Sorensen DCS600-2E, DCS100-12E, DCS50-24E, DCS20-60E, DCS600-1.7E User Manual

...

DCS-E 1kW Series &

DCS-E 1.2kW Series

DC Power Supplies

Operation Manual

This manual covers models:

DCS8-125E DCS33-33E DCS60-18E DCS150-7E

DCS8-140E DCS33-36E DCS60-20E DCS150-8E

DCS10-100E DCS40-25E DCS80-13E DCS300-3.5E

DCS10-120E DCS40-30E DCS80-15E DCS300-4E

DCS20-50E DCS50-20E DCS100-10E DCS600-1.7E

DCS20-60E DCS50-24E DCS100-12E DCS600-2E

SORENSEN

Elgar Electronics Corporation

9250 Brown Deer Road

San Diego, CA 92121-2294

1-800-733-5427

Tel: (858) 450-0085

Fax: (858) 458-0267

Email: sales@elgar.com

www.elgar.com

©2003 by Sorensen, Division of Elgar Electronics Corporation

This document contains information proprietary to Sorensen, Elgar Electronics Corporation. The information

contained herein is not to be duplicated or transferred in any manner without prior written permission from Sorensen.

July 21, 2003 Document No. M362500-01 Rev B

.

SAFETY NOTICE

Before applying power to the system, verify that the DCS Series unit is configured properly for the user’s

particular application.

WARNING!

HAZARDOUS VOLTAGES IN EXCESS OF 280 VRMS, 600V PEAK MAY BE

PRESENT WHEN COVERS ARE REMOVED. QUALIFIED PERSONNEL MUST

USE EXTREME CAUTION WHEN SERVICING THIS EQUIPMENT. CIRCUIT

BOARDS, TEST POINTS, AND OUTPUT VOLTAGES MAY BE FLOATING

ABOVE (BELOW) CHASSIS GROUND.

Installation and service must be performed by qualified personnel who are aware of dealing with attendant

hazards. This includes such simple tasks as fuse verification.

Ensure that the AC power line ground is connected properly to the DCS Series unit input connector

or chassis. Similarly, other power ground lines including those to application and maintenance

equipment must

Always ensure that facility AC input power is de-energized prior to connecting or disconnecting the

input/output power cables.

inadvertent contact with hazardous voltages is eliminated. To guard against risk of electrical shock during

open cover checks, do not touch

can retain an electrical charge. Use safety glasses during open cover checks to avoid personal injury by any

sudden failure of a component.

be grounded properly for both personnel and equipment safety.

During normal operation, the operator does not have access to hazardous voltages within

the chassis. However, depending on the user’s application configuration, HIGH VOLTAGES

HAZARDOUS TO HUMAN SAFETY may be generated normally on the output terminals.

Ensure that the output power lines are labeled properly as to the safety hazards and that any

any portion of the electrical circuits. Even when the power if off, capacitors

Due to filtering, the unit has high leakage current to the chassis. Therefore, it is essential to operate this unit

with a safety ground.

Some circuits are live even with the front panel switch turned off. Service, fuse verification, and

connection of wiring to the chassis must be accomplished at least five minutes

removed via external means; all circuits and/or terminals to be touched must be safety grounded to

the chassis.

After the unit has been operating for some time, the metal near the rear of the unit may be hot enough to

cause injury. Let the unit cool before handling.

Qualified service personnel need to be aware that some heat sinks are not at ground, but at high potential.

These operating instructions form an integral part of the equipment and must be available to the operating

personnel at all times. All the safety instructions and advice notes are to be followed.

Neither Sorensen, San Diego, California, USA, nor any of the subsidiary sales organizations can accept any

responsibility for personal, material or consequential injury, loss or damage that results from improper use of

the equipment and accessories.

