Southbend CM-31 Installation Manual

Ea

FOR FUTURE REFERENCE

Please complete this information

and retain this manual for the life

southbend

A MIDDLEBY COMPANY

of the equipment.

MODEL #

SERIAL #

DATE PURCHASED

i

OWNER’S MANUAL

INSTALLATION

USER’S GUIDE

SERVICE

PARTS

INFRA-RED

IMPORTANT

CHEESE MELTERS

MODELS:

These instructions should be read

and Start Up should be petformd by a qualified service techridan. The Mariutacturer,

Southbend (1100 Old HoneyaRt FM., Fuquay-Varina, hbrih Camfina 2Z26), infomrs you

~atunlessthe.~ninstnrctionsfortheabove~SwthbendFHodud~

~andperformedbyaquatifisd~technician,(apelsan~encedinand

krmhdgeable aweming the instalWon of cofnmefcial gas.aWof ektrkal oook@

equipment) then the terms and conditions of the

rendefedvoidandnowanantyofanykindshaUapply.

If the equipment has been changed, attered, modified or repaired by other than a

quaiified sewice technician during or after the 12~mordh limited warranty period, then

themanufadurershan~beCaMefotanyindde~orconsequentiald;unagestoany

person or to any property which may result from the use of the equipment thereafter.

Some States do not allow the exclusion or limitation of incidental or consequential

~~,so~e~~li~orexdusiontheretomaynot~toyou.

Intheeve~~youhaveanypuestionsconcemingtheinstal(ation,use,care,orsenriceof

the pfocm, write Customer Service Department, Southbend, 1100 Old Honeycult Rd,

Fuquay-Vartna, North Camha 27526.

CM-3lC; CIU-36; CM-32; CM-S-60

CM-mPC, cNl=3lw, CMal, CM-3lP

CMeoc, cM-64,cM-60=60

CNMOPC,

CM4OW, CM-60, CM-6OP

thoroughly before atterrpting instaMion. in&Won

Manufachner’s Limited warranty will be

MFRAIRED

CHEESE MELTERS

(Manual Section BR)

Chqmtdationa! You have jut purched me at the best piecss uf

on the market today.

You

will 5nd that your new equipment, like

some of the

equipment

instabtions in some of the more strenuous commercial cooking applic&m. With proper ca,m and field

maintenance, you will experience years of relisble, &mbb-&ee operation from your So&bend equipment. To

the best msul% it% important that you read tbis manual cmwfizlly.

TABTZ OF CONTENTS

toughest

standards in the indumy -

haa been cn~fblly engineered and

SE~‘.KNO.KNO~-ON

IrltdMon

SEXXONTWO-UsER’SGuIDE

. . . . . . ..--.*..........................*......-.-...................

. . . . . . . . . . . . . . . . . . . . . . . ..-.-.-..........~-...........................

all Southbend equipment, has been designed and manufachaed to

thoss of Southbend Cqmration. Each piece of Southbend

de&ns have ken vsrified through laboratory m end field

heavy-dufy, mefiial e00king

equipment

get

;

. . . . . . . . ..*.....I-...............*...............*-.......~.........

CA-ON: POST INZ?ROiMINENT

Lt2CtUTON~S~UcIIoNS To BE FOLLOWED m

ouredusive Schwank

in8bouth&theusualtime,withlesgas

mheatingsoccmdaryanfacesasisn~in

cfmmictilehumm

!lT?E EVENT THE SMELL OF GAS IS DlZ2YZmD. Z!EIS RWO2’Ui@l7ON S&ALL BE

OBT~ERO~LOCXLWSIP+~

t

I

I

FoRYouRsAEETY

192

1

DO NOT STORE OIt USE GASOLTNE OR OTHBR-LEVAPORSAND

~QUBWINTBEVICINlTYOF’~OZUNYOTHEEtAppw[ANcE.

KEEPAREAAROUND APPLuNcBs~ANDcLEARFaoMcoMB-s.

INTHEEVENTAGASODOEISDETecTeD,~DOWN~UIfMENTA31‘THE

MAIN SHUTOFF VALVE AND CONTACT TEE LOCAL GAS COMPANY OR GAS

-FoR-cE9

l

WARNING-W-

wIuBEvoIDIR

ASERVICEWORKISPERFORMEDBYOTHERTaANAQUAL;IFIED

TlWHNICIAN.

KOTKERTHANGENMNE

souTHBENDBlEPLA~

PAaTs ARE

INSTALLED.

