Page 1

A MIDDLEBY COMPANY

OWNER'S MANUAL

GAS TILTING

BRAISING PAN

southbend

INSTALLATION

USER'S GUIDE

SERVICE

PARTS

$4.00

BPG-40-M 7" PAN MODELS:

BPG-40-M-9 9" PAN

These instructions should be read thoroughly before attempting installation. Set up, installation

and Performance Check should be performed by a qualified service technician. The

Manufacturer, Southbend (1100 Old Honeycutt Rd., Fuquay-Varina, North Carolina 27526),

informs you that unless the installation instructions for the above described Southbend product

are followed and performed by a qualified service technician, (a person experienced in and

knowledgeable concerning the installation of commercial gas and/or electrical cooking

equipment) then the terms and conditions of the Manufacturer's Limited Warranty will be

rendered void and no warranty of any kind shall apply.

If the equipment has been changed, altered, modified or repaired by other than a qualified

service technician during or after the 12-month limited warranty period, then the manufacturer

shall not be liable for any incidental or consequential damages to any person or to any property

which may result from the use of the equipment thereafter. Some States do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion thereto may not apply to you.

In the event you have any question concerning the installation, use, care, or service of the

product, write Customer Service Department, Southbend Corporation, 1100 Old Honeycutt Rd.,

Fuquay-Varina, North Carolina 27526.

GAS TILTING BRAISING PANS

(Manual Section BP)

Page 2

Congratulations! You have just purchased one of the finest pieces of heavy-duty, commercial cooking equipment on

has been designed and manufactured to some of

Southbend Corporatlon Each piece of Southbend equipment has been

carefully engineered and designs have been verified through laboratory tests and field installations in some of the

wIll experience years of

Specifications

1

SECTION TWO

- USER'S GUIDE

Adjustments

1

Service

3

Troubleshooting

3

1100

Old Honeycutt Road

the market today.

You will find that your new equipment, like all Southbend equipment

the toughest standards in the industry - those of

more strenuous commercial cooking applications. With proper care and field maintenance, you

reliable trouble-free operation from your Southbend equipment. To get the best results, it's important that

you read this manual carefully.

TABLE OF CONTENTS:

SECTION ONE - INSTALLATION

Installation 2

Warranty 1

Operation 2

Maintenance 3

SECTION THREE - SERVICE

Schematic Drawings 4

SECTION FOUR - PARTS

Parts List 1

CAUTION: POST IN PROMINENT LOCATION INSTRUCTIONS TO BE FOLLOWED

IN THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION

SHALL BE OBTAINED FROM LOCAL GAS SUPPLIER.

INTENDED FOR COMMERCIAL USE ONLY. NOT FOR

HOUSEHOLD USE.

Retain this manual for future reference.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

KEEP AREA AROUND APPLIANCES FREE AND CLEAR FROM COMBUSTIBLES.

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN EQUIPMENT AT THE MAIN SHUTOFF VALVE

AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER FOR SERVICE.

