Page 1

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this

manual for the life of the equi pment:

Model #: __________________________

Serial #: __________________________

Date Purchased: ___________________

OPERATOR'S MANUAL

Combination (Combi) Oven

Model CG90-1

! WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury or death. Read the installation, operating and maintenance instructions thoroughly before

installing or servicing this equipment.

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

(800) 348-2558 or (919) 552-9161 • FAX (800) 348-2558 or (919) 552-9798

MANUAL 1180963 COMBINATION OVEN

$18.00 MANUAL SECTION CB

Page 2

SAFETY PRECAUTIONS

Before installing a nd opera ting this equipm ent, be sure e ver yone invol ved in its operat ion is f ully tr ained and

aware of precautions. Accidents and problems can be caused by failure to follow fundamental rules and

precautions.

The following s ymbols, found throughout this manual, alert you to potentially dangerous conditions to the

operator, service personnel, or to the equipment.

! DANGER

! WARNING

! CAUTION

NOTICE

This symbol warns of immediate hazards that will result in severe injury or

death.

This symbol refers to a potential hazard or unsafe practice that could result in

injury or death.

This symbol refers to a potential hazard or unsafe practice that could result in

injury, product damage, or property damage.

This symbol refers to information that needs special attention or must be fully

understood, even though not dangerous.

! WARNING

FIRE HAZARD

FOR YOUR SAFETY do not store or use gas oline or other flamm able vapors and liqu ids in the

vicinity of this or any other appliance.

Keep area around appliances free and clear of combustibles.

Purchaser of equipment m ust post in a prom inent location, d etailed instruc tions to be f ollowed in the

event the operator smells gas. Obtain the instructions from the local gas supplier.

! WARNING

SHOCK HAZARD

Do not open panels that require use of tools.

Unit must be cleaned daily and properly maintained to reduce chances of unsafe operating

conditions.

! WARNING

BURN HAZARD

Watch for clogged drain - can crate burn hazard when door is opened.

Stand back when opening doors - hot steam, hot air, and/or hot water may escape from oven.

NOTICE

Be sure this Operator's Manual and important papers are given to the proper author ity to retain for

future reference.

PAGE 2OPERATOR’S MANUAL 1180963

Page 3

COMBINATION OVEN TABLE OF CONTENTS

Congratulations! You have purchased on e of the finest p ieces of heav y-duty comm ercial cook ing equipm ent

on the market.

You will find that your new equipm ent, like all Southbend equipment, has been desig ned and m anufactured

to meet the toughest standards in the indus try. Each piece of Southbend equipm ent is carefully eng ineered

and designs are verified through laboratory tests and field installations. With proper care and field

maintenance, you will experience years of reliable, trouble-free operation. For best results, read this

manual carefully.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Model Numbers

This manual is f or the Southbend C ombination Oven model CG 90-1 . The seria l plate is located behind the

lower front panel on the left side.

Table of Contents

Specifications..........................................................................................................................4

Installation...............................................................................................................................6

Operation ..............................................................................................................................14

Cooking Hints........................................................................................................................17

Cleaning................................................................................................................................22

Troubleshooting ....................................................................................................................24

Parts......................................................................................................................................32

Read these instructions carefully before attempting installation. Installation and initial startup should be

performed by a qualified installer. Unless the installation instructions for this product are followed by a

qualified service tech nician (a person experienced in and knowledge able with the insta llation of comm ercial

gas an/or electric cooking equipm ent) then the terms and conditi ons on the Ma nufactur er's Lim ited W arranty

will be rendered void and no warranty of any kind shall apply.

In the event you have questions concerning the installation, use, care, or service of the product, write to:

Technical Service Department

Southbend

1100 Old Honeycutt Road

Fuquay-Varina, North Carolina 27526 USA

OPERATOR’S MANUAL 1180963 PAGE 3

Page 4

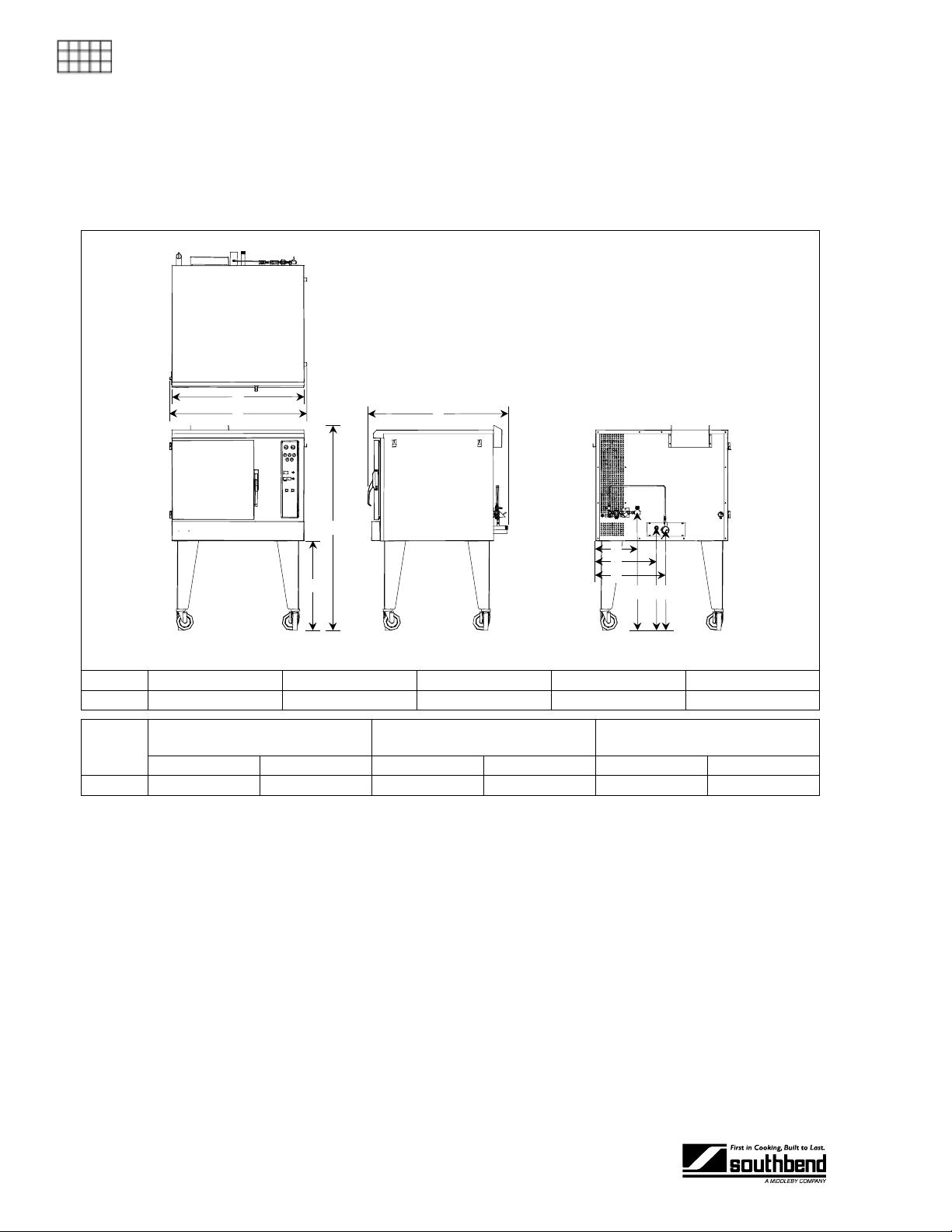

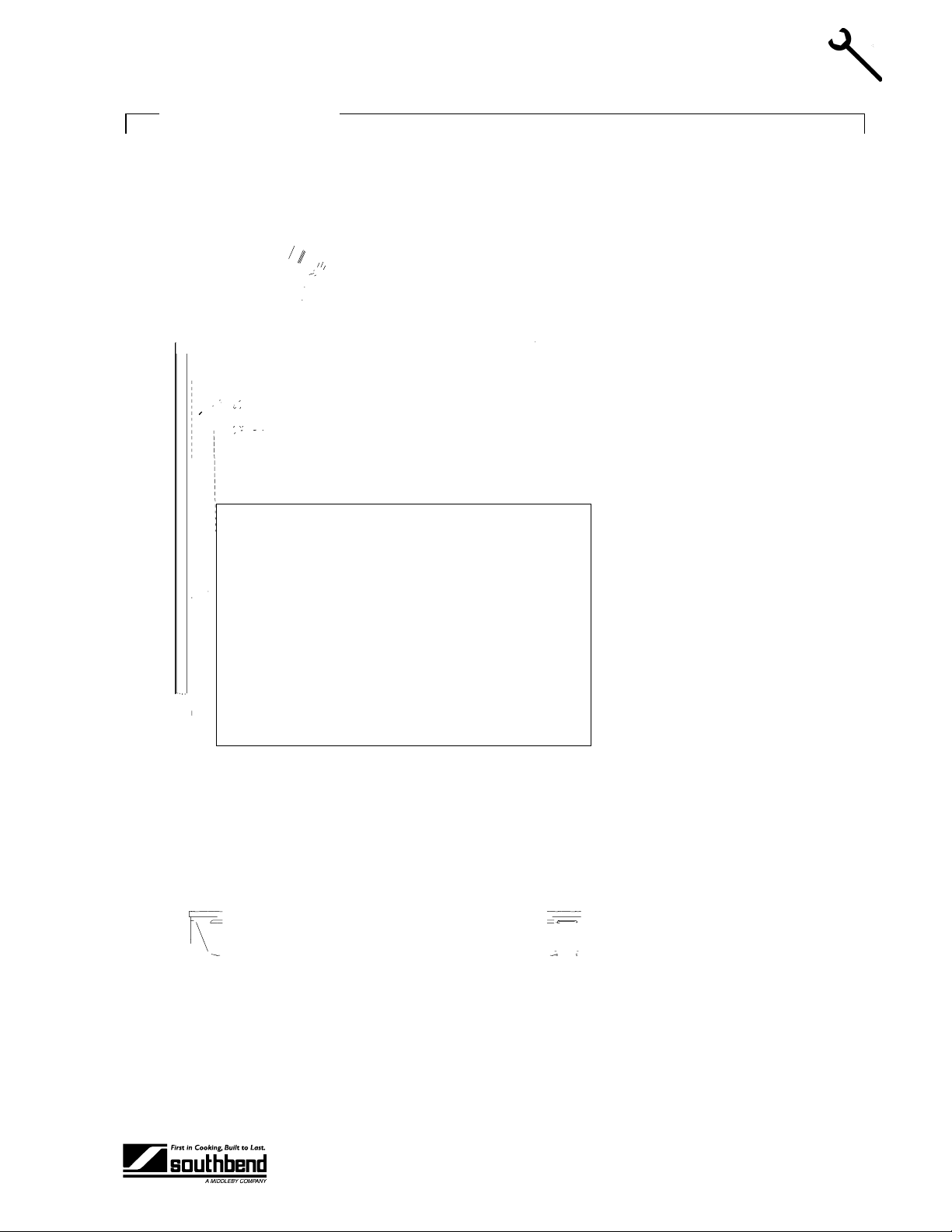

SPECIFICATIONS COMBINATION OVEN

SPECIFICATIONS

SPECIFICATIONS

DIMENSIONS

A

B

E

D

F

G

C

Internal Dimensions: 20.75" Wide, 31.75" Deep, 22" High

Model Cabinet Width (A) Overall Width (B) Leg Height (C) Overall Hei ght (D) Overall Depth (E)

CG90-1 38" 39.6" 25.9" 59.1" 40.3"

Water Connection

Model

CG90-1 12.6" 33.9" 17.5" 29.5" 20.2" 28.9"

3/8" NPT (Female)

From Right (F) Above Floor (I) From Right (G) Above Floor (J) From Right (H) Above Floor (K)

Gas Supply Connection

3/4" NPT (Male)

H

JKI

Drain Tube

2" OD

GAS

Burners total 90,000 BTU. Supply pressure s hould be > 7 " W.C. for natural gas or > 11" W .C. for propane.

One 3/4" NPT male connector located on back, 17.5" from right side, 29.5" above floor (see above figure).

WATER

Cold water consumption is regu lated to approximately 0.5 gallons per minute. Water pressur e 30 psi (205

kPa) minimum, 60 psi. (410 kPa) maximum. To minimize service problems and to meet warranty

requirements, a water treatment system (softener) is recommended if water quality does not meet the

following specif ications: total dissolv ed solids (TDS) 60 ppm , hardness 2 grains or 3 5 ppm, pH f actor7.0 to

7.5. Install a water treatment system ( softener) if necess ary. Connector is a 3/8 " female NPT "tee" loc ated

on the back of the oven, 12.6" from right side, 33.9" above floor (see above figure).

DRAIN

Drain line is a 2" OD t ube extendi ng from the back of the ove n, 20.2" f rom right side, 28.9" abo ve floor (see

above figure). Drain outlet must be unobstructed and free-venting to atmospheric pressure! See page 11.

PAGE 4OPERATOR’S MANUAL 1180963

Page 5

COMBINATION OVEN SPECIFICATIONS

ELECTRIC

Maximum 8.0 amps (use 15 amp circuit breaker). Three voltage options:

120 VAC, 60 Hz, 1 phase: Six-foot cord with three-prong plug (standard option).

208 VAC, 60 Hz, 1 or 3 phase: Wire junction box to terminal block located near rear of motor compartment.

240 VAC, 60 Hz, 1 or 3 phase: Wire junction box to terminal block located near rear of motor compartment.

All units are shipped single-phase. Single-phase units can be easily operated on three-phase systems.

CLEARANCES

See page 8.

CONSTRUCTION (BIDDING) SPECIFICATIONS

Commercial Gas Combination Steamer/Convection Oven, Single Deck:

39.6" Wide, 59.1" High (including 25.9" legs), 40.3" Deep.

Exterior Finish: Oven front, sides, and top #3 finish stainless steel. Back aluminized steel.

Door: Single door, insulated #304 stainless steel construction (interior and exterior), positive door catch,

single action release.

Oven Interior: #304 stainless steel, including heat exchangers and baffle.

Rack & Rack Guides : Stainless s teel heav y-duty removabl e wire rack guides spaced on 1-5/8" c enters of fer

11 rack positions. Stainless steel heavy-duty removable safety-stop racks are provided with each cavity.

SPECIFICATIONS

Blower Fan & Motor : 1/2 horsepo wer, 2-spee d motor, 1725/11 40 rpm. Motor mounte d in na turally v entilated

compartment, away from heat zone. Motor serviceable from right side.

Control Panel: Located on front, at right side of oven, away from heat zone. Panel slides out for easy

servicing.

Solid State Controls allow oper ator to selec t Convection O ven, Convect ion Steam er or Com bination modes,

in addition to controlling fan speed, steam injection, and cool-down modes. Time/temperature dial

controls with digital disp lays.

DESIGN FEATURE SPECIFICATIONS

• Condensate spray with free venting exhaust

• Automatic cool down mode

• Interior washdown hose

• Rear condensate drain

NOTICE

INTENDED FOR COMMERCIAL USE ONLY. NOT FOR HOUSEHOLD USE.

OPERATOR’S MANUAL 1180963 PAGE 5

Page 6

INSTALLATION COMBINATION OVEN

INSTALLATION

Do not locate unit adjacent t o any high heat or greas e pr od uc in g p iece of eq ui pment, such as a range

top, griddle, fryer, etc., that could allow radiant heat to raise the exterior temperature of the

INSTALLATION

combination oven above 130°F (54°C). DO NOT MOUNT ABOVE OTHER COOKING EQUIPMENT.

These installation procedures must be followed by qualified personnel or warranty will be void.

Local codes regarding install ation var y greatly from one area to an other. T he National F ire Protec tion

Association, Inc. states in its NFPA 96 latest edition that local codes are the “authority having

jurisdiction” when it com es to installation r equirements for equipment. Theref ore, installations shou ld

comply with all local codes.

! CAUTION

NOTICE

The unit, when installed, must be electrically grounded and comply with local codes, or in the

absence of local codes with the Nation al Electrical Code, ANSI/NFPA 70, or the Canadian Electr ic

Code, CSA C22.2, as applicable.

Installation must comply with National Fuel Gas Code, ANSI Z223.1, Natura l Gas Installation Code,

CAN/CGA-B149.1, or the Propane Installation Code, CAN/CGA-B149.2, as applicable.

Step 1: Unpack

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers shou ld be examined for dam age before and during unlo ading. The freight car rier has

assumed responsibility for its safe transit and delivery. If damaged equipment is received, either

apparent or concealed, a claim must be made with the delivering carrier.

Apparent damage or l oss m u st be noted on the freight b ill at the t im e of deliver y. T he f reight bi ll m ust

then be signed by the c arrier representative (Dr iver). If the bill is not sign ed, the carrier may ref use

the claim. The carrier can supply the necessary forms.

A request for insp ection must be m ade to the carrier within 15 da ys if there is concea led damage or

loss that is not apparent until after the equipment is uncrated. The carrier should arrange an

inspection. Be certain to hold all contents plus all packing material.

1. Uncrate carefully. Report any hidden damage to the freight carrier IMMEDIATELY.

2. Do not remove any tags or labels until unit is installed and working properly.

PAGE 6OPERATOR’S MANUAL 1180963

Page 7

COMBINATION OVEN INSTALLATION

Step 2: Install the Legs

A set of legs is pac k ed in the unit. The le gs c an be a dj us ted t o o ver come a slightly une ve n f loor. When legs

with casters have been ordered, the casters are provided with a Zerk fitting for proper lubrication when

required.

1. Raise oven sufficiently to allow legs to be bolted to the bottom corners. For safety, “shore up” and

INSTALLATION

OPERATOR’S ANUAL 1180963 PAGE 7

Page 8

INSTALLATION COMBINATION OVEN

Step 3: Check Clearances and Ventilation

There must be adequate clearance between oven(s) and construction. Clearance must also be

provided for servicing and for operation.

