Sorensen Dlm-e 4KW, Dlm-e 3KW, Dcs-e 1KW User Manual

DCS-E 1kW Series,

DLM-E 3kW & 4kW

Power Supplies

M51A Option: Isolated Analog

Programming Manual

Power Supplies

Elgar Electronics Corporation

9250 Brown Deer Road

San Diego, CA 92121-2294

1-800-73ELGAR (1-800-733-5427)

Tel: (858) 450-0085

Fax: (858) 458-0267

Email: sales@elgar.com

www.elgar.com

©2004 Elgar Electronics Corporation

This document contains information proprietary to Elgar Electronics Corporation. The information contained herein is

not to be duplicated or transferred in any manner without prior written permission from Elgar Electronics Corporation.

June 8, 2004 Document No. M362250-01 Rev B

SAFETY NOTICE

Before applying power to the system, verify that the instrument is configured properly for the user’s

particular application.

WARNING!

Hazardous voltages may be present when covers are

removed. Qualified personnel must use extreme caution

when servicing this equipment. Circuit boards, test points,

and output voltages also may be floating with respect to

chassis ground.

Installation and servicing must be performed by qualified personnel who are aware of dealing

properly with attendant hazards. This includes such simple tasks as fuse verification.

Ensure that the AC power line ground is connected properly to the chassis. Similarly, other

power ground lines including those to application and maintenance equipment must

properly for both personnel and equipment safety.

be grounded

Always ensure that facility AC input power is de-energized prior to connecting or disconnecting any

cable.

In normal operation, the operator does not have access to hazardous voltages within the chassis.

However, depending on the user’s application configuration, HIGH VOLTAGES HAZARDOUS TO

HUMAN SAFETY may be normally generated on the output terminals. The customer/user must

ensure that the output power lines are labeled properly as to the safety hazards and that any

inadvertent contact with hazardous voltages is eliminated.

Guard against risks of electrical shock during open cover checks by not touching any portion of the

electrical circuits. Even when power is off, capacitors may retain an electrical charge. Use safety

glasses during open cover checks to avoid personal injury by any sudden component failure.

Some circuits are live even with the front panel switch turned off. Service, fuse verification, and

connection of wiring to the chassis must be accomplished at least five minutes after power has

been removed via external means; all circuits and/or terminals to be touched must be safety

grounded to the chassis.

These operating instructions form an integral part of the equipment and must be available to the

operating personnel at all times. All the safety instructions and advice notes are to be followed.

Neither Elgar Electronics Corporation, San Diego, California, USA, nor any of the subsidiary sales

organizations can accept any responsibility for incidental or consequential injury of personnel, or

loss or damage of equipment or material that results from improper use of the equipment and

accessories.

