Page 1

STp.1120n

User’s Guide

Page 2

Page 3

STp.1120n

User’s Guide

Source Technologies, LLC

2910 Whitehall Park Drive

Charlotte, NC 28273

Phone: 1.800.922.8501

Fax: 704.969.7595

www.sourcetech.com

Page 4

Page 5

Copyright

Copyright ©2012 by Source Technologies, LLC. All rights reserved.

No part of this document may be reproduced or utilized in any form or by any means

electronic or mechanical, including photocopying, recording or by any information

storage and retrieval system, without permission in writing from Source Technologies.

Published in the United States of America by:

Source Technologies, LLC

2910 Whitehall Park Drive

Charlotte, NC 28273

Author: Source Technologies, LLC

Notice

To the best of our knowledge, the information in this publication is accurate: however,

Source Technologies, LLC does not assume any responsibility or liability for the accuracy

or completeness of, or consequences arising from, such information. This document is

intended for informational purposes only. Mention of trade names or commercial

products does not constitute endorsement or recommendation for use by Source

Technologies, LLC. Final determination of the suitability of any information or product for

use contemplated by any user, and the manner of that use is the sole responsibility of the

user. We recommend that anyone intending to rely on any recommendation of materials

or procedures mentioned in this publication should satisfy himself as to such suitability,

and that he can meet all applicable safety and health standards.

All trademarks and registered trademarks appearing in this document are the property of

their respective owners.

Document Number: TP1000UG

Revision: B

STp.1120n User’s Guide

Page 6

Page 7

Agency Compliance

This product complies to the following:

CFR 47 Part 15, Class A Digital Device

This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions: 1) This device may not

cause harmful interference, and 2) this device must accept any

interference received, including interference that may cause

undesired operation.

This Class A digital apparatus complies with Industry Canada ICS003 class A requirements.

UL 60950-1 Safety of Information Technology Equipment Including

Electrical Business Equipment

CAN/CSA-C22.2 No.60950-1 Safety of Information Technology

Equipment Including Electrical Business Equipment

European Council Directive 2004/108/EC “EMC Directive”

EN55022, Emissions, Class A

EN55024, Immunity

EN61000-3-2, Harmonics

EN61000-3-3, Voltage Fluctuations and Flicker

European Council Directive 206/95/EC “Low Voltage Directive”

EN60950-1

IEC 60950-1 (CB Scheme)

IEC 60825-1 Safety of Laser Products (applies to barcode reader

option)

EN 300 328 V1.7.1 (2006-10) - Electromagnetic Compatibility and

Radio Spectrum Matters (applies to 802.11b/g wireless module

option)

EN45014 General Criteria for Suppliers Declaration of Conformity

Directive 93/68/EEC CE Marking

Page 8

GOST-R (Russia)

A

R

12

WEEE Information for Source Technologies Customers and

Recyclers (Europe)

Under the European Union’s Waste Electrical and Electronic

Equipment (WEEE) Directive and implimenting regulations, when

customers buy new thermal printer equipment from Source

Technologies they are entitled to send the new equipment back for

recycling when this ultimately becomes waste.

Instructions to both EU customers and recyclers/treatment

facilities wishing to obtain disassembly information are provided by

following the link below:

http://www.sourcetech.com/support/recycling-disposal/weee

Directive 2002/95/EC Restrictions on the Use of Certain

Hazardous Substances in Electronics and Electric Equipment

(RoHS)

Directive 2002/96/EC Waste Electrical and Electronics Equipment

(WEEE)

Directive 94/62/EC Packaging and Packaging Waste

RoHS Compliant

Page 9

Table of Contents

Table of Contents

1. Safety

Warnings and Cautions ........................................................................................1

General Safety Information ...................................................................................1

2. Overview

About the Printer ...................................................................................................3

Standard Features ................................................................................................6

Options .................................................................................................................7

Unpacking the Printer ...........................................................................................8

Checking the Contents .........................................................................................8

Specifications .......................................................................................................8

3. Connections and Setup

Connections ........................................................................................................11

Media Loading ....................................................................................................11

Media Hanger - Self-Centering ...........................................................................12

Media Hanger - Cantilever ..................................................................................19

Media Hub ..........................................................................................................27

Installing Ribbon .................................................................................................34

Configuring Media and Ribbon Settings ........................ .....................................39

Optional Rewinder ..............................................................................................42

Top-of-Form Sensor ...........................................................................................43

Removing Ribbon Wrinkle ..................................................................................48

Installing Cutter and Tray ...................................................................................51

Print Driver Installation .......................................................................................54

Printer Properties ................................................................................................80

Printing Preferences ...........................................................................................82

4. Menu System

Menu Overview ...................................................................................................87

Layout of the Display ..........................................................................................87

Home Screen ......................................................................................................88

Information Button .............................................................................................89

Feed Button ........................................................................................................93

STp.1120n User’s Guide

Page 10

Menu ..................................................................................................................93

5. Cleaning and Maintenance

Overview ...........................................................................................................123

Intervals ............................................................................................................ 123

Supplies ............................................................................................................ 123

Cleaning the Automatic Loading Sensor ..........................................................124

Cleaning the Top-of-Form Sensor ....................................................................124

Cleaning the Label Low Sensor ........................................................................124

Cleaning the Printhead .....................................................................................124

Cleaning the Cutter ...........................................................................................125

6. Troubleshooting

Errors ................................................................................................................ 127

Warnings ..........................................................................................................128

Troubleshooting ................................................................................................ 128

Troubleshooting Print Quality ...........................................................................131

7. Terms and Definitions

Processing State ..............................................................................................133

Printer State ......................................................................................................133

Media Setup .....................................................................................................133

Basic ................................................................................................................. 133

Advanced ..........................................................................................................134

Tools ................................................................................................................. 138

Test ...................................................................................................................139

8. Appendix A

Symbol Sets .....................................................................................................141

Fonts .................................................................................................................142

Barcodes ..........................................................................................................144

STp.1120n User’s Guide

Page 11

1 Safety

Warnings and Cautions

The following Warnings and Cautions are used throughout this manual:

Warning: Warnings alert you to possible safety risks.

Caution: Cautions alert you to the potential for equipment damage.

General Safety Information

Caution: This product is intended for indoor use only.

All service procedures should be done by properly trained and qualified service personnel.

Any on-site assembly required during the installation process must be performed by properly trained and

qualified service personnel.

The product must be connected to a properly grounded and appropriately rated AC receptacle using the

supplied cord set.

Caution: This product contains sensitive electronic components that could be damaged

if exposed to excessive force.

Caution: Use only factory-approved consumables and cleaning kits. Use of any non-

approved supplies could damage the product and void the warranty.

Caution: Do not connect the wireless antenna connection to any outside plant

connection.

1 STp.1120n User’s Guide

Page 12

1 | Safety

This product must be connected to a properly grounded and appropriately rated AC

receptical.

Figure: 1 - 1 Caution - Hot

The printhead heats during printing. Do not touch.

STp.1120n User’s Guide 2

Page 13

2Overview

About the Printer

Product Tour

The following illustrations show some of the features and available options for the

STp.1120n near edge printer.