1lOOOklHOMyCiJItROild

Fquay.NC27526

(919)662-9161

FAX(919)552-9796

INFRA-RED CHEESE

MELTERS

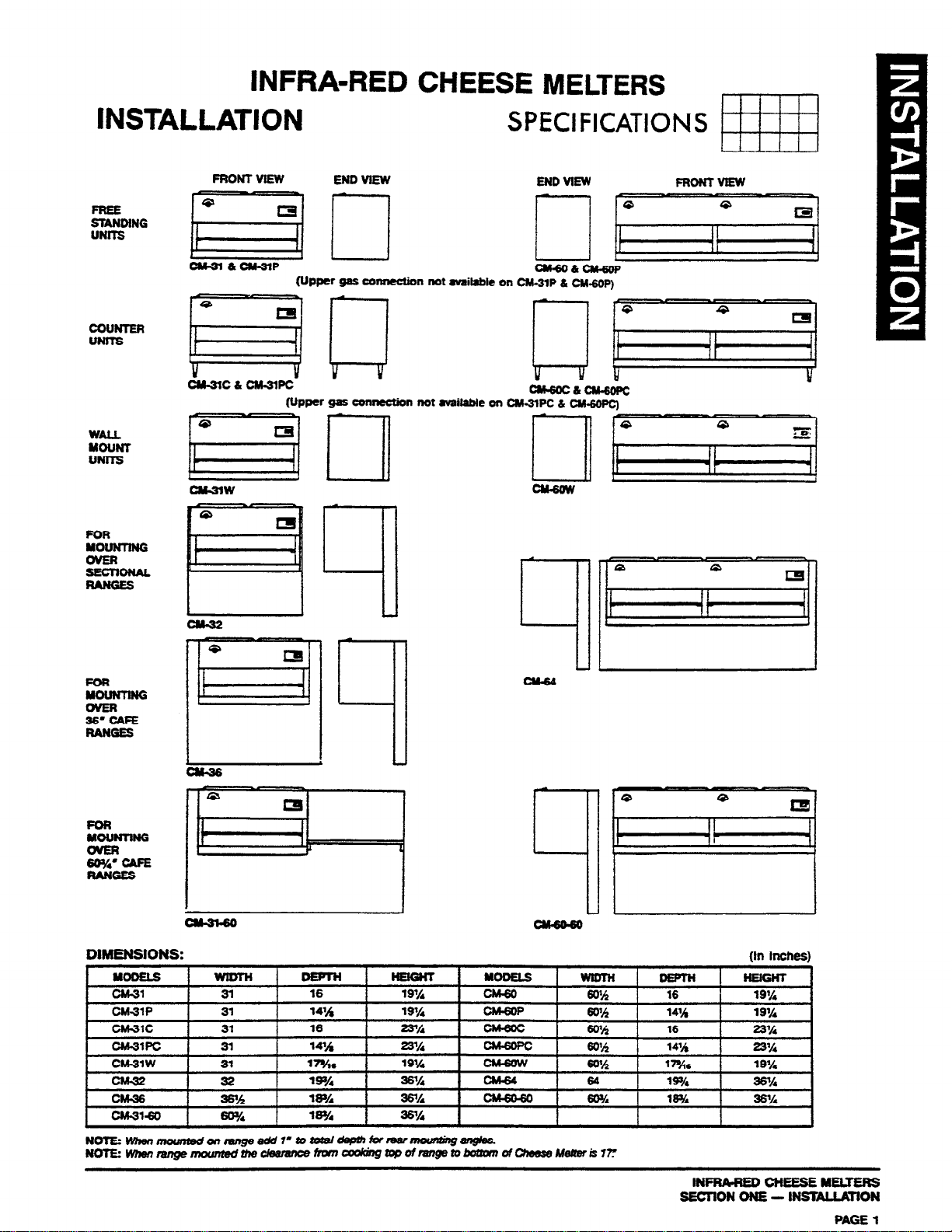

INSTALLATION

FRONT VEW

ClFn&CS3lP

I”i--l

COUNTER

UNITS

RLiJ

CM-3lC&CM-3lPC

(Upper gas comeion not mdable on C%3lPC &

SPECIFICATIONS mj

END VIEW

(Upper gas connection not mfaitablc on W-31P tk chbmop~

END VIEW

cNbOacN-6w

FRONTVIEW

DIMENSIONS:

t

CM-31

CMMP

CMCMC

31

31

16

?4’/$

19%

19%

(In Inches)