Minimum Clearances:

From Combustible Construction From Non-Combustible Construction

Back 7" 0”

INSTALLATION

Adequate clearance must be prov ided in the ais le and at the side and rear to allo w the do or to open

sufficiently to permit the removal of the racks and for serviceability.

No additional clearance is required for service as the ovens are servicable from the front.

Right Side 0" 0"

Left Side 0" 0"

Floor 0" 0"

! WARNING

! WARNING

Improper ventilation can result in personal injury or deat h. Ventilation which f ails to properly rem ove

flue products can cause headaches, drowsiness, nausea, or could result in death.

All units must be installed in s uch a manner that the flow of com bustion and ventilation air are not

obstructed. Provisions f or adequate air sup ply must be provided. Do not obstruct the f ront or rear of

the unit, as combustion air enters through this area. Be sure to inspect and clean the ventilation

system according to the ventilation equipment manufacturer’s instructions.

NOTICE

Proper ventilatio n is the owner's responsibilit y. Any problem due t o improper ventilation will not be

covered by the warranty.

Canopies are set over ranges, ovens, etc., for ventilation purpos es. It is r ecomm ended that a ca nopy extend

6” past the applianc e and the bottom edge be locat ed 6’6” from the f loor. Filters should be installed at an

angle of 45° or m ore from the horizontal . This positio n prevents drippi ng gr ease and faci litates collect ing the

run-off grease in a drip pan, unusually installed with a filt er . A st rong ex haus t f an ten ds to c reat e a vac u um in

the room and may interfere with burner performance or may extinguish pilot flames. Fresh air openings

approximately equal to the fan area will relieve such a vacuum.

The exhaust fan should be installed at least 2” above the vent opening at the top of the unit.

In case of unsatisfactory performance on any appliance, check the appliance with the exhaust fan in the

“OFF” position. Do th is on l y lo ng eno ugh to c heck equipment perf ormance. Then turn hoo d b ac k on and let it

run to remove any exhaust that may have accumulated during the test.

PAGE 8OPERATOR’S MANUAL 1180963

Page 9

COMBINATION OVEN INSTALLATION

Utility Connections

INSTALLATION

OPERATOR’S ANUAL 1180963 PAGE 9

Page 10

INSTALLATION COMBINATION OVEN

Step 4: Electrical Connections

A wiring diagram is located inside the control compartment on the right side of the pull-out control-panel

assembly. To access the control-pan el compartment, rem ove the screw at the top of the control pa nel and

pull the control panel out.

Units ordered with a 115VAC, 60Hz, sin gle-phase elec trical ratin g are fac tory-supplie d with t hree-wire cord

and three-prong plug, which fits any standard three-prong grounded receptacle.

Units ordered with a 208/240VAC, 60Hz, singl e- o r three-phase electric al r a ting are factory-equip pe d with a

2-pole terminal block located behind a cover plate located at the rear of the unit. To connect the supply

wires, remove the a ppropriate cover pl ate. Route t he suppl y wires a nd t he groun ding wire thro ugh th e str ain

relief fitting to the ter minal block . Insert the supply wires , one each, into the t wo poles of the terminal block

INSTALLATION

and tighten the screws. Insert the ground wire into the grounding lug and tighten the screw. Re-attach t he

cover plate.

Three phase units are wired as above, using on ly two supply wires. T he third wire is not used and must be

properly terminated.

All units are shipped wired as sp ecified b y factory order. Conversion between single- phase and three-phase

can be accomplis hed by referring to phase lo ading and line amperes chart on wiring diagram for wire size

and ampere requirements.

! WARNING

A POSITIVE GROUND CONNECTION IS ESSENTIAL. DO NOT ALLOW ANY TAMPERING OR

ADJUSTMENT OF ANY CONTROL OR WIRING. T HE UNIT IS FACTORY SET. ADJUSTING ANY

INTERNAL COMPONENT OTHER THAN THE MAIN FUSE BLOCK CAN VOID THE WARRANTY.

! WARNING

ELECTRICAL GROUNDING INSTRUCTIONS

This appliance is equipped with a three-prong (grounding) plus for your protection against shock

hazard and should b e plugg ed dir ectl y into a pr operl y ground ed thr ee-pro ng rece ptacl e. Do n ot cut or

remove the grounding prong from the plug.

Step 5: Connect Water Supply

Connect a cold water line to the 3/8" fem ale NPT "tee" connector located on the back of the oven (at the

lower left-hand side when facing the back of the oven, see figure on page 9).

To facilitate cleaning, plus allow access to the rear of the unit, flexible connections are recommended.

NOTICE: WATER SPECIFICATION

To meet warranty requirements, supply water must meet the following specification:

Pressure ...........................................30 to 60 psi (205 to 410 kPa)

Total Dissolved Solids (TDS) ...........60 PPM

Hardness ..........................................2 Grains or 35 PPM

pH Factor..........................................7.0 to 7.5

PAGE 10 OPERATOR’S MANUAL 1180963

Page 11

COMBINATION OVEN INSTALLATION

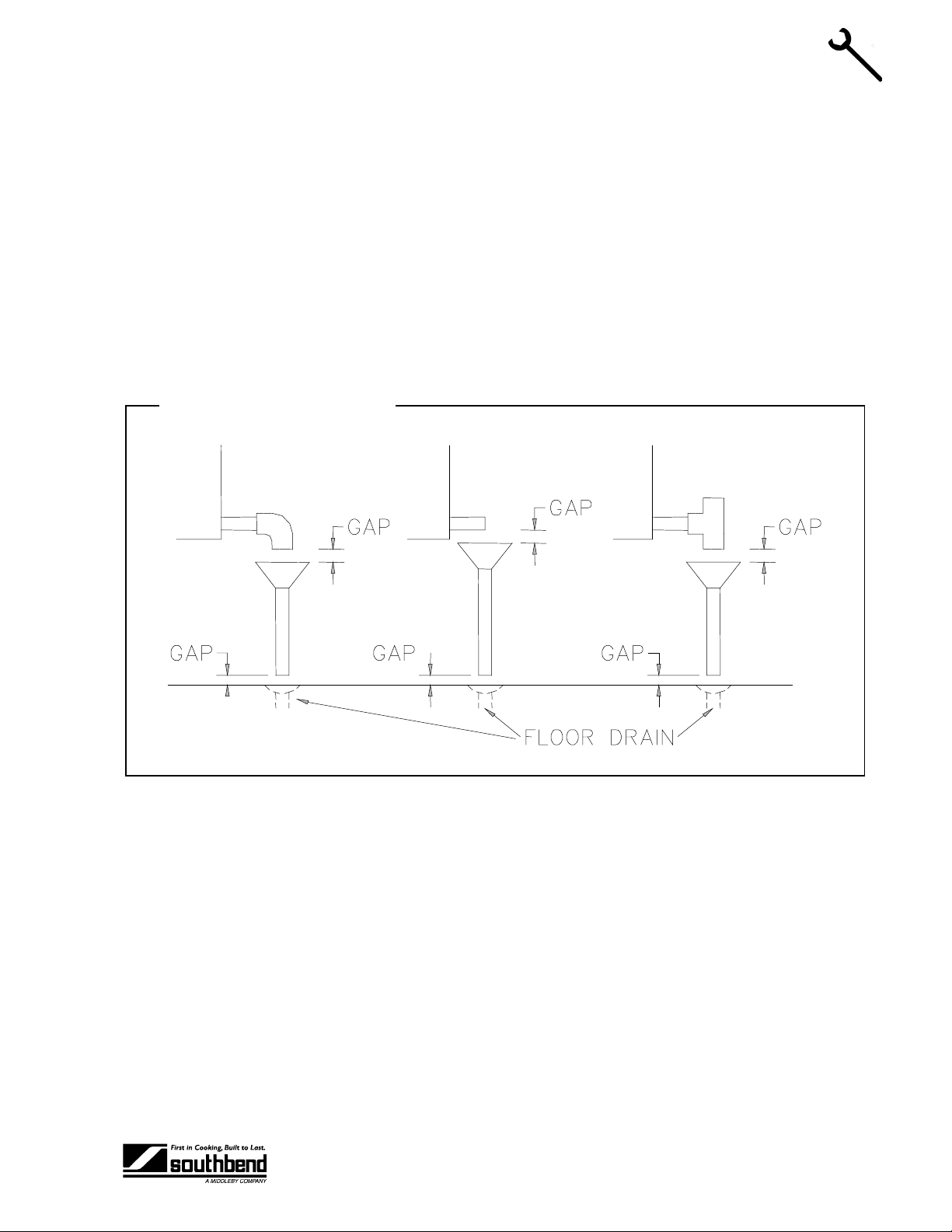

Step 6: Water Drain

The drain line from the oven is a 2" O.D. tube (see figure on page 9) . Positi on the ove n near, but n ot on top

of, an open floor drain. DO NOT directly plumb to the oven unless you also install an “open funnel”

downstream of this connectio n in the drain s ystem. Make the drain li ne f rom the unit to the air g ap a bo ve t he

"open funnel" as shor t as possible. T here should be no h orizontal piping bet ween the oven and the air gap

over the "open funnel." T he "o pen funnel" is in ten ded to el iminate any water from entering the oven bec aus e

of a blocked drain, and it also prevents an y back pressure within the oven cavity. The o ven must be f reeventing to the atmosphere. A ny connection th at allows the b uild-up of back pressure in the o ven (such as a

reduction in pipe s i ze t o a lin e s maller than 2" or a 9 0 de gree angle in the line pr ior to t he "open funn el " dr ain

discharge point) may cause personal or property damage and therefore will void the warranty. This is a

pressureless, free- venting ove n and will not o perate proper ly unless the drain line is short, at a steep angle ,

and open!