Figure: 2 - 1 Front View

1

2

3

4

5

6

1. Touchscreen Control Panel

2. Power LED

3. Error LED

4. Cutter (Optional)

5. Cutter Tray (Optional)

6. USB Host Interface (Optional)

3 STp.1120n User’s Guide

Page 14

2 | Overview

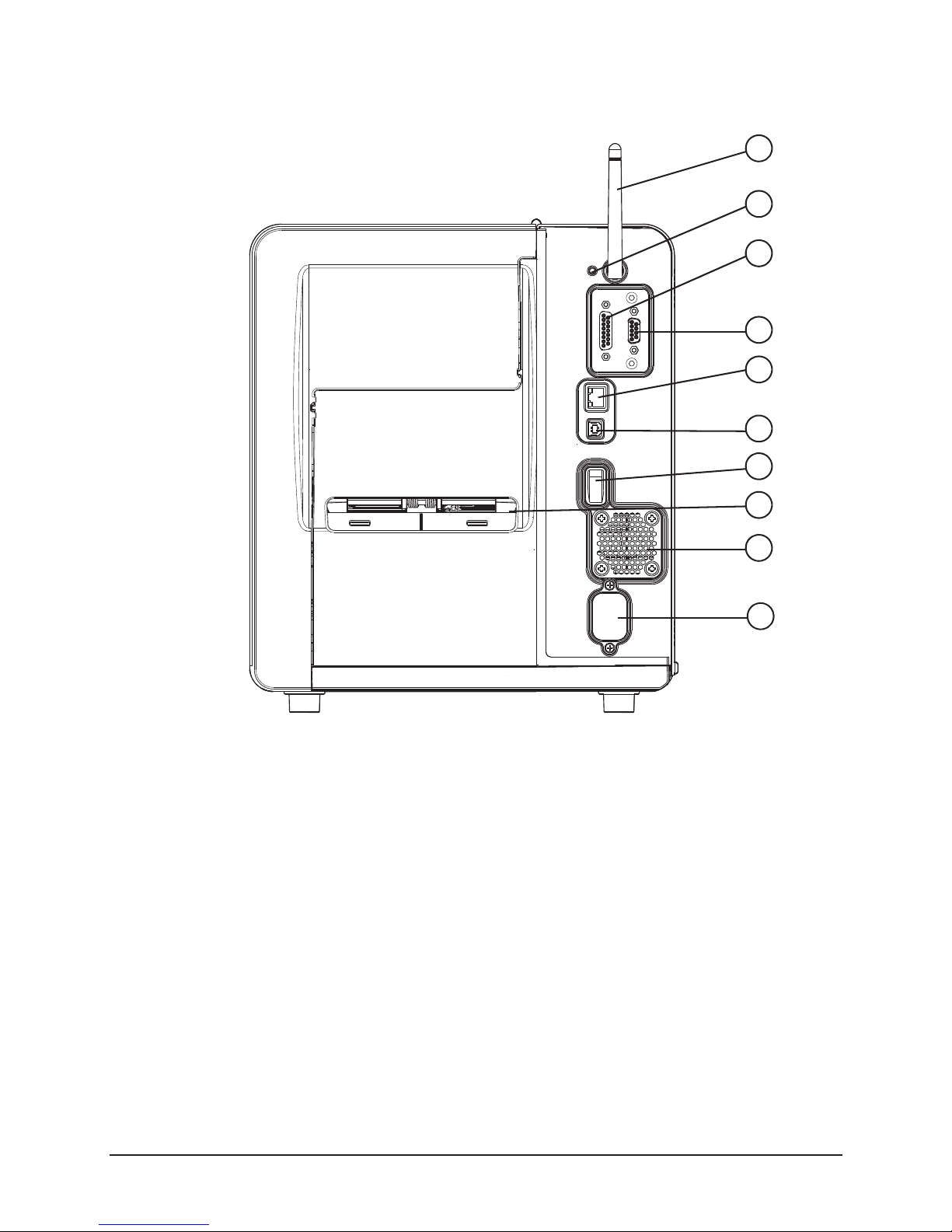

Figure: 2 - 2 Rear View

1

2

3

4

5

6

7

8

1. Wireless Antenna (Optional)

2. Reset Switch

3. GPIO Port (Optional)

4. Serial Port (Optional)

5. Ethernet/Network Port

9

10

6. USB Port

7. Power Switch

8. Fanfold Media Slot

9. Rear Compartment Vent

10.AC Power Inlet

STp.1120n User’s Guide 4

Page 15

Figure: 2 - 3 Media Area

.

1. Power Ribbon Transport Assembly (Optional)

2. Ribbon

3. Media

4. Media Hanger

5. Printhead Carriage Assembly

6. Printhead Latch

7. Printhead Latch Lever

8. Rear Fanfold Media Access Slot

9. Platen Carriage Assembly

10.Media Width Guide Adjustment

Knob

11.Bouncer

12.Lower Fanfold Media Access

Slot

13.Power Media Rewinder

Assembly (Optional)

1

2

3

4

5

6

7

8

9

10

11

12

13

Overview | 2

5 STp.1120n User’s Guide

Page 16

2 | Overview

Standard Features

The thermal printer has the following standard features:

Table 1: Standard Features

Features Descriptions

Max Print Speed 8 IPS / 203 mmps

Resolution 300 dpi / 11.8 dpmm

Memory 32MB Flash (8MB User Space) / 64MB DDR2 SDRAM

Printer Type • Direct Thermal

• Thermal Transfer (Optional)

Media Supply • Fan fold

• Roll-fed

• Die-cut

• Continuous Labels: perforated or continuous tag/ticket stock (8”

[203mm] roll max diameter on 1.0”, 1.5” or 3” [25mm, 38mm or

76mm] core).

Double-sided Top-of-Form

Sensor

Tear Bar Removable bar for tearing off gapped or continuous media.

Media Back Feed Capable of backing up at least 1.0” (for near edge printhead).

Control panel LED backlit color QVGA LCD with touchscreen.

Reset Button Inset on the rear of the unit for recovery or the resetting of the screen

LEDs Two LEDs on the front panel for Power and Error.

Power Switch Positioned on the rear of the unit.

Chassis / Media Cover Diecast construction with a clear side window.

Bar Codes See Appendix A

Fonts See Appendix A

Downloadable Font Types • True-Type Scalable

Adjustable position for center-biased stock:

• Label Gap

•Notch

• Reflective black mark on the bottom or the top of the form

calibration.

• Intellifont Scalable

• PCL Bitmap

Graphics Full support of PCL5e and GL/2 graphics capability.

STp.1120n User’s Guide 6

(Support for various host-based file fomats [PCX, BMP] are not part of

the PCL5e standard but are supported and converted by standard

applications)

Page 17

Features Descriptions

Overview | 2

Industry Standard Printer

Language

Interfaces • USB 2.0 Device

Real Time Clock User replaceable battery

Printer Driver Supported

Operating Systems

Operating Temperature 32°F (0°C) to 104°F (40°C)

Supported Languages in the

Display

HP PJL, HP PCL5e, HP GL/2 and HP XL, printer languages with autolanguage select and extensions for barcode capabilities. Bi-directional

communications capability is also supported.

• LAN 10/100

• Windows XP

• Windows Vista

• Windows 7

Front panel languages are configurable via translation files which may

be loaded on the printer. Check with your distributor for the most recent

list of available translations.

Options

The following options are available:

• Thermal Transfer (Ribbon)

• Internal Power Rewind with Batch Rewind

• Media Present Sensor

• Peel and Present

• Media Cutter

• Media Cutter Tray

• Applicator Port (General Purpose I/O) and Serial Port (RS-232C)

• Wireless Module

•USB Host Port

• Audio Indicator

• Synchronized Media Hanger

• Media Hub with 1.0”,1.5” or 3” Media Hub Adaptors

• Non-US Power Cords

7 STp.1120n User’s Guide

Page 18

2 | Overview

Unpacking the Printer

Upon receiving the printer, verify the box is undamaged. Carefully unpack the printer

from its packaging and visually check for any physical damage that may have occured

during shipment.