. YooEL9 1 NElGHr

16

14’h

INFRA-REO CHEESE MEUERS

SEC’IION ONE - lNSlALLA3lON

19%

19%

CM6OP

@.w

w2

PAGE 1

INSTALLATION

I

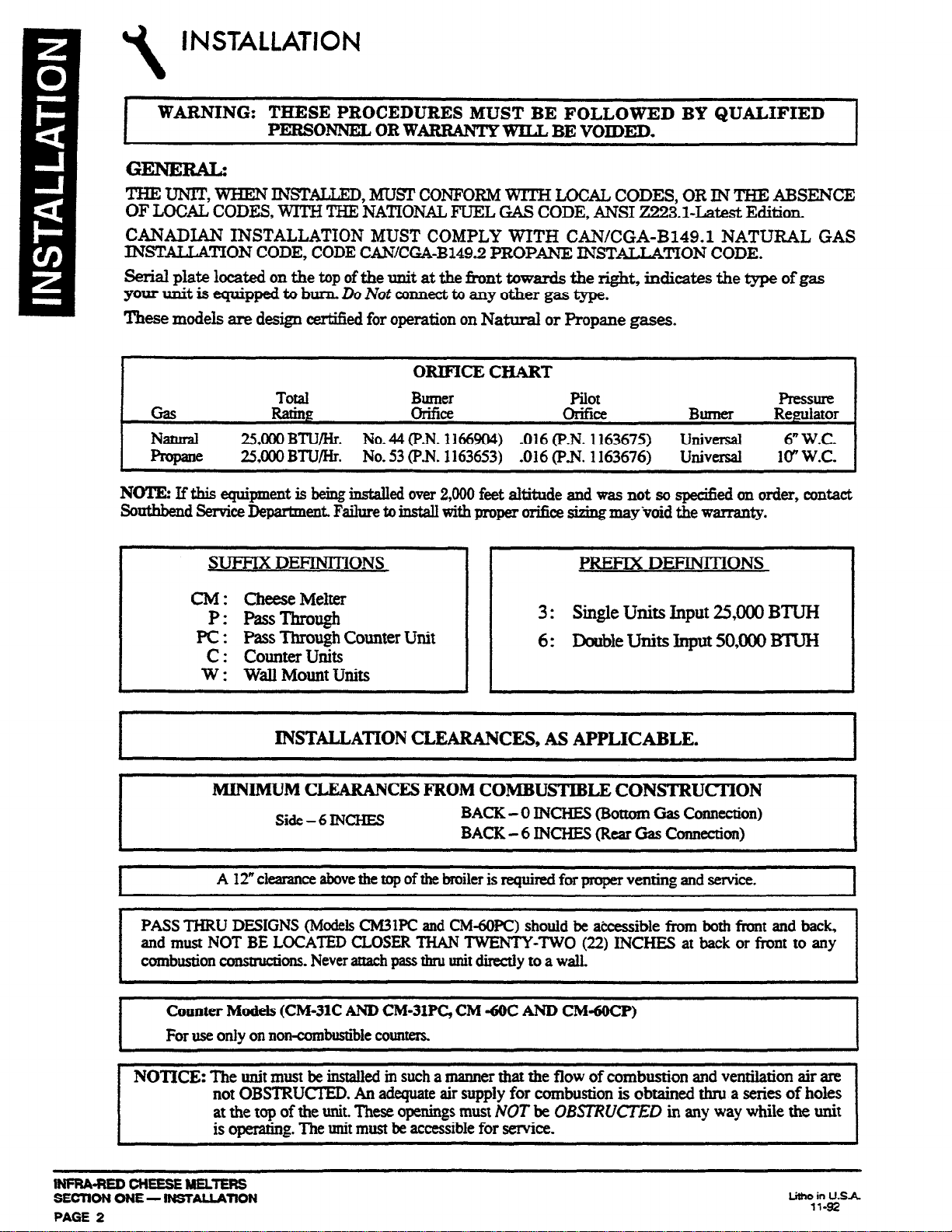

WARNING: THESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED

I

THE UNiT, WHEN INS’T%LLXD, MUSI’ CONFORM WITH LOCAL CODES, OR IN THE ABSENCE

OF LOCAL CODES, WITH THE NATIONAL FUEL MS CODE, ANSI 2!2!23.1-Latest Edition.

CANADIAN INSTALLATION MUST COMPLY WITH CAN/CGA-B149.1 NATURAL GAS

INSTALLATION CODE, CODE CAN/CGA-B149.2 PROPANE INSTALLATION CODE.

Serial plate located on the top of the unit at the hnt towards the right, indicates the type of gas

your unit is equipped to burn, Do Not connect to any other gas type.

These models are design certified for operation on Natural or Propane gases.

Gas

NCitllId 25,000 BTU/Hr. No. 44 (P-N. 3 166904) -016 (P-N. 1163675) universal

Propane

NOTE: If this equipmeat is king installed over 2,000 feet altitude and was not so specified on order, contact

Swthbend Service DepartmenL Failure to install with proper orifice sizing may ‘void the warranty.

PERSONNEL OR WARRANTY

ORIFICECHART

Total Burner

Rating orifice

25,000 BTU/I+. No. 53 (P.N. 1163653) ,016 (P.N. 1163676) universal

WILL BE VOIDED.

pilot

Olifie

Bllnler

Pressure

Regulator

6” W.C.

lo” WC.

I

SUFFlX DEFlNITiONS

CM: CheeseMelter

P: PassThrough

PC :

.

Pass Though Counter Unit

collnter units

c :

Wall Mount Units

W :

PRERX

3: Single Units Input 25,000 BTUH

6: Double Units Input 50,000 BTUH

DEFINITIONS

INSTALLATION CLEARANCES, AS APPLICABLE.

MINIMUM CLEARANCES FROM

Side-6INCHES

I

PASS THRU DESIGNS (Models CM3IPC and CM-6OPC) should be accessible from both front and back,

and must NOT BE LOCATED CLOSER THAN TWENTY-TWO (22) INCHES at back or front to any

combustion constructions. Never attach pass rhru unit directly to a wall.

Counter Models (CM-31C AND CM31PC, CM -6OC AND CM4OCP)

For use only on noncombustible counters.

I

A 12” clearance above the top

of the broiler is required for proper venting and service.

COMBUSTIBLE CONSTRUCTION

BACK - 0 INCHES (Bottom Gas Connection)

BACK-6 INCHES (Rear Gas Connection)

I

I

NOTICE: The unit must be installed in such a manner that the flow of combustion and ventilation air are

not OBSTRUCTED. An adequate air supply for combustion is obtained thm a series of holes

at the top of the unit. These openings must NOT be OBST?WXED in any way while the unit

t

IWRA-WDCHEESEMELTERS

SECTION ONE-INSTALLATION

PAGE 4

is operating. The unit must be accessible for service.

lithoin

11-92

USA

INSTALLATION

NOTE: No additional clearance from the sides and back is required for service, as the units are

serviceable from the front.

