Page 1

SEE MORE AT

Request Quote

Adjustable Dead Band Pressure Switches

The adjustable dead band

pressure switch should be used when there is a

requirement for an adjustable and wide dead band

between the increasing and decreasing set points.

Function

Alarm: Hi — Lo

Control: On — Off

SORInc.com

V3 Weathertight

Explosion Proof

Hermetically Sealed Switches

• 3-year warranty from date of manufacture

•

Safety Certified to IEC 61508 (SIL) SOR products are certified to IEC 61508 for non-redundant

use in SIL1 and SIL2 Safety Instrumented Systems for most models. For more details or values

applicable to a specific product, see the Safety Integrity Level Quick Guide (Form 1528).

• Wide adjustable dead band

• Independent adjustments for increasing and decreasing Set Points

• Field adjustable with fine resolution of Set Points

• Instrument quality — high repeatability

• High overrange and proof pressures

V1 Weathertight Housing

Design and specifications are

subject to change without notice.

For latest revision, see www.sorinc.com.

• Exceptionally long life

Features and Benefits

• Not critical to vibration

• Wide selection of wetted parts materials for process compatibility and containment

Form 281 (05.18) ©SOR Inc.

SORInc.com | 913-888-2630 | Registered Quality System to ISO 9001

1/16

Page 2

Adjustable Dead Band

Pressure Switches

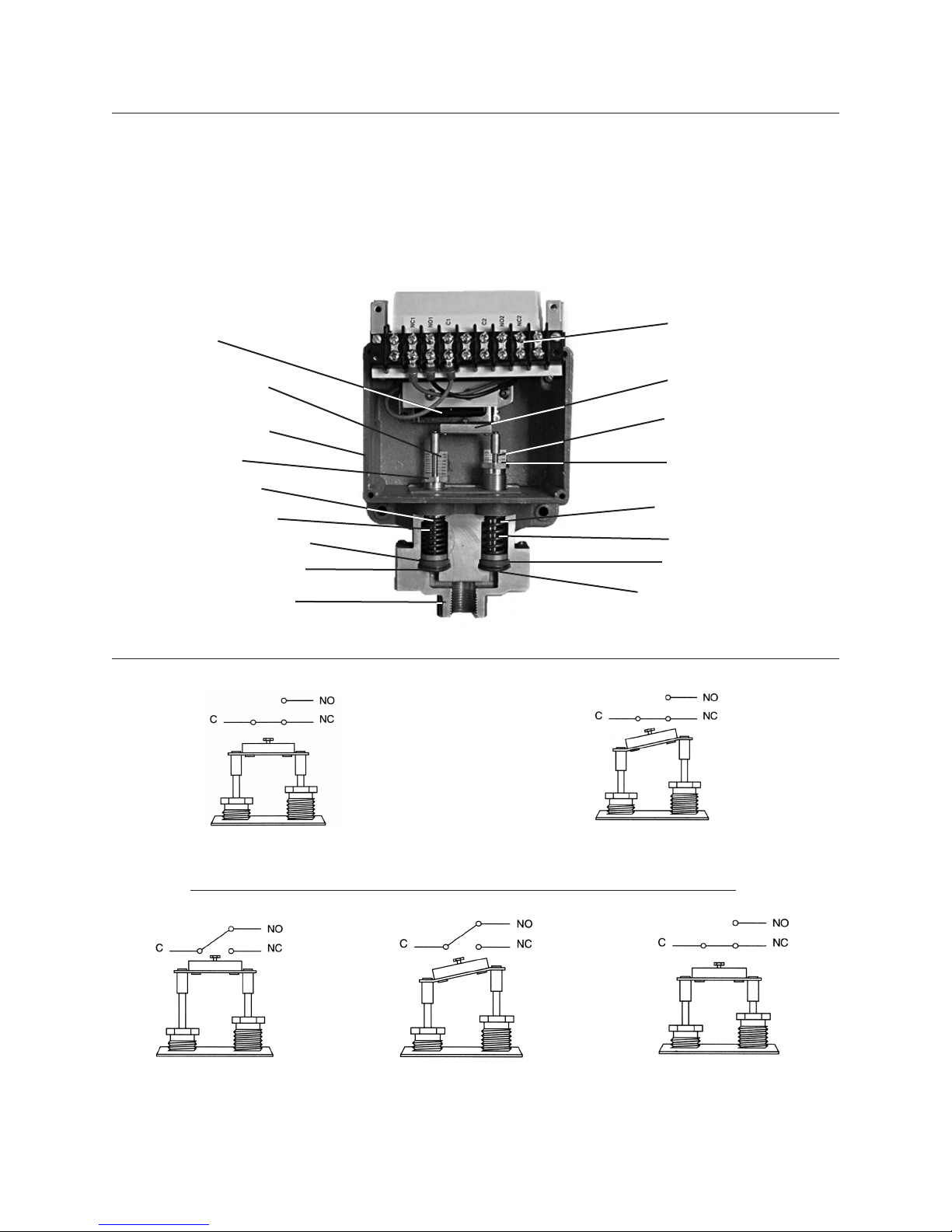

Principle

The SOR Adjustable Dead Band pressure switch incorporates two industry proven Static “O” Ring pressure sensing

elements. Media pressure on the areas of the pistons counteracts the forces of the range springs — each