Checking the Contents

The contents may vary depending on your configuration. It is recommended that all

packaging materials be saved if the printer is to be shipped again. If the packaging

material is discarded, new packaging material may be available from your reseller.

• Printer

• Power Cord

• Driver CD

• Product documentation not included on the CD

• Accessories/Options

Additional items that may be required include the following:

• All Applicable Communication Cables

•Media

• Ribbon

Specifications

Print Characteristics

Table 2: Print Characteristics

4” Near Edge

Print Resolution 300 dpi (11.8 dpmm)

Max Print Width 4.27” (108.5 mm)

Max Print Speed 8 IPS (203 mmps)

Max Feed Speed 10 IPS (254 mmps)

Max Back-up Speed 5 IPS (127 mmps)

Media Width Range* 1” - 4.65” (25.44 mm - 118.1

mm)

Media Thickness Range* .003” - .010” (.076 mm - .254

Ribbon Width Range** 1” - 4.65” (25.44 mm - 118.1

Print Length .2” - 99” (5.08 mm - 2475.6

STp.1120n User’s Guide 8

mm)

mm)

mm)

Page 19

*Media wound out.

**Coated side in or out.

Dimensions and Weight

Table 3: Dimensions and Specifications

Height Width Depth Weight

11.9 in (30.3 cm) 10.8 in (27.4 cm) 18.7 in (47.5 cm) 41 lbs. (19 kg)

Environmental

Table 4: Temperatures

Temperature Humidity

Operating 5°C to 40°C <=20% to 80%

Storage -20°C to 60°C <=35%

Thermal Shock 0°C to 60°C Ambient

Overview | 2

Print Driver Requirements

Table 5: Print Driver Minimum System Requirements

Minimum System Requirements

Processor / Speed 500 MHz processor

RAM 512MB

Hard Drive Space 6MB

Supported Operating Systems Windows XP - x86 & x64

Windows Vista - x86 & x64

Windows 7 - x86 & x64

Configuration Utility

Table 6: Configuration Utility Minimum System Requirements

Minimum System Requirements

Processor / Speed 500 MHz processor

9 STp.1120n User’s Guide

Page 20

2 | Overview

Minimum System Requirements

Supported Operating Systems Windows XP - x86 & x64

Windows Vista - x86 & x64

Windows 7 - x86 & x64

Windows 2003 Server - x86 & x64

Windows 2008 Server - x86 & x64

Windows 2003 Server R2 - x86 & x64

RAM 256MB

Hard Drive Space 5MB

Minimum Screen Resolution 800 x 600

.NET Framework 2.0

STp.1120n User’s Guide 10

Page 21

3 Connections and Setup

Connections

Power

To connect the printer to a viable power source, please follow the steps below.

Caution: Ensure the printer power switch is off before connecting the AC power and

data/network connectivity cables to the printer.

Caution: Adhere to all environmental requirements when installing and using the printer.

Use of the product in an unsuitable environment may affect print quality and the

durability of the printer and may void the manufacturer’s warranty.

1. Place the printer on a suitable level surface capable of securely supporting 50lbs.

2. Connect the AC power cord to the AC power inlet on the back of the printer.

3. Connect the AC power cord to AC utility power.

Data

Printer data connectivity can be accomplished by the following standard or optional

interfaces:

•USB

• Ethernet/Network

• Serial (Optional)

• GPIO (Optional)

Connect the appropriate interface cables for your network configuration.

Media Loading

The printer is designed to print with the media being center-biased. There are three

different media mounts available including two media hangers and one media hub.

The standard cantilever mount requires the manual center-alignment of the media.The

optional media hanger synchronizes the adjustment to facilitate the centering of the

media. The optional media hub is designed to center-bias the media as well.

Please consult your reseller to obtain the appropriate media.

Note: The printer should be connected to AC power and running during media loading.

11 STp.1120n User’s Guide

Page 22

3 | Connections and Setup

1. Inside media adjustment lever

2. Paper Low Sensor (Optional)

3. Self-centering media hanger

4. Outside media adjustment lever

5. Media adjuster knob

1

2

3

4

5

Media Hanger - Self-Centering

Figure: 3 - 1 Self-Centering Media Hanger

Media core size:

• 3” (76.199mm)

Media roll diameter:

• Maximum -- 8”

Media Roll Width:

STp.1120n User’s Guide 12

Page 23

Connections and Setup | 3

• Maximum -- 4.65”

Media thickness:

• .003” to .01”

Media dimensions:

• Minimum specifications - .5” H x 1” W

Note: Ensure there is no tape or adhesive residue on the media roll.

Installing Media for the First Time

1. Open the media cover.

2. Unlock the printhead mechanism by turning the printhead latch lever clockwise

about 190

Note: Do not unlatch the printhead mechanism.

Figure: 3 - 2 Unlock the Printhead Mechanism

°.

13 STp.1120n User’s Guide

Page 24

3 | Connections and Setup

3. Center the media adjuster knob and pull it to widen the gap between the two media

adjustment levers.

Figure: 3 - 3 Self-Centering Media Hanger from Top

4. Rotate the outside media adjustment lever downward.

Figure: 3 - 4 Outside Media Adjustment Lever

STp.1120n User’s Guide 14

Page 25

Connections and Setup | 3

5. Gently route the media core over the outside media adjustment lever onto the

media hanger.

Caution: Be careful not to damage the outside media adjustment lever.

Figure: 3 - 5 Media Installation

6. Rotate the outside media adjustment lever upward.

Figure: 3 - 6 Outside Media Adjustment Lever

7. Slide the media adjuster knob inward to center the media roll on the media hanger.

15 STp.1120n User’s Guide

Page 26

3 | Connections and Setup

Note: Ensure the media roll turns freely. There should be .8mm to 1.5mm clearance

between the media adjustment levers and the media roll.

8. Rotate the media guide adjustment knob counter clockwise to widen the guides

until they are set slightly wider than the width of the media.

Figure: 3 - 7 Media Guide Adjustment Knob

9. Route the media under the bouncer and into the media guides.

Figure: 3 - 8 Media Guides

Media Guides

STp.1120n User’s Guide 16

Page 27

Connections and Setup | 3

10.Press the pinch roller knob and slide the media .25 inches beyond the pinch roller.

Figure: 3 - 9 Pinch Roller

Pinch Roller Knob

Pinch Roller

11.Rotate the media guide adjustment knob clockwise to tighten the guides.

Note: Ensure the guides are neither too tight nor too loose on the media or print quality

will be affected.

Figure: 3 - 10 Tighten Media Guide Adjustment Knob

17 STp.1120n User’s Guide

Page 28

3 | Connections and Setup

12.Rotate the latch lever counter-clockwise until the printhead mechanism is locked.

Figure: 3 - 11 Lock the Printhead Mechanism

Note: If the media has been installed properly and read by the autoloading sensor, it

should automatically feed under the printhead once the printhead carriage assembly has

been latched and locked. If the media does not automatically load, unlatch the printhead

assembly and manually feed the media under the printhead. Upon locking the printhead,

it would be beneficial to both feed the media by selecting the Feed button on the main

menu to properly set the next label and perform a Paper Calibration.

13.Set the Top-of-Form sensor

Note: Refer to the section called “Setting the Top-of-Form Sensor”.

STp.1120n User’s Guide 18

Page 29

Media Hanger - Cantilever

Figure: 3 - 12 Cantilever Media Hanger

Connections and Setup | 3

1

2

3

1. Inside media adjustment lever

2. Cantilever media hanger

3. Outside media adjustment lever

Media Specifications

Media core size:

• 3” (76.199mm)

Media roll diameter:

• Maximum -- 8”

Media Roll Width:

• Maximum -- 4.65”

Media thickness:

• .003” to .01”

Media dimensions:

19 STp.1120n User’s Guide

Page 30

3 | Connections and Setup

• Minimum specifications - .5” H x 1” W

Note: Ensure there is no tape or adhesive residue on the media roll.

