Page 1

Service Manual

for the

Cranex Novus

Dental X-ray Unit

200569 rev. 4 (2011-09)

Page 2

Cranex Novus Contents

Service manual 200569 III

Service Manual for the

Cranex Novus

Dental X-ray Unit

Medical Device Directive

93/42/EEC

Number 200569 rev. 4 (201109)

Manufactured by SOREDEX

Nahkelantie 160,Tuusula

P.O. BOX 148

FI-04301 Tuusula

Finland

Tel. +358 45 7582 2000

Fax. + 358 9 701 5261

Page 3

IV Service manual 200569

Contents Cranex Novus

Soredex endeavours to produce product documentation that is accurate

and up to date. However, our policy of continual product development

may result in changes to products that are not refl ected in the product

documentation. Therefore, this document should not be regarded as an

infallible guide to current product specifi cations.

Soredex maintains the right to make changes and alterations without

prior notice.

Page 4

Cranex Novus Contents

Service manual 200569 V

Contents

1. General Information .......................................................................................... 1

1.1 Introduction ................................................................................................... 1

1.1 Associated documentation ............................................................................ 1

1.2 Service precautions and warnings ................................................................ 1

Servicing precautions ..................................................................................... 1

Warning - Radiation Safety ............................................................................ 1

Warning - Mechanical safety .......................................................................... 2

Warning - Electrical Safety ............................................................................. 2

Caution - electrostatic discharge .................................................................... 3

Warning - Explosion hazard ........................................................................... 4

Warning - Cleaning the unit ............................................................................ 4