Water Drain Open Funnel

INSTALLATION

OPERATOR’S ANUAL 1180963 PAGE 11

Page 12

INSTALLATION COMBINATION OVEN

Step 7: Gas Connection

If this equipment is being installed at over 2, 000 feet altitude an d that information was not specified when

ordered, contact the appropriate authorized Southbend Service Representative or the Southbend Service

Department. Failure to install with proper orifice sizing will result in poor performance and may void the

warranty.

The serial plate is located behind the lo wer f ront pane l on th e lef t side. It ind icates th e t ype of gas the u nit is

equipped to burn. All Southbend equipment is adjusted at the factory. Check type of gas on serial plate.

This appliance should be connected ONLY to the type of gas for which it is equipped.

A 3/4" male NPT line is provided at the rear for the connection. Each oven is equipped with an internal

pressure regulator whic h is s et f o r 4 " W.C. manifold pres s ure f or natur a l g as or 1 0.0 " W.C. manifold pres s ure

INSTALLATION

for propane gas. Use the 1/8" tap on the top of the gas valve for checking pressure.

If applicable, the ven t line from the gas appliance pressure regulator shall be installed to the outdoors in

accordance with local codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1, Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Installation Code, CAN/CGAB149.2, as applicable.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of gas

required for satisf actor y perf ormanc e. Fluctua tions of m ore than 25% on nat ural gas or 10% on pro pane gas

will create problem s and affect burner operating char acteristics. A 1/8” pressure tap is located on the gas

valve to measure the manifold pressure.

An adequate gas s upp ly li ne t o th e u nit s hou ld be n o s maller than the I.D. of the pipe from the unit to which it

is connected.

Purge the supply line to clean out dust, dirt, or other foreign matter bef ore connecting the line to the unit.

Each oven has a manual shut off valve located behind the lower front panel.

Use pipe joint compound which is suitable for use with LP gas on all threaded connections.

! CAUTION

ALL PIPE JOINTS AND CONNECTIONS MUST BE TESTED THOROUGHLY FOR GAS LEAKS.

USE ONLY SOAPY W ATER FOR TESTING O N ALL GASES. NEVER USE AN O PEN FLAME T O

CHECK FOR GAS LEAK S. ALL CONNECTIONS MUST BE CHEC KED FOR LEAKS AFTER T HE

UNIT HAS BEEN PUT INTO OPERATION. TEST PRESSURE SHOULD NOT EXCEED 14” W.C.

PAGE 12 OPERATOR’S MANUAL 1180963

Page 13

COMBINATION OVEN INSTALLATION

Step 8: Installation and Performa nce C heck

The following items should be checked by a qualified service technician:

1. Verify that oven is level.

2. Verify proper electrical characteristics (voltage, cycle, phase).

3. Check ventilation.

4. Check electrical connections (external and internal).

5. Check door(s) for proper alignment, tension, seal, and adjustment.

6. Check timers, switches and motor for proper installation and operation.

7. Check for any damage to unit from shipping or installation.

8. Check for proper clearance from combustible materials.

9. Verify proper type of gas.

10. Verify gas supply pressure (pressure regulator is already installed at factory).

11. Check gas connection and check for gas leaks.

12. Check water connection and check for water leaks.

It is common for new products to require a burn-off time to dry out insulation and metal cooking surfaces.

INSTALLATION

OPERATOR’S ANUAL 1180963 PAGE 13

Page 14

OPERATION COMBINATION OVEN

OPERATION

NOTICE

No attempt should be made to operate oven during a power failure.

A manual gas shutoff valve is located behind front lower panel for turning gas on and off.

OPERATION (FOR STANDARD CONTROL OPTION)

Lighting the Combi – The Combi has an inter m ittent st anding pilot . When the un it is turn ed o n, the light ing

sequence is control led by an ignition module. A hot surface ignitor ignites th e pilot, which stays lit for the

entire time the Combi is turned on and the flame is proven by the flame sensor.

Re-Lighting the Combi – If the Combi does not light on the first attempt, do the following:

1. Shut off all gas.

OPERATION

2. Wait five minutes.

3. Repeat lighting instructions above.

Turning the Combi On and Off – The power switch at t he top left c orner of th e control pane l turns the unit

on and off. When the power switch is tur ned on, the Com bi begins a diagnostic check and in itiates the pilot

lighting sequence. If the diag nostic c heck or the lighti ng se quence fails, a cod e wor d will appear in the t ime

display and operation wi ll be sus pend ed. Ot herwis e the un it wil l beg in opera tio n in th e startu p def ault m ode,

which is oven mode at 350ºF.

Choosing Fan Speed – The Combi has a two speed fan whic h c an b e controlled with the f an speed selector

switch at the upper right hand corner of the control panel.

Choosing the Cooking Mode

Oven Mode is selected by pressing the OVEN button, which causes t he light above the OVEN button to

illuminate. In oven mode, the Combi acts exactly like a convection oven. If when the OVEN mode

button was pressed the unit is not at the setpoint tem perature, the tem perature dis pla y will flash unt il the

setpoint temperature is reached.

Steam Mode is selected by pressing th e STEAM b utton, which ca uses the light above the ST EAM button to

illuminate. In steam mode, the Com bi ac ts ex ac tl y lik e a pr es sur eles s c ou nter to p c on vect ion s t eamer. If

when the STEAM mode button was pressed the uni t is not at the setp oint temperatur e, the temperatur e

display will flash until the s etpoint temperature is reached. In steam m ode, the setpoint temperatur e is

preset to 215ºF, to allow pure, slightly superheated steam to circulate within the cavity.

Combi Mode is selected by pressing th e COMBI button, which c auses the light abov e the COMBI button to

illuminate. In com bi mode, a high m oisture cooking envir onment is create d through caref ully controlled

humidification. If when th e COMBI m ode butto n was press ed the un it is not at t he setpo int temper ature,

the temperature display will flash until the setpoint temperature is reached.

Steam Inject Mode is the only mode that c an used in conjunc tion with another c ooking mode, nam ely oven

mode. Pressing the STEAM INJECT button ca uses s team to be delivered to t he c avi t y for as l ong as th e

button is held. The intent is to provide the des ired surface c haracteristics (crispy, shiny crus t) on bread

products, and for any other products that would benefit from timely steam injections.

Vent/Cool Mode is designed to quickly cool t he cavi ty from a high setpo int tem perature to a low tem perature

using a combination of high fan speed and a cooling spray of water

PAGE 14 OPERATOR’S MANUAL 1180963

Page 15

COMBINATION OVEN OPERATION

Setting Cooking Temperature – The cooking temperature can be s et in oven mode and Com bi mode but

not in steam mode. In steam mode, the setpoint temperature is preset to 215ºF, to allow pure, slightly

superheated steam to circulate within the cavity. The t emperature range in oven mode and Com bi ode is

145ºF to 500ºF.

Setting Cooking Time – The cooking tim e can be set by turning the tim e knob to the d esired setting and

pressing the START/INT ERRUPT button. W hen the tim er tim es out, the alarm sounds. Ho wever, the oven

continues to run in the mo de and at t he temper ature th at w ere in effect when the time expired. If the

cooking mode is changed while the tim er is counting down, the tim er simply continues to count do wn. If the

timer is timed out (00:00) when the cook ing mode is changed, then the unit runs continuously in the new

mode. To disable the beeper after the timer has expired, press the START/INTERRUPT button ag ain. The

CANCEL button will reset the time to zero.

OPERATION

OPERATOR’S ANUAL 1180963 PAGE 15

Page 16

OPERATION COMBINATION OVEN

Operation of Combination Oven with Standard Controls

OPERATION

PAGE 16 OPERATOR’S MANUAL 1180963

Page 17

COMBINATION OVEN COOKING HINTS

COOKING HINTS

All times and tem peratures are estimates and s hould be verified in actua l practice. Starting tem perature of

food, pan size/fullness, and opening oven during cooking will affect cooking times.