E2iHAUST FANSAND CANOPIES:

Canopies are set over ranges, ovens, etc., for ventilation purposes. It is recommended that a canopy

extend 6” past appliance and be located 6’6” from the floor. Filters should be installed at an angle of

45 degrees or more with the horizontal. This position prevents dripping of grease and facilitates

collecting the run-off grease in a drip pan, usually installed with a filter. A strong exhaust fan tends

to create a vacuum in the room and may interfere with burner performance or may extinguish pilot

flames. Fresh air openings approximately equal to the fan area will relieve such vacuum. In case of

unsatisfactory perf

NOTE: Be sure to inspect and clean ventilation system according to the ventilation equipment

manufacturerk instructions.

WARNING: THESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED

I

GAS CONNECTIOM

l.AtX&i.fied

with the unit.

2. If applicable, the vent line from the gas appliance pressure regulator shall be installed to the

outdoors in accordance with local codes or, in the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1-Latest Edition. Canadian installation must comply with CANXGAB149.1 Natural Gas Instahation Code, Code CAN/CGA-B1492 Propane Installation Code.

3. The gas supply connection is l/2” NIT and can be made at either the rear or the bottom on the

left-hand side. Both of these connections are closed by a l/2” NPl’ plug as shipped from the

factory. Pass thru models only have bottom connection.

AREA&

ormance on an appliance, check with the exhaust fan in the “OFE” position.

PERSONNELORWARRANTY

pressme regulator designed for the type of gas for which the unit is equipped is packed

WIUBEVOIDED.

Bemove the 1/2” NPT plug at the rear lefi side. Insert a V2” NPT nipple, 3 inches long, into

this fitting. At the inlet of this I.&!” NPT nipple install the pressure regulator. Take care that

the flow of gas thru this pressure regulator is as indicated by an axrow on this controL Install a

1/2”NPTserviceshutoffvalvetotheregulatorandcoMecta1/2”NPTgassupplylinetothis

valve.

B. BO’ITOE

Remove the l/2” NPT plug at the bottom lefi area and use the same pmcedure as above for the

connection.

CAUTIONBESURETOHOLDPRESSUREREGULAZ#RWIZHAWRENCH~Z7GHlENLNG

SUPPLYPIPEToAVOIDDAMAGEToTIEEREGULA7UR,VvALvE,ANDO7HERCOMPONENZS.

I

4.TheunitshouId13econnected~ytothetypeofgasfarwhichitisequipped.Checktypeof~on

rating plate. On all threaded connections, the pipe compound must be approved for use with

natural and propane gas.

5. Make sure burner valve is in the ‘Ol?F’ position before connecting gas to unit. Test all pipe

connections thoroughly for gas leaks. Use soapy water only for testing on all gases.

6. Turn on burners and bleed supply line, then turn burners off.

7. Light pilot and adjust so that flame is approximately

0ueni.w in the white area of the valve indicator decal.

W8"

long. Adjustment is tbru a 318” dia.

I

I

SUPPLYPrPINGSYSllEMAT~STP~SSURES~UAL~O~LESS~1/2PSIG(3.45KPa).

--- ---- --

--- --- --- -~~ -

wFRA4?EDaEEsEMELlERs

SEmONE-iNSTALL4TlON

1

PAGE 3

INSTALLBTION

\

ST&EB;;~LmOm~D BY QUALIFIED

.

A I” NPT line is provided at the rear for the connection. Each unit is equipped with an internal

pressure regulator which is set

propane gas. Use 1/8” pipe tap on the burner manifold for checking pressure.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the vohrme of

gas requked for satisfactory perhonnauce. A steady supply pressure, 6” W.C. for natural gas aud 10”

W.C. for propane gas, is recommended. With all uuits operating simultaneously, the manifold

pressure on all units should not show any appreciable drop.

natural gas, and 10% on propane gas, will create pilot problems and affect burner operating

characteristics. Contact your gas company for correct supply line sizes.

Purge the supply line to clean out any dust, dirt, or other foreign matter before connecting the line

to the unit. It is recommended that an individual manual shutoff valve be installed in the gas

supply line to the unit. Use pipe joint compound which is suitable for use with LP gas on all

threaded connections. Test pipe connectious thoroughly for gas leaks. USE SOAPY WATER ONLY

FOR TESTING ON ALL GASES. NEVER USE AN OPEN FLAME TO CHECK FOR GAS LEAKS.

ALL CONNECTIONS MUST BE CHECKED FOR IEAKS, AFTER TIIE UNIT HAS BEEN PUT

IN OPERATION.

for 4”

WC. manifold pressure for natural gas and 10” WC. for

Fluctuations of more than 25% on

lNPRAaEDcNEEsEMELTERs

SECTION ONE-INSTALLATION

PAGE 4

INSTALLATION

WARNING: THESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED

I

PERSONNELORWARRANTY

WILL BE VOIDED.

All Cheese Melters are shipped with rack guide

assemblies packaged in the crate. They are easily

assembled to each side as shown above. Rack guides

should be removed periodically for cleaning.

r

I

FIELD ASSEMBLY INSTRUCTIONS

The following section covers Field Assembly installation instructions for the Cheese Melter unit

combinations noted below and shown on SECTION ONE, page 3.