Installing Media for the First Time

1. Open the media cover.

2. Unlock the printhead mechanism by turning the printhead latch lever clockwise

about 190°.

Note: Do not unlatch the printhead mechanism.

Figure: 3 - 13 Unlock the Printhead Mechanism

STp.1120n User’s Guide 20

Page 31

Connections and Setup | 3

3. Rotate the inside media adjustment lever and position the bottom of the lever to the

appropriate width so the media is centered with the printer carriage assembly.

Figure: 3 - 14 Cantilever Media Adjustment

4. Rotate the inside media adjustment lever upward to lock its position.

21 STp.1120n User’s Guide

Page 32

3 | Connections and Setup

5. Rotate the outside media adjustment lever outward.

Figure: 3 - 15 Cantilever Media Adjustment

6. Gently route the media core over the outside media adjustment lever onto the

media hanger.

Caution: Be careful not to damage the outside media adjustment lever.

STp.1120n User’s Guide 22

Page 33

Connections and Setup | 3

7. Slide the outside media adjustment lever inward towards the media core and rotate

the lever upwards to lock in place.

Figure: 3 - 16 Cantilever Media Adjustment

Note: Ensure the media roll turns freely. There should be .8mm to 1.5mm clearance

between the media adjustment levers and the media roll.

23 STp.1120n User’s Guide

Page 34

3 | Connections and Setup

8. Rotate the media guide adjustment knob counter-clockwise to widen the guides

until they are set slightly wider than the width of the media.

Figure: 3 - 17 Media Guide Adjustment Knob

9. Route the media under the bouncer and into the media guides.

Figure: 3 - 18 Cantilever Media Adjustment

Media Guides

STp.1120n User’s Guide 24

Page 35

Connections and Setup | 3

10.Press the pinch roller knob and slide the media .25 inches beyond the pinch roller.

Figure: 3 - 19 Pinch Roller

Pinch Roller Knob

Pinch Roller

11.Rotate the media guide adjustment knob clockwise to tighten the guides.

Note: Ensure the guides are neither too tight nor too loose on the media or print quality

will be affected.

Figure: 3 - 20 Tighten Media Guide Adjustment Knob

25 STp.1120n User’s Guide

Page 36

3 | Connections and Setup

12.Rotate the latch lever counter-clockwise until the printhead mechanism is locked.

Figure: 3 - 21 Lock the Printhead Mechanism

Note: If the media has been installed properly and read by the autoloading sensor, it

should automatically feed under the printhead once the printhead carriage assembly has

been latched and locked. If the media does not automatically load, unlatch the printhead

carriage and manually feed the media under the printhead. Upon locking the printhead, it

would be beneficial to feed the media by selecting the Feed button on the main menu to

properly set the next label.

13.Set the Top-of-Form sensor.

Note: Refer to the section called “Setting the Top-of-Form Sensor”.

STp.1120n User’s Guide 26

Page 37

Media Hub

1

2

3

4

Figure: 3 - 22 Media Hub Layout from Top

5

Connections and Setup | 3

1. Media hub adjustment channels

2. Media hub adjustment lever

3. Hub adjustment slots

4. Media hub

5. Core holders

Media Specifications

Media core size:

• 3” (76.199 mm) standard

• 1” (25.4 mm) optional

• 1.5” (38.099 mm) optional

Media roll diameter:

• Maximum - 8”

Media roll width:

• Maximum - 4.65”

Media thickness:

• .003” to .01”

27 STp.1120n User’s Guide

Page 38

3 | Connections and Setup

Media dimensions:

• Minimum specifications - .5” H x 1” W

Note: Ensure there is no tape or adhesive residue on the media roll.

Installing Media for First Time

1. Open the media cover.

2. Unlock the printhead mechanism by turning the printhead latch lever clockwise

about 190°.

Note: Do not unlatch the printhead mechanism.

Figure: 3 - 23 Unlock the Printhead Mechanism

STp.1120n User’s Guide 28

Page 39

Connections and Setup | 3

3. Press the media hub adjustment lever and pull the media hanger outward using the

handle.

Figure: 3 - 24 Media installation

Media Hub

Adjustment

Lever

Hub

Handle

4. Hold the media hub adjustment lever and place the media core on the core holders.

5. Slide the media hub inward using the handle and release the hub adjustment lever

once the media is supported.

Figure: 3 - 25 Media Installation

29 STp.1120n User’s Guide

Page 40

3 | Connections and Setup

6. Rotate the media guide adjustment knob counter-clockwise to widen the guides

until they are set slightly wider than the width of the media.

Figure: 3 - 26 Media Guide Adjustment Knob

7. Route the media under the bouncer and into the media guides.

Figure: 3 - 27 Media Guide

Bouncer

Media

Media Guide

Guide

STp.1120n User’s Guide 30

Page 41

Connections and Setup | 3

8. Press the pinch roller knob and slide the media .25 inches beyond the pinch roller.

Figure: 3 - 28 Pinch Roller View from Top

Pinch Roller Knob

Pinch Roller

9. While pressing the pinch roller knob, rotate the media guide adjustment wheel until

the media guide touches the media on both sides.

Caution: Ensure the media guides are neither too tight nor too loose or print quality will

be affected and feed issues may develop.

10.Rotate the media guide adjustment knob clockwise to tighten the guides.

31 STp.1120n User’s Guide

Page 42

3 | Connections and Setup

Note: Ensure the guides are neither too tight nor too loose on the media or print quality

will be affected.

Figure: 3 - 29 Tighten Media Guide Adjustment Knob

11.Rotate the latch lever counter-clockwise until the printhead mechanism is locked.

Figure: 3 - 30 Lock the Printhead Mechanism

Note: If the media has been installed properly and read by the autoloading sensor, it

should automatically feed under the printhead once the printhead carriage assembly has

been latched and locked. If the media does not automatically load, unlatch the printhead

carriage and manually feed the media under the printhead. Upon locking the printhead, it

STp.1120n User’s Guide 32

Page 43

Connections and Setup | 3

would be beneficial to feed the media by selecting the Feed button on the main menu to

properly set the next label.

12.Set the Top-of-Form sensor.

Note: Refer to the section called “Setting the Top-of-Form Sensor”.

33 STp.1120n User’s Guide

Page 44

3 | Connections and Setup

Installing Ribbon

For thermal transfer printing, ribbon must be installed. The ribbon should be slightly

wider than the print media being used to ensure proper coverage.

1. Open the media cover.

2. Rotate the printhead latch lever clockwise to unlock and raise the printhead

carriage assembly .

Figure: 3 - 31 Printhead Latch Lever

3. Slide the ribbon core over the ribbon supply hub until the core is centered on the

hub.

STp.1120n User’s Guide 34

Page 45

Note: Only use ribbon with a 1” diameter core.

Figure: 3 - 32 Install Ribbon

Ribbon Supply Hub

Connections and Setup | 3

4. Route the ribbon between the ribbon cam roller and the green top-of-form

adjustment lever .

Note: The printer supports both inside ink and outside ink. Ensure the ink side faces the

media.

Note: See the Menu section for information on setting the printer to run inside or outside

ink.

35 STp.1120n User’s Guide

Page 46

3 | Connections and Setup

Caution: Do not route the ribbon under the green top-of-form sensor.

