Southbend SLGS/12SC, SLGB/12SC General Manual

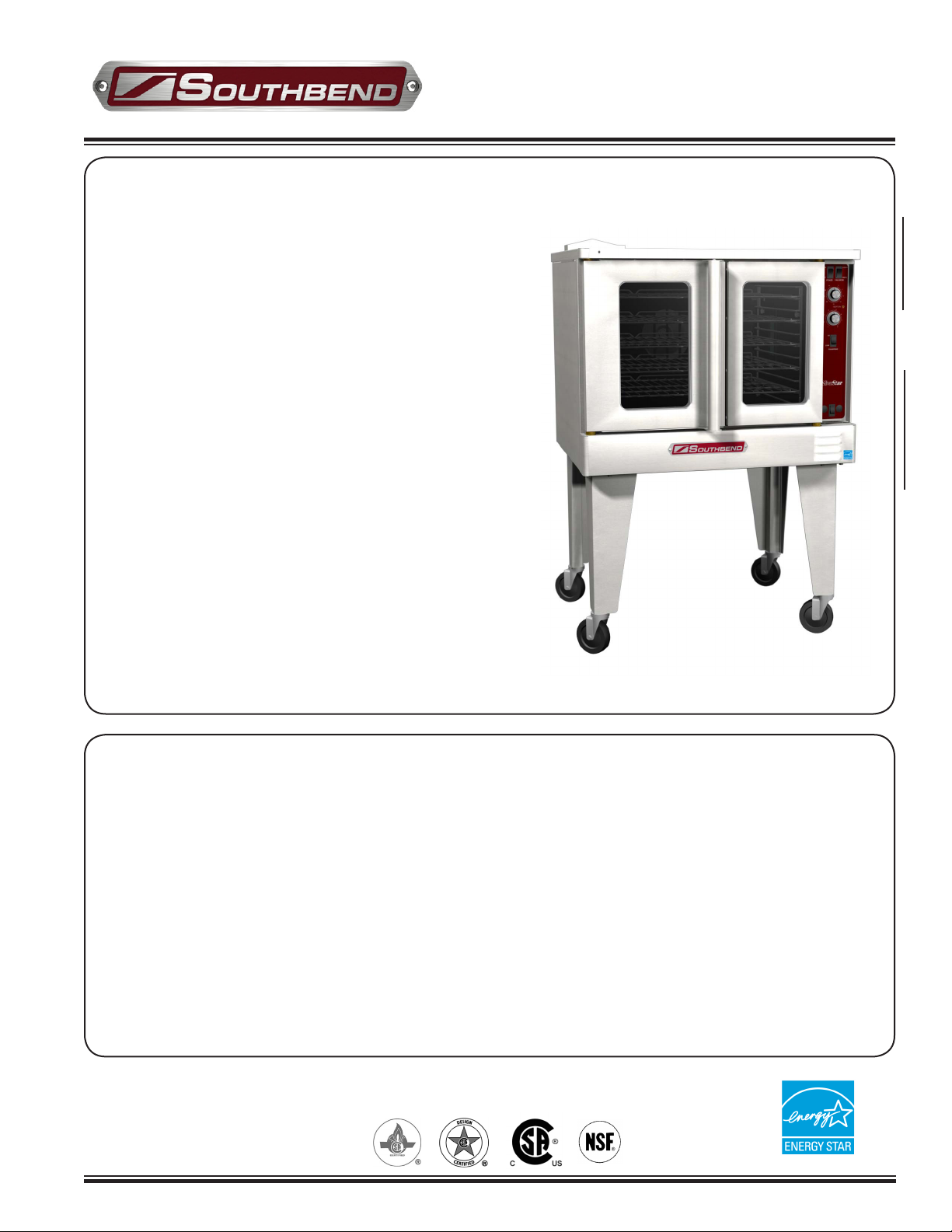

CONVECTION OVEN

SIlVErSTar

GAS,SINGLE DECK

Standard Features

- ENERGY STAR® qualied (standard depth only)

- Patented, high efciency, non-clog Jet Stream burners

- 72,000 BTU (NAT or LP)

- Available standard and bakery depths

- Single deck convection oven is 57-1/2”” in height (with

optional casters)

- Oven interior light

- Patented “plug-in, plug-out” control panel - easy to service

- Stainless Steel front, top and sides

- Dependent doors with windows

- Coved, fastener-free, porcelain interior

- Heavy duty, cool touch, stainless steel door handle

- Soft Air, two speed, 1/2 hp, fan motor

- 11-position rack guides and 5 plated oven racks

- Electronic ignition with solid state temperature controls

- Forced cool down fan mode

- Oven “ready” light

Available Controls

SC-Standard Controls

140°F to 500°F solid state thermostat and 60 minute

mechanical cook timer.