adjustable by a separate adjusting nut — and moves the piston shafts to operate the lever assembly which, in

turn, actuates and deactuates the electrical switching element. Each pressure sensing element of the Adjustable

Dead Band pressure switch is a force balance piston-actuated assembly sealed by a flexible diaphragm and

an o-ring that is static. The only wetted parts are the single pressure port, two diaphragms, and two o-rings all

indicated with asterisks (*) in this illustration.

Electrical Switching

Element (Explosion Proof

Model has Hermetically

Sealed Switching Element

Capsule)

Calibration Scale

Housing

Increasing Set Point

Adjusting Nut

Piston Assembly

Pressure Range Spring

*Diaphragm

*O-Ring

*Pressure Port

Screw Terminal Block

(Weathertight Model Only)

Lever Assembly

Calibration Scale

Decreasing Set Point

Adjusting Nut

Piston Assembly

Pressure Range Spring

*Diaphragm

*O-Ring

Principle Schematic

The lever assembly travel illustrated here has been exaggerated for clarity.

No Pressure: Electrical switching element is

deactuated.

Actuation Deactuation

Pressure equal to or greater than

increasing Set Point: Electrical

switching element is actuated.

Pressure less than increasing Set

Point but greater than decreasing

Set Point: Electrical switching

element remains actuated.

Pressure greater than decreasing Set Point but

less than increasing Set Point. Electrical switching

element remains deactuacted.

Pressure equal to or less than

decreasing Set Point: Electrical

switching element is deactuated.

2/16

Registered Quality System to ISO 9001 | 913-888-2630 | SORInc.com

Form 281 (05.18) ©SOR Inc.