Figure: 3 - 33 Route Ribbon (Inside ink ribbon is shown)

Cam Roller

Inside Ink Shown

Top-of-Form

Sensor Adjustment

Lever

STp.1120n User’s Guide 36

Page 47

Connections and Setup | 3

5. Route the ribbon under the printhead, over the ribbon shield and clockwise around

the ribbon rewinder hub.

Figure: 3 - 34 Route to Ribbon Rewinder Hub

Note: Roll the ribbon around the ribbon rewinder hub at least five (5) times to ensure it

will stay in position.

6. Ensure the thermal transfer option is selected through the control panel.

7. Set the thermal transfer option to coated in (inside ink) or coated out (outside ink)

depending on the ribbon type.

Note: See the menu section for more information about the printer settings.

37 STp.1120n User’s Guide

Page 48

3 | Connections and Setup

8. Rotate the printhead carriage assembly counter-clockwise until it latches.

Figure: 3 - 35 Latch the Printhead Carriage Assembly

9. Rotate the printhead latch lever counter-clockwise to lock the printhead carriage.

Note: Ensure the printhead latch lever has locked the printhead mechanism before

printing or the printer will enter a no-print condition.

Note: When removing the ribbon from the ribbon rewinder hub, grasp the center of the

ribbon, squeeze to compress it and pull outward away from the rewinder hub.

STp.1120n User’s Guide 38

Page 49

Connections and Setup | 3

Configuring Media and Ribbon Settings

Once the media and ribbon have been loaded, the print parameters should be set to

match the type of media and ribbon being used. This will ensure optimal print quality.

Once set, the parameters will not need to be set again unless the media or ribbon types

are changed.

Using Media and Ribbon IDs

Media and ribbons supplied by Source Technologies and other vendors may have a 4digit media ID and ribbon ID assigned. These codes may be entered from the printer

front panel. All relevant print parameters will be automatically configured.

1. Select Menu > Basic > Media > Enter ID.

2. Select the Enter Paper ID field and enter the appropriate 4-digit code.

3. Select the green Accept button to confirm your selection.

4. Select the Enter Ribbon ID field and enter the appropriate 4-digit code.

5. Select the green Accept button to confirm your selection.

6. After selecting the Home button, select the green Accept button to again confirm

your selection or the red Reject button to cancel the changes.

Note: Although using media and ribbon IDs usually produce very good results, minor

adjustments may be required. Refer to the section titled Adjusting Media and Ribbon

Settings.

Selecting Media and Ribbon Types Manually

If media and ribbon IDs are not known, the media and ribbon types may be selected

manually.

1. Select Menu > Basic > Media > Select Type.

2. Using the up and down arrows, select your paper type.

Note: If the paper type is not known, either select Coated Direct Thermal for direct

thermal printing or select Coated Thermal Transfer for printing with a ribbon.

3. Tab to the Ribbon screen.

4. Using the up and down arrow, select your ribbon type.

Note: If the ribbon type is not known, select Wax to start. This selection can always be

changed if required.

5. Tab to the Settings screen.

39 STp.1120n User’s Guide

Page 50

3 | Connections and Setup

6. Select the Paper Sensor Type button until your paper type appears. The options

are as follows:

•Gap

• Mark on Top

• Mark on Bottom

•Notch

• Continuous

Note: For more information, refer to the section Setting the Top-of-Form Sensor.

7. Select the Paper Sensor Side button until the correct option appears. The options

are as follows:

•Outside

• Inside

Note: For more information, refer to the section Setting the Top-of-Form Sensor.

8. Select the Ribbon Mode button until the correct option appears. The options are as

follows:

•None

• Coated In

• Coated Out

Note: For more information, refer to the section Setting the Top-of-Form Sensor.

Note: CSI ribbon (shiny side facing outward) should be installed where the ribbon

unwinds in a counter-clockwise direction. CSO ribbon (dull side facing outward) should

be installed where the ribbon unwinds in a clockwise direction. If these settings do not

match the ribbon type being used, the ribbon supply hub will turn in the wrong direction.

Setting the Media and Ribbon Parameters Manually (Advanced)

There are times when all print parameters must be set manually. This can happen when

a new or specialized media or ribbon are being used. This advanced procedure will use

the Custom Manual utility.

Note: Some values may be grayed-out, meaning they are automatically set by default.

To change these values, select the Auto button next to the value field and then select the

green Accept button to confirm your choice to change to manual mode.

Note: Please see the Menu section for more information.

1. Select Menu > Advanced > Media.

2. Select the Paper Sensor Type field until the correct paper type appears. The

options are as follows:

STp.1120n User’s Guide 40

Page 51

Connections and Setup | 3

•Gap

• Mark on Top

• Mark on Bottom

•Notch

• Continuous

3. Select the Paper Sensor Side field until the correct option appears. The options

are as follows:

•Outside

• Inside

4. Select the Ribbon Mode field until the correct option appears. The options are as

follows:

•None

• Coated In

• Coated Out

5. Tab to the next screen and enter values for Heat and Heat Balance.

6. Tab to the next screen and enter values for Head Pressure and Rewinder

Tension.

7. Tab to the next screen and enter values for Ribbon Tension Front and Ribbon

Tension Rear.

8. Tab to the next screen and enter a value for Ribbon Low Diameter.

9. Select the Home button and select the green Accept button to confirm the settings.

41 STp.1120n User’s Guide

Page 52

3 | Connections and Setup

Optional Rewinder

The rewinder is designed to rewind in either direction but the direction must be set

through the menu.

Note: Either the peel plate or the rewinder plate must be installed.

Installation of Media

1. Route the media through the platen carriage assembly.

Note: Follow the instructions for the installed media hanger.

2. Route the media under the platen carriage and around the rewinder shaft.

3. Remove the metal clasp and wind the media around the rewinder shaft in the

desired direction.

Figure: 3 - 36 Rewinder

Clockwise

Metal Clasp

Counter Clockwise

4. Insert the edge of the media into one of the two grooves on the rewinder shaft.

STp.1120n User’s Guide 42

Page 53

Connections and Setup | 3

Note: For thicker labels, remove the label from the backing and insert the backing into

the groove.

Figure: 3 - 37 Media Rewinder

5. Reinstall the metal clasp into the grooves.

Perform the following steps to set the rewinder direction:

1. Select Menu > Basic > Printer Mode.

2. Select one of the three options.

Note: Upon exiting the utility, a prompt will ask the user to accept the changes or reject

them.

Top-of-Form Sensor

This printer is designed to use several types of media. The top-of-form sensor can read

media characteristics from the center to the left inside edge (viewing from the front of the

printer). Setting the top-of-form sensor to read specific media characteristics is done in

the control panel.

43 STp.1120n User’s Guide

Page 54

3 | Connections and Setup

Media Types Supported

There are five paper types that are supported. These include gap, mark on top, mark on

bottom, notch and continuous.

The following are illustrations of the types of supported media but not every supported

media is illustrated. Please contact your reseller for assistance in selecting the

appropriate media for the printer.

Figure: 3 - 38 Gap Example

Figure: 3 - 39 Notch Example

STp.1120n User’s Guide 44

Page 55

Figure: 3 - 40 Mark on Top Example

Figure: 3 - 41 Mark on Bottom Example

Connections and Setup | 3

Figure: 3 - 42 None

45 STp.1120n User’s Guide

Page 56

3 | Connections and Setup

Mark

Inside Sensor Pod

Outside Sensor Pod

Lever

Top-of-Form

Adjustment

Setting the Top of Form Sensor

The top of form sensor enables the printer to determine where the print should begin and

end. Once the appropriate media has been loaded, the media type can be entered

manually into the control panel.