CCH-Cycle / Cook & Hold Control

150°F to 500°F temperature controller with 140°F to 200°F

“Hold” thermostat Dual digital display shows time and

temperature. A fan cycle timer pulses the fan.

SLGS/12SC, SLGS/12CCH

SLGB/12SC, SLGB/12CCH

(SLGS/12SC shown with optional casters)

Job Item#

STANDARD CONSTRUCTION SPECIFICATIONS

Exterior Finish: Stainless steel front, top and sides. Aluminized

steel back.

Doors: Dependent doors with windows. Stainless steel

construction, heavy-duty welded steel frame and 5/8” diameter

full-length hinge pin.

Oven Interior: Porcelain enamel nish, coved, fastener free.

Single oven interior light.

Rack and Rack Guides: Heavy-duty removable wire rack guides

spaced on 1-5/8” centers offer 11 different rack positions. 5 wire

racks provided with each oven.

Blower Fan and Motor: 1/2hp, 2-speed motor, 1725/1140

r.p.m

Form SLG/12 Rev 5 (November/2009)

www.yatesgd.com www.yatesgraphicdesign.com

Oven Heating: 72,000 BTU (NAT or LP). Oven heating is

regulated by an adjustable solid state thermostat control. Blower

fan circulates air within the cavity “scrubbing” heat to the oven

interior for even heat distribution within the cavity.

Electronic Ignition: Hot surface ignitor with ame safety

device.

Control Panel: Located of front, at right side of oven, away

from heat zone. Removable panel opens downward for easy

servicing.

Legs: 26” Stainless steel, triangular legs standard.

Note: Oven cannot be operated without fan in operation.