1. Installing legs for counter units.

Model Numbers CM-31C and CM-31PC . . . . ..*...-....................

2. Assembliug wall mount hanger and attaching unit for wall mount units.

Model No. CM-31W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SECTION ONE, Page 8

3. Assembling flue risers and attaching unit for mounting over 32 in. Sectional Range.

Model No. CM-32 . . . . . . . . . . . . . . . . . . . ..-........................... SECTION ONE, Pages 9,10

4. Assembling flue riser and attaching unit for mounting over 36 in. Cafe Range.

Model No. CM-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Assembling flue riser and attaching unit for mounting over 60 % in. Cafe Range.

Model No. CM-3160 . . . ..I.............................................

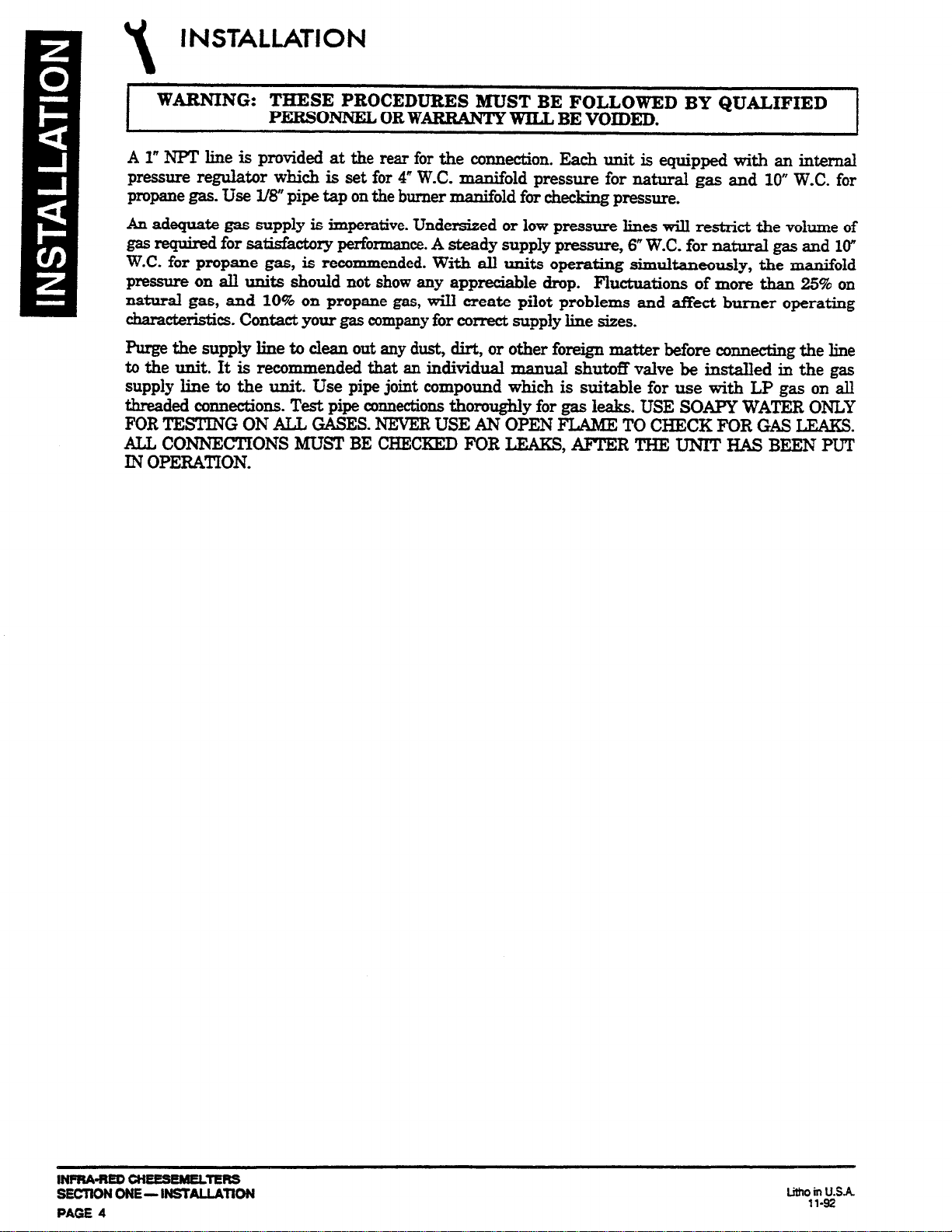

INSTRUCI’IONS: To Install Legs on Counter Models

1. Remove the BASIC Unit from the container.

2. CAREFULLY place the unit on its BACK.

3. Four NSF approved LEGS are packed with the unit.

4. REl? sketcllbelow

Atbreaded~CEPTACLE(R),isattacbedtothe

underside oftbe bottom, at each comer.

Each leg has a threaded STUD (S).

‘I?ghtentbestudoneachlegintoareceptace.Secure

with a wrench on the hexagon section

Each leg has its own NSF approved leveling FOOT (LX

By adjust&these feet, the proper combination can be

achieved whereby the unit will be level and steady.