i

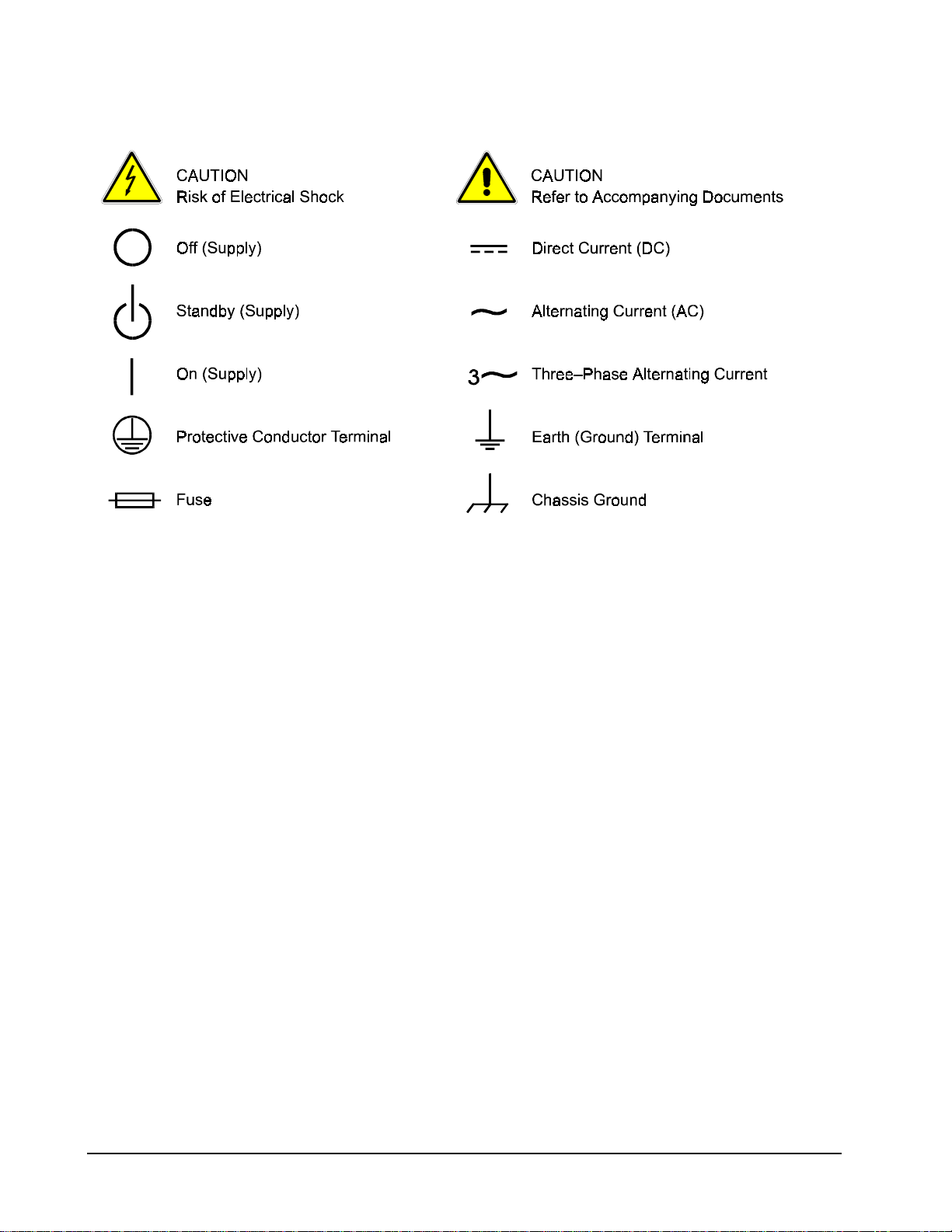

SAFETY SYMBOLS

ii

ELGAR FIVE–YEAR WARRANTY

Elgar Electronics Corporation (hereinafter referred to as Elgar) warrants its products to be free from defects in

material and workmanship. This warranty is effective for one year from the date of shipment of the product to

the original purchaser. Liability of Elgar under this warranty shall exist provided that:

• the Buyer exposes the product to normal use and service and provides normal maintenance on the

product;

• Elgar is promptly notified of defects by the Buyer and that notification occurs within the warranty period;

• the Buyer receives a Return Material Authorization (RMA) number from Elgar’s Repair Department prior to

the return of the product to Elgar for repair, phone 800-73-ELGAR (800-733-5427), ext. 2295;

• the Buyer returns the defective product in the original, or equivalent, shipping container;

• if, upon examination of such product by Elgar it is disclosed that, in fact, a defect in materials and/or

workmanship does exist, that the defect in the product was not caused by improper conditions, misuse,

or negligence; and,

• that Elgar QA seal and nameplates have not been altered or removed and the equipment has not been

repaired or modified by anyone other than Elgar authorized personnel.

This warranty is exclusive and in lieu of all other warranties, expressed or implied, including, but not limited

to, implied warranties of merchantability and fitness of the product to a particular purpose. Elgar, its agents,

or representatives shall in no circumstance be liable for any direct, indirect, special, penal, or consequential

loss or damage of any nature resulting from the malfunction of the product. Remedies under this warranty

are expressly limited to repair or replacement of the product.

CONDITIONS OF WARRANTY

• To return a defective product, contact an Elgar representative or the Elgar factory for an RMA number.

Unauthorized returns will not be accepted and will be returned at the shipper’s expense.

• For Elgar products found to be defective within thirty days of receipt by the original purchaser, Elgar will

absorb all ground freight charges for the repair. Products found defective within the warranty period, but

beyond the initial thirty-day period, should be returned prepaid to Elgar for repair. Elgar will repair the unit

and return it by ground freight pre-paid.