after power has been

i

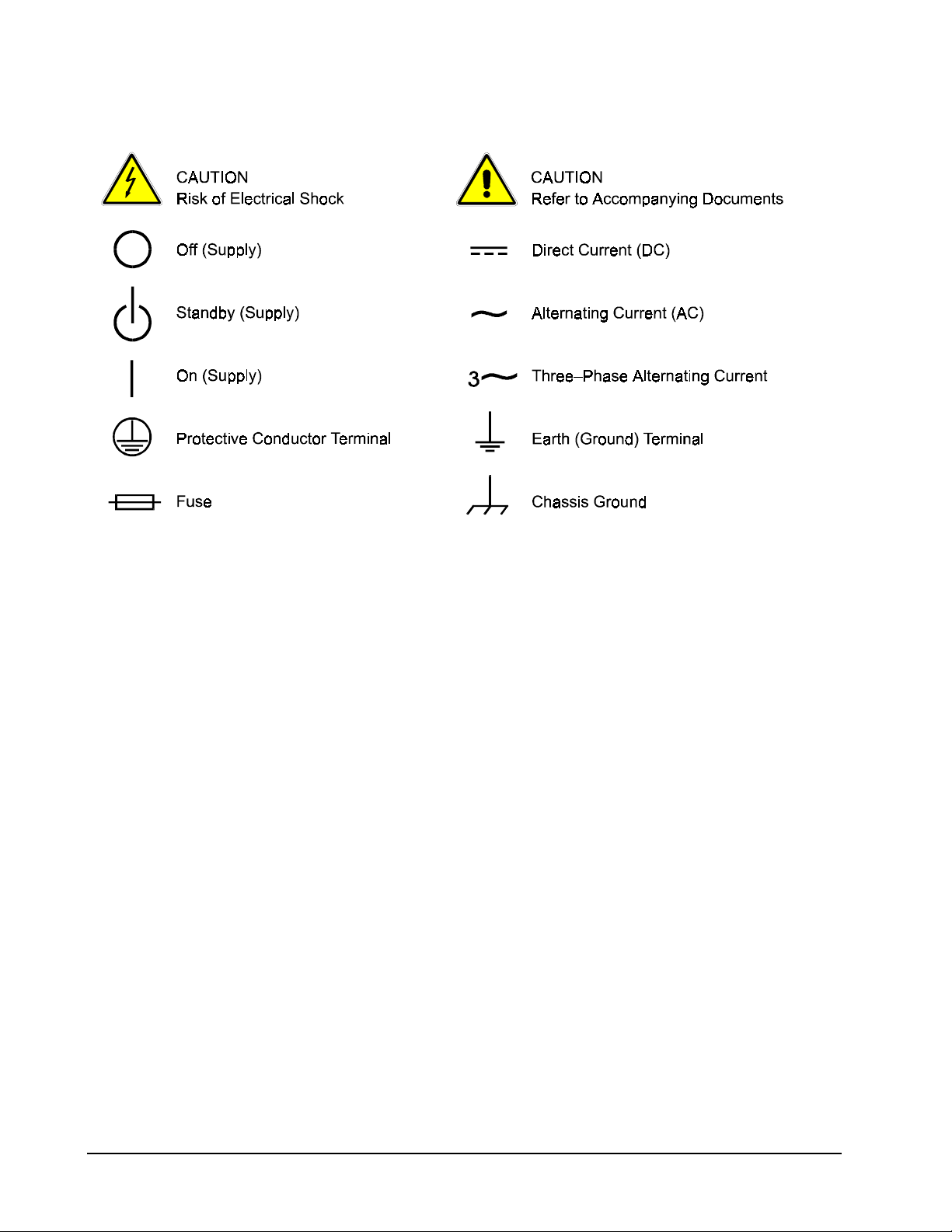

SAFETY SYMBOLS

ii

SORENSEN FIVE–YEAR WARRANTY

Sorensen, a division of Elgar Electronics Corporation, warrants its products to be free from defects in

material and workmanship. This warranty is effective for five years from the date of shipment of the product

to the original purchaser. Liability of Sorensen under this warranty shall exist provided that:

• the Buyer exposes the product to normal use and service and provides normal maintenance on the

product;

• Sorensen is promptly notified of defects by the Buyer and that notification occurs within the warranty period;

• the Buyer receives a Return Material Authorization (RMA) number from Sorensen’s Repair Department

prior to the return of the product to Sorensen for repair, phone 800-458-4258;

• the Buyer returns the defective product in the original, or equivalent, shipping container;

• if, upon examination of such product by Sorensen it is disclosed that, in fact, a defect in materials and/or

workmanship does exist, that the defect in the product was not caused by improper conditions, misuse,

or negligence; and,

• that Sorensen QA seal and nameplates have not been altered or removed and the equipment has not been

repaired or modified by anyone other than Sorensen authorized personnel.

This warranty is exclusive and in lieu of all other warranties, expressed or implied, including, but not limited

to, implied warranties of merchantability and fitness of the product to a particular purpose. Sorensen, its

agents, or representatives shall in no circumstance be liable for any direct, indirect, special, penal, or

consequential loss or damage of any nature resulting from the malfunction of the product. Remedies under

this warranty are expressly limited to repair or replacement of the product.

CONDITIONS OF WARRANTY

• To return a defective product, contact a Sorensen representative or the Sorensen factory for an RMA

number. Unauthorized returns will not be accepted and will be returned at the shipper’s expense.

• For Sorensen products found to be defective within thirty days of receipt by the original purchaser,

Sorensen will absorb all ground freight charges for the repair. Products found defective within the warranty

period, but beyond the initial thirty-day period, should be returned prepaid to Sorensen for repair. Sorensen

will repair the unit and return it by ground freight pre-paid.

• Normal warranty service is performed at Sorensen during the weekday hours of 7:30 am to 4:30 pm Pacific

time. Warranty repair work requested to be accomplished outside of normal working hours will be subject to

Sorensen non-warranty service rates.

• Warranty field service is available on an emergency basis. Travel expenses (travel time, per diem expense,

and related air fare) are the responsibility of the Buyer. A Buyer purchase order is required by Sorensen

prior to scheduling.

• A returned product found, upon inspection by Sorensen, to be in specification is subject to an inspection fee

and applicable freight charges.

• Equipment purchased in the United States carries only a United States warranty for which repair must be

accomplished at the Sorensen factory.