southbend

A MIDDLEBY COMPANY

Fuquay-Vanna. NC 27526

(919) 552-9161

FAX (919) 552-9798

(800) 348-2558

Page 3

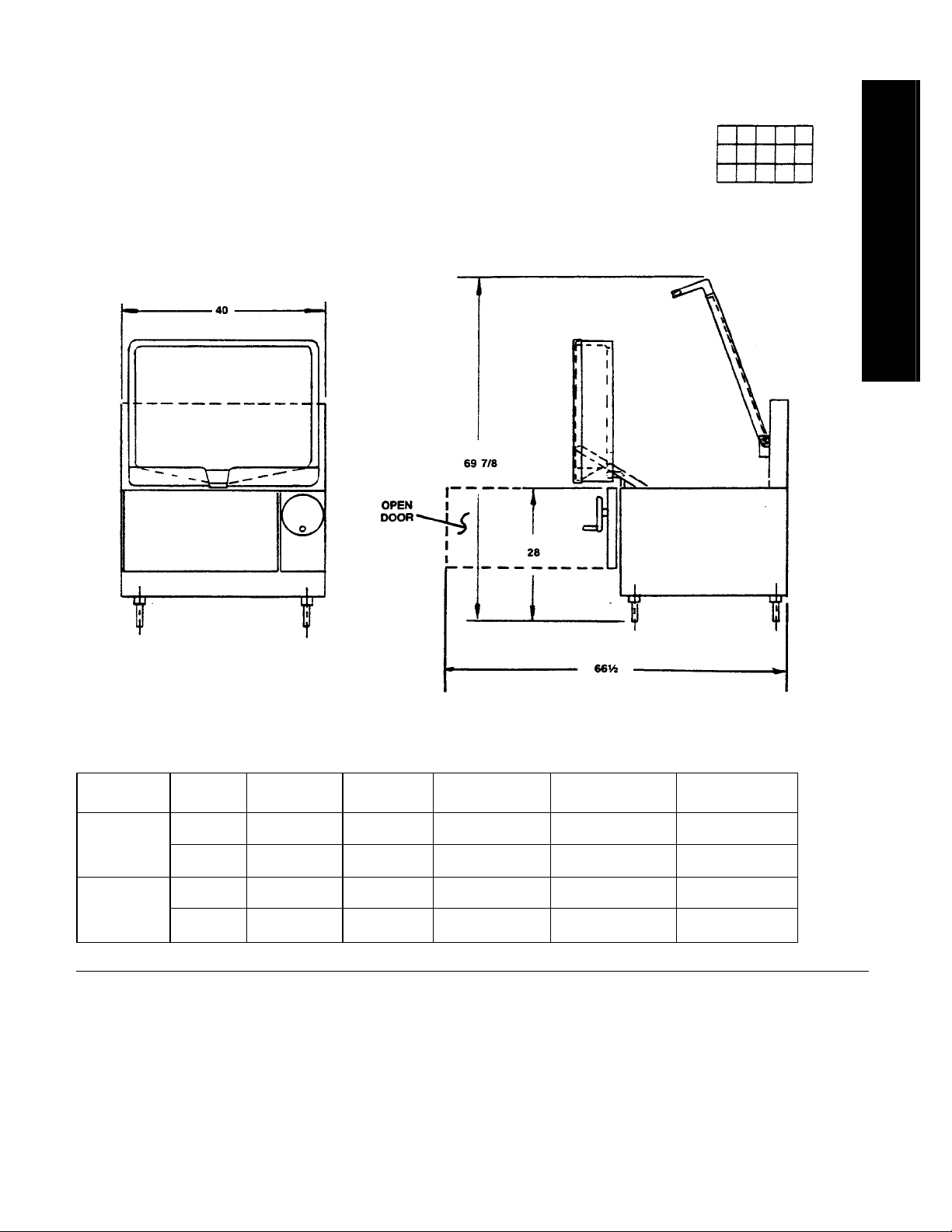

GAS TILTING BRAISING PANS

INSTALLATION

SPECIFICATIONS

INSTALLATION

BURNERS

PILOT

ITEM

MAIN

GAS

TYPE

Natural 4" W.C. 10 8,500 BTU/Hr. 85,000 BTU/Hr. #55 .055" Dia.

LP 10" W.C. 10 8,500 BTU/Hr. 85,000 BTU/Hr. #66 .035" Dia.

Natural 4" W.C. 1 800 BTU/Hr. — #73 .024" Dia.

LP 10" W.C. 1 800 BTU/Hr. — .011" Dia.

MANIFOLD

PRESSURE

NUMBER

PER UNIT

RATE EACH TOTAL RATE

ORIFICE

SIZE

GAS TILTING BRAISING PANS

SECTION ONE — INSTALLATION

PAGE 1

Page 4

INSTALLATION

.

GENERAL:

The installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1-1984, and with the National Electrical Code ANSI NFPA 70-1984.

These models are design certified for operation on natural or propane gases.

The serial plate is located just inside the cabinet door, at the left front of the cabinet bottom.

For orifice sizes and pressure regulator settings, refer to the chart under "SPECIFICATIONS."

An adequate gas supply is imperative. Undersized or low pressure lines restrict the volume of gas necessary for

satisfactory performance. A pressure regulator, which is provided with each unit, is set to maintain a 4" W.C. manifold

pressure for natural gas, and a 10" W.C. manifold pressure for propane gas. However, to maintain these conditions,

INSTALLATION

the pressure on the supply line when all units are operating simultaneously should not drop below 7" W.C. for natural

gas or 11" W.C. for propane gas.

All pipe joints should be tested for leaks with a soap and water solution before operating the unit. The test pressure

should not exceed 14" W.C.

All equipment and its individual shutoff valve must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 14" W.C. In addition, to eliminate the indication of false

leaks in the supply piping, all cooking equipment must be isolated from the gas supply piping system by closing its

individual manual shutoff valve during any pressure testing of that system at test pressures equal to or less than 14"

W.C.

A 1/8" pressure tap is located on the combination gas control inside the cabinet.

The unit must be installed in such a manner that the flow of combustion and ventilation air are not obstructed.

Provisions for an adequate air supply must also be provided. Do NOT obstruct the front of the unit, as combustion air

enters through this area.

CAUTION:

THIS APPLIANCE AND ITS INDIVIDUAL SHUTOFF VALVE MUST BE DISCONNECTED FROM

THE GAS SUPPLY PIPING SYSTEM DURING ANY PRESSURE TESTING OF THAT SYSTEM

AT TEST PRESSURES IN EXCESS OF 1/2 PSIG (3.45 kPa).