Page 3

Adjustable Dead Band

Pressure Switches

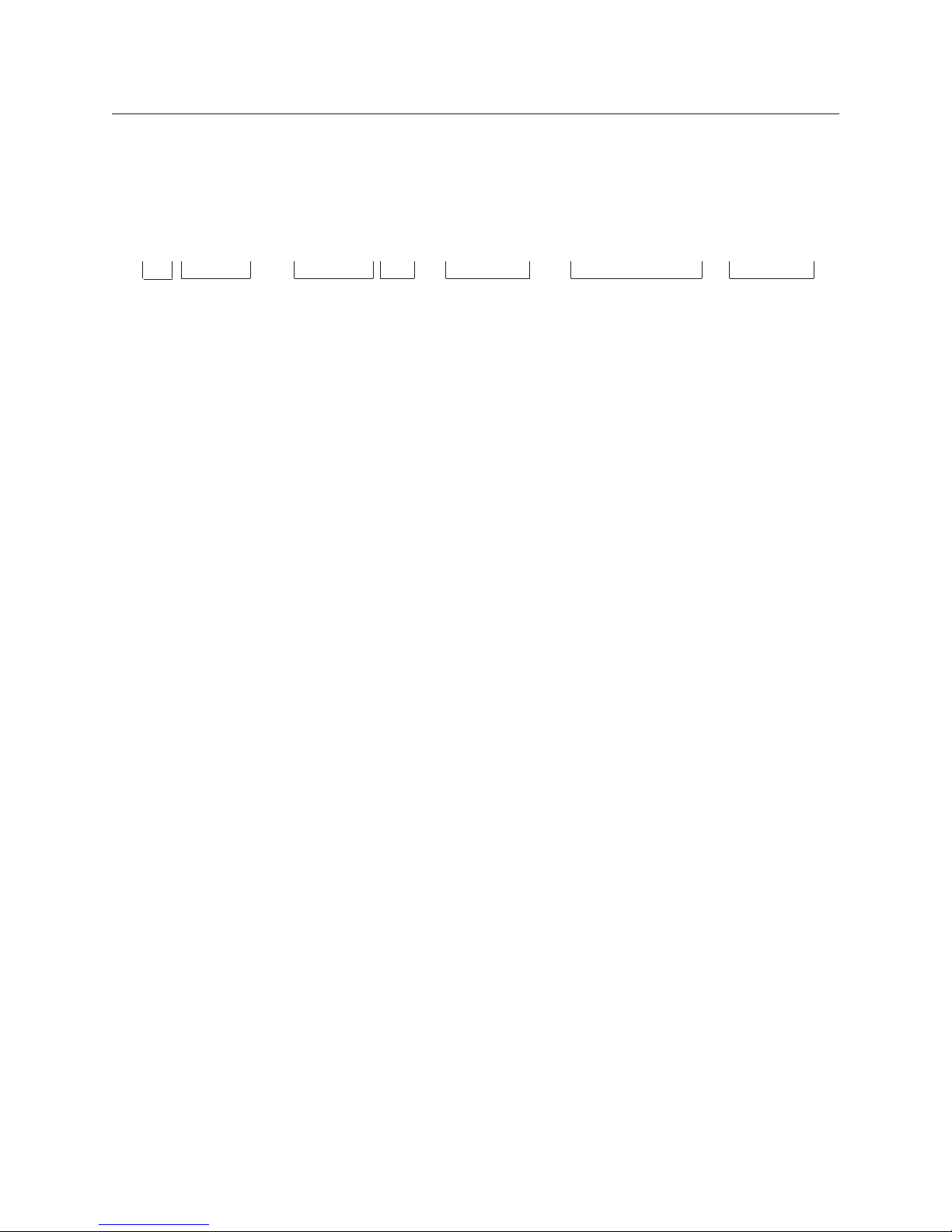

How to Order

Model Number System

5V1-LA3-N6-C1A-YY

Housing DiaphragmSwitching

Element

How to Order

Information and data in this catalog are formatted to provide a convenient guide to assist

instrument engineers, plant engineers and end users in selecting pressure switches for their

unique applications.

Steps 1 through 5 are required. Step 6 is optional. Orders must have complete model numbers,

i.e. each component must have a designator.

Step 1: Select Adjustable Range from pages 4, 5 and 6 to fill in and .

Pressure Port Accessories

Step 2: Select Housing. Weathertight or explosion proof/weathertight (page 6).

Step 3: Select electrical Switching Element for electrical service (page 7).

Step 4: Select Diaphragm and O-Ring for process compatibility and containment (page 8).

Step 5: Select Pressure Port for process compatibility and connection (page 9).

Step 6: Select Accessories required for service (page 9).

If Agency Approved, Certified or Listed pressure switches are required, see page 10 for

components that must be specified.

Form 281 (05.18) ©SOR Inc.