AND DIAGBAMS

SECTION ONE, Page 7

SECTION ONE, Pages 11,X& 13

SECTION ONE, Page 20

of the leg.

Never attach the pass thru unit, Model CM3lP, Directly to a wall.

1NmA-REDcHEEsEMELlERs

SECTIONONE-INSTALLA=

PAGE 5

INSTALLATION

\

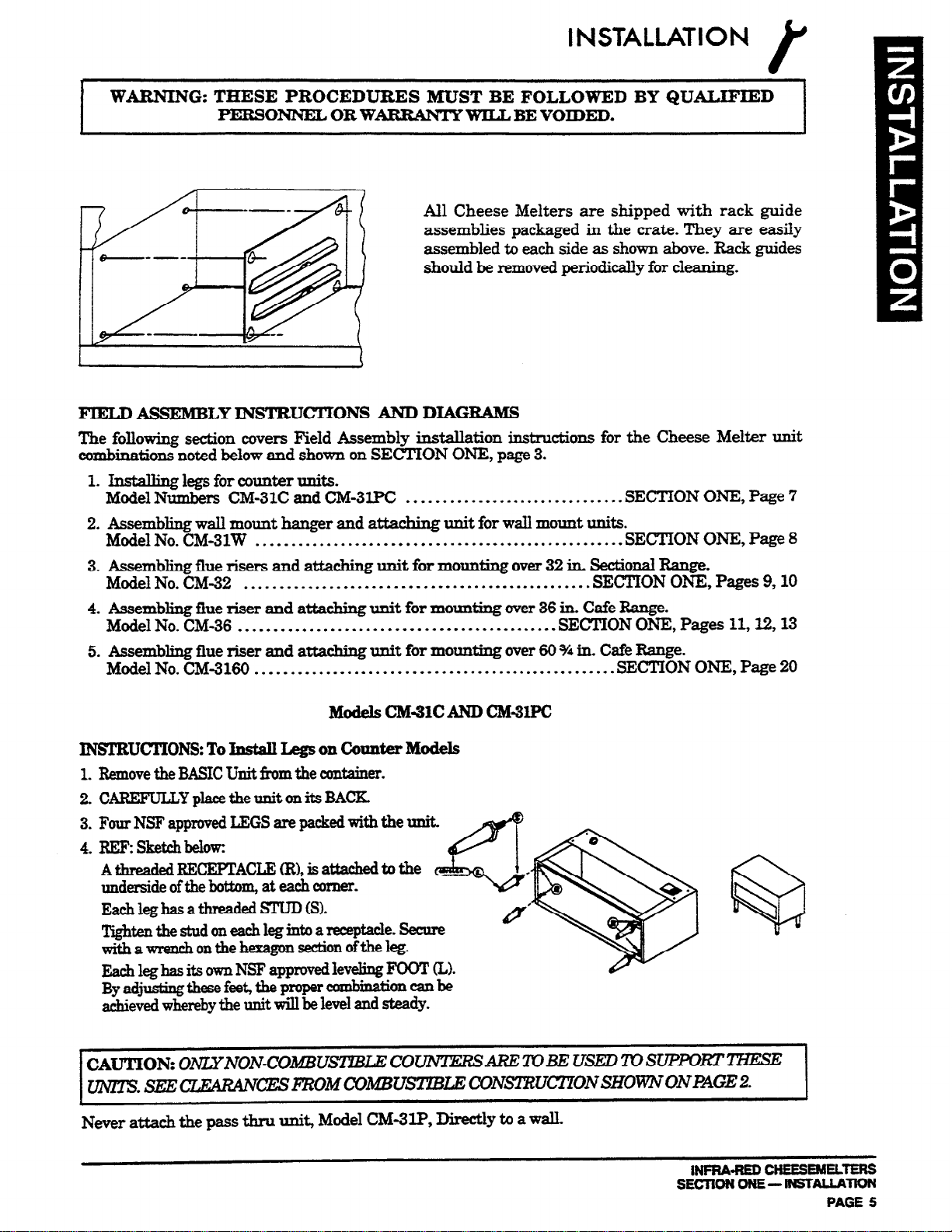

MODEL NO. CM31W

DIAGRAM FOR MOUNTING CHEESE MELTER TO WALL

USING CM-W-31 WALL MOUNT KIT.

%

A-

l/4” -20 x l/2” Hex head Sol. P/N 1146200

with Split Washer P/N 1146500

and

l/4” -20 Hex Nut P/N 1146400

C - #10x 112” Sloted Truss Head Sheet Metal Screw

PIN 1146300

1.

Wall

mouut consists of the following parts:

A.

(1)

Top Bracket - T

B. (1) Bottom Bracket - B

C. (1) Right Side Bracket - R

D.

(1) Left Side Bracket - L

E. (1) Right Filler - FR

F. WLeft Filler-FL

G. Necessary Fasteners

NOTE: Fasteners

2.

Determine method of gas piping, remove pipe plug from unit and if piping fkom the rear, add

for mounting

bracket

zttssembly to wall are

not provided.

===wfittings.

3.

4.

Assemble T, B, L and R as showu. Twill

hook into the

mounting pocket located at the rear of

the unit. B should be positioned so that the bottom flange is flush with the unit bottom when

lllOunted.

5.