1.3 Unauthorized Modifi cations ........................................................................... 4

1.4 Disclaimer ..................................................................................................... 4

1.5 Yearly maintenance ....................................................................................... 5

1.6 Disposal ........................................................................................................ 9

2. Unit description ............................................................................................... 10

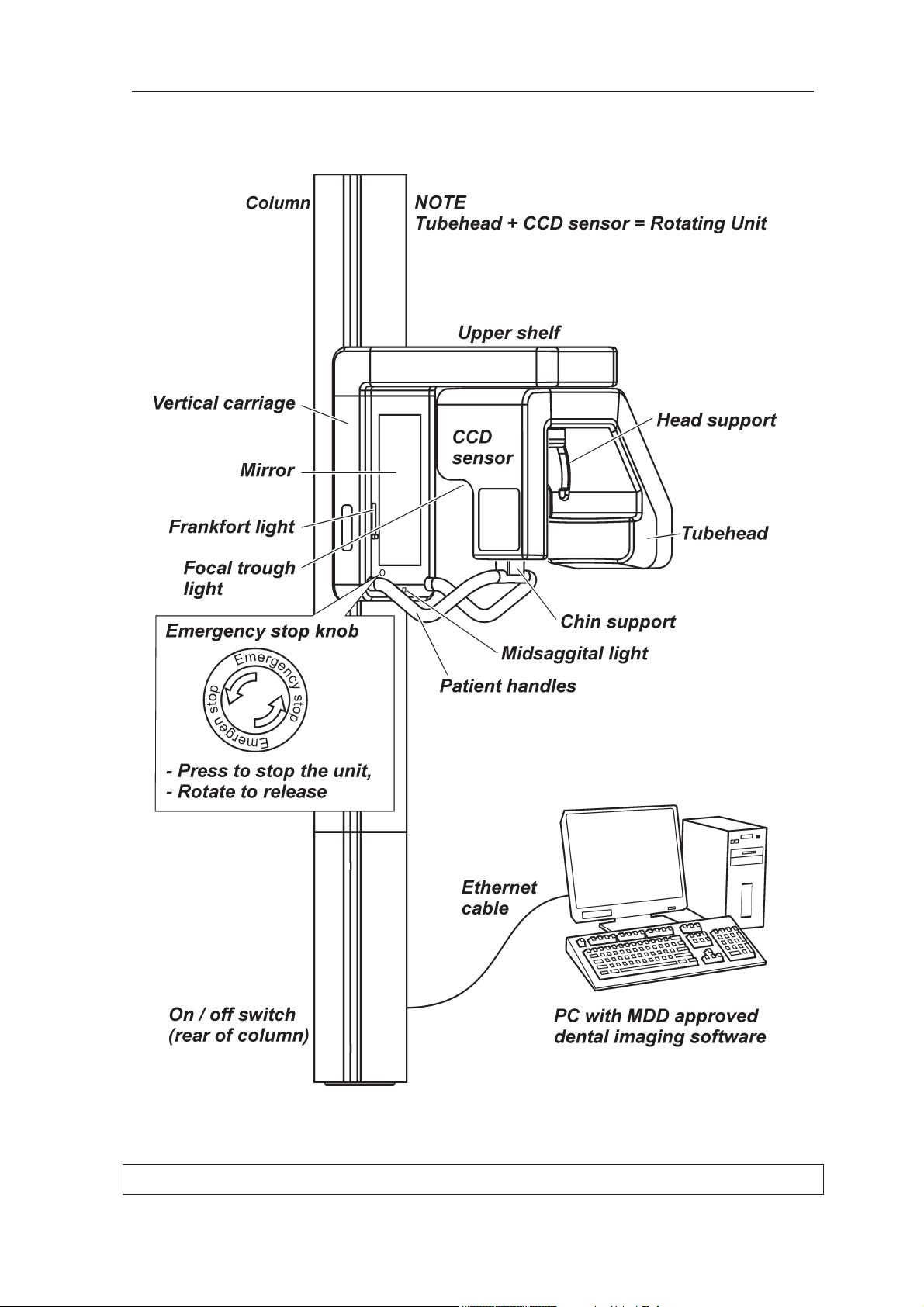

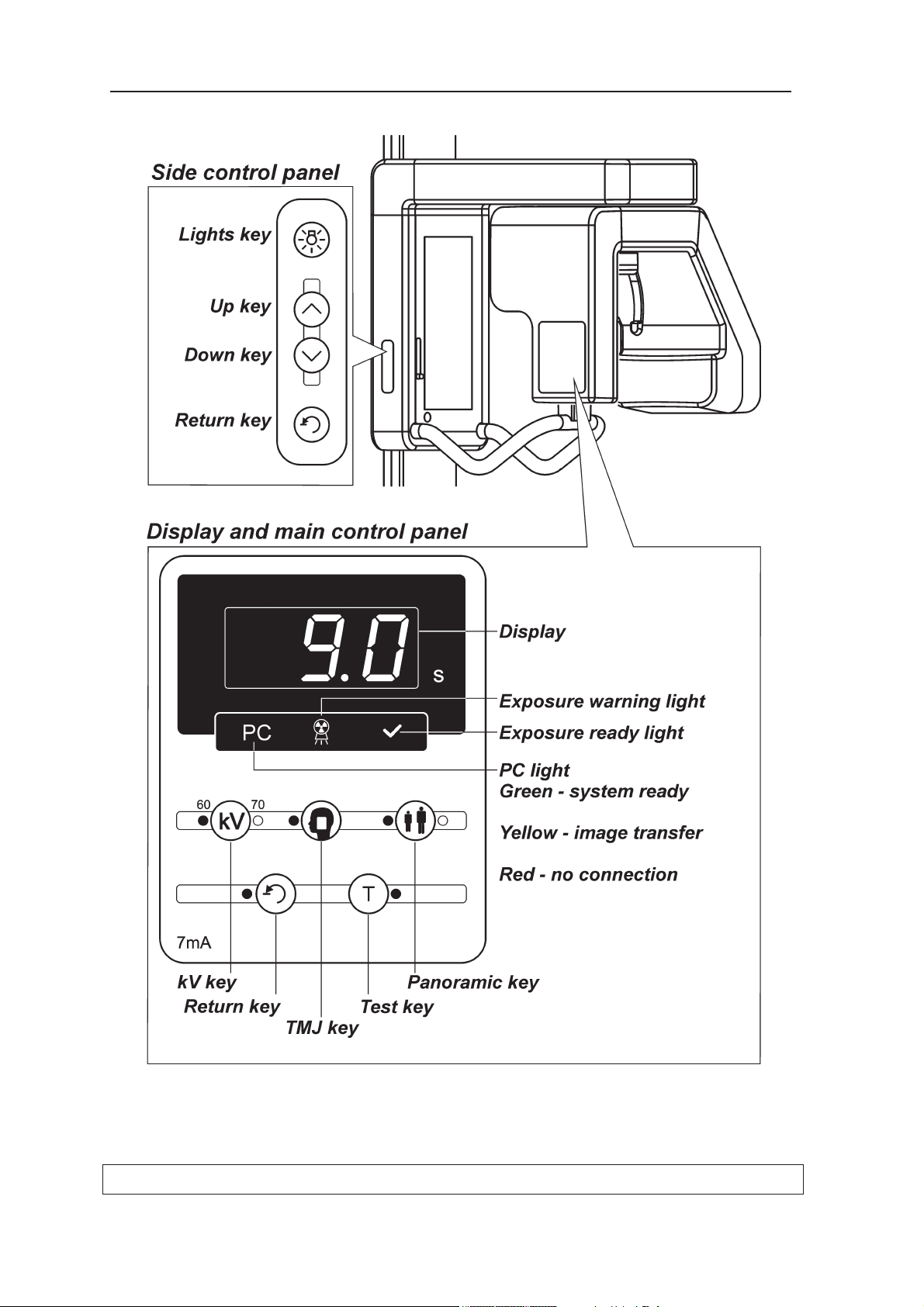

2.1 The Cranex Novus ...................................................................................... 10

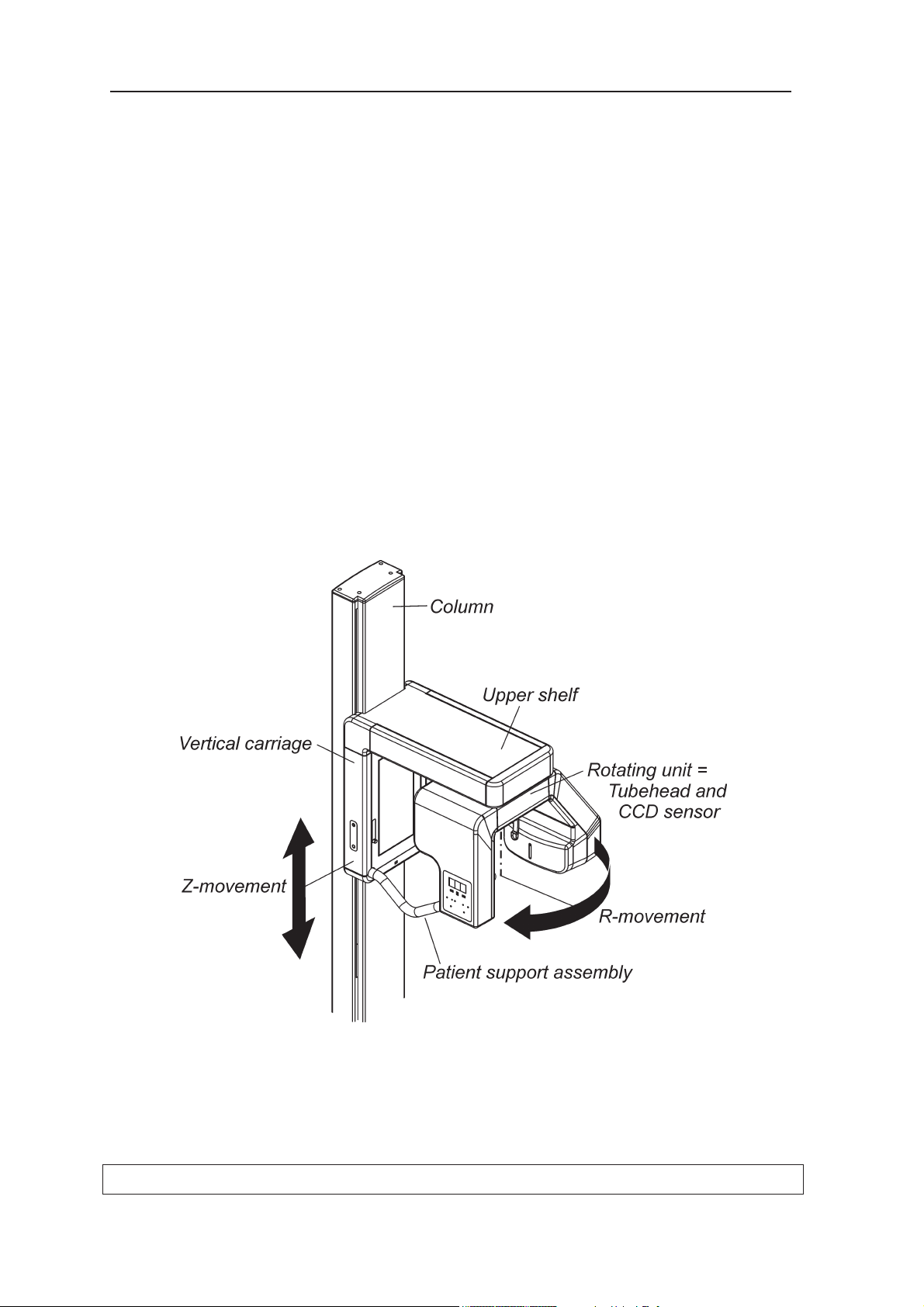

2.2 The main parts and assemblies ..................................................................11

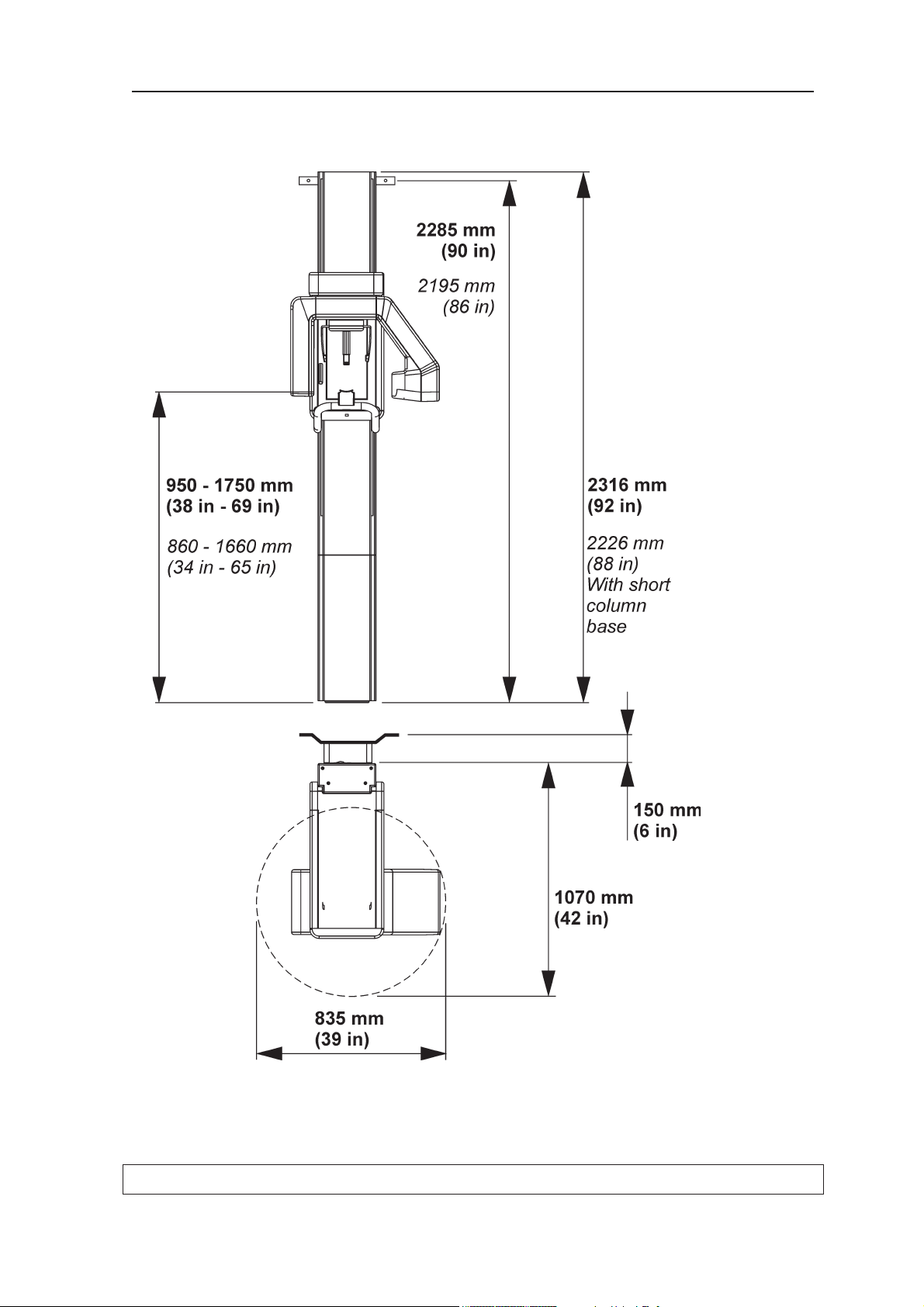

2.3 Unit dimensions ........................................................................................... 13

2.4 Mechanical description ................................................................................ 14

2.5 Electrical description ................................................................................... 16

Circuit boards ............................................................................................... 16

Power supply ................................................................................................ 16

Main fuses .................................................................................................... 16

Unit control .................................................................................................. 17

Motors and motor control ............................................................................. 17

Exposure logic .............................................................................................. 18

Position control ............................................................................................. 19

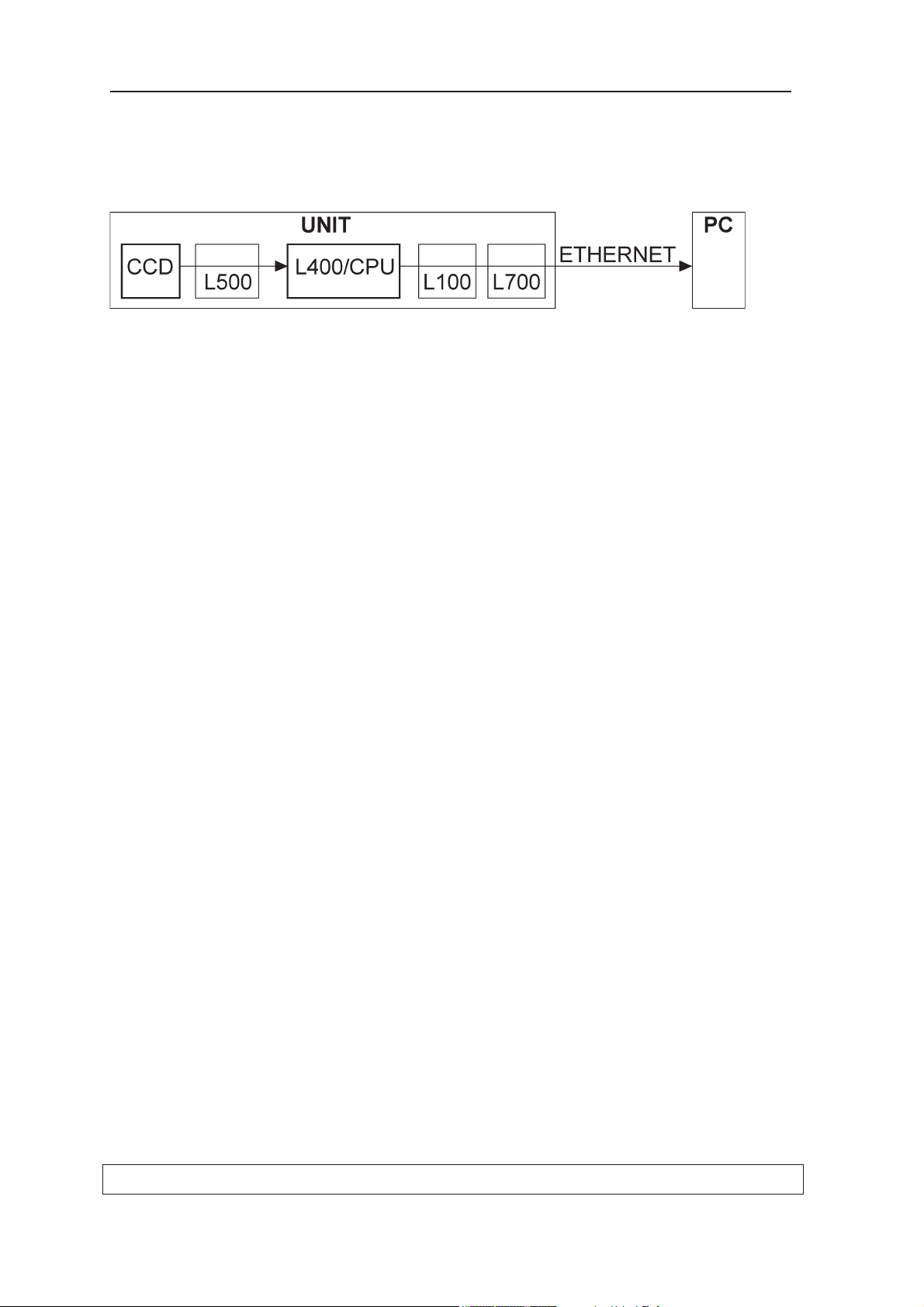

A overview of the Imaging Chain .................................................................. 19