1. Select Menu > Basic > Media from the control panel.

2. Select Select Type.

3. Select the paper and ribbon type.

4. Select Paper Sensor Type.

5. Select the paper sensor side, either inside or outside, that correlates with the type of

media being used.

Note: For example, media types with marks in the middle of the media, select Outside.

Note: The LED of the selected sensor will illuminate.

6. Unlock and release the printhead carriage assembly allowing it to open.

7. Using the adjustment lever, slide the top-of-form sensor so the appropriate LED-lit

sensor pod is centered over the mark, notch or gap that was selected.

Figure: 3 - 43 Example of Top-of-Form Sensor Adjustment on “Mark on Top” media

STp.1120n User’s Guide 46

Page 57

Connections and Setup | 3

Note: For illustration purposes, the image of the printhead carriage assembly was

removed in the image above. The LED sensor pods can be viewed from the front of the

printer, under the printhead carriage assembly. The active sensor pod is lit by an LED.

Note: If the wrong pod is active for your media type, check your settings.

8. Close and lock the printhead carriage assembly.

47 STp.1120n User’s Guide

Page 58

3 | Connections and Setup

Removing Ribbon Wrinkle

1. Center the supply ribbon core so the ribbon overlaps the media equally on both

sides.

2. Verify there are no folds or creases in the ribbon.

3. Adjust the front ribbon shield to the middle position of the mounting slot.

Figure: 3 - 44 Ribbon Shield

Front Ribbon Shield

4. Set the printer to print ten (10) consecutive Quality Labels from the Test menu.

5. Print the labels.

6. Check for ripples drifting left or right in the ribbon between the ribbon supply and the

cam roller.

STp.1120n User’s Guide 48

Page 59

Connections and Setup | 3

Note: If the ripples are vertically straight, advance to step 12 to adjust the ribbon plate.

Figure: 3 - 45 Supply Side Inspection

7. If excessive ripples exist, loosen the 3mm cam roller hex head screw enough to

allow the cam roller to spin.

Figure: 3 - 46 Cam Roller

Cam Roller

Screw

Cam Roller

Adjuster

8. Turn the cam roller adjuster until the ripples are either gone or are vertical.

49 STp.1120n User’s Guide

Page 60

3 | Connections and Setup

Note: The ripples must never drift left or right.

9. Tighten the cam roller screw.

10.Print ten (10) Quality Labels from the test menu.

Note: If wrinkles still appear continue with the adjustment procedure.

11.Loosen the ribbon shield adjustment screws.

12.While printing test labels, slowly adjust the lower shield until the ribbon tension is

constant from left to right and the wrinkles disappear.

Note: Adjust the ribbon shield by adding tension to the side with wrinkling or light print.

Note: Adjustment should eliminate side-to-side wrinkles.

STp.1120n User’s Guide 50

Page 61

Connections and Setup | 3

Installing Cutter and Tray

Warning: To prevent serious injury, never place a finger or object other than media near

the cutter mechanism.

Caution: Never cut paper or media in an area where adhesives exist. Doing so will

damage the cutter and void the manufacturer’s warranty.

Caution: The media cover will not close with both the cutter and present sensor installed

at the same time.

Caution: The printer must be powered off and disconnected from AC utility power prior

to the cutter installation.

The cutter and cutting tray are available options that must be installed after receiving the

printer.

Cutter

Perform the following procedure to install the cutter.

Note: The printer and the cutter tray must be on the same level surface.

1. Remove the lower cover from the printer.

Figure: 3 - 47 Lower Cover

51 STp.1120n User’s Guide

Page 62

3 | Connections and Setup

2. Loosen and remove the media plate thumbscrew and the media plate.

Figure: 3 - 48 Remove Media Plate

Note: Retain the thumbscrew for cutter installation.

3. Align the cutter with the power/data connector and install the thumbscrew to secure

it to the platen carriage assembly.

Figure: 3 - 49 Cutter Installation

STp.1120n User’s Guide 52

Page 63

Connections and Setup | 3

4. Rotate the cutter until it magnetically locks into place.

5. Activate the cutter option in the Options menu by selecting Menu > Advanced >

Printer > Options > Cutter.

Note: Feed a label through the printer and observe the cut distance to ensure it cuts on

the gap. If it cuts on the label, adjust your Cut Distance Adjust settings in the

Adjustments menu.

Note: A negative value moves the cut line toward the current label being printed. A

positive value moves the cut line toward the next label to be printed.

Cutter Tray

The cutter tray collects labels and media after they have been cut. The tray may be

installed before or after the installation of the cutter.

1. Place the tray mounting hooks into the baseplate slots.

Note: For a clearer illustration, the cutter has been removed from the illustration below.

Figure: 3 - 50 Cutter Tray Installation

Mounting Hooks

Baseplate

Slots

53 STp.1120n User’s Guide

Page 64

3 | Connections and Setup

Print Driver Installation

Overview

This section is intended to instruct the user about the installation of the Performance

Series Print Driver Setup Utility on a Windows® -based computer. The Setup Utility is

installed and used to successfully install the print driver for USB or network-connected

printers.

This installation should be executed only on a computer where no printer driver or print

driver utility has been installed unless otherwise noted.

The installer should note the following:

• The printer driver files are inst alled into the Windows print system so when a USB

printer is connected or a network printer is added, the system will automatically

recognize the printer and install the driver for it.

• The print driver utility is inst alled as a Windows program on the computer. The utility is a Windows program that can be accessed at any time to add additional Performance Series printers.

Requirements

The Performance Series print driver setup is supported on the following 32-bit or 64-bit

operating systems:

• Windows XP

• Windows V i sta

• Windows 7

• Windows Server 2003

• Windows Server 2008

• Windows Server 2008 R2

STp.1120n User’s Guide 54

Page 65

Connections and Setup | 3

Installation Instructions

Downloading the Performance Series Print Driver From the Website

Note: The installation file is also accessible from the product CD that shipped with the

printer.

1. Enter the following URL into the Web browser:

http://www.sourcetech.com/support/drivers-downloads/drivers

2. Select Midrange Thermal Printers.

3. Select STpSeriesPrintDrive Setup (x86 & x64).

Note: The File Download window is displayed.

Figure: 3 - 51 File Download Window

4. Select Save and browse to the appropriate location where the file can be saved.

Note: For future reference, be sure to note the directory where the file has been saved.

5. Select Save from the Save As window.

6. Select Close from the Download Complete window.

Accessing the Performance Series Print Driver from the Product CD

1. Load the product CD in the computer CD/DVD drive.

Note: The main installation screen should be displayed. If not, select Start > My

Computer > Device w/Removable Storage. Then select the drive letter that

corresponds with your CD/DVD drive.

55 STp.1120n User’s Guide

Page 66

3 | Connections and Setup

2. Select Software.

Figure: 3 - 52 Installation Utility - Software

3. Select Windows Print Driver and proceed with the installation instructions.

Figure: 3 - 53 Installation Utility - Windows Print Driver

STp.1120n User’s Guide 56

Page 67

Connections and Setup | 3

Installing the Print Driver for a USB Connected Printer

Caution: If your printer is not connected via USB, do not execute this step. Instead, refer

to the installation instructions for connecting locally or to a network.

Caution: Do not connect a USB cable to the printer at this point.

1. Locate the Performance Series Print Driver setup file from the saved location or

from the product CD launch.

2. Double-click STpSeriesPrintDriverSetup.msi.

Note: This step is not required if continuing from the product CD launch.