Committed to Quality...Striving for Excellence

iii

This page intentionally left blank.

iv

CONTENTS

SECTION 1 FEATURES AND SPECIFICATIONS ................................1-1

1.1 Description.......................................................................................................1-1

1.2 Operating Modes.............................................................................................1-1

1.3 Power Supply Features ...................................................................................1-1

1.4 Specifications...................................................................................................1-3

1.4.1 Electrical Specifications for 1kW Models.............................................1-3

1.4.2 Electrical Specifications for 1.2kW Models..........................................1-4

1.4.3 Physical Specifications........................................................................1-5

1.4.4 Mechanical Specifications ...................................................................1-6

SECTION 2 INSTALLATION AND OPERATION..................................2-1

2.1 General............................................................................................................2-1

2.2 Initial Inspection............................................................................................... 2-1

2.3 Installation........................................................................................................2-1

2.3.1 Input Voltage Selection........................................................................2-1

2.3.2 Input Line Impedance..........................................................................2-2

2.3.3 Ventilation Requirements.....................................................................2-2

2.3.4 Output Voltage Biasing........................................................................2-2

2.3.5 Rack Mounting.....................................................................................2-2

2.4 Controls, Connectors, and Indicators ..............................................................2-4

2.4.1 Front Panel..........................................................................................2-4

2.4.2 Rear Panel...........................................................................................2-4

2.4.3 J3 Program, Sense and Monitor Connector Description .....................2-5

Operation Manual v

Contents Sorensen DCS Series 1kW and 1.2kW Supplies

2.5 Initial Functional Tests .....................................................................................2-6

2.6 Standard Operation..........................................................................................2-7

2.6.1 Load Conductor Ratings ......................................................................2-7

2.6.2 Load Connection and Grounding.........................................................2-7

2.6.3 Inductive Loads....................................................................................2-8

2.6.4 Remote Sensing...................................................................................2-8

2.6.5 Negative Output Operation ..................................................................2-9

2.7 Single Supply Operation (Local Mode) ............................................................2-9

2.8 Multiple Supplies............................................................................................2-10

2.8.1 Series Operation................................................................................2-10

2.8.2 Parallel Operation ..............................................................................2-10

2.8.3 Split Supply Operation .......................................................................2-11

2.9 Over Voltage Protection (OVP)......................................................................2-11

2.9.1 Front Panel OVP Operation...............................................................2-11

2.9.2 Remote Programming of OVP With External Voltage Sources..........2-12

2.9.3 Remote Programming of OVP with an External Resistance.............. 2-13

2.9.4 Remote Programming of OVP with External Current Sources...........2-14

2.9.5 Remote OVP Sensing........................................................................2-15

2.10 Remote ON/OFF............................................................................................2-15

2.10.1 Remote ON/OFF by Contact Closure...............................................2-16

2.11 Remote Programming of Output Voltage and Current Limit ..........................2-16

2.11.1 Programming With External Voltage Sources..................................2-17

2.11.2 Programming With an External Resistance ..................................... 2-18

2.11.3 Programming With an External Current Source...............................2-19

2.12 Remote Monitoring and Status Indicators......................................................2-21

SECTION 3 THEORY OF OPERATION

3.1 Power Circuit (A2 Assembly) ...........................................................................3-1

3.1.1 Basic Off-Line Switching Regulator Theory .........................................3-1

3.1.2 Simplified Full Bridge Converter Theory ..............................................3-3

3.1.3 Detailed Circuit Description..................................................................3-3

3.2 Meter Circuit (A1 Assembly) ............................................................................3-9

3.2.1 Voltmeter............................................................................................3-10

3.2.2 Current Meter.....................................................................................3-10

vi Operation Manual

Sorensen DCS Series 1kW and 1.2kW Supplies Contents

SECTION 4 MAINTENANCE, TROUBLESHOOTING, AND CALIBRATION

4.1 General............................................................................................................4-1

4.2 Periodic Service...............................................................................................4-1

4.3 Troubleshooting............................................................................................... 4-1

4.3.1 Preliminary Checks..............................................................................4-2

4.3.2 Troubleshooting at the Operation Level...............................................4-2

4.4 Calibration........................................................................................................4-3

SECTION 5 PARTS LISTS

5.1 General............................................................................................................5-1

5.2 Parts Ordering .................................................................................................5-1

5.3 Parts Lists........................................................................................................ 5-2

SECTION 6 DRAWINGS AND SCHEMATICS

Operation Manual

vii

Contents Sorensen DCS Series 1kW and 1.2kW Supplies

LIST OF FIGURES

Figure 2-1 DCS Series Power Supply......................................................................... 2-3

Figure 3-1 Simplified Full Bridge Converter................................................................3-2

Figure 4-1 Trimpot Locations...................................................................................... 4-4

LIST OF TABLES

Table 2–1 Wire Size and Length................................................................................. 2-7

Table 4–1 Troubleshooting Guide............................................................................... 4-2

Table 5–1 DCS 1kW and 1.2kW Fuse Ratings........................................................... 5-2

Table 5–2 DCS 1kW Parts Lists by Model Number....................................................5-2

Table 5–3 DCS 1kW Parts Lists .................................................................................5-3

Table 5–4 DCS 1.2kW Parts Lists by Model Number.................................................5-4

Table 5–5 DCS 1.2kW Parts Lists ..............................................................................5-5

viii Operation Manual

SECTION 1

FEATURES AND SPECIFICATIONS

1.1 Description

DCS Series power supplies are 1000W and 1200W supplies designed to provide highly stable,

continuously variable output voltage and current for a broad range of development, system, and

burn-in applications. The DCS Series employs high frequency switching regulator technology to

achieve high power density and small package size.

The series consists of twelve 1000W models and twelve 1200W models. The model numbers

are designated by the DCS prefix, followed by the output voltage and current ratings. For

example, the model number DCS 60-18E indicates that the unit is rated at 0-60 Vdc and 0-18

Amps while a model DCS 20-50E is rated at 0-20 Vdc and 0-50 Amps.

1.2

Operating Modes

The DCS Series supply has two basic operating modes: Constant Voltage and Constant

Current. In constant voltage mode the output voltage is regulated at the selected value while

the output current varies with the load requirements. In constant current mode the output

current is regulated at the selected value while output the voltage varies with the load

requirements.