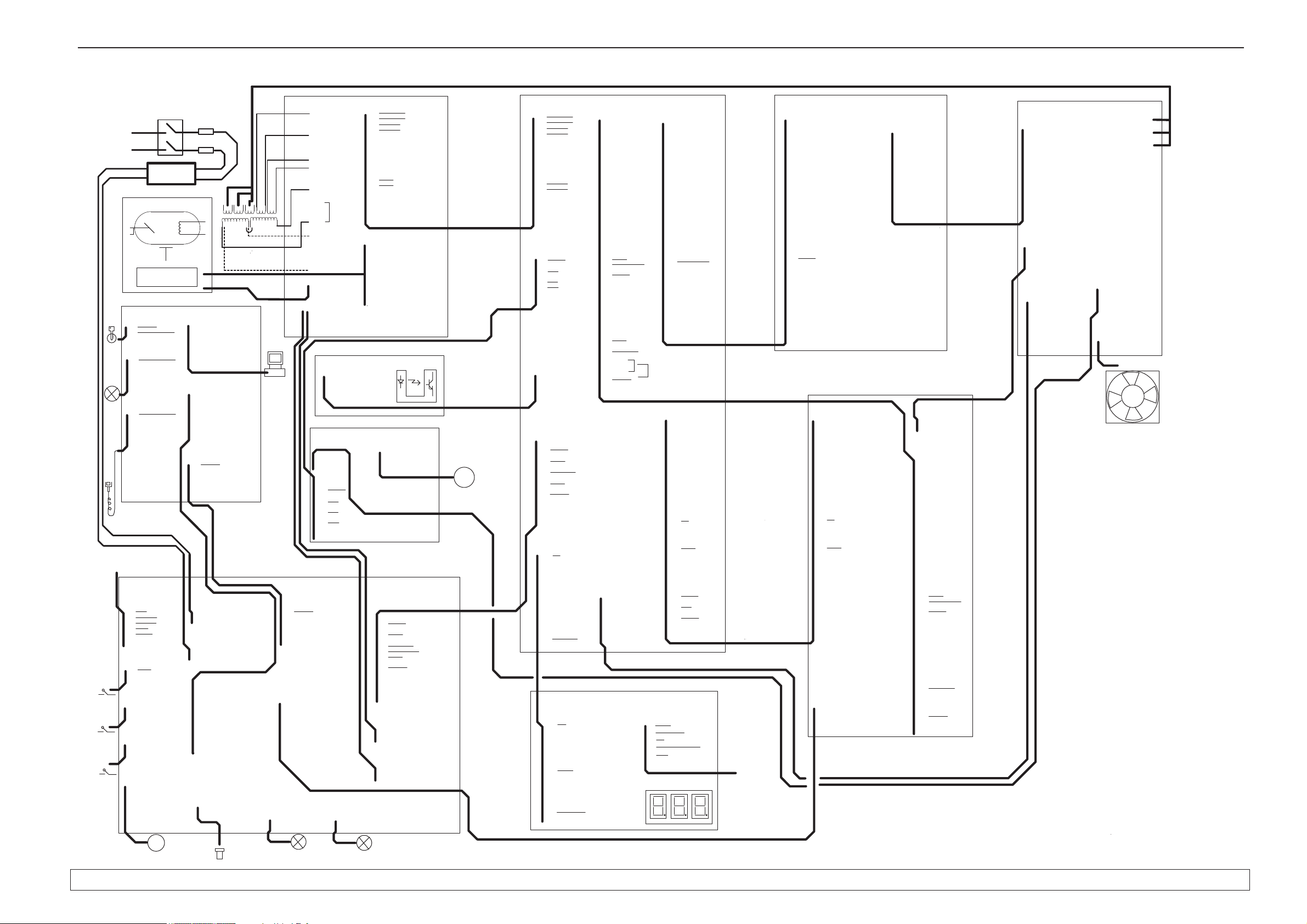

2.6 Wiring diagram - overview ........................................................................... 21

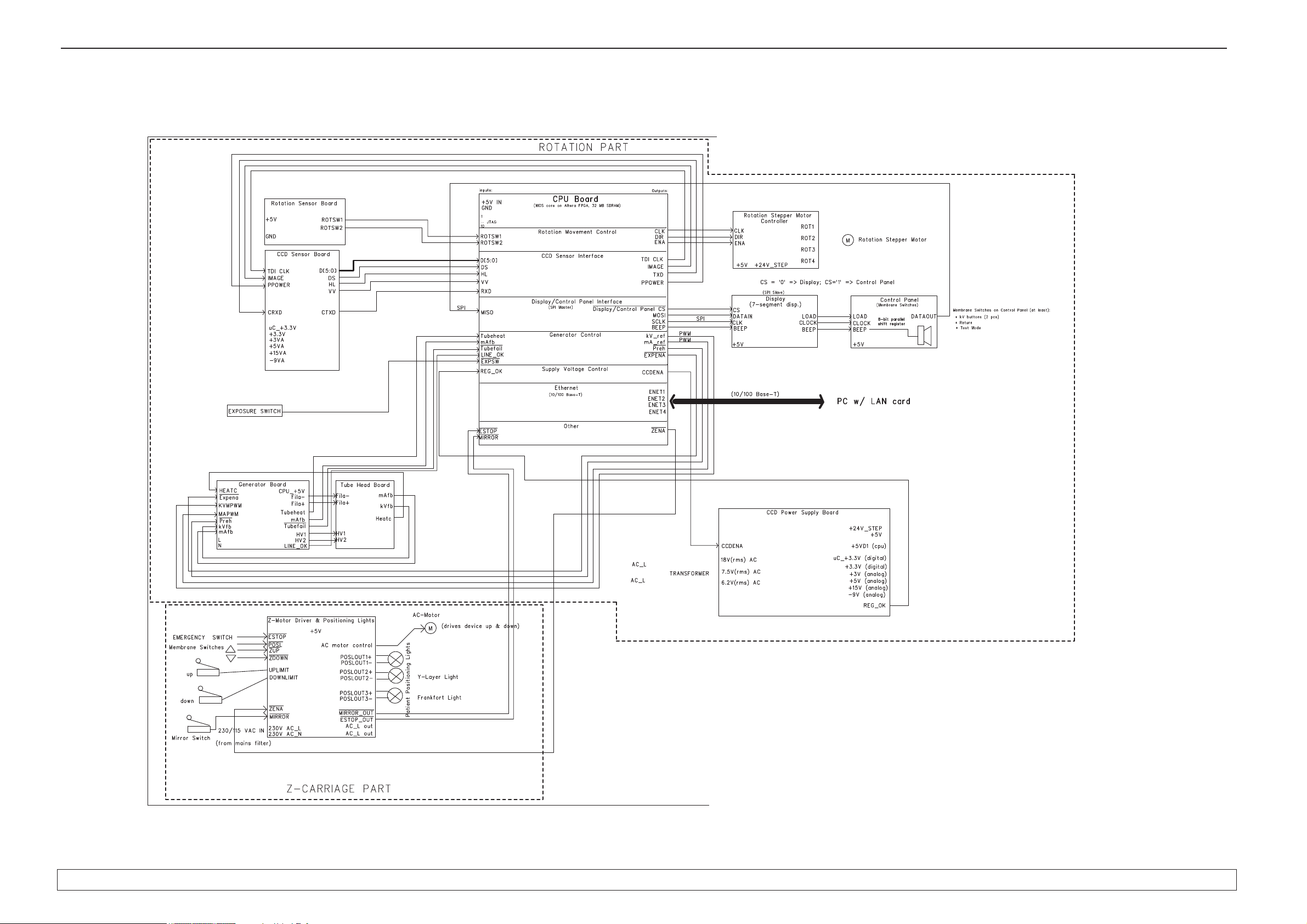

2.7 Block diagram ............................................................................................. 22

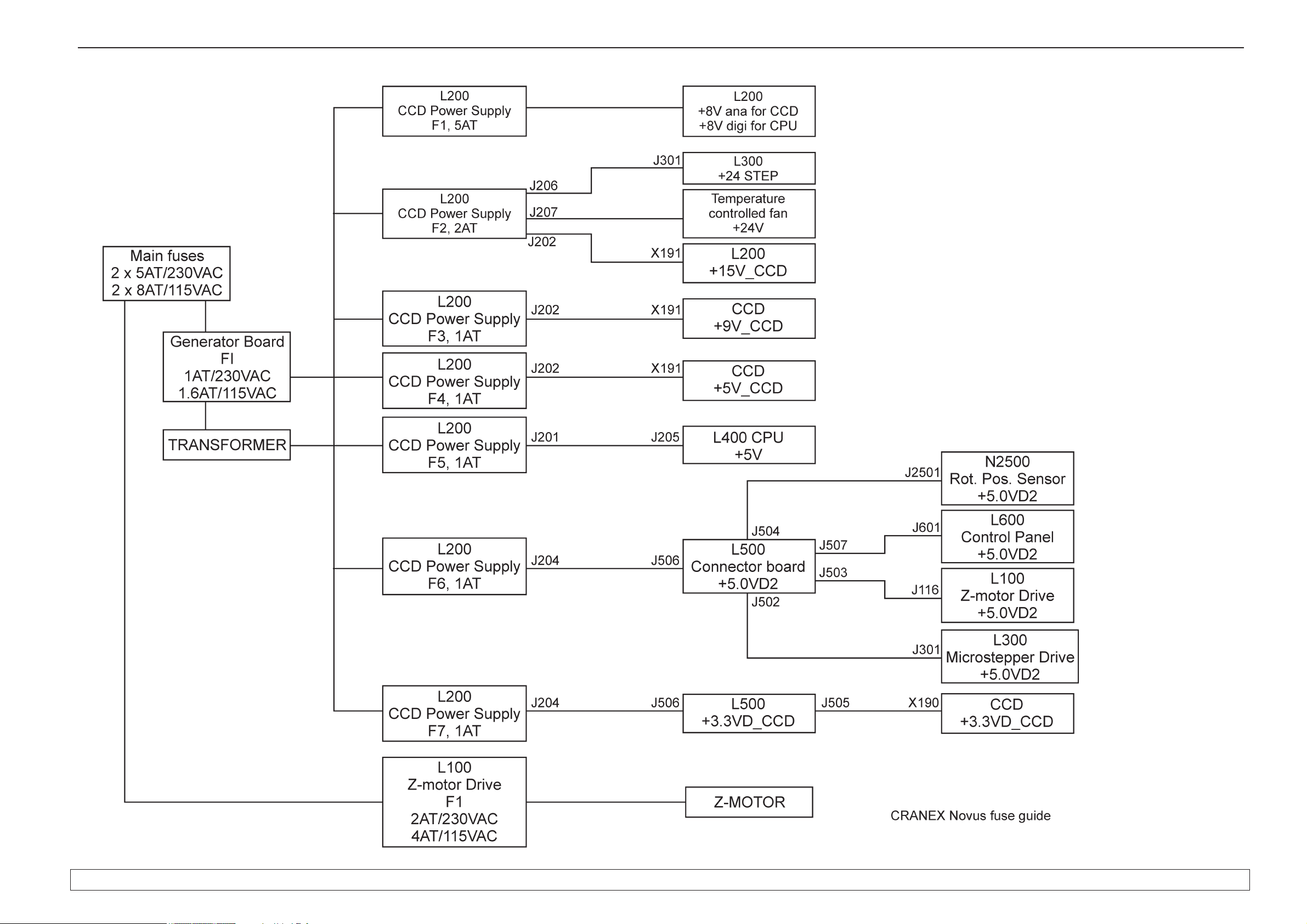

2.8 Fuse diagram .............................................................................................. 23

Page 5

VI Service manual 200569

Contents Cranex Novus

3. Circuit Boards .................................................................................................. 25

3.1 L100, Z-Motor Driver (Pt. no. 200395) ........................................................ 25

3.2 L200, CCD Power Supply (Pt. no. 200396) ................................................ 35

3.3 L300, 3-Phase Microstepper Driver (Pt. no. 200397) .................................. 44

3.4 L400 CPU Board (Pt. no. 200398) ............................................................. 48

3.5 L500 Connector Board (Pt. no. 200399) .................................................... 63

3.6 L600 Control Panel (Pt. no. 200400) .......................................................... 73

3.7 L700 Interface Board (Pt. no. 200401) ....................................................... 79

3.8 N2500 Rotation Position Sensor Board (Pt. no. 4801143) ......................... 84

3.9 Generator Board (Pt. no. 200404) .............................................................. 88

3.10 CCD Sensor (Pt. no. 200412) .................................................................. 96

4. Troubleshooting .............................................................................................. 99

4.1 Initial checks ................................................................................................ 99

Restarting the unit ........................................................................................ 99

Error Codes .................................................................................................. 99

Checking circuit boards ................................................................................ 99

Checking cables and connectors ............................................................... 100

Power supply problems .............................................................................. 100

4.2 Problems during start up ........................................................................... 101

Nothing happens when the unit is switched on .......................................... 101

The on/off switch light does not come on. ...................................................... 101

The on/off switch light comes on but the control panel does not light up. ...... 101

Error E 5 (Line voltage tolerance) .............................................................. 103

Error E 16 (Exposure switch or control panel) ........................................... 103

Error E 20 (Flash check error) .................................................................... 103

4.3 Problems while preparing the unit for an exposure ................................... 104

None of the control panel indicator nor alphanumeric

LEDs come on (Error E 18 on service assistant) ...................................... 104

The control panel indicator and alphanumeric

LEDs do not come on when they should .................................................. 104

The control panel Return key does not work .............................................. 104

Error E 7 (Positioning error) ....................................................................... 105

Error E 9 (Rotating motor timeout) ............................................................. 105

Rotating unit stop rotating, no error code ................................................... 105

Patient positioning light(s) do not come on ................................................ 106

One of lights does not come on. .................................................................... 106

None of the lights come on. ........................................................................... 106

Up/down (Z-motor) keys do not work ......................................................... 107

Error E 8 (Z-motor timeout) ........................................................................ 108

Page 6

Cranex Novus Contents

Service manual 200569 VII

4.4 Problems during exposure ........................................................................ 109

Nothing happens when the exposure button is pressed ............................ 109

Error code H1 (Exposure interupted) ......................................................... 109

Error codes E0, E1 and E2 .........................................................................110

Error E 6 (Exposure timeout) ......................................................................112

Error E 10 (CCD initialization/confi guration failure) .....................................112

Error E 11 (CCD error) ................................................................................112

Error E 12 (CCD error) ................................................................................113

Error E 13 (CCD error) ................................................................................113

4.5 Problems after exposure ............................................................................113

Error E 4 (Tubehead temperature) ..............................................................113

Vertical white stripes on the image ..............................................................114

Horizontal white stripes on the image .........................................................114

4.6 Bad quality images .....................................................................................115

Incorrect patient positioning ........................................................................115

A badly aligned unit .....................................................................................115

The CCD sensor .........................................................................................115

5. Service Assistant and service functions ......................................................116

5.1 Using the Service assistant ........................................................................116

5.2 The Service comands.................................................................................118

6. Updating the unit fi rmware and the core ..................................................... 127

6.1 The unit fi rmware....................................................................................... 127

6.2 Updating the core ...................................................................................... 130

7. Replacing parts.............................................................................................. 131

7.1 Removing covers ...................................................................................... 131

7.2 Replacing the tubehead ............................................................................ 132

Appendix A. Technical Information ...................................................................A-1

Page 7

VIII Service manual 200569

Contents Cranex Novus

Page 8

Cranex Novus 1. General information

Service manual 200569 1

1. General Information

1.1 Introduction

This manual describes how to service all versions of the

Cranex Novus and OEM versions of the Cranex Novus.

1.1 Associated documentation

The Cranex Novus User's manual.

The Cranex Novus Installation manual.

The Cranex Novus Spare-parts manual.

1.2 Service precautions and warnings

Servicing precautions

Only service personnel trained and approved by

Soredex are allowed to service the Cranex Novus.

Before attempting to service the device make sure that

you know how to operate it. Read the Cranex Novus

User's Manual.

Read and familiarize yourself with the warnings and

precautions listed in the Cranex Novus User's

Manual.

Only use original Soredex spare parts when repairing

the device or replacing parts.

The device is factory set to operate using either a

230VAC power supply or a 115VAC power supply.

Never connect the device to a power supply different to

the voltage marked on the device.

Warning - Radiation Safety

Before servicing the device familiarize yourself with

local and national radiation safety standards and

requirements relating to dental x-ray equipment.

When taking test exposures take adequate precautions

to protect yourself from radiation. Stand behind a

suitable radiation shield positioned at least two metres

(six feet) from the unit.

Page 9

2 Service manual 200569

1. General Information Cranex Novus

Warning - Mechanical safety

Disconnect the device from the main power supply before removing any covers.

Disconnect the device from the main power supply before repairing or replacing mechanical parts or installing

accessories.

Be careful when operating the device not to get body

parts or clothing trapped between moving parts.

During operation some surfaces and components may

become hot. Take precautions to avoid burning yourself.

The aperture plate in the collimator is made of lead (Pb)

which is toxic. Do not touch it with your bare hands.

Do not open the tubehead. There are no serviceable

parts, mechanical or electrical, inside the tubehead.

Warning - Electrical Safety

Disconnect the device from the main power supply

before replacing circuit boards or other electrical components.

If there are capacitors on a circuit board or electrical

component wait ten (10) minutes, after disconnecting

the device from the power supply, before handling the

board or component.

If you have to leave the device unattended during servicing or maintenance, disconnect the unit from main

power supply to protect people, who may touch the unit,

from electric shock.

This device should be used only in areas that are provided with a protective earth connection to ensure an

equipotential ground connection.

Page 10

Cranex Novus 1. General information

Service manual 200569 3

Caution - electrostatic discharge

Electrostatic Discharge (ESD) can damage or destroy

electronic components.

When servicing the device take precautions to avoid

electrostatic build up and discharge (ESD). Follow the

recommendations for the prevention of ESD that are

used in the country in which you are working. If no

recommendations are available, follow the guidelines

below:

- Leave all new or replacement circuit boards and electrical parts in their protective packaging until the boards

are needed.

- Before handling circuit boards and electrical parts

make sure that any static electricity charge that has

built up in you body is discharged.

- When examining and checking circuit boards use an

antistatic wrist wrap which is connected to a ground

point through a 1 Mohm current limiting cable. For a

ground point use water pipes, radiators or other objects

that are known to be connected to the ground. Also use

a cable to connect the unit to the same ground potential

as the wrist wrap.

- When handling circuit boards hold them by their edges

and do not touch any components or connectors.

- If an antistatic mat is used, connect the wrist wrap to

the mat and the mat to the ground potential.