Baked Goods

Menu Item Mode Temperature Cooking Time Proper Pan Tips

Apple pie, mile-high Oven 350°F/175°C 50 min. Pie tins on

wire racks

Biscuits Oven 325°F/165°C 15 min. Sheet pan Can also use Combi mode at

350°F/175°C

Biscuits, cinnamon raisin Oven 325°F/165°C 15 min. Sheet pan Also try in Combi mode

Bread sticks (soft style, raw

dough)

Cake layers Oven 300°F/150°C 25 min. Sheet pans

Carrot cake layers Oven 325°F/165°C 25 min. Sheet pans

Cheesecake Combi 325°F/165°C 1 hour

Cherry crisp Combi 325°F/165°C 30 min. 2 ½” pan,

Chocolate brownies Oven 325°F/165°C 25 min. Sheet pans

Coffee cake, apple Oven 300°F/150°C 25 min.

Coffee cake, sour cream Oven 300°F/150°C 25 min. Also try in Combi mode

Cookies, butter sugar Combi 300°F/150°C 10 min. Sheet pan Also try in oven mode

Cookies, oatmeal raisin Oven 325°F/165°C 15 min. Sheet pan

Cookies, peanut butter

chocolate chunk

French bread Combi 375°F/190°C 20 min. Sheet pan See hard roll procedure

Hot seasoned apples Combi 250°F/120°C 15 min. 2 ½” pan,

Combi 325°F/165°C 10 min. Sheet pan 375°F/190°C for crispier sticks

uncovered

Oven 300°F/150°C 12 min. Sheet pan Higher temperature for crispier

cookies

uncovered

COOKING HINTS

Muffins (blueberry, banana nut) Oven 350°F/175°C 20 min. Muffin pans Preheat to 400°F/205°C, load

oven,, turn off for 6-8 min., then

bake at indicated temperature

Rolls, dinner Combi 325°F/165°C 20 min.

Rolls, hard Combi 375°F/190°C

250°F/120°C

350°F/175°C

Rolls, sweet Combi 325°F/165°C 20 min. Sheet pan Also try in oven mode

Rolls, whole wheat Combi 325°F/165°C 25 min. Sheet pan

OPERATOR’S MANUAL 1180963 PAGE 17

Preheat

5 min.

15 min.

Sheet pan Low temp stage produces better

crust – can be eliminated – keep

total time

Page 18

COOKING HINTS COMBINATION OVEN

Beef and Veal

Menu Item Mode Temperature Cooking Time Proper Pan Tips

BBQ beef (raw brisket) Combi 250°F/120°C

375°F/190°C

Beef Sausage links Steam 350°F/175°C 10 min. May also be steamed

Braised beef w/mushrooms Combi 250°F/120°C 1 hour 2 ½” pan,

Corned beef hash Combi 250°F/120°C 25 min. 2 ½” solid pan

Fillet steak Combi 500°F/260°C 10 min. Oiled sheet

Grilled flank steak Combi 500°F/260°C 10 min. Wire rack Oil steak

Hamburger pie Combi 325°F/165°C 30 min. 2 ½” pan,

Hamburgers (Frozen patties) Combi 400°F/205°C 10 min. Perforated

Herbed pot roast Combi 250°F/120°C 3 hours 2 ½” solid pan

Hot dogs Steam N/A 7 min. 2 ½”

London broil Combi 500°F/260°C 15 min. Preheated

COOKING HINTS

90 min. + 10

min at higher

temp.

Cook with sauce at low heat,

raise temp. to set glaze

uncovered

pan

uncovered

sheet pan

perforated

Oil steaks

racks

Marinated sirloin steak Combi 500°F/260°C 10 min. Oiled sheet

pan

Meatloaf Combi 300°F/150°C 40 min. 2 ½” pan,

uncovered

New York strip Combi 500°F/260°C 8 min. Wire racks Oil steaks

Prime Rib Combi 275°F/135°C 2 ½ hours Wire rack Bone in - Export 10-12lbs

Ribeye sandwich steak Combi 500°F/260°C 5 min. Wire rack and

catch pan on

bottom

Roast beef Combi 275°F/135°C 2 ½ hours Sheet pan or

wire rack

Roast beef hash (re-therm) Combi 250°F/120°C 25 min. 2 ½” solid pan

Rump steak Combi

Salisbury steak w/gravy

(re-therm)

Teriyaki steak Combi 400°F/205°C 10 min. Sheet pan

Combi 250°F/120°C 20 min. 2 ½” solid pan

Brush w/melted butter, preheat

oven well

PAGE 18 OPERATOR’S MANUAL 1180963

Page 19

COMBINATION OVEN COOKING HINTS

Fish and Shellfish

Menu Item Mode Temperature Cooking Time Proper Pan Tips

Crab Steam N/A 8-10 min. 2 ½”

perforated pan

Halibut Combi 325°F/165°C 6 -7 min. ½ size sheet

pan

Perch Oven 400°F/205°C 5 min. Sheet pan Brush pan w/oil and season fish

Salmon (fresh) Combi 325°F/165°C 8-10 min. 2 ½”

perforated

Shrimps – frozen Steam N/A 3-5 min. 2 ½”

perforated pan

Trout Oven 400°F/205°C 5 min. Sheet pan Brush pan w/oil and season fish

20-25 ct.

Pork and Lamb

Menu Item Mode Temperature Cooking Time Proper Pan Tips

Bacon slices Combi 325°F/165°C 15 min. Sheet pan Single layer

Baked ham Combi 300°F/150°C 1 hour Sheet pan

Baked pork chops Combi 325°F/165°C 20 min. Sheet pan Single layer

BBQ boneless rib for sandwich

(retherm)

BBQ pork for sandwich (Boston

butts, raw)

Bratwurst Steam N/A 10 min. 2 ½”,

Canadian bacon Combi 400°F/205°C 5 min. Sheet pan Single layer

Grilled butterflied pork chops Combi 400°F/205°C 10 min Sheet pan Oil chops

Grilled ham slice Combi 400°F/205°C 10 min. Wire rack Preheat to 450F

Combi 250°F/120°C 15 min. Sheet pan

Combi 250°F/120°C 2 hours Sheet pan,

with sauce

uncovered

COOKING HINTS

Grilled pork cutlet Combi 400°F/205°C 15 min. Sheet pan Single layer

Grilled pork tenderloin Combi 400°F/205°C 15 min. Oiled, wire

rack

Italian sausage Combi 375°F/190°C 15 min. Sheet pan

Kielbasa Combi 375°F/190°C 15 min. Sheet pan Single layer

Knockwurst Steam N/A 15 min. 2 ½”

perforated pan

Pork sausage link Combi 350°F/175°C 15 min. Sheet pan Single layer

Roast pork Combi 300°F/150°C 50 min. Sheet pan or

wire rack

Sausage patties Combi 300°F/150°C 15 min. Sheet pan Steam for better yield

OPERATOR’S MANUAL 1180963 PAGE 19

150F internal, rest 20 minutes

Page 20

COOKING HINTS COMBINATION OVEN

Potatoes, Pasta, and Grains

Menu Item Mode Temperature Cooking Time Proper Pan Tips

Baked potatoes Oven 375°F/190°C 40 min. Sheet pan

Poultry

Vegetables

COOKING HINTS

New, red potatoes Steam N/A 17 min. 2 ½”

perforated

Rice (short grain) Steam N/A 20 min. 2 ½” pan,

covered

Menu Item Mode Temperature Cooking Time Proper Pan Tips

Chicken wings Combi 375°F/190°C 15 min. Sheet pan

Chicken, half Combi 325°F/165°C 25 min. Sheet pan

Chicken, whole Combi 325°F/165°C 35 min. Sheet pan

Turkey Combi 375°F/190°C 2 hrs, 15 min. Sheet pan

Turkey breast Combi 325°F/165°C 1 hour Sheet pan

Menu Item Mode Temperature Cooking Time Proper Pan Tips

Asparagus Steam N/A 8 min. 2 ½”

perforated

Asparagus & egg au gratin Steam N/A 14 min. 2 ½” solid

Cut in quarters

2 parts rice, 1 part stock

Beans (frozen, whole or cut) Steam N/A 12 min. 2 ½”

perforated

Broccoli (fresh spears) Steam N/A 8 min. perforated

Broccoli cheese casserole Combi 300°F/150°C 30 min. 2 ½” solid

Cabbage Steam N/A 15 min. 2 ½”

perforated

Cabbage, red (frozen) Steam N/A 18 min. 2 ½”

perforated

Carrots, fingerling Steam N/A 10 min. 2 ½”

perforated

Carrots, glazed (frozen

w/ sauce)

Carrots, sliced (raw) Steam N/A 12min. 2 ½”

Cauliflower (fresh florets) Steam N/A 8 min. 2 ½”

Corn (frozen niblets) Steam N/A 8 min. 2 ½”

Corn on the cob Steam N/A 12 min. 2 ½”

Steam N/A 10 min. 2 ½” pan,

uncovered

perforated

perforated

perforated

perforated

Blanch fresh, cold water

Remove stalk

PAGE 20 OPERATOR’S MANUAL 1180963

Page 21

COMBINATION OVEN COOKING HINTS

Vegetables, continued

Menu Item Mode Temperature Cooking Time Proper Pan Tips

Green beans w/water chestnuts Steam N/A 10 min. 2 ½”

perforated

Green beans, French cut

(frozen)