• Normal warranty service is performed at Elgar during the weekday hours of 7:30 am to 4:30 pm Pacific

time. Warranty repair work requested to be accomplished outside of normal working hours will be subject to

Elgar non-warranty service rates.

• Warranty field service is available on an emergency basis. Travel expenses (travel time, per diem expense,

and related air fare) are the responsibility of the Buyer. A Buyer purchase order is required by Elgar prior to

scheduling.

• A returned product found, upon inspection by Elgar, to be in specification is subject to an inspection fee and

applicable freight charges.

• Equipment purchased in the United States carries only a United States warranty for which repair must be

accomplished at the Elgar factory.

Committed to Quality...Striving for Excellence

iii

CONTENTS

SECTION 1 M51A OPTION OVERVIEW .............................................1-1

1.1 Introduction ...................................................................................................... 1-1

1.2 General Description ......................................................................................... 1-1

1.3 Specifications................................................................................................... 1-2

1.3.1 Electrical Specifications ....................................................................... 1-2

1.3.2 Supplemental Characteristics .............................................................. 1-2

SECTION 2 ISOLATED ANALOG PROGRAMMER OPERATION .........2-1

2.1 SW1 Switch ..................................................................................................... 2-1

2.1.1 SW1 Switch Setup ............................................................................... 2-2

2.2 ISOLATED ANALOG PROGRAMMER Connector (J4)................................... 2-3

2.2.1 ISOLATED ANALOG PROGRAMMER Functions ............................... 2-4

2.3 Remote Programming Configuration ............................................................... 2-7

2.3.1 Voltage Source Programming of Output Voltage................................. 2-7

2.3.2 Voltage Source Programming of Output Current................................. 2-8

2.3.3 Voltage Source Programming of OVP ................................................. 2-9

2.3.4 Resistance Programming of Output Voltage ..................................... 2-10

2.3.5 Resistance Programming of Output Current...................................... 2-11

2.3.6 Resistance Programming of OVP...................................................... 2-12

2.3.7 4-20mA Current Source Programming of Output Voltage ................. 2-13

2.3.8 4-20mA Current Source Programming of Output Current.................. 2-14

2.3.9 Programming the Shutdown Function ............................................... 2-15

2.3.10 TTL Shutdown ................................................................................. 2-15

2.3.11 Shutdown Application – Contact Closure ........................................ 2-16

2.3.12 Local/Remote Application ................................................................ 2-18

2.4 Remote Monitoring ........................................................................................ 2-19

2.5 Remote Digital Status Signals ....................................................................... 2-19

M51A Option v

Contents DLM-E Series and DCS-E Series

LIST OF TABLES

Table 2–1. SW1 SETUP Switch.................................................................................. 2-1

Table 2–2. ISOLATED ANALOG PROGRAMMER Connector Pinout ........................ 2-3

Table 2–3. Remote Monitoring................................................................................. 2-19

Table 2–4. Remote Digital Status Signals ............................................................... 2-19

LIST OF FIGURES

Figure 2–1. Rear Panel View, DLM-E Series 3kW and 4kW Power Supply ............... 2-2

Figure 2–2. Rear Panel View, DCS-E Series 1kW Power Supply .............................. 2-2

Figure 2–3. Using Shutdown with a DC Input (Positive Logic) ................................. 2-15

Figure 2–4.

Figure 2–5.

Figure 2–6.

Figure 2–7 Using Local/Remote Operation with Contact Closure ............................ 2-18

Using Shutdown with Contact Closure of a Normally OPEN Relay

(SW1-6 ON)

Using Shutdown with Contact Closure of a Normally OPEN Relay

(SW1-6 OFF)

Using Shutdown with Contact Closure of a Normally CLOSED Relay

(SW1-6 ON)

........................................................................................... 2-16

......................................................................................... 2-17

........................................................................................... 2-17

vi M51A Option

SECTION 1

M51A OPTION OVERVIEW

1.1 Introduction

This manual is to be used in conjunction with the DCS-E 1kW Series & DCS-E 1.2kW Series

DC Power Supplies Operation Manual, Sorensen Document No. M362500-01 and the DLM-E

3Kw & 4Kw Series Power Supplies Operation Manual, Sorensen Document No. M362000-01.