- Wash the wrist wrap and check that it is in good condition frequently.

Page 11

4 Service manual 200569

1. General Information Cranex Novus

Warning - Explosion hazard

Certain disinfectants and cleaning agents may vaporize

to form an explosive vapour. If such chemicals are used

the vapour should be allowed to disperse before switching the device on.

Warning - Cleaning the unit

Switch the unit off and disconnect it from the main

power supply before cleaning or disinfecting the unit.

1.3 Unauthorized Modifi cations

Unauthorized changes or modifi cations to any part of

the unit or its equipment can have hazardous consequences. Changes or modifi cations must not be made

unless specifi cally authorized by Soredex.

When properly assembled with a compatible beamlimiting device, the diagnostic source assembly will fully

meet the United States of America Federal Performance Standards for Diagnostic X-Ray Systems and

Their Components (21 CFR 1020. 30-32) provided no

components or parts are removed from the unit and no

unauthorized adjustments are made to the beam-limiting device or tube housing assembly.

Never remove or remanufacture any part of the tube

housing assembly or beam-limiting device.

Never adjust any part of the beam-limiting device unless under the direction of Soredex or their authorized

distributor.

1.4 Disclaimer

Soredex shall have no liability for consequential damages, personal injury, loss, damage or expense directly or

indirectly arising from the use of its products. No agent,

distributor or other party is authorized to make any warranty or other liability on behalf of Soredex with respect

to its products.

Page 12

Cranex Novus 1. General information

Service manual 200569 5

1.5 Yearly maintenance

The following tests and inspections must be carried out

annually by an authorized service person to verify that

the device meets the specifi cations and performance

criteria essential for correct and safe operation.

When taking measurements that require a multimeter,

always use a digital multimeter (DMM).

kV test

WARNING: X-rays are generated when this test is car-

ried out. PROTECT YOURSELF FROM RADIATION.

1. Connect the +probe of a DMM to test pin TP14

(kVfb) and the -probe to TP17(GND) on the Generator board.

2. Select service command exp and an exposure time

of 2000 ms (refer to section 4 Service assistant and

service functions, in this manual).

3. Protect yourself from radiation and take an exposure. Check the feedback values from the DMM.

The feedback values must be within the tolerances.

Selected kV kVfb Tolerance (V)

60 3.0 ±0.2 (2.8 - 3.2)

70 3.5 ±0.2 (3.3 - 3.7)

If the values are not within the tolerances, recalibrate the Generator board, see section 5.2 Service

Commands (the calib command).

Page 13

6 Service manual 200569

1. General Information Cranex Novus

mA test

WARNING: X-rays are generated when this test is car-

ried out. PROTECT YOURSELF FROM RADIATION.

1. Connect the +probe of a DMM to test pin TP18

(mAfb) and the -probe to TP17(GND) on the Generator board.

2. Select service command exp and an exposure time

of 2000 ms (refer to section 4 Service assistant and

service functions, in this manual).

3. Protect yourself from radiation and take an exposure. Check the feedback values from the DMM.

The feedback values must be within the tolerance.

Selected mA mAfb (V) Tolerance (V)

7 2 ±0.2 (1.8 - 2.2)

If the value is not within the tolerance, recalibrate

the Generator board, see section 5.2 Service Commands (the calib command).

Beam alignment test

Check the beam alignment. Refer to the Installation and

set-up manual for information on how to do this.

Ground test

Disconnect the unit from the main power supply before

carrying out this test.

Check the safety ground continuity by measuring the

grounding resistance between the ground pin on the

connector of the mains power supply cable and any

metal part of the unit.

The resistance MUST be <0.2 ohm.

Page 14

Cranex Novus 1. General information

Service manual 200569 7

Motor movements

Switch the unit off and then manually rotate the rotating unit to check that all the stepper motor moves freely

and without any looseness.

Switch the x-rays off and then take an exposure to

check that the motors operate smoothly and without any

noise.

Press the up/down keys to check the Z-motor (vertical

carriage movement). The motor must operate smoothly

and without any noise.

Position detectors

Press the up key and drive the unit up. Make sure that

the unit stops moving at its uppermost position.

Press the down key and drive the unit down. Make sure

that the unit stops moving at its lowermost position.

Use service command optotest, see section 5.2 Service Commands, to check the rotating unit optosensors.

Patient Positioning Lights

Check that the patient positioning lights work and are

positioned correctly. Refer to the Installation and set-up

manual for information on how to do this.

Mains power supply cable

Check the condition of main power supply cable and

replace it if damaged.

Tubehead

Make sure that oil is not leaking from the tubehead. If

the tubehead shows signs of oil leakage, replace it.

Page 15

8 Service manual 200569

1. General Information Cranex Novus

Covers and Labels

Check that all covers are correctly installed and in good

condition. Also check that all the labels are attached to

the unit and that they are all legible.

Fire risk

WARNING: Disconnect the unit from the main power

supply before carrying out the next task.

Use a vacuum cleaner to remove all dust that has accumulated inside the unit to eliminate the risk of fi re.

Page 16

Cranex Novus 1. General information

Service manual 200569 9

1.6 Disposal

At the end of useful working life of the device, its spare

and replacement parts and accessories make sure that

you follow all local, national and international regulations regarding the correct and safe disposal and/or

recycling of the device, its spare and replacement parts

and accessories.

The device and its spare parts and accessories may

include parts that are made of or include materials that

are non-environmentally friendly or hazardous. These

parts must be disposed of in accordance with all local, national and international regulations regarding the

disposal of non-environmentally friendly or hazardous

materials.

The following hazardous materials and substances can

be found in the device, its spare and replacement parts

and assemblies:

- Lead (Pb): circuit boards, tubehead.

- Cadmium (Cd): none

- Mercury (Mg): none

- PBB Polybrominated biphenyls: none

- PBDE polybrominated diphenyl ethers: none

Other materials and substances in the device, its spare

parts and assemblies that could be hazardous and are

non-environmentally friendly are:

- Phosphor: beam alignment tools

- Mineral oil: tubeheads

The locations of all the device parts, spare and replacement parts and assemblies listed above can be found in

the device service and/or installation manual.

Page 17

10 Service Manual 200569

2. Unit Description Cranex Novus

2. Unit description

2.1 The Cranex Novus

The Cranex Novus digital extraoral x-ray unit is designed to take exposures of the dento-maxillofacial

region.

The units cannot be used to take x-ray exposures of

any other part of the human anatomy.

The Cranex Novus can be used to take adult panoramic

(full width), child panoramic (reduced width) and TMJ

images.

All units are factory set to operate using either a 230

VAC power supply or a 115 VAC power supply.

The voltage setting CANNOT be changed.

The Cranex Novus is used with a PC in which Digora

for Windows or some other MDD approved dental imaging software is installed.

Page 18

Service Manual 200569 11

Cranex Novus 2. Unit Description

2.2 The main parts and assemblies

Page 19

12 Service Manual 200569

2. Unit Description Cranex Novus

Page 20

Service Manual 200569 13

Cranex Novus 2. Unit Description

2.3 Unit dimensions

Page 21

14 Service Manual 200569

2. Unit Description Cranex Novus

2.4 Mechanical description

The unit comprises a column, a vertical carriage, an

upper shelf, a rotating unit and a patient support assembly.

The column rests on the fl oor and is fi xed to the wall

using wall bracket. If the unit is used in areas prone to

earthquakes the base of the column MUST also be

fi xed to the fl oor.

If the unit needs to be free standing it can be attached

to the show stand (part no. 9802666).

The vertical carriage is attached to the column and

can slide up and down the column (Z-movement, for

unit height adjustment). The upper shelf is attached to

the top of the vertical carriage.

The rotating unit, which comprises the tubehead and

collimator and the CCD sensor assembly, is attached

to the underside of the upper shelf. The rotating unit

rotates to take panoramic exposures (R-movement).

Page 22

Service Manual 200569 15

Cranex Novus 2. Unit Description

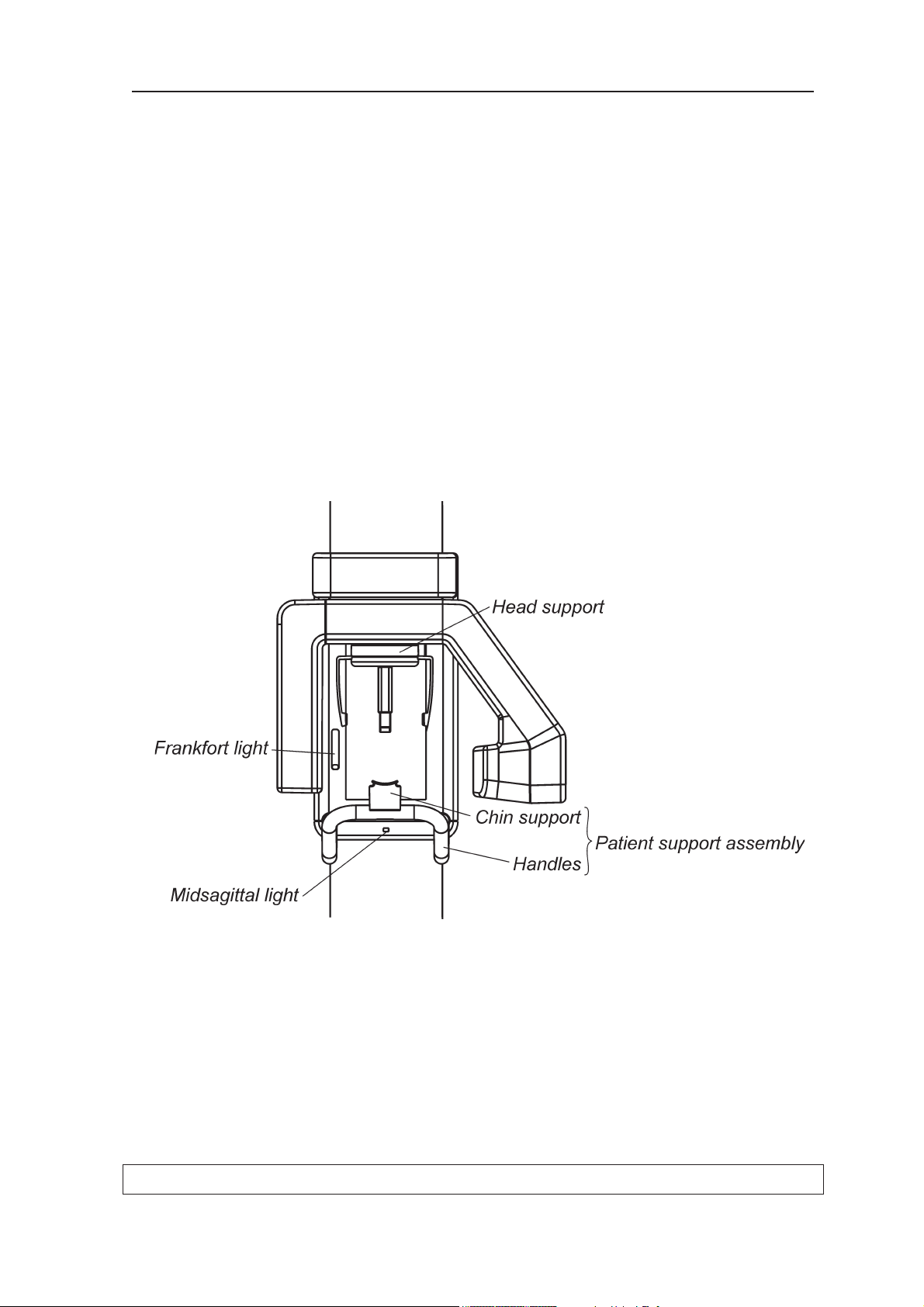

Inside the tubehead there is the x-ray tube. It is a fi xed

tungsten anode type with a focal spot of 0.5 mm. The

maximum anode voltage is 70kV and maximum current

is 7mA.

The patient support assembly is attached to the bottom of the vertical carriage. It comprises handles for

the patient to hold and a chin support.

The patient is held in position with a four-point support

system. The head support (attached to the rotating

unit) supports the patient's head with temple supports

and the forehead support. The patient support assem-

bly supports the patients lower jaw on the chin support,

using either the chin rest or lip support.

There are two patient positioning laser lights, midsagit-

tal light and Frankfort (horizontal) light.

Page 23

16 Service Manual 200569

2. Unit Description Cranex Novus

2.5 Electrical description

Circuit boards

Circuit boards are described in detail in section 3. Circuit Boards.

Power supply

Power (230VAC or 115VAC) is supplied to the unit

through L100 (Z-Motor Driver). From L100, power is

routed through the Generator board to a transformer

which produces low voltages (+3, +3.3, +5, -9.4, +15

and +24V) that are supplied to L200, a linear mode

power supply, which distributes the voltages to the

other boards in the unit. The transformer also produces

27VAC and 19VAC voltages that are supplied directly

(not through L200) to the Generator board.

The power for the AC-motor (z-motor), 230VAC or

115VAC, is taken directly from L100 and not from the

Generator board.

Capacitors on the Generator board produce the 310V

needed to power the tubehead from the 230VAC or

115VAC supplied by L100.

Main fuses

Two 5AT/230VAC or 8AT/115VAC, dimensions 5mm x

20mm, UL approved.

They are located below the main power supply cable at

the rear of the column.