An automatic crossover system enables the unit to switch operating modes in response to

varying load requirements. If, for example, the unit is operating in voltage mode and the load

current attempts to increase above the setting of the current control, the unit will switch

automatically from voltage mode to current mode. If the load current is subsequently reduced

below the setting of the current control the unit will return to voltage mode automatically.

1.3

Power Supply Features

•

Twelve 1kW models with voltage ranges from 0-8 Vdc to 0-600 Vdc and current

outputs from 1.7A to 125A.

•

Twelve 1.2kW models with voltage ranges from 0-8 Vdc to 0-600 Vdc and current

outputs from 2A to 140A.

•

115/230 Vac selectable input voltage, 50-60 Hz single phase,

Installation Category II. For Indoor Use.

•

Simultaneous digital display of both voltage and current.

Operation Manual 1-1

Features and Specifications Sorensen DCS Series 1kW and 1.2kW Supplies

•

Automatic mode crossover into current or voltage mode.

•

Ten turn potentiometer voltage and current controls permit high resolution setting of

the output voltage and current from zero to the rated output.

•

Flexible output configuration: multiple units can be connected in parallel or series to

provide increased current or voltage.

•

High frequency switching technology allows high power density, providing increased

power output in a small, light package.

•

Remote sensing to compensate for losses in power leads.

•

Adjustable Over-Voltage Protection (OVP)

•

External TTL, AC or DC shutdown

•

Remote voltage, resistive, current limit and OVP programming with selectable

programming constants.

•

External indicator signals for remote monitoring of OVP status, local/remote

programming status, thermal shutdown, and output voltage and current.

•

Optional IEEE-488 interface for complete remote programming and readback

capability.

1-2 Operation Manual

Sorensen DCS Series 1kW and 1.2kW Supplies Features and Specifications

1.4 Specifications

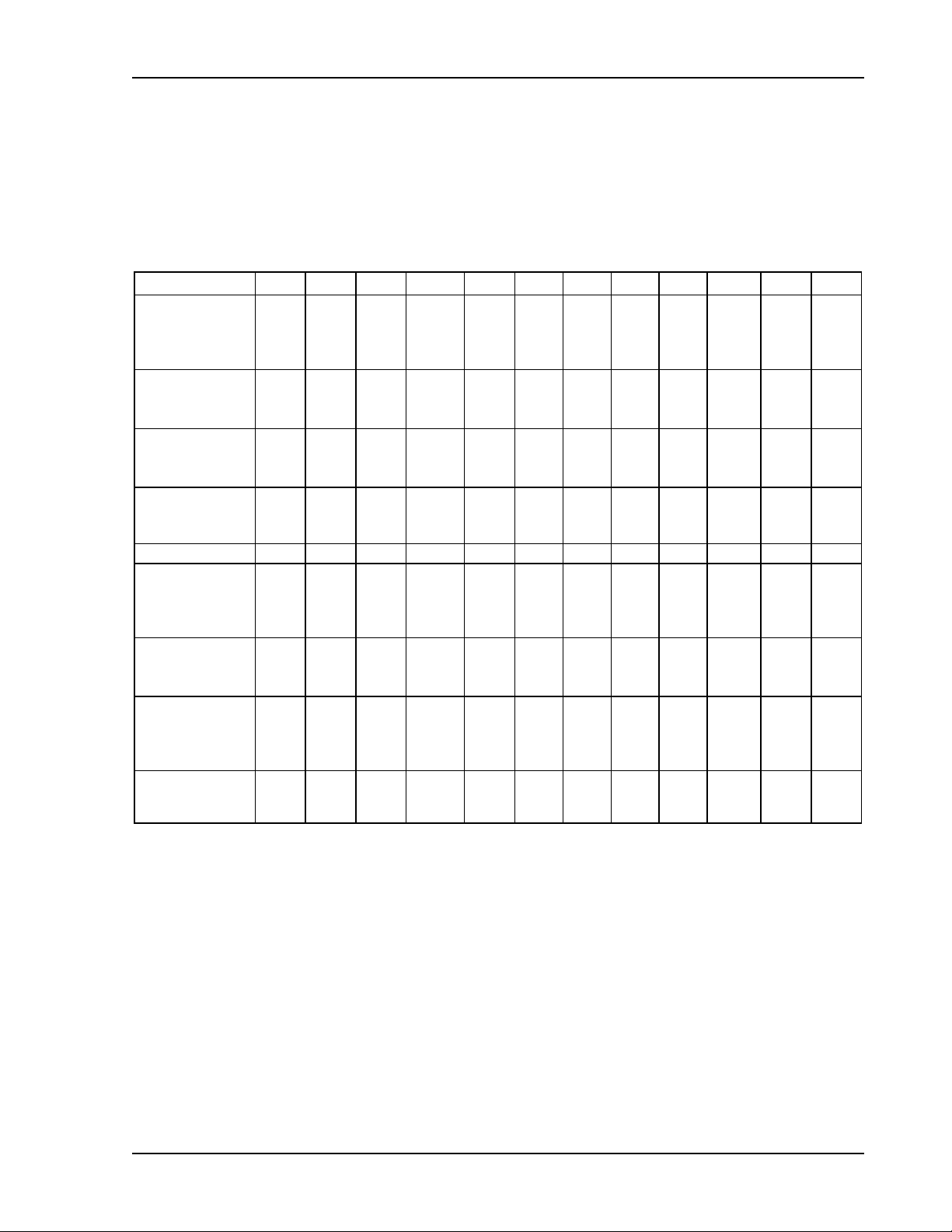

1.4.1 Electrical Specifications for 1kW Models

Specifications are warranted over a temperature range of 0-50°C with default local sensing.