THIS APPLIANCE MUST BE ISOLATED FROM THE GAS SUPPLY PIPING SYSTEM BY

CLOSING ITS INDIVIDUAL MANUAL SHUTOFF VALVE DURING ANY PRESSURE TESTING OF

THE GAS SUPPLY PIPING SYSTEM AT TEST PRESSURES EQUAL TO OR LESS THAN 1/2

PSIG (3.45 kPa).

EXHAUST FANS AND CANOPIES:

Canopies are set over ranges, ovens, etc., for ventilation purposes. It is recommended that a canopy

extend 6" past appliance and be located 6' 6" from the floor. Filters should be installed at an angle of 45

degrees or more with the horizontal. This position prevents dripping grease and facilitates collecting the

run-off grease in a drip pan, usually installed with a filter. A strong exhaust fan tends to create a vacuum

in the room and may interfere with burner performance, or may extinguish pilot flames. Fresh air

openings approximately equal to the fan area will relieve such vacuum. In case of unsatisfactory

performance on any appliance, check with the exhaust fan in the "OFF" position.

Minimum clearances from combustible construction:

No additional clearance from the sides and back is required for service as the unit is serviceable from the

front.

6 INCHES FROM SIDES 6 INCHES FROM BACK

GAS TILTING BRAISING PANS

SECTION ONE — INSTALLATION

PAGE 2

Litho in U.S.A.

8-88

Page 5

INSTALLATION

LEGS OR OPTIONAL CASTERS:

1. Braising pans are shipped completely assembled with the exception of the legs.

2. A set of 6" legs is packed in the drain container. A threaded receptacle is fastened to the base frame at each

corner. Each leg has a similar mating thread.

3. Raise unit sufficiently to allow legs to be screwed into the receptacles. For safety, "shore up" and support the

raised section with an adequate blocking arrangement strong enough to support the load.

4. The legs can be adjusted to overcome an uneven floor. Use a spirit level in the pan to level unit.

5. Bring the unit to its upright position gently. Never drop or allow the unit to fall.

6. Install the lower base panel on the unit. Keyholes for mounting the panel are provided.

WARNING:

FOR AN APPLIANCE EQUIPPED WITH CASTERS, THE INSTALLATION SHALL BE MADE WITH A

CONNECTOR THAT COMPLIES WITH THE STANDARD FOR CONNECTORS FOR MOVABLE GAS

APPLIANCES, ANSI Z21.69-1979, AND ADDENDA Z21.69a-1983, AND A QUICK-DISCONNECT DEVICE

THAT COMPLIES WITH THE STANDARD FOR QUICK-DISCONNECT DEVICES FOR USE WITH GAS

FUEL, ANSI Z21.41-1978, AND ADDENDA Z21.41a-1981 AND Z21.41b-1983. ADEQUATE MEANS MUST

BE PROVIDED TO LIMIT THE MOVEMENT OF THE APPLIANCE WITHOUT DEPENDING ON THE

CONNECTOR AND THE QUICK-DISCONNECT DEVICE OR ITS ASSOCIATED PIPING TO LIMIT THE

APPLIANCE MOVEMENT.

INSTALLATION

WARNING:

IF DISCONNECTION OF THIS RESTRAINT IS NECESSARY TO MOVE THE APPLIANCE FOR CLEANING,

ETC., RECONNECT IT WHEN THE APPLIANCE IS MOVED TO ITS ORIGINALLY INSTALLED POSITION.

WATER SUPPLY OPTION:

When a water supply with a flexible hose and spray head is furnished as an optional feature, the water line is

brought through an opening in the rear, into the lower compartment, where it is connected to the faucet. A rubber

hose and its fittings, suitable for conditions in a commercial kitchen are recommended, particularly for units which

are moved for cleaning.

GAS CONNECTION:

1. All braising pans are factory equipped with pressure regulator which is set for the type of gas denoted on the

serial plate.

The gas connection is made on the lower left at the rear of the unit. The connection can be made in one of two

2.

ways:

Rear Connection:

A.

1. Make connection directly to the 3/4" NPT (male) pipe protruding from the lower left of the unit at rear.

Bottom Connection:

B.

1. Cap the 3/4" NPT (male) pipe protruding from the unit on the lower left at the rear.

2. Remove the plug from the tee at the left rear corner on the bottom of the unit. The tee is recessed

approximately 3" into the hole which passes through the bottom of the unit. A 3-1/4" box-type socket

with an extension will be required.

3. Insert a 3/4" supply pipe with a 3/4" NPT thread through the hole in the bottom of the unit. Screw the

pipe securely into the tee.