Page 24

Service Manual 200569 17

Cranex Novus 2. Unit Description

Unit control

The unit is controlled by a microprocessor on L400

(CPU board). It continually monitors and controls the

operation of the unit. A serial peripheral interface communication protocol (SPI - RS485) and direct digital I/O

are used to monitor most of the unit functions.

The microprocessor:

- monitors the optosensors

- monitors control panel keys

- controls unit movements during exposures

- starts, controls and stops x-ray generation

- controls the digital imaging chain

The necessary unit settings and parameters for all the

imaging programs are stored in the memory which is

also on L400.

Motors and motor control

There is one stepper motor and one AC-motor in the

unit.

The stepper motor drives the rotating unit (R-movement). The stepper motor is driven and controlled by

L300 (3-Phase Microstepper Driver).

The AC-motor (Z-motor) adjusts the height of the unit

(Z-movement), and the motor is activated by L100. To

activate the Z-motor L100 must receive a control signal

from L400 and a separate control (enable) signal from

the Z-movement (up/down) keys.

An emergency switch on the front of unit disables the Zmotor (Z-movement) and stepper motor (R-movement)

when pressed.

Page 25

18 Service Manual 200569

2. Unit Description Cranex Novus

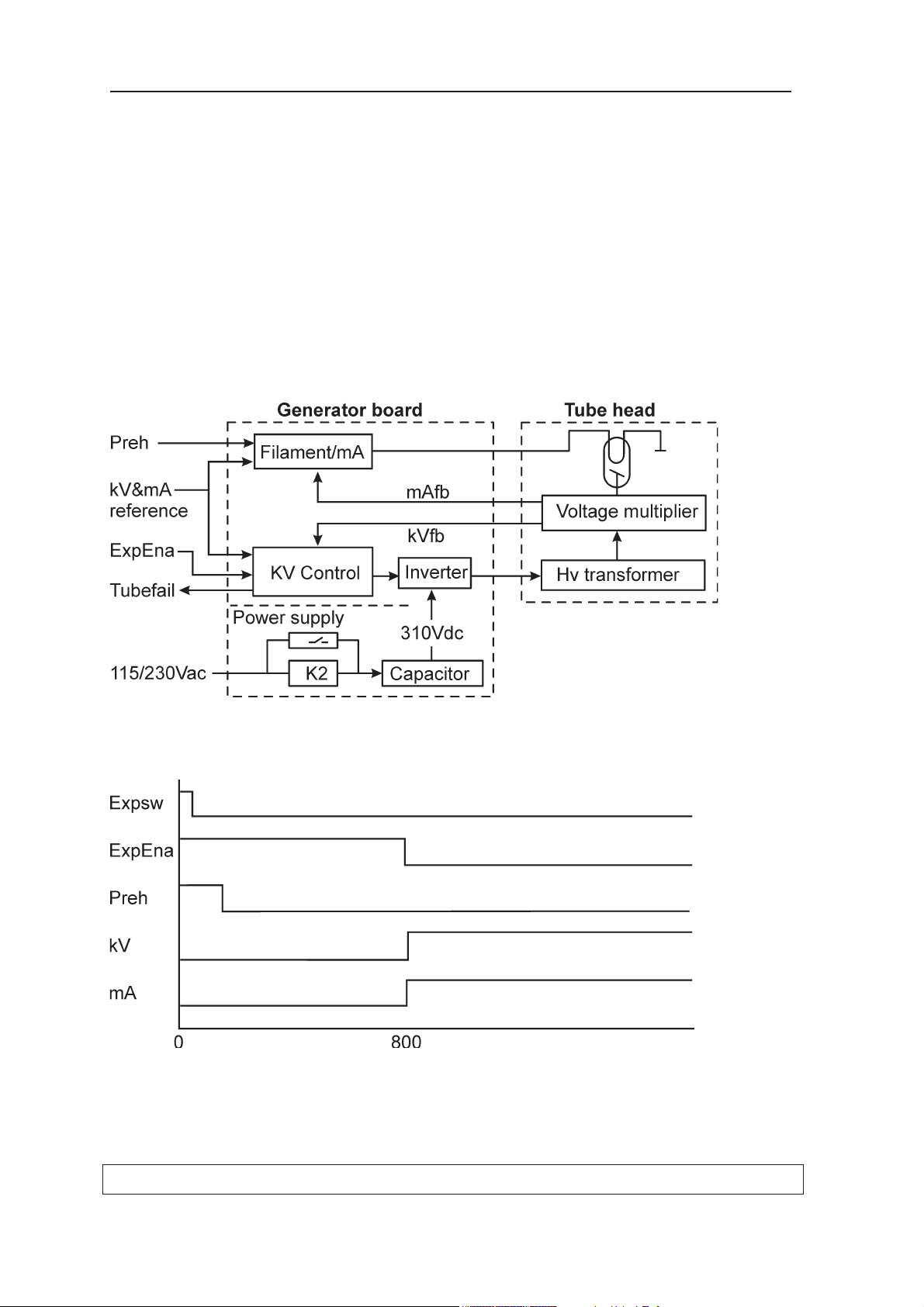

Exposure logic

An exposure can only be taken when the unit is in the

ready state (the exposure ready light on the control

panel is on) and the exposure button is pressed and

held down.

The Generator board receives the correct kV and mA

references from the CPU (L400). A few milliseconds

after the exposure button is pressed (Expsw) preheat

is enabled (Preh). After 800ms the exposure will start

(ExpEna). The tubehead will receive power from the

Generator board and the Generator board will also start

to regulate the mA and kV according to mA- and kVfeedback.

Page 26

Service Manual 200569 19

Cranex Novus 2. Unit Description

Position control

The position of the rotating unit (R-movement) is monitored by optosensors on N2500 (Rotation Position Sensor Circuit). The optosensors indicate in which sector

the rotating unit is. The optosensors ensure that the

rotating unit is in the correct position, start or PIO (Patient In/Out), for an exposure.

The statuses of the optosensors are monitored continually by the unit software.

The upper and lower limits of the vertical carriage (Zmovement) are monitored by microswitches.

A overview of the Imaging Chain

This description assumes that the unit is ready to take

an exposure.

Image acquisition is controlled by a software component, Digora Software Driver (DSD) which is installed in

the PC connected to the unit.

When an exposure is taken L400 (the CPU) then sends

a PPOWER (pan) and CCDON signal. CCDON signal

activates

linear regulators on L200 which then produce

the power supply voltages for the CCD sensor.

The CPU's control software continuously monitors the

status of the connection with the DSD driver. After image exposure but before image transfer the CPU sends

a label that includes the imaging parameters (—kV/—

mA/ —s) and an imaging program identifi er.

The CPU enables the IMAGE signal to activate pixel

clocking. The CPU then produces the TDI clock signal,

which clocks the pixels from the CCD sensor. Derivation

of several CCD clock signals from the TDI clock is done

by the CCD sensor board.

Radiation striking the CCD sensor is converted to visible light which is detected by the CCD cell. A binning

procedure is carried out on individual pixels, i.e. two adjacent pixels in a row and column (2 x 2 binning) forms

one large pixel (96µm x 96µm). The output voltage of

the CCD is fed to a 14-bit A/D converter.

Page 27

20 Service Manual 200569

2. Unit Description Cranex Novus

The CCD sensor board sends the image data (now 12

bits) to the CPU board where they are saved on the

SDRAM. The image information is transferred to the PC

via the Ethernet cable.

In the PC there is a Network Interface Card (NIC). After

image data transfer the DSD preprocesses the raw

image, for example it interpolates gaps between CCD

chips, and carries out dark current correction and gain

correction (the pixels do not have equal characteristics).

Page 28

Cranex Novus 1. General information

M

PC

CCD SENSOR 200394

GND40

39 GND

GND38

37 GND

uC+3.3V36

35 uC+3.3V

34

33

PAN_CAM_DET32

31 PAN_CAM_DET

30

29

28

27

RESET

26

25 CTXD

CRXD24

GND23

22

GND21

GND20

19 DS

18 GND

17

PPOWER16

15 TDICLK

14 IMAGE

13

VV12

11 HL

10

9

D58

76D4

D3

D2

D1

D0

GND

GND

5

4

3

2

1

X190

PINHEADER 2 x 20

L700 INTERFACE BOARD 200401

5

4

GND

EXPLT3

2 READYLT

EXPSW_LOCK

1

6

J701

RJ-12

J703

J705

RJ-45

6

7

8

1 TP0+

TP0-2

3 TP1+

TP1-

4

5

1EXPSW

READYLT2

3EXPLT

GND4

AMP MODU II B-1X6M

Molex 95009-2661

PINHEADER 2 x 8

13 +5V

+5V14

1516GND

GND

-9V

-9V1211

10 +3V

+3V9

8 +15V

+15V7

X191

1GND

GND2

3GND

GND4

56+3.3V

+3.3V

Cranex Novus Wiring Diagram v1.1 17.03.2008

5

6

GND

L100 Z-MOTOR DRIVER 200395

GND

GND

EXPLT

READYLT

EXPSW

16

15

14

13

12

11

J116

ZACT

RETURN2

ZENA

ESTOP

+5V

1

2

3

4

5

+5V

6

7

8 MIRRORSW

9

10

AMP MODU II 2x8M

GND2

1

ZTOP

ZBOTTOM

1

2GND

J102

J103

AMP MODU II 1x2M

AMP MODU II 1x2M

6

ZDOWN

5

4

3

2

1

ZUP

ZACTIN

RETIN

AMP MODU II 1x6M

J100

PLIN

GND

AMP MODU II 1x2M

J101

GND2

1

MSW

GND

EXPLT

EXPSW

READYLT

1

2

3

4

J111

J112

MOLEX RJ-45

6

7

8

1 TP0+

TP0-2

3 TP1+

TP1-

4

5

4

TP1+3

2 TP0-

TP0+1

J113

5

6

GND

67TP1-

5

PLENA

PLSW

GND

8

J110

ESTOP_5V2

1

+5V

4

AC1TR6OUT3

2

AC1TR4OUT1

J104

AMP MODU I 1x8M

67AC2TR5OUT

5

8

AMP FASTON TAB CONTACT

J105

AC12

1

AC1

J106

AC22

1

AC2

J108

POSLOUT2-2

1

ESTOP_5V

J114

AC12

1

AC1

J115

AC2

2

1

AC2

AMP FASTON TAB CONTACT

AMP MODU II 1x2M

AMP MODU II 1x2M

AMP MODU II 1x6M

MOLEX RJ-45

AMP FASTON TAB CONTACT

AMP FASTON TAB CONTACT

GND

N2500 ROTATION POSITION SENSOR

4

3

2

+5V1

ROTSW1

ROTSW2

J2501

AMP MODU II B-1x4M

(280371-2)

ENA

(280385-2)

AMP MODU II 2x8M

+5V

AMP MODU II 1x4M

J302

Phase #3

Phase #2

1Phase #1

2

3

4

16

GND

15

14

13

GND

12

DIR

11

GND

L300 3-PHASE MICROSTEP DRIVER 200397

J301

CLK

GND

GND

+24V

+24V

1

2

3

4

5

PGND

PGND

6

7

8 HICUR

9

10

(280371-2)

2GND

+5V1

AMP MOD I 1x2M

J205

TP0+1

2 TP0-

TP1+3

4 TP1-

J204_CPU

AMP MODU II 1x4M

J3

PINHEADER 2x25

GND50

49 +3.3V

EXPSW

48

47 HL

PLSW46

45

44

43 TUBEFAIL

MIRRORSW42

41 ZACT

J203_CPU

PINHEADER 2x20

1

2

3

4

5

TUBEHEAT

A/D_1

LINEOK6

7

8MAFB

9

10 KVFB

11

12 GND

GND13

GND14

GND15

16 GND

GND17

GND18

GND19

20 +5V

21 +5V

22 +5V

23 +5V

24 +5V

25

26 ZENA

RESET_CCD

27

28 PL_ENA

HICUR

29

30 FAN_PWM

OUT131

32 OUT2

OUT333

34 ROTSW1

ROTSW235

36 RXD

MISO37

38

39

40

GND40

39 +5V

GND38

37 ENA

GND36

35 DIR

GND34

33 CLK

PPOWER32

31 CCDENA

TXD30

29 TDI_CLK

A/D_228

27 IMAGE

GND26

25 EXPON

PREH

24

KV_REF23

MA_REF22

BEEP21

GND20

19 CS

18 GND

17 SCLK

GND16

15 MOSI

14 GND

13 REGTEMP

D512

11 D4

D310

D29

D18

76D0

GND

DS

GND

VV

GND

+5V

5

4

3

2

1

L400 CPU BOARD 200398

(280370-2)

(280371-2)

(280610-1)

(280373-2)

FANPWM

LINEOK (U_IN)

L200 CCD POWER SUPPLY 200396

4

3

9V AC (-)

9V AC (+)

6

5

4

8V AC (+)

8V AC (-)3

2

18V AC (+)

18V AC (-)1

MOLEX 5566-06A

J205

2GND

+24_RAW1

AMP MODU II 1x2M

J207

J201

AMP MODU I 1x4M

1 +5.0VD1

GND2

8

7

J204

AMP MODU II 1x8M

1 +5.0VD2

GND2

3 +3.3VD_CCD

GND4

56REGTEMP

CCDENA

13 +5.0V_CCD

+5.0V_CCD14

1516GND

GND

-9V_CCD

-9V_CCD

12

11

10 +3.0V_CCD

+3.0V_CCD9

8 +15V_CCD

+15V_CCD7

J202

1GND

GND2

3GND

GND4

56+3.3V_CCD

+3.3V_CCD

4GND

GND3

2 +24V_STEP

+24V_STEP1

AMP MODU II 1x4M

J206

(280379-2)