From temperatures of 50-70°C, derate output 2% per °C.

Models

Output Ratings:

Output Voltage

Output Current

Output Power

Line Regulation:1

Voltage

Current

Load Regulation:2

Voltage

Current

Meter Accuracy:

Voltage

Current

OVP Adjustment Range 0.4-8.8V 0.5-11V 1.0-22V 1.65-36.3V 2-44V 2.5-55V 3-66V 4-88V 5-110V 7.5-165V 15-330V 30-660V

Output Noise/Ripple(V)3

Rms

p-p

(20Hz-20MHz)

Stability:4

Voltage

Current

Temperature

Coefficient:

Voltage

Current

Maximum Remote

Sense Line Drop

Compensation/line

1

For input voltage variation over the AC input voltage range, with constant rated load

2

For 0-100% load variation, with constant nominal line voltage

3

Typical P-P noise and ripple

4

Maximum drift over 8 hours with constant line, load, and temperature, after 20-minute warm-up

5

Change in output per °C change in ambient temperature, with constant line and load

6

Line drop subtracts from the maximum available output voltage at full rated power

8-125 10-100 20-50 33-33 40-25 50-20 60-18 80-13 100-10 150-7 300-3.5 600-1.7

0-50V

0-20A

1000W

50 mV

20 mA

50 mV

20 mA

0.6V

0.30A

4 mV

60 mV

25 mV

10 mV

10 mV

6 mA

4V 4V 4V 4V 4V 4V

0-33V

0-33A

1089W

33 mV

33 mA

33 mV

33 mA

0.43V

0.43A

4 mV

60 mV

16.5 mV

16.5 mA

6.6 mV

9.9 mA

0-8V

0-125A

1000W

8 mV

125 mA

8 mV

125 mA

0.09V

1.35A

4 mV

60 mV

4 mV

62.5 mA

5

1.6 mV

37.5 mA

6

0-10V

0-100A

1000W

10 mV

100 mA

10 mV

100 mA

0.11V

1.1A

4 mV

60 mV

5 mV

50 mA

2 mV

30 mA

4V 4V 4V

0-20V

0-50A

1000W

20 mV

50 mA

20 mV

50 mA

0.3V

0.6A

4 mV

60 mV

10 mV

25 mA

4 mV

15 mA

4V

0-40V

0-25A

1000W

40 mV

25 mA

40 mV

25 mA

0.5V

0.35A

4 mV

60 mV

20 mV

12.5 mA

8 mV

7.5 mA

0-60V

0-18A

1080W

60 mV

18 mA

60 mV

18 mA

0.7V

0.28A

4 mV

60 mV

30 mV

9 mA

12 mV

5.4 mA

0-80V

0-13A

1040W

80 mV

13 mA

80 mV

13 mA

0.9V

0.23A