Printed in USA

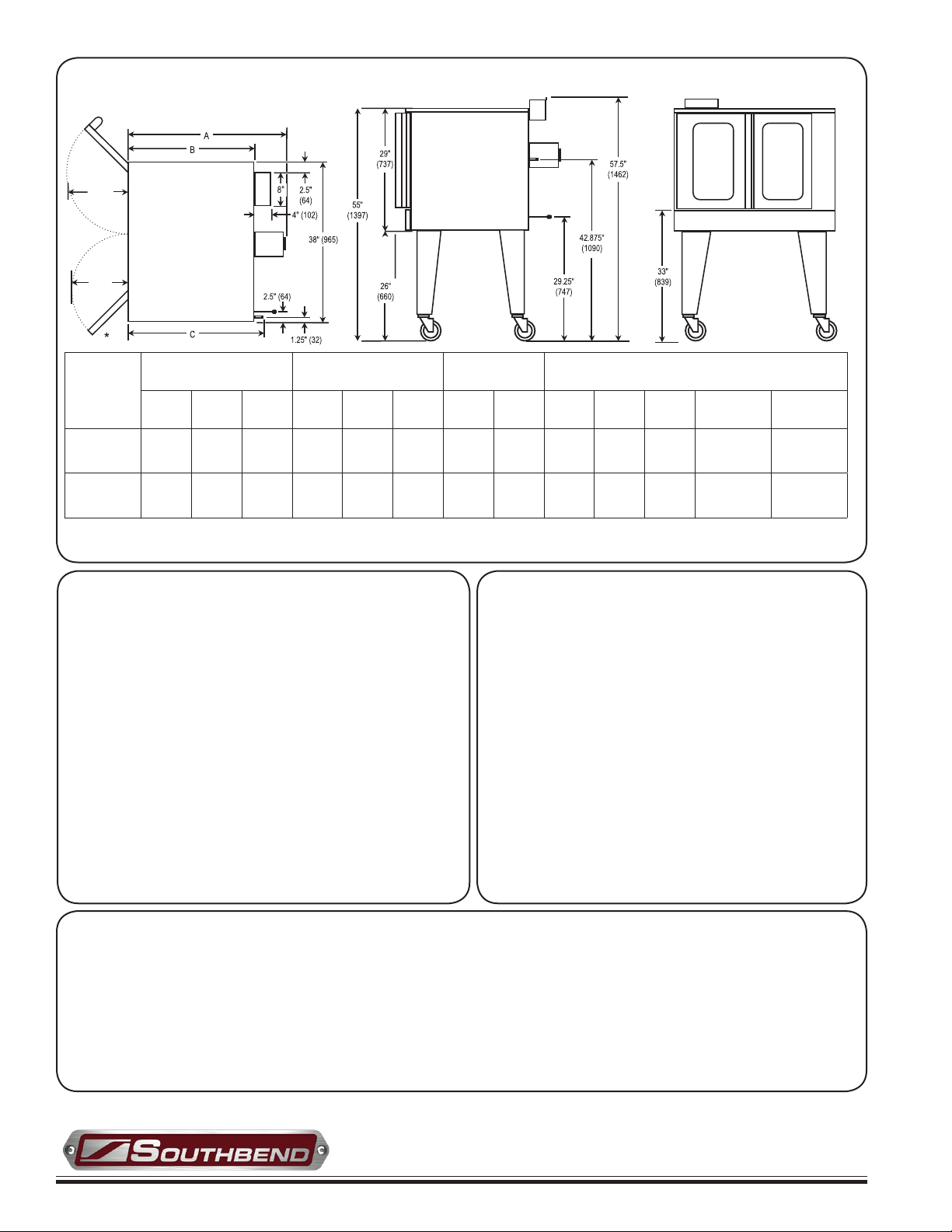

Models:

SLGS/12SC SLGS/12CCH SLGB/12SC SLGB/12CCH

Dimensions -in (mm)

17”

(432)

12.75”

(324)

DEpth OvEn IntErIOr rack cLEarancE ShIppIng cratE

MODEL

a B c WIDth DEpth hEIght WIDth DEpth WIDth DEpth hEIght vOLuME WEIght

SLGS/12

SLGB/12

Note: When shipped on legs, crated height is 69” (1753 mm)

39.75”

(1010)

46.75”

(1187)

30”

(763)

36.38”

(924)

34.38”

(873)

40.75”

(1035)

29”

(737)

29”

(737)

22.5”

(572)

28”

(711)

optional casters.

reduces height

20”

(508)

20”

(508)

UTILITY INFORMATION

GAS: • Standard and Bakery Depth: 72,000 BTU (NAT or LP) per

oven cavity

• One 3/4” male connection

• Required minimum inlet pressure:

- Natural gas 7” W.C.

- Propane gas 11” W.C.

ELECTRIC: Standard: 120/60/1 phase, furnished with 6’ cord w/3prong plug (1 plug/deck). NEMA #5-15p. Total maximum amps 7.9.

Optional: 208/60/1 or 3* phase (190-219 volts). Supply must be wired

to junction box with terminal block located at rear. Total maximum amps

4.3 per deck. Optional: 240/60/1 or 3* phase (220-240 volts). Supply

must be wired to junction box with terminal block located at rear. Total

maximum amps 3.8 per deck. Optional: 240/50/1 or 3* phase (208-240

volts). Supply must be wired to junction box with terminal block located

at rear. Total maximum amps 6.0 per deck

* All units are shipped single phase. Single phase units can be easily

converted to three phase

Shown with

Legs only

by 3”

28.25”

(718)

28.25”

(718)

22”

(559)

27.25”

(692)

48”

(1220)

48”

(1220)

57”

(1448)

57”

(1448)

46”

(1168)

46”

(1168)

Shown with

optional casters.

Legs only

reduces height

by 3”

65.2 cu. ft.

(1.85 cu. m.)

65.2 cu. ft.

(1.85 cu. m.)

MISCELLANEOUS

• If using ex hose connector, the I.D should not be smaller

than 3/4” and must comply with ANSI Z 21.69.

• If casters are used with ex hose, a restraining device

should be used to eliminate undue strain on the ex hose.

• Clearances from combustibles: Top-0”, bottom-0”, right

side-0” and left-3”

• Recommend - install under vented hood

• Check local codes for re and sanitary regulations

• If the unit is connected directly to the outside ue, an

A.G.A approved down draft diverter must be installed at

the ue outlet of the oven

• Oven cannot be operated without fan in operation

Notice: Southbend reserves the right to change specications and product design without notice. Such revisions do

not entitle the buyer to corresponding changes, improvements, additions, or replacements for previously purchased

equipment.

620 lbs

(281.2 kg.)

690 lbs

(313.0 kg.)

Stainless Steel rear jacket

Stainless Steel oven interior

Stainless Steel exterior bottom

6” stainless steel legs

208/240V 50/60 cycle ( for use on 1

or 3 phase)

Form SLG/12 Rev 5 (November/2009)

OPTIONS AND ACCESSORIES

Bolt-down anged legs

Swivel Caster - front with locks

Knocked down packaging

Export Crating

Extra oven racks

Down draft diverter for direct ue

3/4” quick disconnect with exible hose

(specify length: 3ft, 4ft, or 5ft)

2” air insulation panel (stainless steel

only)

INTENDED FOR COMMERCIAL USE ONLY.

NOT FOR HOUSEHOLD USE.

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

(919) 762-1000 www.southbendnc.com

Loading...

Loading...