Yamaichi FAP-16-08-2-2-0af

AMP MODU II 1x6M 90

J602

1

2

3

4

5

6

kV

TEST

TMJ

RETURN1

PATIENT_SIZE

GND

RIBBON CABLE CONNECTOR

16

15

14

13

12

11

GND

GND

GND

GND

GND

+5V

RETURN2

GND

READYLIGHT

MISO

MOSI

CS

SCLK

BEEP

+5V

DIG4

L600 CONTROL PANEL 200400

10

9

8

7

6

5

4

3

2

1

J601

(280372-2)

AMP MODU II B-1x2M

1EXPSW

EXPSW_LOCK2

J702

(280370-2)

GND

5

4

GND

EXPLT3

2 READYLT

EXPSW_LOCK

1

6

RJ-12

J704

Molex 95009-2661

GND

Molex 95009-2881

J706

RJ-45

6

7

8

1 TP0+

TP0-2

3 TP1+

TP1-

4

5

Molex 95009-2881

(280371-2)

FILAMENT VOLTAGE (-)

10

FILAMENT VOLTAGE (+)9

GND8

GND7

6GND

GND5

MAFB4

KVFB1

GND2

3 HEATCURRENT

MOLEX 90136-1210

X50

HV2

MOLEX 5566-02A

X48

HV1

1

2

27V AC (-)

27V AC (-)3

4

27V AC (+)

MOLEX 5566-04A

X43

27V AC (+)1

2

19V AC (-)

MOLEX 5566-02A

X44

19V AC (+)1

2

MOLEX 5566-04A

X47

L

N1

2

3

4

N

L

KVFB

KVFB

MOLEX 87089-2016

X49

TUBEHEAT20

19 TUBEHEAT

MAFB18

MAFB17

GND

KVPWM

EXPENA

TUBEFAIL

1

2

3

4

5

TUBEFAIL

EXPENA

KVPWM6

7

8GND

9

10

GND11

12 GND

PREH

13

PREH

14

MAPWM15

16 MAPWM

GENERATOR BOARD 200404

TUBE HEAD ASSEMBLY

L

5

6

MOLEX 5566-06A

X45

1

2

3

4

N

(62409-1)

(62409-1)

(280370-2)

(280370-2)

(280612-1)

(280370-2)

(280370-2)

(280370-2)

(280372-2)

(95052-2887)

(95052-2887)

(280372-2)

(280385-2)

(62409-1)

(62409-1)

LINEOK

CCDENA

5 REGTEMP

6

7

8

FANPWM

(280373-2)

AMP MODU II 1x8M

J506

+3.3VD_CCD

GND

1 +5.0VD2

2

3

4

GND

+3.3VD_CCD

(280371-2)

GND

PLSW

PL_ENA

(280385-2)

(280373-2)

ENA

DIR

6

5

4GND

CLK

3

2GND

HICUR

1

AMP MODU II 1x8M

J502

7

8

+5.0VD2

GND

KVFB

KVFB

RIBBON CABLE

16

15

14

13

12

11

GND

GND

GND

GND

GND

+5.0VD2

RETURN2

GND

READYLT

MISO

MOSI

CS

SCLK

BEEP

+5.0VD2

DIG3

10

9

8

7

6

5

4

3

2

1

J507

AMP MODU II 1x4M

J504

ROTSW2

ROTSW1

1 +5.0VD2

2

3

4

GND

RIBBON CABLE (1mm)

GND

GND

EXPLT

READYLT

EXPSW

16

15

14

13

12

11

J503

ZACT

RETURN2

ZENA

ESTOP

+5.0VD2

1

2

3

4

5

+5.0VD2

6

7

8 MIRRORSW

9

10

AMP MODU II 2x8M

1

2

3

4

5

GND

GND

D0

D1

D2

D3D46

7

8D5

9

10

HL11

12 VV

13

IMAGE_OUT14

TDICLK_OUT15

16 PPOWER_OUT

17

GND18

DS19

20 GND

21 GND

22

23 GND

24 TXD_OUT

RXD25

26 RESET_CCD

27

28

29

30

PAN_CAM_DET31

32 PAN_CAM_DET

33

34

+3.3VD_CCD35

36

GND37

38 GND

GND39

40 GND

J505

MAPWM16

15 MAPWM

14 PREH_2

13 PREH_2

GND12

11 GND

10

9

GND8

7

6KVPWM

EXPENA

TUBEFAIL

5

4

3

2

1

TUBEFAIL

EXPENA

KVPWM

GND

17 MAFB

18 MAFB

TUBEHEAT19

20 TUBEHEAT

J501

40

39

38

37 MISO

RXD36

35 ROTSW2

ROTSW134

33

32

31

FANPWM30

29 HICUR

PL_ENA28

27 RESET_CCD

ZENA26

25

24

23

22

21

20

19 GND

18 GND

17 GND

GND16

15 GND

14 GND

13 GND

GND12

11

KVFB_OUT10

9

MAFB_OUT8

7

6LINEOK

TUBEHEAT_OUT

5

4

3

2

1

ZACT

41

42 MIRRORSW

TUBEFAIL

43

44

45

46 PLSW

HL47

48 EXPSW

49

50 GND

PINHEADER 2x25

J508

PINHEADER 2x20

J509

1

2

3

4

5

GND

VV

GND

DS

GNDD06

7

8D1

9D2

10 D3

D411

12 D5

(A/D_1)13

GND14

MOSI15

16 GND

SCLK17

GND18

CS

19

20 GND

21 BEEP

22 MA_REF

23 KV_REF

24 PREH

EXPON25

26 GND

IMAGE27

28 REGTEMP

TDI_CLK29

30 TXD

CCDENA31

32 PPOWER

CLK_1

33

34 GND

DIR

35

36 GND

ENA_1

37

38 GND

39

40 GND

L500 CONNECTOR BOARD 200399

MEMBRANE

STRAIGHT 2mm

PINHEADER 2 x 8

STRAIGHT 2mm

STEPPER

SIDE CONTROL

EMERGENCY

SWITCH

AC-MOTOR

KEY LOCK

MICRO

SWITCH

MICRO

SWITCH

MICRO

SWITCH

J109

POSLOUT1-2

1

ESTOP_5V

AMP MODU II 1x2M

(280370-2)

LASER #1

LASER #2

MAINS SWITCH

EXPOSURE SWITCH

EXTERNAL

LIGHTS

MOTOR

PINHEADER 2 x 20

STRAIGHT 2mm

STRAIGHT 2mm

MIRROR

ZUP

ZDOWN

PaloDEx Group Oy

PANEL

+5V

+5V

+5V

+5V

+5V

+5V

+5V

(230V setup)

Cascade Board

X-Ray Tube

Y-Cable

M

L

5

6

MOLEX 5566-06A

X46

1

2

3

4

N

(115V setup)

L

N

+310V DC

18VAC / 9VAC / 8VAC

SWITCHES

SWITCHES

230/115 VAC

Fuses: 2 x T5L 250V (for 230V device)

2 x T8L 250V (for 115V device)

L (230/115 VAC)

N

ETHERNET

ETHERNET

230/115 VAC

MAINS TRANSFORMER

230VAC: 2 prim windings

115VAC: 1 prim winding

ETHERNET

18VAC 9VAC 8VAC

27VAC

19VAC

115VAC 115VAC

MAINS FILTER

2 OPTO SENSORS

7-segment display

L

NN

L

N

L

FAN

24V DC

1

2

3

4

5

2.6 Wiring diagram - overview

Service manual 200569 21

Page 29

1. General Information Cranex Novus

2.7 Block diagram

22 Service manual 200569

Page 30

Cranex Novus 1. General information

2.8 Fuse diagram

Service manual 200569 23

Page 31

1. General Information Cranex Novus

24 Service manual 200569

Page 32

Cranex Novus 3. Circuit Boards - L100, Z-Motor Driver

Service manual 200569 25

3. Circuit Boards

NOTE: An asterisk (*) after a signal name indicates an active low-level signal.

3.1 L100, Z-Motor Driver (Pt. no. 200395)

L100 - Location

On the upper shelf.

To access remove front panel and then top cover plate

(see section 7.1).

Page 33

26 Service manual 200569

3. Circuit Board - L100, Z-Motor Driver Cranex Novus

L100 - Field replaceable parts

Fuse F1.

NOTE:

The fuses used MUST be the approved type, UL listed

and CSA certifi ed.

Approved fuses:

- for units rated 230VAC:

2AT/250VAC Cooper Bussmann MDL-2

or SIBA ELU 70 065 65.

- for units rated 115VAC:

4AT/250VAC Cooper Bussmann MDL-4

or SIBA ELU 70 065 65.

Dimensions 6.3 mm x 32 mm.

L100 - Description

L100 (Z-motor Driver) controls the AC-motor that drives

the unit up and down. Membrane switches on the side

of the vertical carriage are used to activate the ACmotor. The positions of the Z-carriage and the Rotating

Unit are also monitored by L100.

Micro switches at the top and bottom of the column

monitor the upper and lower positions of the Z-movement. Based on the logic on the circuit board, the movement of the AC motor is enabled or prohibited. Three

triacs control the Z-motor currents. Outputs are optocoupled from the user inputs with TLP3063 circuits. The

board also includes light controls for the laser positioning lights.

Page 34

Cranex Novus 3. Circuit Boards - L100, Z-Motor Driver

Service manual 200569 27

L100 - Block diagram

Page 35

28 Service manual 200569

3. Circuit Board - L100, Z-Motor Driver Cranex Novus

L100 - Indicator lamp

Lamp Function Indicates

LA1 GLIM AC indicator lamp L100 receiving 230 or 115VAC line voltage.

L100 - Indicator LEDs

LED Colour Indicates

D1 green +5V on

D2 green ZACT-movement key pressed

D3 green ZON on

D4 red ESTOP on. Emergency stop button is on.

L100 - Test Points

Number Signal Value

TP1 ESTOP_5V +5V normally, 0 ... +0.5V when emergency

switch pressed down

TP2 ZDIR 0V driving up, +4.8V...+5V driving down

TP3 ZON Text wrong (+5V). Correct value +3V when

up/down key pressed. Otherwise 0V.

TP4 +5V +5V

TP5 GND 0V

TP6 ZACT* 0 ... +0.5 when up/down key pressed,

otherwise close to +5V.

L100 - Test Switches

DANGER - HIGH VOLTAGE!

Take great care when pressing the switches SW1, SW2, SW3 not to touch

indicator lamp LA1 which is 230 / 115VAC.

Switch Operation

SW1

SW1 + SW2 Press simultaneously to drive vertical carriage up.

SW2

SW2 + SW3 Press simultaneously to drive vertical carriage down.

SW3

Page 36

Cranex Novus 3. Circuit Boards - L100, Z-Motor Driver

Service manual 200569 29

L100 - Connectors

J100

Pin Signal Description

1 ZUP* Z-movement drive up key pressed

2 ZDOWN* Z-movement drive down key pressed

3 ZACTIN* Z-movement key pressed

4 PLIN* Position lights key pressed

5 RETIN* Return key pressed

6 GND GND (logic)

J101

Pin Signal Description

1 MSW* Mirror switch

2 GND GND (logic)

J102

Pin Signal Description

1 ZTOP Z-movement reached top

2 GND GND (logic)

J103

Pin Signal Description

1 ZBOTTOM Z-movement reached bottom

2 GND GND (logic)

J104

Pin Signal Description

1 AC1TR4OUT AC motor power signals

3 AC1TR6OUT AC motor power signals

6 AC2TR5OUT AC motor power signals

J105

Pin Signal Description

1,2 AC1 230 or 115 VAC line voltage

Page 37

30 Service manual 200569

3. Circuit Board - L100, Z-Motor Driver Cranex Novus

J106

Pin Signal Description

1,2 AC2 230 or 115 VAC line voltage

J107

Pin Signal Description

1 ESTOP_5V Emergency stop

2 POSLOUT3* Position light 3

J108

Pin Signal Description

1 ESTOP_5V Emergency stop

2 POSLOUT2* Position light 2

J109

Pin Signal Description

1 ESTOP_5V Emergency stop

2 POSLOUT1* Position light 1

J110

Pin Signal Description

1 +5V Supply voltage (logic)

2 ESTOP_5V Emergency stop

J111

Pin Signal Description

1 EXPSW* Exposure switch

2 READYLT Ready light

3 EXPLT Exposure light

4,6 GND GND (logic)

J112

Pin Signal Description

1 TP0+ Ethernet, twisted pair 0

2 TP0- Ethernet, twisted pair 0

3 TP1+ Ethernet, twisted pair 1

6 TP1- Ethernet, twisted pair 1

Page 38

Cranex Novus 3. Circuit Boards - L100, Z-Motor Driver

Service manual 200569 31

J113

Pin Signal Description

1 TP0+ Ethernet, twisted pair 0

2 TP0- Ethernet, twisted pair 0

3 TP1+ Ethernet, twisted pair 1

6 TP1- Ethernet, twisted pair 1

J114

Pin Signal Description

1,2 AC1 230 or 115 VAC line voltage

J115

Pin Signal Description

1,2 AC2 230 or 115 VAC line voltage

J116

Pin Signal Description

1,2 +5V Supply voltage (logic)

3 ESTOP* Emergency stop on

4 PLENA Position lights enable

5 ZENA* Z-movement enable

7 RETURN2* Rotating unit return

8 MIRRORSW Mirror switch

9 ZACT* Z-movement activity

10 PLSW Position light switch

11 EXPSW* Exposure switch

12,15,16 GND GND (logic)

13 READYLT Ready light on

14 EXPLT Exposure light

Page 39

32 Service manual 200569

3. Circuit Board - L100, Z-Motor Driver Cranex Novus

Page 40

Cranex Novus 3. Circuit Boards - L100, Z-Motor Driver

Service manual 200569 33

Page 41

34 Service manual 200569

3. Circuit Board - L100, Z-Motor Driver Cranex Novus

Page 42

Cranex Novus 3. Circuit Boards - L200, CCD Power Supply

Service manual 200569 35

3.2 L200, CCD Power Supply (Pt. no. 200396)

L200 - Location

In the rotating unit on the the CCD sensor side.