When tightening the supply pipe be sure to hold the mating pipe extending from the unit securely with a wrench. This

will prevent any damage or distortion to the internal piping and controls of the unit.

On all threaded connections, the pipe compound must be approved for use with natural and LP gas.

Check all connections thoroughly for gas leaks before lighting the pilot. Use soapy water only; NEVER use a flame.

No electrical connections are required.

GAS TILTING BRAISING PANS

SECTION ONE — INSTALLATION

PAGE 3

Page 6

INSTALLATION

g.

LIGHTING:

A.

Open compartment door.

1.

Manual gas valve must be "OPEN."

2. The screws and the right angle shield assemblies at the rear of the burner compartment are for shipping

purposes only and must be removed prior to initially lighting the unit.

3.

Turn thermostat to "OFF."

Pilot can be ignited with a match or taper through a hole between the mixer tubes of the first and second

4.

burners from the left, or by raising the pan.

INSTALLATION

B.

a.

Turn the knob on the Unitrol to the pilot position. Depress knob by pushing down.

b. While holding knob depressed, ignite pilot and hold knob depressed for about 30 seconds. If pilot does

not stay ignited when knob is depressed, procedure must be repeated and knob held in longer.

Adjustment of pilot flame may be required.

c.

When pilot stays ignited, put pan in horizontal position.

d.

Turn knob on Unitrol to "ON."

e. Turn thermostat to desired temperature. Pilot will ignite carry-over burner and main burner's ignition

will follow.

f. Main burner will remain "ON" until thermostat is satisfied and it interrupts millivolt circuit. Burners are

either full ON or OFF.

Raising the pan more than 10 inches also causes the mercury tilt switch to interrupt the circuit,

causing the burners to be OFF.

SHUT-DOWN PROCEDURE:

Stand-by: Turn dial on the Unitrol control to the Pilot position. At this setting, only the pilot burner will remain

ignited.

Complete shut-down: Turn dial to the pilot position, then depress and continue turn to the "OFF" position. For

continued shut-down or for service work, the main manual valve can be closed.

RELIGHTING:

C.

1.

Shut off all gas.

2.

Wait 5 minutes.

3.

Repeat "LIGHTING" instructions in Section "A."

CAUTION:

IF YOU SMELL GAS DURING THE LIGHTING PROCEDURE, IMMEDIATELY

SHUT OFF THE GAS SUPPLY UNTIL THE LEAK HAS BEEN CORRECTED.

GAS TILTING BRAISING PANS

SECTION ONE — INSTALLATION

PAGE 4

Litho in U.S.A.

8-88

Page 7

GAS TILTING BRAISING PAN

USER’S GUIDE

USER'S GUIDE

LIMITED WARRANTY

Southbend warrants that the equipment, as supplied by the factory to the original purchasers, is free from defects in materials and workmanship.

Should any part thereof become defective as a result of normal use within the period and limits defined below, then at the option of Southbend such

parts will be repaired or replaced by Southbend or its Authorized Service Agency. This warranty is subject to the following conditions:

If upon inspection by Southbend or its Authorized Service Agency it is determined that this equipment has not been used in an appropriate manner,

has been modified, has not been properly maintained, or has been subject to misuse or misapplication, neglect, abuse, accident, damage during

transit or delivery, fire, flood, riot or Act of God. then this warranty shall be void.

Specifically excluded under this warranty are claims relating to installation: examples are improper utility connections and improper utilities supply.

Claims relating to normal care and maintenance are also excluded: examples are calibration of controls. and adjustments to pilots and burners.

Equipment failure caused by inadequate water quality is not covered under the warranty. WATER QUALITY must not exceed the following limits, Total

Dissolved Solids (TDS) - 60 PPM (Parts Per Million), Hardness - 2 Grains or 35 PPM. PH Factor - 7.0 to 7.5. Water pressure 30 PSI minimum, 60 PSI

Maximum. Boiler maintenance is the responsibility of the owner and is not covered by warranty.

This equipment is intended for commercial use only. Warranty is void if equipment is installed in other than commercial application.

Repairs under this warranty are to be performed only by a Southbend Authorized Service Agency. Southbend can not be responsible for charges

incurred from other than Authorized Southbend Agencies.

THIS WARRANTY MUST BE SHOWN TO AN AUTHORIZED SERVICE AGENCY WHEN REQUESTING IN-WARRANTY SERVICE WORK. THE

AUTHORIZED SERVICE AGENCY. MAY AT HIS OPTION REQUIRE PROOF OF PURCHASE DATE.

This warranty does not cover services performed at overtime or premium labor rates nor does Southbend assume any liability for extended delays in

replacing or repairing any items in the equipment beyond the control of Southbend. "Southbend shall not be liable for consequential or special

damages of any nature that may arise in connection with such product or part." Should service be required at times which normally involve overtime or

premium labor rates, the owner shall be charged for the difference between normal service rates and such premium rates.