Green beans, whole Steam N/A 10 min. 2 ½”

Italian vegetables (frozen) Steam N/A 13 min. 2 ½”

Mixed vegetables (frozen) Steam N/A 10 min. 2 ½”

Mushrooms Steam N/A 8 min. 2 ½” solid pan Sprinkle w/lemon, white wine

Peas and mushroom (frozen) Steam N/A 14 min. 2 ½”

Peas, garden (frozen) Steam N/A 7 min. 2 ½”

Ratatouille Combi 300°F/150°C 20 min. 2 ½” solid pan Toss with oil before cooking

Snap peas, sugar (frozen,

seasoned)

Spinach (fresh) Steam N/A 7 min. 2 ½”

Spinach (frozen) Steam N/A 14 min. 2 ½”

Steam N/A 10 min. 2 ½”

perforated

perforated

perforated

perforated pan

perforated

perforated

Steam N/A 10 min. 2 ½” pan,

uncovered

perforated pan

perforated

Separate ice-encased

vegetables

Separate ice-encased

vegetables

COOKING HINTS

Squash (fresh) Steam N/A 7 min. 2 ½”

perforated

Vegetable primavera casserole Combi 275°F/135°C 30 min. 2 ½” solid pan

Vegetarian stir-fry Combi 375°F/190°C 10 min. 2 ½”

perforated

Zucchini (fresh) Steam N/A 7 min. 2 ½”

perforated

Zucchini w/ basil Steam N/A 7 min. 2 ½”

perforated

Toss w/oil, add sauce after

cooking

OPERATOR’S MANUAL 1180963 PAGE 21

Page 22

CLEANING COMBINATION OVEN

CLEANING

Southbend equipment is constructed with the best quality materials and is designed to provide durable

service when properl y maintained. To expect the b est performance, your equipment must be m aintained in

good condition and cleaned dail y. Naturally, the frequenc y and extent of cleaning depends on the amount

and degree of usage.

Following daily and more extensi ve peri odic maintenance proced ur es will increase the l if e of your equipment.

Climatic conditions (i.e., salt air, seasonings, and water quality) may result in the need for more thorough and

more frequent cleaning in order to keep equipment performing at optimal levels.

! WARNING: BURN HAZARD

For proper and safe operation, this oven must be cleaned daily as described in this manual. Failure

to do so could result in serious injury or damage.

Drains must be kept clean and clear of debris.

! WARNING: SHOCK HAZARD

DO NOT GET WATER IN THE CONTROLS.

This could result in expensive repairs and/or electrical shock.

CLEANING

VENT SYSTEM: At least twice a year, the unit's venting system should be examined and cleaned.

MOTOR: Lubrication information can be found on the permanent label located on motor.

DAILY CLEANING

• Use pump-up spr ayer (So uthbend P art# 1180973) supp lied with the unit to spra y RCS Specia l Clea ning

Agent (Southbend Par t# 1180974) ins ide the oven cav ity, behind the air baffle, and on t he inner side of

the door. (CAUTION : Do not spray RCS Special Cleaning A gent into a hot oven! Discolorat ion of the

interior surfaces wil l result. The oven tem perature must be be low 130ºF (55ºC) bef ore spraying cleaner

into the cabinet.)

• Turn the oven on and place the oven in STEAM mode for 15 minutes.

• If the unit is heavily soiled, repeat the above steps.

• Thoroughly rinse th e inside of the oven ca vity with the spra y nozzle and spra y hose assembly sup plied

with the unit.

De-energize all power to equipment before cleaning the equipment.

NOTICE

• Make sure drain opening is clear.

• Leave the door open at night after clean in g.

• Do not clean the door gasket with a high-chlorine solution or bleach.

• Do not use steel wool or other metallic pads in the oven.

PAGE 22 OPERATOR’S MANUAL 1180963

Page 23

COMBINATION OVEN CLEANING

PERIODIC CLEANING

• If lime or mineral deposit star ts to build up in the i nterior , clean t he u nit b y using Southb end “ descal er” or

other non-caustic de liming solution. Fol low manufacturer’s r ecommended procedures. T horoughly rinse

out unit with clean water.

• To remove normal dirt, grease, or product residue from stainless steel, use ordinary soap and water

applied with a sponge or cloth. Dr y thoroughly with a clean cloth. Nev er use vinegar o r any corrosiv e

cleaner.

• To remove grease and food splatter or condensed vapors that have baked on the equipment, apply

cleanser to a dam p cloth or sponge and r ub cleanser on the metal in th e direction of the po lishing lines

on the metal. Rubbing cleanser as gent l y as possi ble in the direction of the polished lin es will not mar the

finish of the stainles s steel. NEVER RUB WITH A CIRCU LAR MOTION. So il and burnt dep osits which

do not respond to the above procedure c an usually be remove d by rubbing the surf ace with SCOTCHBRITE scouring pads . DO NOT USE ORDINAR Y ST EEL WOOL, as any par tic les lef t on t he s urf ace will

rust and further spoi l the appearance of the finish. NEVE R USE A WIRE RUSH, STE EL SCOURING

PAD, SCRAPER, FILE OR OTHER ST EEL TOOLS. Surf aces which are marr ed collect dirt m ore rapidl y

and become more difficult to clean. Marring also increases the pos sibilit y of corros ive attack . Refinish ing

may then be required.

SEMIANNUAL CLEANING

At least twice a year, have your Southbend Authorized Service Agency or another qualified service

technician clean and adjust the unit for maximum performance.

Consult the Southbend Authorized P arts/Servic e Distributor list for th e Authorized Service Representat ive in

your area or contact Southbend at 1-800-348-2558 for this information.

CLEANING

OPERATOR’S MANUAL 1180963 PAGE 23

Page 24

TROUBLESHOOTING COMBINATION OVEN

TROUBLESHOOTING

NOTICE

Service work should be performed only by a qualified technician who is experienced in, and

knowledgeable of, the operation of commercial gas cooking equipment. Contact the authorized

Southbend Service Agency for reliable service, dependable advice or other assistance, and for

genuine factory parts.

Warranty will be void and the manufacturer is relieved of all liability if:

(A) Service work is performed by other than a qualified technician,

OR

(B) Other than genuine Southbend replacement parts are installed.

! CAUTION

Whenever servicing or cleaning the oven, the main power supplies to the oven must be disconnected.

This section cont ains a tr oubl eshootin g k ey and r eferenc ed f lowchar ts to as sist a qua lifie d serv ice tech nic ian

in the servicing of a Southbe nd Com bi oven. T he South bend Com bi is e quipped with a print ed circ uit b oard

controller that undergoes a diagnostic check every time the Combi is turned on. This diagnostic check

requires between 35 and 105 seconds. During this time, every segment in the display LEDs will be

illuminated. In the event of a diagnostic error, “Err” will appear in the TEMPERATURE display and a

descriptive error code will app ear in the TIME display. To recover from error mode, the problem must be

fixed and the unit turned off and back on again. A table of error codes and their causes is listed below:

Error Code Cause

CP:U The controller has failed a check of its on-board RAM (controller will need replaced)

bu:tn A button on the control panel is sticking in the down position or a button was held by the operator during startup

FA:n The cavity temperature limit switch or the centrifugal switch incorporated into the motor has tripped, indicating a

possible failure of the blower motor

GA:S A gas error can be caused by a variety of problems and is listed separately as a symptom in the following

troubleshooting guide (see page 28)

Pr:0b At least one of the RTD probes has failed in either an open or shorted condition.

TROUBLESHOOTING

PAGE 24 OPERATOR’S MANUAL 1180963

Page 25

COMBINATION OVEN TROUBLESHOOTING

TROUBLESHOOTING KEY

Find the symptom below that corresponds to th e malfunction, then tur n to t he c or res p ond ing f igure and page.

Follow the flowchart on that page until the problem is solved.

Symptom Page

Unit Not Working, No Lights 26

Unit Not Heating Properly (No Gas Error) 27

Gas Error 28

Unit Not Steaming Properly in Steam Mode or Combi Mode 29

Blower Not Running Properly 30

TROUBLESHOOTING FIGURES AND PROCEDURES

Figure and/or Procedure Page

Electric Schematic for 120 Volt 60 Hz Models 31

OPERATOR’S MANUAL 1180963 PAGE 25

TROUBLESHOOTING

Page 26

TROUBLESHOOTING COMBINATION OVEN

Unit Not Working, No Lights

Unit Not Working, No Lights.

Check circuit breaker

Ensure 120V between terminals TBA1

and TBA2 of terminal block A.

Check voltage between where Wire 57

attaches to fuseblock and TB-B2.

Is voltage

No Yes

approximately

120 volts?

Test and

replace fuse,

as necessary.

between TB-B1 and TB-B2.

No Yes

Test and

replace power

switch, as

necessary.

With switch in "ON"

position, check voltage

Is voltage

approximately

120 volts?

Check voltage between

terminals TB-B3 and TB-B6.

No Yes

Test and replace

transformer, as

necessary.

Is voltage

approximately 24

volts?

Check wiring.