4 mV

60 mV

40 mV

6.5 mA

16 mV

3.9 mA

0-100V

0-10A

1000W

100 mV

10 mA

100 mV

10 mA

1.1V

0.11A

6 mV

60 mV

50 mV

5 mA

20 mV

3 mA

0-150V

0-7A

1050W

150 mV

7 mA

150 mV

7 mA

1.6V

0.08A

12 mV

160 mV

75 mV

3.5 mA

30 mV

2.1 mA

0-300V

0-3.5A

1050W

300 mV

3.5 mA

300 mV

3.5 mA

4.0V

0.045A

20 mV

200 mV

150 mV

1.75 mA

60 mV

1.05 mA

0-600V

0-1.7A

1020W

600 mV

1.7 mA

600mV

1.7 mA

7.0V

0.018A

TBD mV

TBD mV

300 mV

0.85 mA

4V 4V

120 mV

0.51 mA

AC Input: 200-250 Vac at 9A rms or 100-130 Vac at 18A rms, 47-63 Hz

Maximum Voltage Differential from output to safety ground: 150 Vdc

Operation Manual 1-3

Features and Specifications Sorensen DCS Series 1kW and 1.2kW Supplies

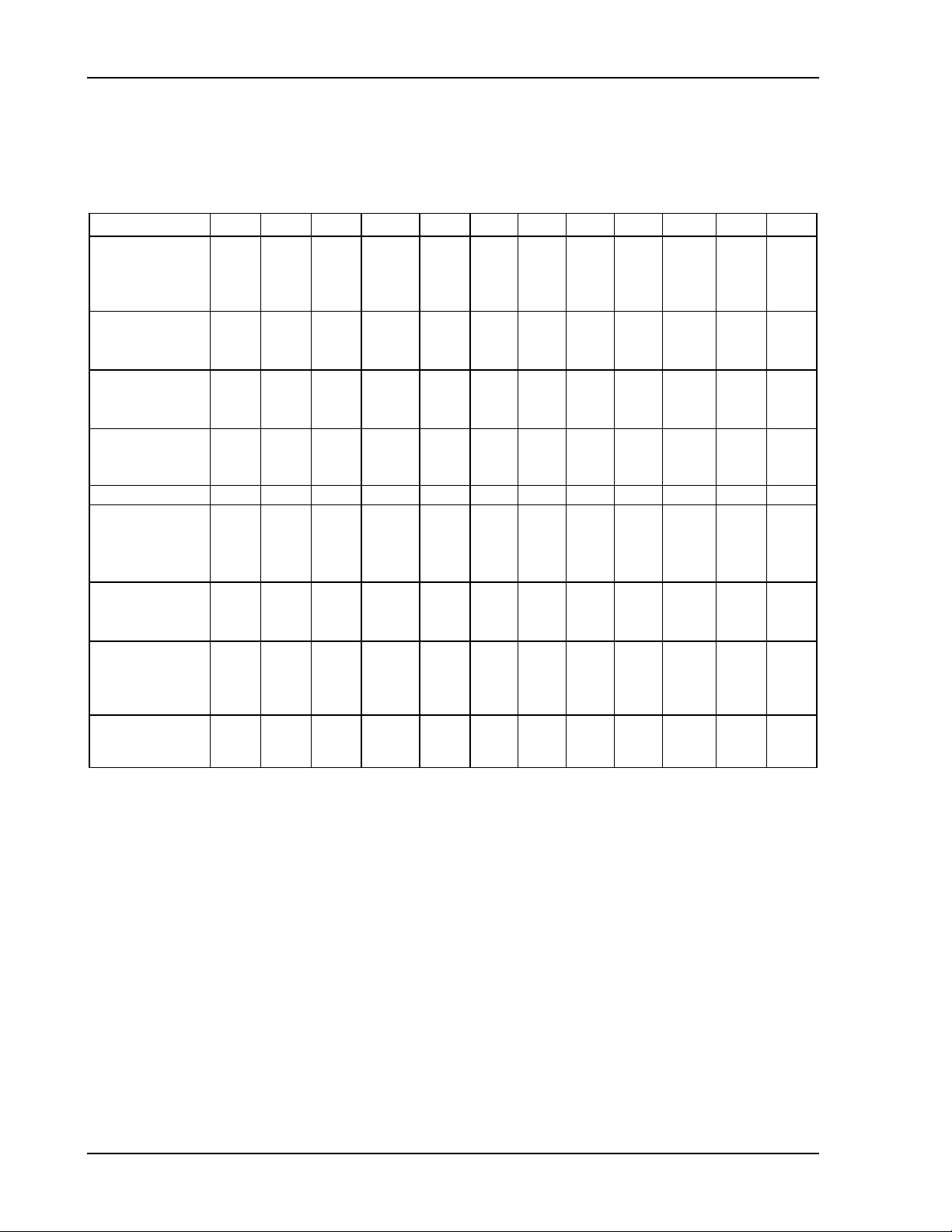

1.4.2 Electrical Specifications for 1.2kW Models

Specifications are warranted over a temperature range of 0-50°C with default local sensing.

From temperatures of 50-70°C, derate output 2% per °C.

Models

Output Ratings:

Output Voltage

Output Current

Output Power

Line Regulation:7

Voltage

Current

Load Regulation:8

Voltage

Current

Meter Accuracy:

Voltage

Current

OVP Adjustment Range 0.4-8.8V 0.5-11V 1.0-22V 1.65-36.3V 2-44V 2.5-55V 3-66V 4-88V 5-110V 7.5-165V 15-330V 30-660V

Output Noise/Ripple(V)

Rms

p-p

(20Hz-20MHz)

Stability:10

Voltage

Current

Temperature

Coefficient:

Voltage

Current

Maximum Remote

Sense Line Drop

Compensation/line

7

For input voltage variation over the AC input voltage range, with constant rated load

8

For 0-100% load variation, with constant nominal line voltage

9

Typical P-P noise and ripple

10

Maximum drift over 8 hours with constant line, load, and temperature, after 20-minute warm-up

11

Change in output per °C change in ambient temperature, with constant line and load

12

Line drop subtracts from the maximum available output voltage at full rated power