To access remove side cover left and the EMC shield

(see section 7.1).

Page 43

36 Service manual 200569

3. Circuit Boards - L200, CCD Power Supply Cranex Novus

L200 - Field replaceable parts

Fuse 1, 2 and 3

NOTE:

The fuses used MUST be the approved type, UL listed

and CSA certifi ed.

Fuse F1, 5AT/250VAC Cooper Bussmann S506-series

Fuse F2, 2AT/250VAC Cooper Bussmann S506-series

Fuse F3, 1AT/250VAC Cooper Bussmann S506-series

Dimensions, 5mm x 20mm.

L200 - Description

L200 supplies different voltages to most of the circuit

boards in the unit. L200 receives three transformed AC

voltages (18VAC, 9VAC, and 8VAC) from the Generator

board, and rectifi es and regulates them to produce the

various voltages that the unit requires.

The CCD sensor require +3.3V, +3.3V, +3V, +15V, -9V,

+5V.

The fan (it cools L200) and the 3-phase stepper motor

require 24V.

L400 and pheripheral electronics require two regulated

5VDC power supplies.

Page 44

Cranex Novus 3. Circuit Boards - L200, CCD Power Supply

Service manual 200569 37

L200 - Block diagram

Page 45

38 Service manual 200569

3. Circuit Boards - L200, CCD Power Supply Cranex Novus

L200 - Indicator LEDs

LED Colour Indicates

D1 green +5.0VD1 on

D2 green +5.0VD2 on

D3 green +3.3VD_CCD on

D14 green +15V on

D15 green +3.0V_CCD on

D16 green +5.0V_CCD on

D23 green +3.3V_CCD on

D33 green +15V_CCD on

L200 - Test Points

Number Description Value

TP1 GND (logic) 0V

TP2 +24V +24V

TP5 +5.0VD1

TP6 GND (logic) 0V

TP7 +3.0V_CCD

TP8 +5.0V_CCD

TP9 +3.3V_CCD

TP10 +8V_RAW

TP11 +5.0VD2

TP12 +15V

TP13 FAN VOLTAGE >20V

TP14 +3.3V_CCD

TP16 CCDENA 5V on, 0V off

TP17 -9.4V_CCD

TP18 U_IN Between 2.2V and 2.8V

L200 - Connectors

J201

Pin Signal Description

1 +5.0VD1 Supply voltage (L400 CPU)

2 GND GND (logic)

Page 46

Cranex Novus 3. Circuit Boards - L200, CCD Power Supply

Service manual 200569 39

J202

Pin Signal Description

1-4,15,16 GND GND (logic)

5,6 +3.3V_CCD Continuous supply voltage (CCD)

7,8 +15V_CCD Supply voltage (CCD)

9,10 +3.0V_CCD Supply voltage (CCD)

11,12 -9V_CCD Supply voltage (CCD)

13,14 +5.0V_CCD Supply voltage (CCD)

J204

Pin Signal Description

1 +5.0VD2 Supply voltage (logic)

2,4 GND GND (logic)

3 +3.3V_CCD Continuous supply voltage (CCD)

5 REGTEMP Regulator temperature

6 CCDENA CCD sensor supply voltage, +5V when active

7 U_IN Line voltage peak level detection

8 FANPWM Temperature controlled fan

J205

Pin Signal Description

1,4 18 VAC Transformer secondary voltage

2,5 9 VAC Transformer secondary voltage

3,6 8 VAC Transformer secondary voltage

J206

Pin Signal Description

1,2 +24V_STEP Supply voltage (stepper motors)

3,4 GND GND (logic)

J207

Not used

J208

Pin Signal Description

1 FAN Supply voltage (temperature controlled fan)

2 GND GND (logic)

Page 47

40 Service manual 200569

3. Circuit Boards - L200, CCD Power Supply Cranex Novus

Page 48

Cranex Novus 3. Circuit Boards - L200, CCD Power Supply

Service manual 200569 41

Page 49

42 Service manual 200569

3. Circuit Boards - L200, CCD Power Supply Cranex Novus

Page 50

Cranex Novus 3. Circuit Boards - L200, CCD Power Supply

Service manual 200569 43

Page 51

44 Service manual 200569

3. Circuit Boards - L300, 3-Phase Microstepper Driver Cranex Novus

3.3 L300, 3-Phase Microstepper Driver (Pt. no. 200397)

L300 - Location

Inside the rotating unit, above the head support. To access, remove the head support, lower protective cover

and then the left aperture cover (see section 7.1).

L300 - Field replaceable parts

None.

Page 52

Cranex Novus 3. Circuit Boards - L300, 3-Phase Microstepper Driver

Service manual 200569 45

L300 - Description

L300 controls the 3-phase stepper motor that drives the

Rotating Unit. The board receives in three control signals: clock, dir, and ena. It produces phase voltages for

the stepper motor windings.

L300 - Indicator LEDs

LED Colour Indicates

D1 green +5V on

D2 green +24V on

L300 - Test Points

Number Description Value

TP1 GND 0V

TP2 VREF 0.97V ±0.1V; when HICUR* = '1'

1.95V ±0.1V; when HICUR* = '0' (default value)

TP3 CLK +5V freq <15kHz

TP4 ENA +5V active, 0V idle

TP5 DIR +5V when idle or when moving to the PIO position.

0V when driving to end position.

TP6 PGND 0V

L300 - Connectors

J301

Pin Signal Description

1,3 +24V Power supply

2,4 PGND Power GND

7,9,11,13,15 GND GND (logic)

8 HICUR* High current selection

10 CLK* Stepper motor clock

12 DIR* Stepper motor direction

14 ENA* Stepper motor enabled

16 +5V Power supply (logic)

J302

Pin Signal Description

1 Phase #1 Stepper motor driver's phase voltages

2 Phase #2 Stepper motor driver's phase voltages

3 Phase #3 Stepper motor driver's phase voltages

Page 53

46 Service manual 200569

3. Circuit Boards - L300, 3-Phase Microstepper Driver Cranex Novus

Page 54

Cranex Novus 3. Circuit Boards - L300, 3-Phase Microstepper Driver

Service manual 200569 47

Page 55

48 Service manual 200569

3. Circuit Boards - L400, CPU Board Cranex Novus

3.4 L400 CPU Board (Pt. no. 200398)

L400 - Location

In rotating unit on the the CCD sensor side. To access

remove side cover left and the EMC shield (see section

7.1).

L400 - Field replaceable parts

None.

Page 56

Cranex Novus 3. Circuit Boards - L400, CPU Board

Service manual 200569 49

L400 - Description

The CPU board controls the unit. It controls the rotation and Z movements, the operation of the X-ray tube

and reads the signals from the control panel. It uses an

embedded microcontroller on an Altera Cyclone FPGA

circuit. The board also has an Ethernet transceiver (for

PC connection), I/O buffers, and a 14-bit A/D converter.

The image bits are saved in an SDRAM.

L400 - Indicator LEDs

LED Colour Indicates

D1 green 100-Base-T (100MBit/s) in use

D2 green Ethernet signal activity

D3 green Full Duplex mode in use

D4 green 10-Base-T (10Mbit/s) in use

D6 green +5V on

L400 - Connectors

J203_CPU

Pin Signal Description

1 +5V_CPU Power supply CPU

2,4,6 GND GND (logic)

3 VV Valid video

5 DS Data strobe

7 D0 Data bit 0

8 D1 Data bit 1

9 D2 Data bit 2

10 D3 Data bit 3

11 D4 Data bit 4

12 D5 Data bit 5

13 REGTEMP Temperature of the regulators on L200 board.

14,16,18,20 GND GND (logic)

15 MOSI SPI signal

17 SCLK SPI clock

19 CS* Chip select

21 BEEP Beeper enable

22 mA_ref Current reference

23 kV_ref Voltage reference

24 PREH* Preheat

25 EXPON Exposure on (CPU enabled)

26,34,36,38 GND GND (logic)

27 IMAGE Enables A/D conversion on CCD Sensor Board

28 A/D_2 NOT USED

29 TDI CLK Time Delay Integration Clock (CCD)

30 TXD Transmit data (serial connection)

Page 57

50 Service manual 200569

3. Circuit Boards - L400, CPU Board Cranex Novus

31 CCDENA Enables the supply voltages for the CCD sensor

32 PPOWER CCD sensor's supply voltages are on

33 CLK Stepper motor clock

35 DIR Stepper motor direction

37 ENA Stepper motor enabled

39 +5V_CPU CPU Power supply CPU

40 GND GND (logic)

J204_CPU

Pin Signal Description

1 TP0+ Ethernet, twisted pair 0

2 TP0- Ethernet, twisted pair 0

3 TP1+ Ethernet, twisted pair 1

4 TP1- Ethernet, twisted pair 1

J205_CPU

Pin Signal Description

1 +5V Power supply (logic)

2 GND GND (l ogic)

J3_CPU

Pin Signal Description

1 - NOT USED

2 TUBEHEAT The X-ray tube's temperature (analog signal)

3 - NOT USED

4 A/D_1 NOT USED

5 - NOT USED

6 LINEOK Line voltage

7 - NOT USED

8 mAfb mA feedback

9 - NOT USED

10 kVfb kV feedback

11 - NOT USED

12-19 GNDA A/D converter's ground

20-24 +5VA A/D converter's supply voltage

25 - NOT USED

26 ZENA* Z-motor movement enabled

27 RESET_CCD* Resets CCD sensor

28 PL_ENA Position lights enabled

29 HICUR* High current selection

30 FAN_PWM Temperature controlled fan

Page 58

Cranex Novus 3. Circuit Boards - L400, CPU Board

Service manual 200569 51

31 OUT1 NOT USED

32 OUT2 NOT USED

33 OUT3 NOT USED

34 ROTSW1 Rotation position switch signal

35 ROTSW2 Rotation position switch signal

36 RXD Receive data (serial connection) from CCD

37 MISO SPI signal

38 - NOT USED

39 - NOT USED

40 - NOT USED

41 ZACT* Up/down key on side control panel

pressed

42 MIRRORSW Mirror switch

43 TUBEFAIL* X-ray tube failure

44 - NOT USED

45 - NOT USED

46 PLSW Position light switch

47 HL High/low bit

48 EXPSW* Exposure switch

49 +3V3 Power supply

50 GND GND (logic)

Page 59

52 Service manual 200569

3. Circuit Boards - L400, CPU Board Cranex Novus

Page 60

Cranex Novus 3. Circuit Boards - L400, CPU Board

Service manual 200569 53

Page 61

54 Service manual 200569

3. Circuit Boards - L400, CPU Board Cranex Novus

Page 62

Cranex Novus 3. Circuit Boards - L400, CPU Board

Service manual 200569 55

Page 63

56 Service manual 200569

3. Circuit Boards - L400, CPU Board Cranex Novus

Page 64

Cranex Novus 3. Circuit Boards - L400, CPU Board

Service manual 200569 57

Page 65

58 Service manual 200569

3. Circuit Boards - L400, CPU Board Cranex Novus

Page 66

Cranex Novus 3. Circuit Boards - L400, CPU Board

Service manual 200569 59

Page 67

60 Service manual 200569

3. Circuit Boards - L400, CPU Board Cranex Novus

Page 68

Cranex Novus 3. Circuit Boards - L400, CPU Board

Service manual 200569 61

Page 69

62 Service manual 200569

3. Circuit Boards - L400, CPU Board Cranex Novus

Page 70

Cranex Novus 3. Circuit Boards - L500, Connector Board

Service manual 200569 63

3.5 L500 Connector Board (Pt. no. 200399)

L500 - Location

In rotating unit on the the CCD sensor side. To access

remove side cover left and the EMC shield (see section

7.1).

L500 - Field replaceable parts

None.

Page 71

64 Service manual 200569

3. Circuit Boards - L500, Connector Board Cranex Novus

L500 - Description

L500 routes most of the signals to the other boards.

L500 receives signals from the tubehead (kVfb, mafb,

and tubeheat) and scales the voltage swing (0…+5V)

linearly to (1.25V…3.75 V) which is the input for the

A/D converter on the CPU board. L500 also includes

external warning and ready light circuitry. The ESTOP

signal enables stepper motor rotation and the exposure

sequence.