3. Select Next from the “Performance Series Print Driver Setup Wizard” window.

Figure: 3 - 54 Performance Series Print Driver Setup Wizard

57 STp.1120n User’s Guide

Page 68

3 | Connections and Setup

4. Select Install Driver Files Only and then select Next.

Figure: 3 - 55 Performance Series Install Files/Add Printer Selection

5. Browse to the appropriate folder location, select the user option and then select

Next.

Figure: 3 - 56 Installation Folder

STp.1120n User’s Guide 58

Page 69

6. Select Next.

Figure: 3 - 57 Confirm Installation

Connections and Setup | 3

Note: The “Installing Source Technologies Performance Series Print Driver” progress

window will display.

Figure: 3 - 58 Print Driver Installation Progress Window

59 STp.1120n User’s Guide

Page 70

3 | Connections and Setup

7. Select Close.

Figure: 3 - 59 Installation Complete

Note: The following window may appear after selecting close. Select Continue

Anyway.

Figure: 3 - 60 Hardware Installation Warning Window

Note: The appearance of this window may be different from the illustration depending on

your operating system.

STp.1120n User’s Guide 60

Page 71

Connections and Setup | 3

Note: The “Copying Files” dialog box will display while the driver files are copied to the

system. When the dialog box closes, the installation is complete.

Figure: 3 - 61 Copying Files Dialog Box

8. Confirm the Performance Series printer is powered on.

9. Connect a USB cable from the computer to the USB port on the Performance

Series printer.

Note: If using Windows XP, continue the installation using the Found New Hardware

Wizard. If using another operating system, your installation is complete.

10.Select No, not this time and then select Next.

Figure: 3 - 62 Found New Hardware Wizard Welcome Window

61 STp.1120n User’s Guide

Page 72

3 | Connections and Setup

11. Select Install the software automatically (Recommended) and then select Next.

Figure: 3 - 63 Found New Hardware - Install the Software

Note: The wizard progress window will display while the printer driver files are located.

Figure: 3 - 64 Found New Hardware Wizard Progress Window

STp.1120n User’s Guide 62

Page 73

Connections and Setup | 3

Note: The following window may appear. Select Continue Anyway.

Figure: 3 - 65 Hardware Installation Window

The following steps are not always seen on all Windows® XP systems.

12.Select OK.

Figure: 3 - 66 Insert Disk Window

13.Browse to C:\Source Technologies LLC\STpSeriesDriver.

Figure: 3 - 67 Files Needed Window

14.Select the appropriate file with one of the following extensions and then select

Open:

•.ini

•.dll

63 STp.1120n User’s Guide

Page 74

3 | Connections and Setup

•.gpd

Figure: 3 - 68 Locate File Window

15.Select OK.

Figure: 3 - 69 Files Needed Window

STp.1120n User’s Guide 64

Page 75

16.Select Finish.

Figure: 3 - 70 Completing the Found New Hardware WIzard Window

Connections and Setup | 3

The printer has been installed and is available to Windows applications.

65 STp.1120n User’s Guide

Page 76

3 | Connections and Setup

Installing the Print Driver for a Network-Connected Printer

Caution: If your printer in not a network-connected printer, do not execute this step.

Instead, refer to the installation instructions for installing the print driver for a

USB connected printer.”

1. Locate the Performance Series Print Driver Setup file from the saved location or the

product CD launch.

2. Double-click STpSeriesDriverSetup.msi.

Note: This step is not required if continuing from the product CD launch.

3. Select Next from the “Performance Series Print Driver Setup Wizard” window.

Figure: 3 - 71 Performance Series Print Driver Setup Wizard

STp.1120n User’s Guide 66

Page 77

4. Select Install Driver Files and Add Printer.

Figure: 3 - 72 Install Files/Add Printer WIndow

Connections and Setup | 3

5. Select Next.

Figure: 3 - 73 Confirm Installation

67 STp.1120n User’s Guide

Page 78

3 | Connections and Setup

Note: The wizard progress window will display while the printer driver files are located.

Figure: 3 - 74 Print Driver Installation Progress Window

6. Select Close.

Figure: 3 - 75 Installation Complete

Note: The “Welcome to the Add Printer Wizard” will display.

STp.1120n User’s Guide 68

Page 79

Connections and Setup | 3

7. Select Next.

Figure: 3 - 76 Add Printer Wizard Welcome Window

Note: The “Install Printer Software” screen will display with a list of supported

Performance Series printers.

8. Select the Performance Series printer model of the printer being installed and then

select Next.

Figure: 3 - 77 Install Printer Software

69 STp.1120n User’s Guide

Page 80

3 | Connections and Setup

9. Select Finish to complete the installation.

Figure: 3 - 78 Completing the Add Printer WIzard

Note: The “Hardware Installation” window will display although the screen may appear

differently depending on the operating system.

10.Select Continue Anyway.

Figure: 3 - 79 Hardware Installation

Note: The “Copying Files” dialog box will display while the driver files are being copied to

the system. The dialog box will close once the installation is complete.

Figure: 3 - 80 Copying Files

STp.1120n User’s Guide 70

Page 81

Connections and Setup | 3

Note: The screenshot may appear different from the illustration depending on the

operating system being used.

Once the installation is complete, the printer is available to Windows applications.

71 STp.1120n User’s Guide

Page 82

3 | Connections and Setup

Add Printer - USB Connected Printer

Caution: This procedure should only be followed if the Performance Series Print Driver

Utility has already been installed.

1. Confirm that the Performance Series printer is powered on.

2. Connect the USB cable from the computer to the USB port on the Performance

Series printer.

Note: For operating systems other than Windows XP, the print driver installation and the

printer installation are complete.

Perform the following steps only if using the Windows XP operating system.

3. Select No, not this time and then select Next.

Figure: 3 - 81 Found New Hardware Wizard

STp.1120n User’s Guide 72

Page 83

Connections and Setup | 3

4. Select Install the software automatically (Recommended), then select Next.

Figure: 3 - 82 Found New Hardware - Install the Software

Note: The wizard progress window will display while the printer driver files are located.

Figure: 3 - 83 Wizard Progress Window

73 STp.1120n User’s Guide

Page 84

3 | Connections and Setup

Note: The following window may appear. Select Continue Anyway.

Figure: 3 - 84 Hardware Installation Window

The following steps are not always seen on all WIndows XP systems.

5. Select OK.

Figure: 3 - 85 Insert Disk Window

6. Browse to C:\Source Technologies LLC\STpSeriesDriver.

Figure: 3 - 86 Files Needed Window

STp.1120n User’s Guide 74

Page 85

Connections and Setup | 3

7. Select the appropriate file with one of the following extensions and then select

Open:

•.ini

•.dll

•.gpd

Figure: 3 - 87 Locate File Window

8. Select OK.

Figure: 3 - 88 Files Needed Window

75 STp.1120n User’s Guide

Page 86

3 | Connections and Setup

9. Select Finish.

Figure: 3 - 89 Completing the Found New Hardware Wizard Window

The printer has been installed and is available to WIndows applications.

STp.1120n User’s Guide 76

Page 87

Connections and Setup | 3

Add Printer - Network-Connected Printer

Caution: This procedure should only be followed if the Performance Series Print Driver

Utility has already been installed.

1. Select Start > All Programs > Source Technologies LLC > STp Series Printer

Driver > Add Printer.

Note: The “Add Printer Wizard” will display.

Figure: 3 - 90 Add Printer Wizard

2. Select Next.

Note: The “Install Printer Software” screen will display with a list of supported

Performance Series printers.

77 STp.1120n User’s Guide

Page 88

3 | Connections and Setup

3. Select the Performance Series printer model for the printer being installed and then

select Next.

Figure: 3 - 91 Install Printer Software

Note: If at any time this screen does not display a pre-populated list of supported

Performance Series printers, select Have Disk or browse to the print driver software.