Mount wall mount assembly securely to the wall in the desired location.

Liftunit andplace~eonTiato~partafrearmountingpocket.Positionunit as desired

6.

fromrighttoleftalld

7.

Rocf3ed with gas connections as discus& in the forward section of this mauual.

INFRARED CHEESE MELTERS

SECIION ONE - INsTc\LLATIoN

secure bottom of unit through slots in horizontal flange ufB through CL

INSTALLATION

I

WARNING: FOR AN APPLIANCE EQUIPPED WITH CASTERS, TRE INSTALTXf’ION

SHALL BE MADE WITB A CONNECTOR TEIAT COMPLIES WITH TEE STANDARD FOR

CONNECTORS FOR MOVABLE GAS APPLIANCES, ANSI

MS7 AND A

FOR

QUICK-DISCONNECT DEVICES FOR USE

AND

ADDENDA,

MUST BE PROVIDED TO IJMXT THE

DEPENDING ON THE CONNECTOR AND THE QUICK-DISCONNECT DEVICE OR ITS

QUlCX-DISCONNECT DEVICE THAT COMPLIES WITH THE STANDARD

WITH GAS FUEL, ANSI 221.41-1978,

Z21.41a-1981, ZZ1.41b-1983 AND CAN1 6.9 M79. ADEQUATE MEANS

MOVEMENT OF THE

ASSOCIATEDPIPlNGTOIJMITTFIEAPPLL4NCEMOVEMENT.

221.69-198‘7, CAN/CGA-6.16.

APPLJANCE WITHOUT

~iJlI?+I&ISCO.~~ON OF THIS

CIZANING, EYI’C, RECONNECT IT WHEB TEIE APPIJANCE IS

MOVED TO ITS ORIGINALLY INSTALLED POSITION.