L500 - Block Diagram

L500 - Test Points

Number Description Value

TP1 GND 0V

TP2 GND 0V

Page 72

Cranex Novus 3. Circuit Boards - L500, Connector Board

Service manual 200569 65

L500 - Connectors

J501

Pin Signal Description

1, 2 TUBEFAIL* X-ray tube failure

3, 4 EXPENA* Exposure enabled

5, 6 KVPWM kV-reference

7, 8 GND Ground

9, 10 KVFB kV-feedback

11, 12 GND Ground

13, 14 PREH_2* Preheat

15, 16 MAPWM mA-reference

17, 18 MAFB mA-feedback

19, 20 TUBEHEAT X-ray tube's temperature

J502

Pin Signal Description

1 HICUR* High current selection

2 GND GND (logic)

3 CLK* Stepper motor clock

4 GND GND (logic)

5 DIR* Stepper motor direction

6 ENA* Stepper motor enabled

7 +5.0VD2 Supply voltage

8 GND GND (logic)

J503

Pin Signal Description

1 +5.0VD2 Supply voltage

2 +5.0VD2 Supply voltage

3 ESTOP* Emergency stop

4 PL_ENA Position lights enabled

5 ZENA* Z-motor movement enabled

6 - NOT USED

7 RETURN2* Return membrane switch (side control panel)

8 MIRRORSW Mirror switch

9 ZACT* Z-movement activity

10 PLSW Position light switch

11 EXPSW* Exposure switch

12 GND GND (logic)

13 RDYLT Ready light

14 EXPLT Exposure light

15 GND GND (logic)

16 GND GND (logic)

Page 73

66 Service manual 200569

3. Circuit Boards - L500, Connector Board Cranex Novus

J504

Pin Signal Description

1 +5.0VD2 Supply voltage

2 ROTSW1 Rotation position optoswitch #1

3 ROTSW2 Rotation position optoswitch #2

4 GND GND (logic)

J505

CAUTION:

When reconnecting this connector make sure that it is aligned correctly before switch the unit on. If the connector is misaligned the fuses on L200 may

blow when the unit is switched on.

Pin Signal Description

Pin Signal Description

1 GND GND (logic)

2 GND GND (logic)

3 D0 Data bit 0

4 D1 Data bit 1

5 D2 Data bit 2

6 D3 Data bit 3

7 D4 Data bit 4

8 D5 Data bit 5

9 - NOT USED

10 - NOT USED

11 HL HIGH/LOW bit

12 VV Valid video

13 - NOT USED

14 IMAGE_OUT Activates A/D conversion on CCD sensor board

15 TDICLK_OUT Time Delay Integration

16 PPOWER_OUT CCD sensor's supply voltages on CCD

17 - NOT USED

18,20,21,23 GND GND (logic)

19 DS Data strobe

20 GND GND (logic)

21 GND GND (logic)

22 - NOT USED

23 GND GND (logic)

24 TXD_OUT Transmit data (serial connection)

25 RXD Receive data (serial connection)

26 RESET_CCD* Resets the CCD sensor

27 - NOT USED

28 - NOT USED

29 - NOT USED

30 - NOT USED

Page 74

Cranex Novus 3. Circuit Boards - L500, Connector Board

Service manual 200569 67

31 PAN_CAM_DET Panorama sensor mode, value +5.0VD2

32 PAN_CAM_DET Panorama sensor mode, value +5.0VD2

33 - NOT USED

34 - NOT USED

35 +3.3VD_CCD Supply voltage (CCD sensor's uC-voltage)

36 +3.3VD_CCD Supply voltage (CCD sensor's uC-voltage)

37 GND GND (logic)

38 GND GND (logic)

39 GND GND (logic)

40 GND GND (logic)

J506

Pin Signal Description

1 +5.0VD2 Supply voltage

2 GND GND (logic)

3 +3.3VD_CCD Supply voltage (CCD sensor's continuous voltage)

4 GND GND (logic)

5 REGTEMP Regulator temperature

6 CCDENA CCD enabled

7 LINEOK Line voltage

8 FANPWM Fan's PWM control

J507

Pin Signal Description

1 CS* Chip select

2 GND GND (logic)

3 SCLK SPI clock

4 GND GND (logic)

5 MOSI (Data out)

6 GND GND (logic)

7 MISO (Data in)

8 GND GND (logic)

9 BEEP Beeper control

10 +5.0VD2 Supply voltage

11 READYLT Ready light

12 GND GND (logic)

13 DIG4 Control voltage for external warning/exposure

lights

14 GND GND (logic)

15 +5.0VD2 Supply voltage

16 RETURN2* Return membrane switch on side control panel

Page 75

68 Service manual 200569

3. Circuit Boards - L500, Connector Board Cranex Novus

J508

Pin Signal Description

1 - NOT USED

2 TUBEHEAT_OUT Tube head temperature

3 - NOT USED

4 - NOT USED

5 - NOT USED

6 LINEOK Line voltage level

7 - NOT USED

8 MAFB_OUT mA feedback

9 - NOT USED

10 KVFB_OUT kV feedback

11 - NOT USED

12 GND (logic) Ground

13 GND (logic) Ground

14 GND (logic) Ground

15 GND (logic) Ground

16 GND (logic) Ground

17 GND (logic) Ground

18 GND (logic) Ground

19 GND (logic) Ground

20 +5V_AD A/D converter's supply voltage

21 +5V_AD A/D converter's supply voltage

22 +5V_AD A/D converter's supply voltage

23 +5V_AD A/D converter's supply voltage

24 +5V_AD A/D converter's supply voltage

25 - NOT USED

26 ZENA* Z-motor movement enabled

27 RESET_CCD* CCD sensor's reset

28 PL_ENA Position lights enabled

29 HICUR* High current selection

30 FANPWM Fan control

31 - NOT USED

32 - NOT USED

33 - NOT USED

34 ROTSW1 Rotation switch 1

35 ROTSW2 Rotation switch 2

36 RXD Receive data (serial connection)

37 MISO SPI signal

41 ZACT* Z-movement activity

42 MIRRORSW Mirror switch

43 TUBEFAIL* X-ray tube failure

44 PLSW Position light switch

45 HL High/Low bit

46 PLSW Position light switch

47 HL High/Low bit

48 EXPSW* Exposure switch

49 - NOT USED

50 GND GND (logic)

Page 76

Cranex Novus 3. Circuit Boards - L500, Connector Board

Service manual 200569 69

J509

Pin Signal Description

1 +5V_AD AD converter's supply voltage

2 GND GND (logic)

3 VV Valid video

4 GND GND (logic)

5 DS Data strobe

6 GND GND (logic)

7 D0 Data bit 0

8 D1 Data bit 1

9 D2 Data bit 2

10 D3 Data bit 3

11 D4 Data bit 4

12 D5 Data bit 5

13 - NOT USED

14 GND GND (logic)

15 MOSI SPI signal

16 GND GND (logic)

17 SCLK SPI clock

18 GND GND (logic)

19 CS* Chip select

20 GND GND (logic)

21 BEEP Beeper control

22 MA_REF Reference current

23 KV_REF Reference voltage

24 PREH* Preheat

25 EXPON* Exposure on

26 GND GND (logic)

27 IMAGE Activates A/D conversion on CCD sensor

28 REGTEMP Regulator temperature

29 TDICLK Time Delay Integration clock

30 TXD Transmit data (serial connection)

31 CCDENA Activates CCD the supply voltages

32 PPOWER CCD sensor's supply voltages

33 CLK_1* Stepper motor clock

34 GND GND (logic)

35 DIR* Stepper motor direction

36 GND GND (logic)

37 ENA_1* Stepper motor enable

38 GND GND (logic)

39 +5V_AD AD converter's supply voltage

40 GND GND (logic)

Page 77

70 Service manual 200569

3. Circuit Boards - L500, Connector Board Cranex Novus

Page 78

Cranex Novus 3. Circuit Boards - L500, Connector Board

Service manual 200569 71

Page 79

72 Service manual 200569

3. Circuit Boards - L500, Connector Board Cranex Novus

Page 80

Cranex Novus 3. Circuit Boards - L600, Control Panel

Service manual 200569 73

3.6 L600 Control Panel (Pt. no. 200400)

L600 - Location

In rotating unit on the the CCD sensor side. To access

remove left side cover (see section 7.1).

L600 - Field replaceable parts

None.

Page 81

74 Service manual 200569

3. Circuit Boards - L600, Control Panel Cranex Novus

L600 - Description

L600 monitors the state of the membrane switches,

converts the signals from parallel to serial and sends

them to the CPU board via the SPI (Serial Pheripheral

Interface). An 8-bit LED display driver controls three

3.4mm x 2.4mm seven segment displays and several

indicator LEDs.

L600 - Indicator LEDs

LED Colour Indicates

D2 red/green PC LED.

Green = connection

Red = No connection

Orange = Data transfer

D3 red/green PC LED (As above)

D4 red/green PC LED (As above)

D5 red/green PC LED (As above)

D6 green Tube voltage 60kV

D7 green Tube voltage 70kV

D8 green TMJ imaging

D9 green Patient size child

D10 green Patient size adult

D11 green Drive rotating unit to the PIO position

D12 green Test program without x-rays

L600 - Test Points

Number Description Value

TP1 GND 0V

L600 - Connectors

J601

Pin Signal Description

1 CS* Chip select

2 GND GND

3 SCLK SPI clock

4 GND GND

5 MOSI SPI signal

6 GND GND

7 MISO SPI signal

8 GND GND

9 BEEP* Beeper control

10 +5V Power supply

Page 82

Cranex Novus 3. Circuit Boards - L600, Control Panel

Service manual 200569 75

11 Readylight

12 GND GND

13 DIG4 Cathode voltage of the LEDs

14 GND GND

15 +5V Power supply

16 RETURN2* Return membrane switch (side control panel)

J602

Pin Signal Description

1 TEST* Test key pressed

2 RETURN1* Return key pressed

3 kV* Voltage selection key pressed

4 PATIENT SIZE* Patient size key pressed

5 TMJ* TMJ imaging key pressed

6 GND GND

Page 83

76 Service manual 200569

3. Circuit Boards - L600, Control Panel Cranex Novus

Page 84

Cranex Novus 3. Circuit Boards - L600, Control Panel

Service manual 200569 77

Page 85

78 Service manual 200569

3. Circuit Boards - L600, Control Panel Cranex Novus

Page 86

Cranex Novus 3. Circuit Boards - L700, Interface Board

Service manual 200569 79

3.7 L700 Interface Board (Pt. no. 200401)

L700 - Location

At the rear of the column near the base. To access remove the cover from the front of the column.

L700 - Field replaceable parts

None.

Page 87

80 Service manual 200569

3. Circuit Boards - L700, Interface Board Cranex Novus

L700 - Description

L700 serves as an external interface to the outside environment. The Ethernet cable that goes to the PC and

the exposure button cable are connected to this board.

L700 - Connectors

J701

Pin Signal Description

1 EXPSW* Exposure switch

2 READYLT Ready light

3 EXPLT Exposure light

4 GND GND

5 - NOT USED

6 GND GND

J702

Pin Signal Description

1 EXPSW* Exposure switch

2 EXPSW_LOCK* Exposure switch

J703

Pin Signal Description

1 EXPSW_LOCK* Exposure switch

2 READYLT Ready light

3 EXPLT Exposure light

4 GND GND

5 - NOT USED

6 GND GND

J704

Pin Signal Description

1 EXPSW_LOCK* Exposure switch

2 READYLT Ready light

3 EXPLT Exposure light

4 GND GND

5 - NOT USED

6 GND GND

Page 88

Cranex Novus 3. Circuit Boards - L700, Interface Board

Service manual 200569 81

J705

Pin Signal Description

1 TP0+ Ethernet, twisted pair 0

2 TP0- Ethernet, twisted pair 0

3 TP1+ Ethernet, twisted pair 1

4 - NOT USED

5 - NOT USED

6 TP1- Ethernet, twisted pair 1

7 - NOT USED

8 - NOT USED

J706

Pin Signal Description

1 TP0+ Ethernet, twisted pair 0

2 TP0- Ethernet, twisted pair 0

3 TP1+ Ethernet, twisted pair 1

4 - NOT USED

5 - NOT USED

6 TP1- Ethernet, twisted pair 1

7 - NOT USED

8 - NOT USED

Page 89

82 Service manual 200569

3. Circuit Boards - L700, Interface Board Cranex Novus

Page 90

Cranex Novus 3. Circuit Boards - L700, Interface Board

Service manual 200569 83

Page 91

84 Service manual 200569

3. Circuit Boards - N2500, Rot. pos. sen. Board Cranex Novus

3.8 N2500 Rotation Position Sensor Board (Pt. no. 4801143)

N2500 - Location

Inside the rotating unit under the head support. To

access, remove the head support and then the lower

protective cover (see section 7.1).

N2500 - Field replaceable parts

None.

Page 92

Cranex Novus 3. Circuit Boards - N2500, Rot. pos. sen. Board

Service manual 200569 85

N2500 - Description

N2500 is used to detect the position of the rotating unit.

N2500 has two optical switches that generate sensor

signals ROTSW1 and ROTSW2 according to which

position is activated.

N2500 includes a transmitter LED, and a receiver, or

base. The sensor signals remain on as long as the base

receives light from the LED. When the light to the base

is cut off by the positioning rail, the sensor signal is

switched off.

N2500 - Connectors

J2501

Pin Signal Description

1 +5V Supply voltage

2 ROTSW1 Sensor signal 1

3 ROTSW2 Sensor signal 2

4 GND Ground

Page 93