In all circumstances, a maximum of one hundred miles in travel and two and one half hours (2.5) travel time shall be allowable.

In all cases the closest Southbend Authorized Agency must be used.

The actual warranty time periods and exceptions are as follows:

This warranty only covers product shipped into the 48 Contiguous United States and Hawaii, one year labor, one year parts effective from the date of

original purchase. There will be no labor coverage for equipment located on any island not connected by roadway to the mainland.

Exceptions to standard warranty, effective within above limitations:

Glass Windows, Door Gaskets, Rubber Seals, Light Bulbs, Ceramic Bricks,

Sight Glasses, Cathodic Descalers or Anodes .................................................................................................................... 90 days material and labor.

Stainless Steel Fry Pot .................................................................................................. 4 years extended material warranty on fry pot only - No labor.

Stainless Steel Open Top Burners .............................................................................. 4 years extended material warranty on burners only - No labor.

Pressure Steam Boiler Shell .................................................................................. Prorated 4 years extended warranty on boiler shell only - No labor.

(Boiler shells which have not been properly maintained will not be covered by warranty.)

In all cases parts covered by a five year warranty will be shipped FOB the factory after the first year.

Our warranty on all replacement parts which are replaced in the field by our Authorized Service Agencies will be limited to three months on labor, six

months on materials (parts) effective from the date of installation. See LIMITED WARRANTY - REPLACEMENT PARTS for conditions and limitations.

If the equipment has been changed, altered, modified, or repaired by other than a qualified service technician during or after the one year limited

warranty period, then the manufacturer shall not be liable for any damages to any person or to any property which may result from the use of the

equipment thereafter.

"THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS, AND CONSTITUTES THE ENTIRE LIABILITY OF SOUTHBEND. IN NO EVENT DOES THE

LIMITED WARRANTY EXTEND BEYOND THE DURATION OF ONE YEAR FROM THE EFFECTIVE DATE OF SAID WARRANTY."

SOUTHBEND - Effective February 1, 1990

GAS TILTING BRAISING PANS

SECTION TWO — USER'S GUIDE

PAGE 1

Page 8

OPERATION

Litho in U.S.A.

THERMOSTAT:

The thermostat controls the operation of the burners. Set the thermostat to the desired temperature. The burners

will come on until the thermostat is satisfied. They will cycle "ON" and "OFF" to maintain this temperature.

Turn the thermostat to the "OFF" position to shut down the braising pan.

TIMER:

Turn the dial beyond five minutes and then set for the desired time. The bell will sound at the end of the interval.

The timer is only a reminder. It does NOT control the burners and will NOT shut off the burners.

USER’S GUIDE

TILTING PAN:

Turn the handwheel clockwise to raise the rear of the pan. Be sure a container has been placed below the front

pouring spout. Stand on right side of unit, not directly in front of pouring spout.

Turn handwheel counterclockwise to lower pan.

Although the unit has a safety switch to shut off the burners when the pan is raised, it is recommended that the

thermostat be turned "OFF" before raising the pan.

Be sure lid has been raised before attempting to raise pan.

GAS TILTING BRAISING PANS

SECTION TWO — USER'S GUIDE

PAGE 2

8-88

Page 9

MAINTENANCE

cloth.

WARNING:

ALL ADJUSTING AND SERVICE SHOULD BE PERFORMED BY A PERSON

KNOWLEDGEABLE IN MAKING SUCH ADJUSTMENTS. IF IN DOUBT - CALL YOUR

AUTHORIZED SERVICE AGENCY.

Following daily and periodic maintenance procedures will enhance long-life for your equipment. Climatic conditions

— salt air — may require more thorough and frequent cleaning, or the life of the equipment could be adversely

affected.

MAINTENANCE:

Keep exposed, cleanable areas of unit clean at all times.

1.

Daily:

A. Remove condensate pan from lower compartment; empty and clean thoroughly.

B. Thoroughly wash pan and lid.

Monthly:

A. Clean around burner air mixer and orifices if lint has accumulated.

B. Visually assure carry-over ports are unobstructed.

USER’S GUIDE

Vent System:

At least twice a year the unit venting system should be examined and cleaned.

STAINLESS STEEL:

1. To remove normal dirt, grease, or product residue from stainless steel that operates at LOW temperature, use

ordinary soap and water (with or without detergent) applied with a sponge or cloth. Dry thoroughly with a clean

2. To remove grease and food splatter or condensed vapors that have BAKED on the equipment, apply cleanser

to a damp cloth or sponge and rub cleanser on the metal in the direction of the polishing lines on the metal.