The Sorensen M51A Option provides a remote isolated analog programming interface, which

has safety isolation from the output terminals. This allows the remote analog interface to be

connected to user–accessible, Safety Extra Low Voltage, (SELV) control circuits, even though

the output terminals are floated at a high potential with respect to the chassis.

1.2

The M51A Option provides isolation for all programming, monitoring, and digital I/O signals that

are available through the standard rear panel analog interface connector. This isolation barrier

eliminates the connection that exists in the standard models between the non-isolated remote

interface circuits and the power supplies output return (negative) terminal. All control and

monitoring signals on the M51A option are optically coupled from the power supply output, and

can are user accessible irrespective of the float potentials that could exist at the output

terminals.

General Description

The M51A Option provides a full complement of programming, monitoring, and control

functions. Remote programming is available for output voltage, current, and overvoltage

protection (OVP). Analog output monitor signals are available for the output voltage and

current. Digital I/O signals provide indication of the operational state, and a means of enabling

the remote interface and the output.

The type and range of the control and monitor signals are user-selectable with a rear panel

setup switch and connector jumpers. The output voltage, current, and OVP can be programmed

with a 0-5VDC, 0-10VDC, or 0-5kΩ resistance; in addition, the output voltage and current can

be programmed with 4-20mA signals. The output voltage and current monitors can produce

0-5VDC, 0-10VDC, or 4-20mA signals. Isolated 1mA current sources are provided to facilitate

the utilization of 0-5kΩ programming resistances.

Except for the isolated remote analog interface, the installation and operation of the power

supplies remains as presented in the Operation Manual. The following sections provide a

detailed description of the new features and the differences in operation.

M51A Option 1-1

M51A Option Overview DLM-E Series and DCS-E Series

1.3 Specifications

1.3.1

Remote Voltage Programming Accuracy, 0-5/10V Inputs:

Output Voltage: 0.5% of Vmax

Output Current: 0.75% of Imax

OVP: 1.0% of 1.1 X Vmax

Remote 4-20 mA Programming Accuracy:

Output Voltage: 1.0% of Vmax

Output Current: 1.0% of Imax

1.3.2

Remote Resistance Programming Accuracy, 0-5kΩ Input:

Output Voltage: 1.0% of Vmax

Output Current: 1.5% of Imax

OVP: 1.5% of 1.1 X Vmax

Remote Monitor Accuracy:

Output Voltage, 0-5/10V ranges: 0.5% of Vmax

Output Voltage, 4-20mA: 1.0% of Vmax

Output Current, 0-5/10V ranges: 0.75% of Imax

Output Current, 4-20mA: 1.0% of Imax

Electrical Isolation:

500 VDC from all isolated inputs to supply output

Electrical Specifications

Burden voltage of 6.25 VDC (312.5 ohms nominal)

Supplemental Characteristics

1-2 M51A Option

SECTION 2

ISOLATED ANALOG

PROGRAMMER OPERATION

2.1

The SW1 SETUP switch is accessible from the rear panel of the unit. It provides user selection

of the programming/monitoring ranges and shutdown logic signal level. Setting a switch to the 1

or 0 position changes a range. The factory default settings are shown below.

Refer to Figure 2–1 for a rear panel view of the DLM-E 3kW and 4kW models.

Refer to Figure 2–2 for a rear panel view of the DCS-E 1kW models.

Switch

Position

* Indicates default settings

SW1 Switch

1

2

3

4

5

6

Voltage Programming

Range Select

Current Programming

Range Select

OVP Programming

Range Select

Output Voltage Monitor

Range Select

Output Current Monitor

Range Select

Remote ON-OFF Level

Function OFF (0) Position ON (1) Position

* 0-5 VDC, 4-20mA

Select

0-10 VDC

0-10 VDC * 0-5 VDC, 4-20mA

0-10 VDC * 0-5 VDC

* 0-5 VDC 0-10 VDC

* 0-5 VDC 0-10 VDC

Active Low Signal * Active High Signal

Table 2–1. SW1 SETUP Switch

M51A Option 2-1

Loading...

Loading...