor Parts

Key Part Number

1 1181032 1 1

2 1181501 6 -

1181771 - 6

1181502 6 1181772 - 6

1181503 6 1181773 - 6

1181504 6 -

1181774 - 6

3 1185197 3 3

4 1185177 1 1

Quantity*

3EZ 5EZ

Description

CONTACTOR 208-240V

HEATER CARTRIDGE, 208V 60HZ (for Model STRE-3)

HEATER CARTRIDGE, 208V 60HZ (for Model STRE-5)

HEATER CARTRIDGE, 220V 50/60HZ (for Model STRE-3)

HEATER CARTRIDGE, 220V 50/60HZ (for Model STRE-5)

HEATER CARTRIDGE, 240V 60HZ (for Model STRE-3)

HEATER CARTRIDGE, 240V 60HZ (for Model STRE-5)

HEATER CARTRIDGE, 480V 60HZ (for Model STRE-3)

HEATER CARTRIDGE, 480V 60HZ (for Model STRE-5)

HIGH TEMP LIMIT THERMOSTAT

CONTROL THERMOSTAT

* Quantity of part used may depend on model (STRE-3EZ or SRTE-5EZ).

PAGE 40 OF 44 OWNER’S MANUAL 1185184

Page 41

STRATOSTEAM COUNTERTOP STEAMER SERVICE

Figure 27

Water-Train Parts

See parts list on previous page.

Water Train Parts

See drawing on following page.

Key Part Number Qty Description

1 1176385 4

2 1185292 1 TUBE, FLEX .375 × 18″

3 1184260 1 STRAINER, Y IN-LINE 1/8″ NPTF

4 1176384 1 NIPPLE, CLOSE 1/8NPT, 3/4″ LONG

5 1174933 1

6 1187477 1

7 1189315 1

8 1189314 1

9 1178552 1

10 1189006 1

11 1189005 1

12 1189022 1

13 1185106 1

14 1146910 1

15 1146805 1 NIPPLE, PIPE, BLK, 3/4″ × 5″

FITTING, 1/8NPT × 3/8CC STRAIGHT

VALVE, 240/60 SOLENOID

TUBE, FLEX .375 × 5

TOP PANEL W/A STRE-EZ

COVER, WATER TANK STRE-EZ

COVER W/A, DRAIN, EZ-3

MOUNTING WELL, WATER LVL SENSR

LEVEL SENSOR, WTR, CAPACATIVE

RELAY, TIME DELAY

VALVE, DRAIN STR STEAMER

ELBOW, STREET, BLK, 3/4″, 90 DEG

OWNER’S MANUAL 1185184 PAGE 41 OF 44

Page 42

SERVICE STRATOSTEAM COUNTERTOP STEAMER

Cabinet Base Parts

See drawing on following page.

Key Part Number Qty Description

1 1188933 2

2 1188934 2

3 1183987 2

* 1182637 2

4 1183985 1

5 1183983 1

6 1183984 1

* 1183986 1

7 1184527 1

8 1185144 1

9 1188936 1

10 1188935 2

11 1172650 4

12 1146500 16

13 1146201 16

14 1174260 1

* 1174262 1

* Not shown on drawing.

PANEL, 12" SS DOOR

LINING, 12" SS DOOR

HANDLE, CATCH DOOR

CATCH, MAGNETIC, SGS

HINGE ASSEMBLY, UPPER LEFT

HINGE ASSEMBLY, UPPER RIGHT

HINGE ASEMBLY, LOWER RIGHT

HINGE ASSEMBLY, LOWER LEFT

COVER, 24" BASE BOTTOM

PANEL, TOP CABINET

BODY BACK, 12" CABINET

BODY SIDE, 12" CABINET

LEG PAD (3/4 X 10 HOLE)

1/4 LOCK WASHER

1/4 X 30 X 3/4 HEX HEAD

LEG PACKAGE (set of four legs, not including bolts, leg pads, or lock washers)

EARTHQUAKE LEGS SS (set of four)

PAGE 42 OF 44 OWNER’S MANUAL 1185184

Page 43

STRATOSTEAM COUNTERTOP STEAMER SERVICE

Figure 28

Cabinet-Base Parts

See parts list on previous page.

9

8

1

2

10

4

3

5

12

13

14

15

7

6

11

OWNER’S MANUAL 1185184 PAGE 43 OF 44

Page 44

STRATOSTEAM COUNTERTOP STEAMER

StratoSteam

Countertop Steamer

Models STRE-3EZ and STRE-5EZ

A product with the Southbend name incorporates the best in durability and low maintenance. We all recognize,

however, that replacement parts and occasional professional service may be necessary to extend the useful life of

this appliance. When service is needed, contact a Southbend Authorized Service Agency, or your dealer. To avoid

confusion, always refer to the model number, serial number, and type of your appliance.

Southbend

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

www.southbendnc.com

PAGE 44 OF 44 OWNER’S MANUAL 1185184

Loading...

Loading...