Replace

control board.

TROUBLESHOOTING

PAGE 26 OPERATOR’S MANUAL 1180963

Page 27

COMBINATION OVEN TROUBLESHOOTING

Unit Not Heating Properly (No Gas Error)

Unit Not Heating Properly (No Gas Error)

Disconnect power. Remove control panel thumbscrew and

slide control panel out, Reconnect power.

Start unit. Check gas supply pressure. (There is an inlet

pressure tap on the gas combination valve that can be used

for this purpose.) Supply pressure should be > 7" W.C. for

natural gas and > 11" W.C. for propane.

Remove front lower panel and burner box cover.

With door

No

Place unit in oven

mode at 500

°F.

Close door.

closed, do main

burners come

on?

Yes

Place unit in oven

mode at 200°F.

Open door.

Depress door switch.

Check voltage between

HI terminal and C

terminal of gas valve.

No Yes

approximately 24

Replace control board.

Is voltage

volts?

Replace gas valve.

No

Go to page 29,

Blower Not

Running Properly.

No Yes

Replace gas

combination valve.

Does

blower come

on?

Check gas manifold pressure.

(There is a tap on the gas

combination valve for this

purpose.) Pressure should be

approximately 4.0" W.C. for

natural gas or approximately

10.0" W.C. for propane.

Does gas

pressure meet

specifications?

Yes

TROUBLESHOOTING

Check gas

valve wiring.

OPERATOR’S MANUAL 1180963 PAGE 27

Page 28

TROUBLESHOOTING COMBINATION OVEN

Gas Error

Gas Error

Ensure that gas shut-off valve is open.

Check gas supply pressure. (There is an inlet pressure tap on the gas combination valve that can be

used for this purpose.) Supply pressure should be > 7" W.C. for natural gas or > 11" W.C. for propane.

Remove front lower panel and burner box cover. Turn unit on. Observe ignitors for first 101 seconds after

turning unit on. Ignitors should begin glowing and continue to glow for approximately 37 seconds.

(If the flame does not light on first attempt, this process will be repeated two additional times.)

Do

Does

one ignitor

glow?

No

YesNo

both ignitors

glow?

Yes

No

Do both pilot

flames light (at least

temporarily)?

Yes

Place test leads

between terminal

TB-C2 and TB-C1.

Turn unit on. Check

voltage during first

30 seconds of

operation.

Is voltage

No Yes

Replace RAM

module.

Check manifold pressure during first 30

seconds of operation. (There is a tap on

gas combination valve for this purpose.)

approximately 24

volts?

Test and replace

bad ignitor, as

required.

Replace both

ignitors.

Check voltage

between P and C

terminals on gas

valve during first 30

seconds of operation.

Is voltage

Yes

approximately 24

volts?

Check and replace

RAM module, as

necessary.

Make sure that flame

sensors are

positioned at tip of

inner core of pilot

flame and are not

touching any metal

surface. Retry.

No

Does main

burner come

on (with door

closed)?

Check and replace RAM

module and flame sensor,

as necessary.

YesNo

Done

No

TROUBLESHOOTING

Replace gas valve.

PAGE 28 OPERATOR’S MANUAL 1180963

Is manifold pressure approximately

4" W.C. for natural gas or approximately

10" W.C. for propane?

Remove burner box. Remove pilot supply tube from pilot(s) not lighting.

Examine and replace pilot orifice if necessary. Replace pilot if damaged.

Ensure that ignitor is positioned properly relative to pilot. Adjust as necessary.

Yes

Page 29

COMBINATION OVEN TROUBLESHOOTING

Unit Not Steaming Properly in Steam Mode or Combi Mode

Unit Not Steaming Properly in Steam Mode or Combi Mode.

Check water pressure at unit with unit running.

Disconnect plug PL3 and place test leads in harness side of

plug. Operate unit in steam mode. Wait until steam mode

LED stops flashing. Check voltage.

Does voltage

No Yes

rise and fall from 0 to

approximately

24 volts?

Check wiring.

Replace board.

No Yes

Replace

solenoid valve.

Remove screen from

strainer on back of unit.

Clean or replace screen.

Turn unit on in steam

mode.

Turn unit off. Remove

right side exterior cover

from unit, if desired.

Check solenoid valve

coil resistance.

Is resistance

between 1 and 10

megaohms?

Turn-off water supply to unit. Remove

water-supply copper tube from

compression fitting at inlet to solenoid

valve inside unit. Attach one end of 1/4"

ID hose to tube and place other end in

drain or bucket. Turn water supply on.

No Yes

Significant

water flow

(>1/2 gpm)?

TROUBLESHOOTING

Remove solenoid valve and

flow regulator. Examine for

deposits or debris that would

impede water flow. Clean and

replace as necessary.

No Yes

Replace pressure

regulator on back of unit.

Unit steaming

properly?

Finished

OPERATOR’S MANUAL 1180963 PAGE 29

Page 30

TROUBLESHOOTING COMBINATION OVEN

Blower Not Running Properly

Blower Not Running Properly (with Door Closed)

No

Does

blower run when unit is

cold (door closed)?

Yes

Disconnect 4-pin connector. Place fan switch in

"HIGH FAN" position. Locate the terminals

where Wires 21 and 55 are attached and check

for continuity between these terminals. Place

the fan switch in "LOW FAN" position. Locate

the terminals where Wires 22 and 56 are

attached. Check for continuity.

Is there

No Yes

Replace

fan switch.

continuity in both

cases?

No Yes

Reconnect 4-pin connector.

Slide control panel out. Disconnect plug PL2.

Place test leads in terminals on switch side of plug.

Close door. Check for continuity.

Open door. Check for continuity.

Is there continuity with door closed

and no continuity with door open?

Blower motor is overheating. Check operation

of cooling fan in control compartment and

replace as necessary.

Check door switch actuator mechanism by

closing door and observing movement of door

switch lever. Adjust or repair as necessary.

Replace door switch as necessary.

Put fan switch in "LOW FAN" position.

TURN OFF GAS SHUT OFF VALVE.

Close door.

motor. Turn unit on. Check voltage between

Wires 25 and 8 by inserting test leads into the

harness side of plug PL8.

No Yes

TROUBLESHOOTING

Replace control

board.

PAGE 30 OPERATOR’S MANUAL 1180963

Disconnect 3-pin connector at

Is voltage

approximately

120 VAC?

Replace motor.

Page 31

COMBINATION OVEN TROUBLESHOOTING

Figure 4

Electric Schematic for 120 Volt 60 Hz Models

OPERATOR’S MANUAL 1180963 PAGE 31

TROUBLESHOOTING

Page 32

PARTS COMBINATION OVEN

PARTS

NOTICE

INSTALLATION OF OTHER THAN GENUINE SOUTHBEND PARTS WILL VOID T HE WARRANTY

ON THIS EQUIPMENT.

The serial plate with voltage, m odel, and seria l inform ation is l ocated b ehind the lower f ront panel on the lef t

side.

Replacement parts may be ordered either thr ough a Southbend Auth orized Parts Dis tributor or a S outhbend

Authorized Service Agency.

When ordering parts, please suppl y the Model Number, Serial Number, Part Num ber, Description, Finish,

and Electrical Character istic s as appl icab le.

For parts not listed, consult a Southbend Authorized Parts Distributor or Southbend Authorized Service

Agency. Consult the Southbend Authori zed Parts/Servic e Distributor list f or the Authorized P arts supplier in

your area. If this list is not available, call Southbend at 1-800-348-2558 to obtain this list.

Index of Combination Oven Parts Diagrams

Page Number Description Module or S/A #

33 Blower and Motor Parts 0-11-0045

34 Control Panel Subassembly Parts 0-11-0046

36 Frame and Exterior Parts 0-11-0047

38 Cavity Parts 0-11-0048

40 Door Subassembly Parts 0-11-0049

41 Sprayer and Water Train Parts 0-11-0050

42 Burner and Gas Train Parts 0-11-0051

44 Water Inlet Subassembly Parts 1180668 (S/A)

45 Black Legs with Casters Parts 0-40-0498

PARTS

PAGE 32 OPERATOR’S MANUAL 1180963

Page 33

COMBINATION OVEN PARTS

Blower and Motor Parts 0-11-0045

Key Part Number Qty Description

1 1180934 1 Blower Wheel Weld Assembly

2 1180932 1 Packing Material, FDA Approved

3 1180910 1 Washer, Flat

4 1180909 1 Washer, Wave Spring, SS

5 1180903 1 Fitting, Motor Shaft Seal

6 1180686 1 Motor Pocket S/W/A

7 1180633 1 Fan, Water Dispersing

8 1180621 1 Motor, 115V 60CC 2 Speed

9 1179710 4 Spacer, Blower, Motor

PARTS

OPERATOR’S MANUAL 1180963 PAGE 33

Page 34

PARTS COMBINATION OVEN

Control Panel Subassembly Parts 0-11-0046

See drawing on following page.