The default location is C:\Source Technologies LLC\STpSeriesDriver.

4. Select Finish to complete the installation.

Figure: 3 - 92 Completing the Add Printer WIzard

Note: The “Hardware Installation” window will display although the screen may appear

differently depending on the operating system.

STp.1120n User’s Guide 78

Page 89

Connections and Setup | 3

5. Select Continue Anyway.

Figure: 3 - 93 Hardware Installation

Note: The “Copying Files” dialog box will display while the driver files are being copied to

the system. The dialog box will close once the installation is complete.

Figure: 3 - 94 Copying Files

Note: The screenshot may appear different from the illustration depending on the

operating system being used.

Once the installation is complete, the printer is available to Windows applications.

79 STp.1120n User’s Guide

Page 90

3 | Connections and Setup

Printer Properties

The properties panel allows the user to set the printer properties via a tabbed interface.

Select the appropriate tab to change settings.

Properties - Print File

The Print File tab allows users to print files with the following extensions:

•.txt

•.pcl

•.pjl

Figure: 3 - 95 Print File Tab

Two actions can be selected:

Table 1: Firmware Update Actions

Name Description

Select File Allows the user to browse and select the appropriate file to be

Send File to Printer Once a file has been selected, the button is enabled and used

STp.1120n User’s Guide 80

sent to the printer.

to send the selected file to the printer.

Page 91

Connections and Setup | 3

Properties - About

The about tab in the properties panel displays driver information for the users to

reference when needed. This information contains the file names and their versions.

Figure: 3 - 96 Properties - About

Your version number may vary from this example.

81 STp.1120n User’s Guide

Page 92

3 | Connections and Setup

Printing Preferences

Printing Preferences - Media Settings

The Media Settings tab allows the user to manage the printer’s media settings. These

include the following:

Table 2: Properties - Media Settings

Name Description

Units of Measure Allows the user to set the units of measure to Imperial or Metric.

Orientation Allows the user to set the orientation of the print job.

Number of Copies Allows the user to set the number of copies for the specified

print job.

Media Size The user may select a predefined media size or click on the

Custom button and create a custom media size.

Settings Allows the user to save the configuration of the print driver

settings.

Figure: 3 - 97 Media Settings

STp.1120n User’s Guide 82

Page 93

Figure: 3 - 98 Media Size

Connections and Setup | 3

Printing Preferences - Print Settings

The following print settings may be adjusted:

Table 3: Print Settings

Name Description

Print Speed The speed at which the printer will print the labels.

Slew Speed* The rate of paper movement between printing areas when

using the GPIO applicator.

Feed Speed The rate of label movement during feed.

Reverse Speed The rate of the label movement during backup positioning.

Print Darkness Allows for the adjustment of the darkness of the printed image

due to printhead thermal variations.

Horizontal Offset Shifts the horizontal start of the print position on the labels.

Vertical Offset Shifts the vertical start of the print position on the labels.

Settings Allows the configuration settings to be saved.

* Future

83 STp.1120n User’s Guide

Page 94

3 | Connections and Setup

Figure: 3 - 99 Print Settings

Whenever a speed setting has been changed, the following warning may appear:

Figure: 3 - 100Speed Warning

STp.1120n User’s Guide 84

Page 95

Connections and Setup | 3

Printer Preferences > Custom Commands

Job commands may be set.

Table 4: Custom Commands

Name Description

Start of Job w/FF Sends the FF command at the beginning of the job.

End of Job w/FF Sends the FF command at the end of the job.

Figure: 3 - 101Custom Commands

85 STp.1120n User’s Guide

Page 96

3 | Connections and Setup

STp.1120n User’s Guide 86

Page 97

4 Menu System

Menu Overview

The printer is designed with a touchscreen display. Functions can be enabled and

disabled and settings can be changed through the on-screen menu. Press the buttons on

the screen with the light touch of a finger.

Caution: Do not touch the screen with excessive force or by using sharp objects. Doing

so will damage the touchscreen and may void the manufacturer’s warranty.

Layout of the Display

Navigation

The menu screens have buttons for advancing or returning to screens.

Back Button

The Back button provides the user with the option to return to a previous menu

screen.

Home Button

Selecting the Home button sends the user to the main screen.

Tabbed Browsing

Blue left and right arrow buttons are provided at the bottom right of the screen to

navigate tabbed menus. Select the right arrow to advance to the next tab or the left

arrow to return to the previous tab.

Scrolling

Some menu screens allow for scrolling. Select the appropriate up or down arrow.

Changing V alues

Numeric values can be entered or changed by selecting the field and entering the

values using the numeric keypad. They can also be increased or decreased using

the subsequent plus or minus buttons.

Other menu options are changed by pressing the button until the appropriate

selection appears.

87 STp.1120n User’s Guide

Page 98

4 | Menu System

Ready

Printer

Status

Buttons

Date / Time

Operator Action

Fault Information

Area

Area

Model ID

Connected Devices

and

Mode Indicators

Home Screen

The home screen presents several options to the user.

Thu July 21 11:58:33 2012

Menu Feed Info

Printer Status

The printer status area displays the state of the printer. These states include the

following:

Operator Action Area

Information about the current printer action will be displayed in this area. For example,

“Printing 1 of 3” might be displayed when printing the first of three labels for a print job.

Date / Time

The time and date may be toggled on by pressing the upper right corner of the display.

After pressing the blank area, the current date and time will be displayed on the screen.

Once the home button is pressed, a screen will appear asking the user if the date and

time will be displayed. Select the green Accept button to display the time or the red

Reject button to cancel.

• Ready - The printer is idle and ready to accept internal or external commands.

• Busy - Appears when printing or feeding paper.

• Fault - The printer is busy processing or executing a command. The screen will

become yellow for a warning condition and red for a fault condition.

• Cooling Down - The printer has paused while it is cooling down.

• Waiting - The printer is blocked by the optional Applicator or Present Sensor.

STp.1120n User’s Guide 88

Page 99

Menu System | 4

Fault Information Area

Warnings and faults will be displayed in this area. Once the fault has been corrected, the

message will disappear .

Connected Devices

The symbol for devices connected to the USB host will be presented in this area.

Mode Indicators

The printer will display modes that have been activated. If options have been installed

but not enabled, they will not appear in this area of the display.

Information Button

By selecting the information button from the task bar, the following information can be

accessed.

• System Info

• Settings Report

• Network Report

• Extended Status

• Serial Report

• Applicator Report

• Fonts Report

System Information

The following will be displayed upon selection of the System Info button:

• Printer Model

• Printhead Model

• Sof tware Version

• Firmware Version

• Ribbon Version

•Boot Version

•Board ID

•RAM Size

• Flash Size

• Security Key

• Printer Odometer

89 STp.1120n User’s Guide

Page 100

4 | Menu System

• Printhead Odometer

• Paper Type

• Ribbon Type

• Detected Options

Note: Selecting the down or up arrow will display additional information.

Settings Report

The settings report provides information on the printer settings.

Media Settings

• Paper Sensor Type

• Paper Sensor Side

• Ribbon Mode

•Heat

• Heat Balance

• Head Pressure

• Rewinder Tension

• Ribbon Tension Front

• Ribbon Tension Rear

• Ribbon Low Diameter

Printer Settings

• Cutter Mode

• Rewinder Mode

• Present Sensor Enable

• Print Speed

• Feed Speed

• Reverse Speed

• Present Dist ance

• Error Sound

• Warning Sound

• Disable Paper Low Warning

• Disable Paper Out Warning

• Disable Cover Open Warning

STp.1120n User’s Guide 90

Loading...

Loading...