8-140 10-120 20-60 33-36 40-30 50-24 60-20 80-15 100-12 150-8 300-4 600-2

0-150V

0-8A

1200W

150 mV

8 mA

150 mV

8 mA

1.6V

0.09A

15 mV

160 mV

75 mV

4 mA

30 mV

2.4 mA

0-50V

0-24A

1200W

50 mV

24 mA

50 mV

24 mA

0.6V

0.34A

5 mV

60 mV

25 mV

12 mV

10 mV

7.2 mA

4V 4V 4V 4V 4V 4V

0-33V

0-36A

1200W

33 mV

36 mA

33 mV

36 mA

0.43V

0.46A

5 mV

60 mV

16.5 mV

18 mA

6.6 mV

10.8 mA

0-8V

0-140A

1200W

8 mV

140 mA

8 mV

140 mA

0.09V

1.55A

9

5 mV

60 mV

4 mV

70 mA

11

1.6 mV

42 mA

12

0-10V

0-120A

1200W

10 mV

120 mA

10 mV

120 mA

0.11V

1.3A

5 mV

60 mV

5 mV

60 mA

2 mV

36 mA

2V 2V 4V

0-20V

0-60A

1200W

20 mV

60 mA

20 mV

60 mA

0.3V

0.7A

5 mV

60 mV

10 mV

30 mA

4 mV

18 mA

4V

0-40V

0-30A

1200W

40 mV

30 mA

40 mV

30 mA

0.5V

0.40A

5 mV

60 mV

20 mV

15 mA

8 mV

9 mA

0-60V

0-20A

1200W

60 mV

20 mA

60 mV

20 mA

0.7V

0.3A

5 mV

60 mV

30 mV

10 mA

12 mV

6 mA

0-80V

0-15A

1200W

80 mV

15 mA

80 mV

15 mA

0.9V

0.25A

5 mV

60 mV

40 mV

7.5 mA

16 mV

4.5 mA

0-100V

0-12A

1200W

100 mV

12 mA

100 mV

12 mA

1.1V

0.13A

10 mV

60 mV

50 mV

6 mA

20 mV

3.6 mA

0-300V

0-4A

1200W

300 mV

4 mA

300 mV

4 mA

4.0V

0.05A

25 mV

200 mV

150 mV

2 mA

60 mV

1.2 mA

4V 4V

0-600V

0-2A

1020W

600 mV

2 mA

600 mV

2 mA

7.0V

0.021A

TBD mV

TBD mV

300 mV

1 mA

120 mV

0.6 mA

AC Input: 200-250 Vac at 10A rms or 100-130 Vac at 20A rms, 47-63 Hz

Maximum Voltage Differential from output to safety ground: 150 Vdc

1-4 Operation Manual

Sorensen DCS Series 1kW and 1.2kW Supplies Features and Specifications

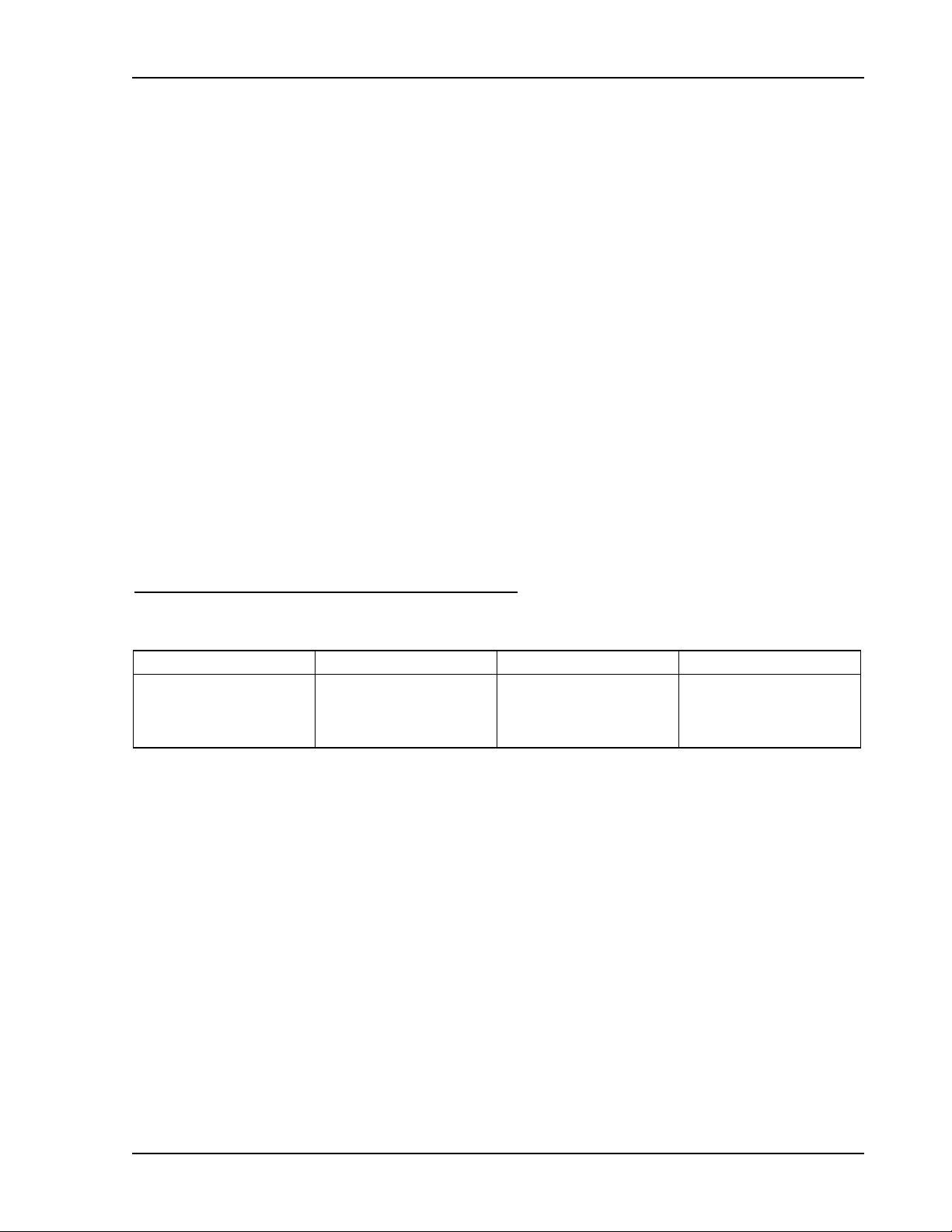

1.4.3 Physical Specifications

Altitude: 2000M (6562 ft.)

Storage Temperature Range: -55 to +85°C

Humidity Range: 0 to 80% Non-condensing

Time Delay from power on until output stable: 3 seconds maximum

Voltage Mode Transient Response Time: 500µS recovery to 1% band for 30% step load

change from 70% to 100% or 100% to 70%

Remote Start/Stop and Interlock: TTL compatible input, Contact Closure, 12-250 Vac or

12-130 Vdc

Switching Frequency: Nominal 70 kHz typical (140 kHz output ripple)

Analog Programming Linearity: Typical error is less than 0.5% setting.