REJ

STRAINT Is NECESSARY To REMOVE

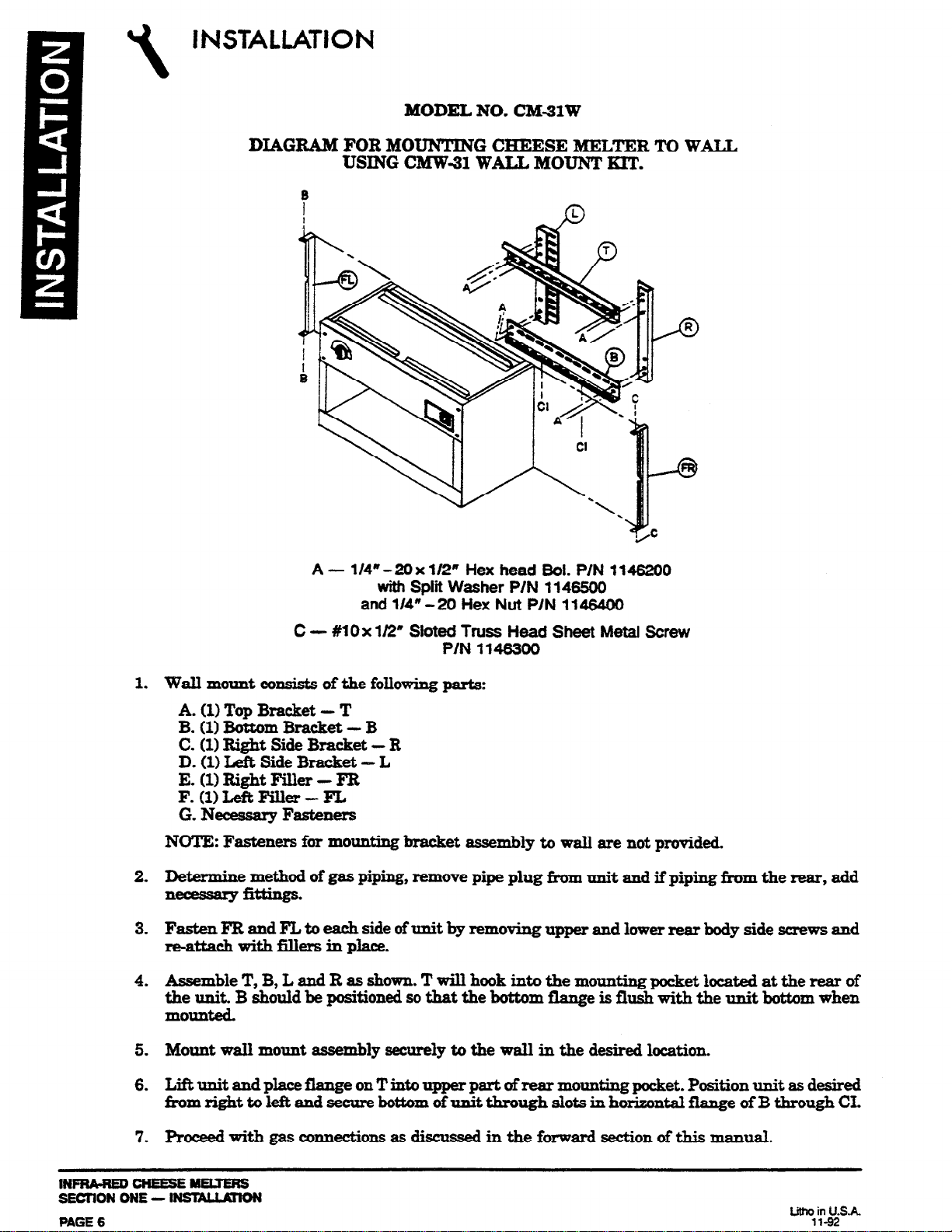

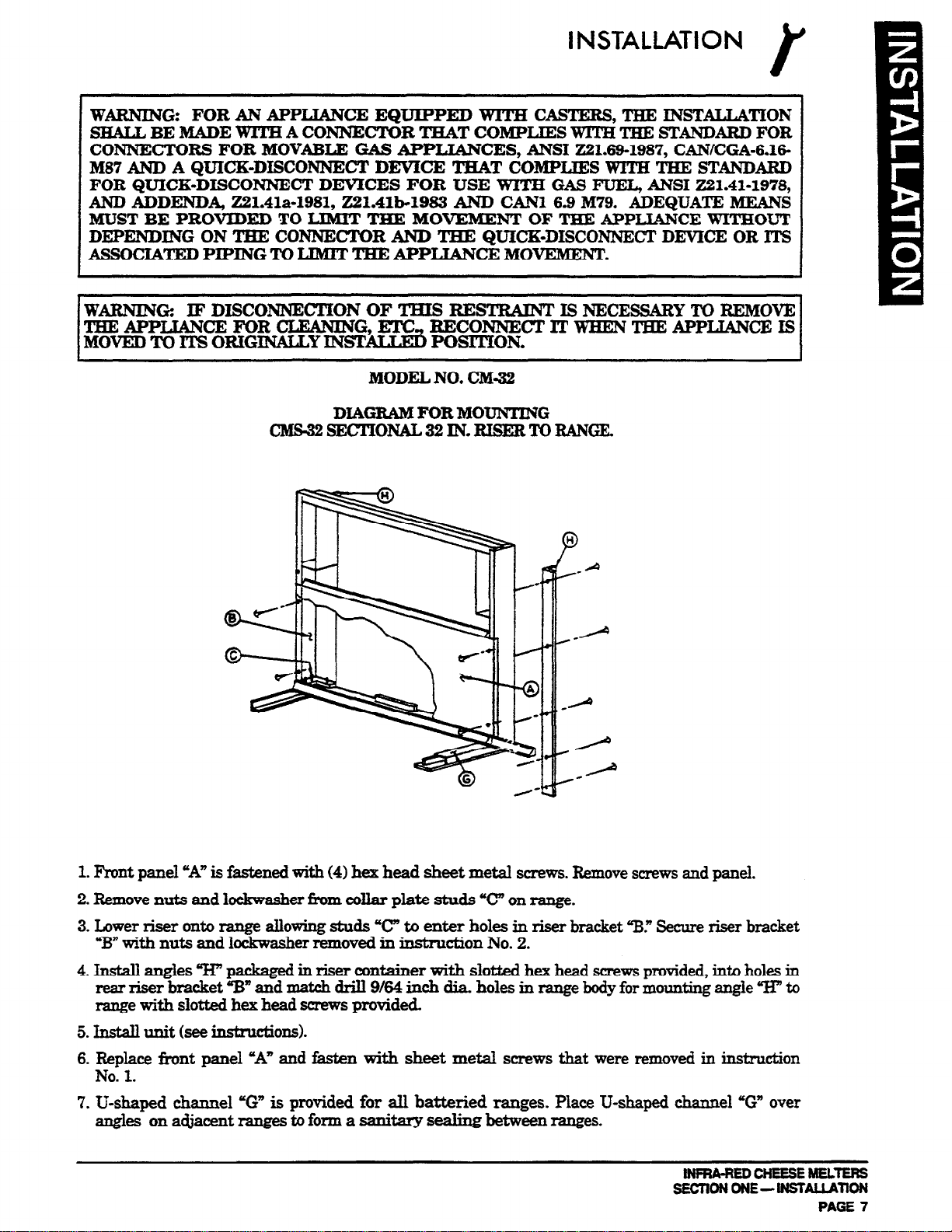

MODEL NO. CM-32

DIAGM FOR MOUNTING

CMS-32SECTIONAL32IN.RzsERTORANGE,

1. Front

2.

3.

panel “A” is fastened with (4) hex head sheet metal screws. Remove screws and panel.

Remove nuts and lockwasher f+om collar plate studs “C” on range.

Lower riser onto range allowing studs “C” to enter holes in riser bracket ‘EV Secure riser bracket

%= with nuts and lockwasher removed in instru~on No. 2.

4. Install angles W packaged in riser container with slotted hez head screws provided, into holes in

rear riser bracket ‘W and match drill 964 inch dia. holes in range body for mounting angle “IT to

range with slotted hex head screws provided.

5.

Install unit (see instnlctioIls).

6.

F&place fkont panel uA” and fasten with sheet metal screws that were removed in in&r&ion

No. 1.

7. U-shaped channel ‘G” is provided for all batteried ranges. Place U&aped channel ‘G” over

angles on adjacent ranges to form a sanitary sealing between ranges.

iNFRA-i?EDCHEESEMELTERS

sEcnoNoNE-lNsTALLAnoN

PAGE 7

Loading...

Loading...