Rubbing cleanser as gently as possible in the direction of the polished lines will not mar the finish of the

stainless steel. NEVER RUB WITH A CIRCULAR MOTION. Soil and burnt deposits which do not respond to

the above procedure can usually be removed by rubbing the surface with SCOTCH-BRITE scouring pads or

STAINLESS scouring pads. DO NOT USE ORDINARY STEEL WOOL, as any particles left on the surface will

rust and further spoil the appearance of the finish. NEVER USE A WIRE BRUSH, STEEL SCOURING PADS

(EXCEPT STAINLESS), SCRAPER, FILE OR OTHER STEEL TOOLS. Surfaces which are marred collect dirt

more rapidly and become more difficult to clean. Marring also increases the possibility of corrosive attack.

Refinishing may then be required.

3. To Remove Heat Tint: Darkened areas sometimes appear on stainless steel surfaces where the area has

been subjected to excessive heat. These darkened areas are caused by thickening of the protective surface of

the stainless steel and are not harmful. Heat tint can normally be removed by the foregoing, but tint which does

not respond to this procedure calls for a vigorous scouring in the direction of the polish lines using SCOTCHBRITE scouring pads or a STAINLESS scouring pad in combination with a powdered cleanser. Heat tint action

may be lessened by not applying, or by reducing heat to equipment during slack periods.

BLACK BAKED ENAMEL:

1. Allow unit to cool somewhat after use and wash exterior with a hot, mild detergent or soap solution; particularly

clean off all grease deposits. Dry thoroughly with a dry cloth.

GAS TILTING BRAISING PANS

SECTION TWO — USER'S GUIDE

PAGE 3

Page 10

MAINTENANCE

Litho in U.S.A.

PAN:

Because your Braising Pan is in use for a wide variety of foods — for breakfast, lunch and dinner service — clean it as soon as

possible after each use.

Before starting to clean, make sure that gas is OFF; then follow this recommended procedure:

1. Flush the pan thoroughly with lukewarm water, then drain — to remove as much loose soil as possible.

2. For average soil, use a cleaning solution (mix with hot water per cleaning solution instructions) and brush thoroughly all

parts, including pouring lip, that touch or are splashed by food, particularly underside of cover. (Use fiber bristle brush.)

3. For cooked-on or hardened soil, use a stronger solution as recommended by solution instructions. Soak for at least 30

USER’S GUIDE

minutes, making sure that cleaning solution covers the highest food soil rings. Then brush thoroughly as outlined above.

4. Brush and clean all exterior surfaces. Use cleaning solution from the pan. Rinse well.

5. Flush entire unit with clear, tepid water.

6. To prevent development of undesirable odors and flavors, rinse the pan with a solution of a recommended sanitizing agent,

then drain. Spray or fog inner surfaces with clear water to rinse. Keep cover closed until ready to resume cooking.

For mineral deposits and film caused by hard water and resistant food residues: Let pan cool until cold to touch, then clean

7.

inside and outside with a recommended solution. (Obtain a suitable formula from your supplying dealer.) It may be

necessary to soak the deposits well before scrubbing them off with a brush. In hard water areas, this procedure should be

carried out weekly.

IMPORTANT: Never use steel wool, metal sponges or scouring powders when cleaning your Braising Pan. The resulting

scratches, no matter how minute, will shorten the life of the equipment, detract from its appearance, make subsequent

cleaning increasingly difficult, and harbor bacteria which will multiply and lead to food contamination.

MECHANICAL:

This depends on the degree of usage.

1. Trunnion bearings at the front of the pan, where it tilts, have a zerk fitting. A small amount of cup grease should be forced

into these bearings once or twice a year. These zerk fittings are accessible when the front enclosure is removed.

2. This enclosure should be opened occasionally and its inside cleaned out.

3. The pillow bearings on the SAGINAW screw shaft also have ZERK FITTINGS. They should be lubricated occasionally.

Excess grease should be spread over the threads of the shaft.

4. The NEEDLE bearing immediately behind the handwheel should be lubricated. All needle bearings shown on drawing

number 1074101 should also be oiled.

GAS TILTING BRAISING PANS

SECTION TWO — USER'S GUIDE

PAGE 4

8-88

Page 11

MAINTENANCE

SECTION TWO

— USER'S GUIDE

Part No. Description

1163453 Upper Drive Shaft

1056700 Bearing for rod - 2-piece

1058500 Thrust Washers - 2-piece

1041200 Spring Pin - Holds crank wheel on shaft

USER’S GUIDE

COMPOSITE SKETCH SHOWING PARTS OF BOTH HAND & POWER LIFTS BRAISING

PAN MECHANISM DRG. NO. 1074101

GAS TILTING BRAISING PANS

PAGE 5

Page 12

MAINTENANCE

USER’S GUIDE

GAS TILTING BRAISING PANS

SECTION TWO — USER'S GUIDE

PAGE 6

BRAISING PAN LID MECHANISM DRG NO. 1074102

Litho in U.S.A.