Maximum error is 1% of rated output.

Agency Approvals: CE Pollution Degree 2 (UL pending)

Remote Analog Programming (Full Scale Input)

Scales are selectable via an internally-mounted switch.

Parameter Resistance Voltage Current

Voltage

Current

OVP

5 kΩ

5 kΩ

5 kΩ

5V, 10V 1 mA

5V, 10V 1 mA

5V, 10V 1 mA

Operation Manual 1-5

Features and Specifications Sorensen DCS Series 1kW and 1.2kW Supplies

1.4.4 Mechanical Specifications

Size: 44mm H x 482.6mm W x 508mm D (1.75” H x 19” W x 20” D)

Weight: 8.2 kg (18 lbs)

Output Connector

Models DCS-E 8V through DCS 100V

Connector type: Nickel plated copper bus bars.

Approximate dimensions: 1.365" x 0.8" x 0.125"

Distance between positive and negative bus bar centers: 2.2"

Load wiring mounting holes: Two 0.257" diameter holes on 0.5" centers (1/4" hardware)

Models DCS-E 150V through DCS 600V

Connector type: Six–pin Amp Universal Mate-N-Lok connector

Chassis mounted parts: Housing: Amp part number 1-480705-0

Mating connector parts: Housing: Amp part number 1-480704-0

Note: Six Socket pins and one mating connector housing are supplied with each 150V through

600V unit.

Two 0.191" diameter holes on 0.4" centers (#10 hardware)

Pins: Amp part number 350547-1

Socket pins: Amp part number 350550-1

Input Connector

2 position terminal block plus safety ground screw.

Note: Input power cord not supplied.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

1-6 Operation Manual

SECTION 2

INSTALLATION AND OPERATION

2.1 General

After unpacking, perform an initial inspection and function test to ensure that the unit is in good

working order. If the unit was damaged in shipment, notify the carrier immediately. Direct repair

problems to the Sorensen Customer Service Department at 1-800-458-4258.

2.2

The equipment should be inspected for damage as follows:

Initial Inspection

•

Inspect for obvious signs of physical damage.

•

Turn front panel controls from stop to stop. Rotation should be smooth.

•

Test the action of the power switch. Switching action should be positive.

•

If internal damage is suspected, remove the cover and check for printed circuit board

and/or component damage. Reinstall cover.

2.3 Installation

2.3.1

Before using the DCS power supply, the correct AC input voltage must be selected and an

appropriate line cord and plug attached, or hook up wire sized for input current based on NEC

or local electrical code. The frequency of the AC input voltage must be maintained between 47

and 63 Hz.

All units are shipped in a configuration requiring a 200-250 Vac input. The unit can be converted for use with a 100-130 Vac input or purchased preset for 115 Vac with the M1 Option.

For use with a 200-250 Vac input, connect a 250 Vac 10 Amp plug and cord to the rear panel

AC connector and the safety ground screw. (Note that the NEUT. and LINE designations above

the AC connector do not apply to 200-250V operation.)

Input Voltage Selection

CAUTION

Attempted operation of the DCS power supply with the incorrect input voltage may

result in internal damage to the unit.

Operation Manual 2-1

Installation and Operation Sorensen DCS Series 1kW and 1.2kW Supplies

To convert the unit for use with a 100-130 Vac input, perform the following steps:

1. Ensure that the unit is switched off and disconnected from any power source.

2. Remove the Phillips head screws that secure the cover and then remove the cover.

3. Remove the 230 Vac voltage selector jumper located at the front center of the PCB from

its mating header (P1 on the PCB) and install the attached 115 Vac jumper in its place.

4. Remove the adhesive backed 115 Vac 20A label from fan and cover the 230 Vac 10A

input specification above the rear panel AC connector.

5. Reinstall the cover and replace screws.

6. Install a 125 Vac 20A plug and cord ensuring that the neutral (white) wire and line

(black) wire are connected in the correct positions and that the safety ground wire is

connected to the ground screw.

Note that both the 1kW and 1.2kW models can exceed the 15A standard wall outplet

capacity at full load.

NOTE: To provide protection for personnel in the case of unit failure and to

ensure proper power supply operation, the safety ground wire of the AC input line

cord must always be connected to the ground screw provided.

2.3.2

The maximum input line impedance for operation at full rated output is 0.5 ohm. Higher source

impedances can be tolerated by raising the input line voltage or by reducing the output voltage

and/or current.

2.3.3

The DCS power supply may be used in rack mounted or benchtop applications. In either case

sufficient space must be allowed for cooling air to reach the ventilation inputs on each side of

the unit and for the fan exhaust air to exit from the rear of the unit.

2.3.4

Input Line Impedance

Ventilation Requirements

Output Voltage Biasing

WARNING

If the output voltage is to be biased relative to safety ground, the power

supply outputs may be biased up to a maximum of 150 Vdc with respect

to the chassis.

2.3.5 Rack Mounting

The DCS power supply is designed to fit in a standard 19" equipment rack. When installing the

unit in a rack, be sure to provide adequate support for the rear of the unit while not obstructing

the ventilation inlet on the sides of the unit. Use adjustable support angles such as Hammond

RASA22WH2, or a support bar such as Hammond RASB19WH2.

2-2 Operation Manual

Loading...

Loading...