Key Part Number Qty Description

1 1172275 2 Plastic Knob

2 1177515 1 Bracket, Ignition Module

3 1178391 1 Fuseblock, Controls

4 1178534 1 Bracket, On/Off Switch

5 1180617 1 Control Panel, Subassembly (assembled)

6 1180635 1 Ignition Module

7 1180636 1 Control Board

8 1180906 1 Fuse, Time-Delay, 20 A

9 1180931 1 Panel Weld Assembly, Control

10 1180971 1 Transformer 115V, 24V, 75VA

11 1180987 2 Switch, Rotary, Actuator

12 1180988 1 Switch, Rotary, NO/NC

13 1180989 1 Switch, Rotary, NO

14 1180990 2 Bezel, Rotary Switch, Black

* 1170336 1 Marker Strip

* 1180610 1 Polypanel

* 1180637 1 Wiring Harness

* 1180638 1 Electrical Schematic

* 1180970 1 Sticker, Fuse Replacement

* 1180972 8 Spacer, Control Panel (Combi)

* not shown on drawing.

PARTS

PAGE 34 OPERATOR’S MANUAL 1180963

Page 35

COMBINATION OVEN PARTS

Control Panel Subassembly Parts

See parts list on previous page.

6 POSITION TERMINAL STRIP

(PART OF WIRING HARNESS, 1880637)

2 POSITION TERMINAL STRIP

(PART OF WIRING HA RNE S S, 1880637)

OPERATOR’S MANUAL 1180963 PAGE 35

PARTS

Page 36

PARTS COMBINATION OVEN

Frame and Exterior Parts 0-11-0047

See drawing on following page.

Key Part Number Qty Description

1 1180641A 1 Trough, Drain

2 1180974 1 Switch, CO High Limit

3 1180953 2 Hanger, Hose

4 1180936 1 Frame, Vertical, Weld Assembly

5 1180935 2 Frame, Horizontal, Cavity, Weld Assembly

6 1180660 2 Bracket, Front and Rear Pipe Support

7 1180655 1 Base Weld Assembly

8 1180649 1 Retainer, Insulation

9 1180642 1 Cover, Drain Trough

10 1180631 2 Rail, Slide

11 1180625 2 Frame, Horizontal, Left/Right

12 1180624 2 Frame, Horizontal, Front/Back

13 1180623 3 Frame, Vertical

14 1180615 1 Flue Riser

15 1180613 1 Cover, Gas and Drain

16 1180612 1 Front Lower Panel

17 1180609 1 Body Back

18 1180607 1 Body Top

19 1180606 1 Body Front

20 1180605 1 Body Side, Left

21 1180604 1 Body Side, Right

22 1179709 1 Plug, Fan Power Cord

23 1179704 1 Fan, Cooling, 120V

24 1177523 1 Bracket, Rear Gas Pipe

25 1172769 1 CO Power Cord

26 1172285 1 Bushing, Strain Relief

27 1160031 1 Lug, Grounding

PARTS

PAGE 36 OPERATOR’S MANUAL 1180963

Page 37

COMBINATION OVEN PARTS

OPERATOR’S MANUAL 1180963 PAGE 37

PARTS

Page 38

PARTS COMBINATION OVEN

Cavity Parts 0-11-0048

See drawing on following page.

Key Part Number Qty Description

1 P6016 1 Fitting, Brass, STRT, 68C-6-4

2 1180998 2 Baffle, Weld Assembly

3 1180997 1 Disk, Pressure Relief

4 1180996 1 Spring, Relief Valve

5 1180992 1 Insul. Cover for Flue

6 1180983 1 Probe Bracket

7 1180982 1 Probe Bracket Clamp

8 1180962 1 Door Switch Assembly

9 1180961 1 Cover, Probe

10 1180921 8 Bolt, Shoulder 1/4-20

11 1180911 2 Rack Guide, 11 Position

12 1180682 2 Fitting, 1/4 inch MPT x 3/16 inch Tube

13 1180671 1 Flue Duct Weld Assembly

14 1180670 1 Tube, Water Supply

15 1180656 1 Baffle, Air

16 1180639 5 Racks

17 1180616 1 Cavity Weld Assembly

18 1172753 2 Thermostat Probe

PARTS

PAGE 38 OPERATOR’S MANUAL 1180963

Page 39

COMBINATION OVEN PARTS

Cavity Parts

See parts list on previous page.

OPERATOR’S MANUAL 1180963 PAGE 39

PARTS

Page 40

PARTS COMBINATION OVEN

Door Subassembly Parts 0-11-0049

Key Part Number Qty Description

1 1180977 2 Hinge, Door

2 1180940 1 Panel, Door, Weld Assembly

3 1180938 1 Door Latch & Striker

4 1180691 1 Insulation, Door

5 1180685 1 Panel Assembly, Inner Door

6 1180627 1 Gasket, Door

7 1180618 1 Door Subassembly (assembled)

8 1180614 1 Door Gasket Retainer

9 1146363 3 Screw, 1/4 -20x2, SS, Slotted Flat Head

10 1146303 8 Screw, #8 x 1/2

PARTS

PAGE 40 OPERATOR’S MANUAL 1180963

Page 41

COMBINATION OVEN PARTS

Sprayer and Water Train Parts 0-11-0050

OPERATOR’S MANUAL 1180963 PAGE 41

PARTS

Page 42

PARTS COMBINATION OVEN

Burner and Gas Train Parts 0-11-0051

See drawing on following page.

Key Part Number Qty Description

1 1036600 4 Orifice Fitting

2 1036603 8 Screw, Brass, 5/16-18x3/4 Hexhead

3 1036604 4 Nut Air Collar

4 1036605 4 Air Collar PLTD

5 1036607 4 Burner, Fry Pot, 4 inch

6 1036611 4 Burner Orifice - Nat #44 Drill

1036610 1 Orifice Spud Propane #54 Drill (option)

7 1054118 2 Pilot Orifice - Nat

1054111 1 Orifice, R-011, Propane (option)

8 1061298 1 Union, Brass

9 1099114 1 Nut, Male

10 1146304 6 Screw, #10 x 1/2 Phil Truss Head

11 1146398 4 Screw, 6-32x3/8, SS, Phil Pan Head

12 1146405 4 Nut, 6-32, Hex

13 1146501 4 Lockwasher, 3/16

14 1146526 2 Washer, #10, Flat

15 1146529 8 Washer, 5/16, Lock, SS

16 1146806 1 Nipple, Pipe, Close, Blk, 1/2"

17 1146913 1 Elbow, Red., Blk, 3/4 x 3/8, 90 Deg

18 1147007 1 Plug, Pipe Blk. 1/8

19 1160008 3 Elbow, Brass

20 1173524 1 Tee, 1/4 Tube Compr All Direct

21 1173595 2 Insert, Knurled, Threaded

22 1175283 2 Flame Sensor

23 1177545 2 Ignitor, Hot Surface

24 1180634 1 Gas Valve, Nat

1180955 1 Gas Valve, Propane (option)

25 1180659 1 Tube, Gas Supply

26 1180667 1 Cover, Burner Box

27 1180675 1 Burner Box

28 1180676 1 Manifold

29 1180678 2 Tube, Pilot Supply

30 1180679 1 Tube, Main Pilot, Up

31 1180681 1 Tube, Burner Supply

32 1180692 1 Tube, CV Outlet

33 1180693 1 Tube, Main Pilot, Down

34 1180694 2 Bracket, Pilot Mounting

35 1180945 1 Tail Pipe

36 1180960 2 Pilot

37 1180964 1 Union, Brass, 5/8 CC

38 1-5771 1 Valve, Shut Off, 1/2"

39 P9158 1 Connector, Brass, 68C-10-8

PARTS

PAGE 42 OPERATOR’S MANUAL 1180963

Page 43

COMBINATION OVEN PARTS

OPERATOR’S MANUAL 1180963 PAGE 43

PARTS

Page 44

PARTS COMBINATION OVEN

PARTS

PAGE 44 OPERATOR’S MANUAL 1180963

Page 45

COMBINATION OVEN PARTS

Black Legs with Casters Parts 0-40-0498

Key Part Number Qty Description

1 1174265 1 Caster Package, 4 Bolt

2 1177850 1 Leg Assembly, Caster

* 1146213 20 Bolt, 3/8-16x1 Hex Head

* 1146505 20 Washer 5/16, Flat

* 1146513 20 Washer 3/8, Lock

* 1176351 1 Sticker. Legs

* not shown on drawing.

OPERATOR’S MANUAL 1180963 PAGE 45

PARTS

Page 46

COMBINATION OVEN

COMBINATION OVEN

A product with the So uthbend name incor porates the best in dur ability and low m aintenance. We

all recognize, however, that replacement parts and occasional professional service may be

necessary to extend the useful life of this unit. When service is needed, contact a Southbend

Authorized Service Agenc y, or your dea ler. T o a void conf usion, alwa ys refer to the m odel num ber ,

serial number, and type of your unit.

Southbend

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

(800) 348-2558 or (919) 552-9161 • FAX (800) 348-2558 or (919) 552-9798

PAGE 46 OPERATOR’S MANUAL 1180963

Loading...

Loading...