8-88

Page 13

GAS TILTING BRAISING PAN

SERVICE

ADJUSTMENTS

WARNING:

AT LEAST TWICE A YEAR HAVE YOUR SOUTHBEND AUTHORIZED SERVICE AGENCY

CLEAN AND ADJUST THE UNIT FOR MAXIMUM PERFORMANCE.

All units are adjusted at the factory. In case of problems in operation at initial installation, check type of gas and

manifold pressure and compare with information listed on the serial plate.

AUTO SAFETY PILOT:

The pilot flame should be 1/2" to 3/4" in length. It must be large and sharp enough to cause the bulb to glow to a dull

red, or sufficient to hold the safety valve open.

1. Remove pilot adjustment cap (see wiring diagram, page 4 this Section).

2. Adjust pilot key to provide properly sized flame.

3. Replace pilot adjustment cap.

MAIN BURNERS:

The orifices on the manifold are the fixed type, sized for the respective gas supply.

The burner flame characteristics are controlled by varying the primary air mixer. There should be a clear blue flame

with a distinct inner cone on each port. Excessive primary air may cause "blowing off" or the flames leaving the

ports. Lack of primary air causes soft or yellow tipped flames.

Keep primary air shutters free from lint and accumulations which affect burners operating characteristics.

GAS TILTING BRAISING PANS

SECTION THREE — SERVICE

SERVICE

PAGE 1

Page 14

ADJUSTMENTS

PRESSURE REGULATOR:

The pressure regulator is factory set at 4" W.C. for natural gas and 10" W.C. for LP gas. To check the manifold pressure:

1. Turn thermostat "OFF" and Unitrol knob to "PILOT" setting.

2. Remove pressure tap plug from outlet side of Unitrol body (see diagram page 4, this Section).

3. Install a fitting appropriate to connect a manometer.

4. Turn Unitrol dial to "ON" position and thermostat "ON." The burners will ignite.

5. With burners on, read manometer.

SERVICE

6. If manometer does not read 4" W.C. for natural gas or 10" W.C. for LP gas, adjust regulator.

7. Remove regulator adjustment screw cap (see diagram page 4, this Section).

8. With small screwdriver rotate adjustment screw "CLOCKWISE" to increase or "COUNTER-CLOCKWISE" to decrease

pressure. Be sure to adjust with burners "ON."

9. Turn thermostat "OFF" and set Unitrol knob to "PILOT" position.

10.

Remove manometer and replace pressure tap plug.

11.

Replace adjustment screw cap.

THERMOSTAT: To Recalibrate

1. Remove knob from dial shaft "B."

2. Turn screw "A" clockwise to decrease and counterclockwise to increase temperature.

3. 1/4 turn changes the temperature 35° F.

4. Replace knob on dial shaft.

GAS TILTING BRAISING PANS

SECTION THREE — SERVICE

PAGE 2

Litho in U.S.A.

8-88

Page 15

TROUBLE SHOOTING:

SERVICE

Problem Look for —

Burners do not come on

Pilot will not stay ignited

Pilot produces carbon deposits

Burners produce carbon deposits

gas supply to unit off.

-

manual gas valve in unit off.

-

Unitrol in "OFF" or "PILOT" position.

-

pilot not ignited.

-

- thermostat not "ON."

pan not in lowest position.

-

Unitrol in "OFF" position.

-

pilot gas not adjusted properly.

-

gas supply to unit off.

-

valve in unit off.

-

bad thermopile.

-

dirty thermopile connections at Unitrol.

-

bad magnet in Unitrol.

-

clogged orifice.

-

draft condition.

-

air in gas line.

-

improper ventilation system.

-

unit connected to wrong gas supply.

-

pressure regulator not adjusted correctly.

-

pilot gas not adjusted correctly.

-

wrong size orifices.

-

burner air not adjusted properly.

-

connected to wrong gas supply.

-

pressure regulator not adjusted correctly.

-

SERVICE

GAS TILTING BRAISING PANS

SECTION THREE — SERVICE

PAGE 3

Page 16

SERVICE

SERVICE

GAS TILTING BRAISING PANS

SECTION THREE — SERVICE

PAGE 4

Litho in U.S.A.

8-88

Page 17

GAS TILTING BRAISING PAN

For parts not listed, consult a Southbend Authorized Parts Distributor or Southbend Authorized Service Agency. If

PARTS

PARTS

WARNING:

INSTALLATION OF OTHER THAN GENUINE SOUTHBEND PARTS WILL VOID THE

WARRANTY ON THIS EQUIPMENT.

The serial plate is located inside the cabinet on the bottom, at the left edge. An "E" suffix at the end of the model

number indicates the unit is equipped with electronic ignition.

Replacement parts may be ordered either through a Southbend Authorized Parts Distributor or a Southbend

Authorized Service Agency.

When order parts, please supply the Model Number, Serial Number, Part Number, Description, plus Finish, Type

of Gas and Electrical Characteristics, as applicable.

necessary, please consult Southbend Parts Department for assistance.

PART NO. PART NAME PART NO. PART NAME

1029502 HANDLE CHAIN 0438 GREASE DRAWER ASM.

1057300 SPROCKET (LOWER) 1082401 TURNBUCKLE ROD - RT.

1083196 MOUNT BRACKET ASM. 1056899 HANDWHEEL ASM.

1056700 NEEDLE BEARING 1057000 LID HANDLE

13109 STABILIZER SPRING 1085895 LID HINGE PLATE - RT.*

1041200 SPRING PIN 1085894 LID HINGE PLATE - LT.*

1163453 DRIVE SHAFT (UPPER) 1062100 WIRE CONNECTOR

1063801 DRIVE SHAFT (LOWER) 1055899 THERMOSTAT (T3)

1063399 FLEX COUPLING 1057700 MERCURY TILT HEAT CONTROL SWITCH

1058799 PILLOW BEARING ASM.

9130-P ROLLER BALL BEARING 1163454 SLIP CLUTCH & SPROCKET

1059200 SAGINAW SCREW 1163455 FRONT COVER

1162241 BALL NUT HOUSING ASM. 1064498 BURNER

1126598 TILT ARM & BUSHING 1059000 CARRY OVER

1058001 BRONZE BEARING 1055999 UNITROL CONTROL - NAT. GAS

1164825 DOOR CATCH (FRICTION CLIP) 15771 MANUAL VALVE

6404-P MINUTE MINDER (MECH. 60 MIN.) 1063555 BURNER ORIFICE - NAT. GAS

1124500 HINGE HOOK 7" PAN 1063566 BURNER ORIFICE - LP GAS

1124501 HINGE HOOK 9" PAN 1056224 PILOT ORIFICE - NAT. GAS

1019100 SPROCKET LID CHAIN 1056211 PILOT ORIFICE - LP GAS

1029503 LID CHAIN 1056299 PILOT ASM. - NAT. GAS

1089-P SPRING-LID MECHANISM 1056298 PILOT ASM. - LP GAS

1082400 TURNBUCKLE ROD - LT. 1055998 UNITROL CONTROL - LP GAS

1029400 TURNBUCKLE 1056400 THERMOPILE AND LEAD

1165686 LID HINGE PLATE -RT.** 1165682 LID HINGE PLATE - LT.**

1165678 LID STAKE ASM. (ALUM.) 1167549 CASTER ASM. - SWIVEL

— RT. OR LT. 1167550 CASTER ASM. - SWIVEL W/LOCK

*This Lid Hinge Plate is used on units manufactured prior to October, 1983.

**This Lid Hinge Plate is used on units manufactured after October, 1983, with aluminum lid stakes bolted to lid.

For Braising Pans without a Slip Clutch (no '-2' suffix on the serial number) make the following part number

substitutions:

1167093 STAINLESS STEEL LEGS - 1-1/4" x 8-3/8"

(S7)

PARTS

FOR: USE:

1163453 1063800 Upper Drive Shaft

1163454 1057300 Sprocket

GAS TILTING BRAISING PANS

SECTION FOUR - PARTS

PAGE 1

Page 18

southbend

A MIDDLEBY COMPANY

1100

Old Honeycutt

Fuquay

-

Varina, NC

Pizza ovens

Steam kettles

Salamander broilers

(919) 552-9161

FAX (919) 552-9798

(800) 348-2558

Convection ovens Fryers Cooker/mixer kettles

Cook & hold convection ovens Special & custom equipment Floor model broilers

Bake & roast ovens Convection steamers Under fired broilers

Ranges Tilting braising pans Cheese melters

Page 19

GAS TILTING

1100

Old Honeycutt

Fuquay

-

Varina. NC

(919) 552

-

9161 FAX

(919) 552

-

9798 (

800) 348

-

2556

FAX

(919) 552 9798

Litho in U.S.A.

BRAISING PAN

A product with the Southbend name incorporates the best in durability and low

maintenance. We all recognize however, that replacement parts and occasional

professional service may be necessary to extend the useful life of this unit. When

service is needed, contact a Southbend Authorized Service Agency, or your

dealer. To avoid confusion, always refer to the model number, serial number, and

type of your unit.

southbend

A MIDDLEBY COMPANY

GAS TILTING BRAISING PAN

(Manuel Section BP)

8-88

Loading...

Loading...