SORInc.com | 913-888-2630 | Registered Quality System to ISO 9001

3/16

Page 4

Adjustable Dead Band

Pressure Switches

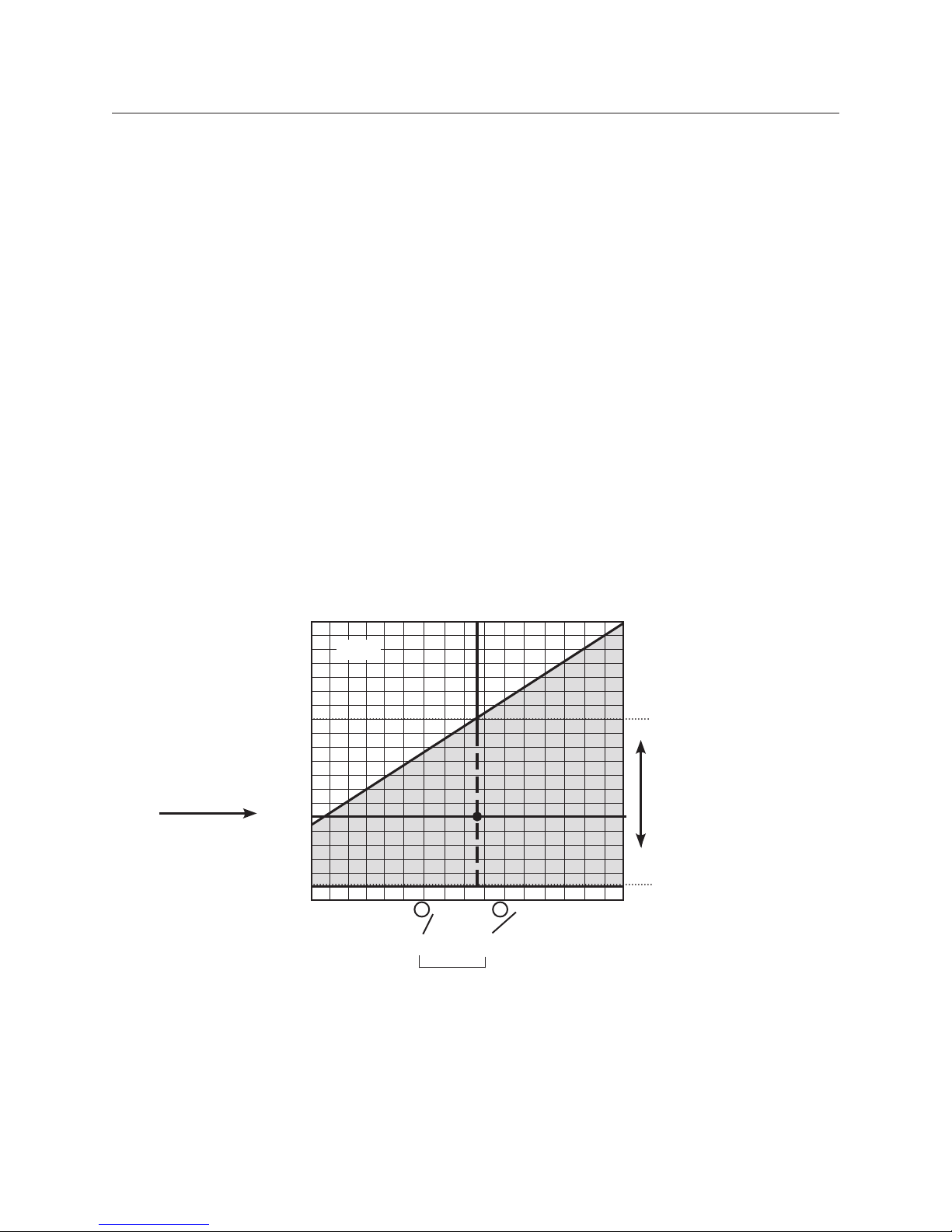

Step 1: Adjustable Range

5V1-LA3-N6-C1A-YY

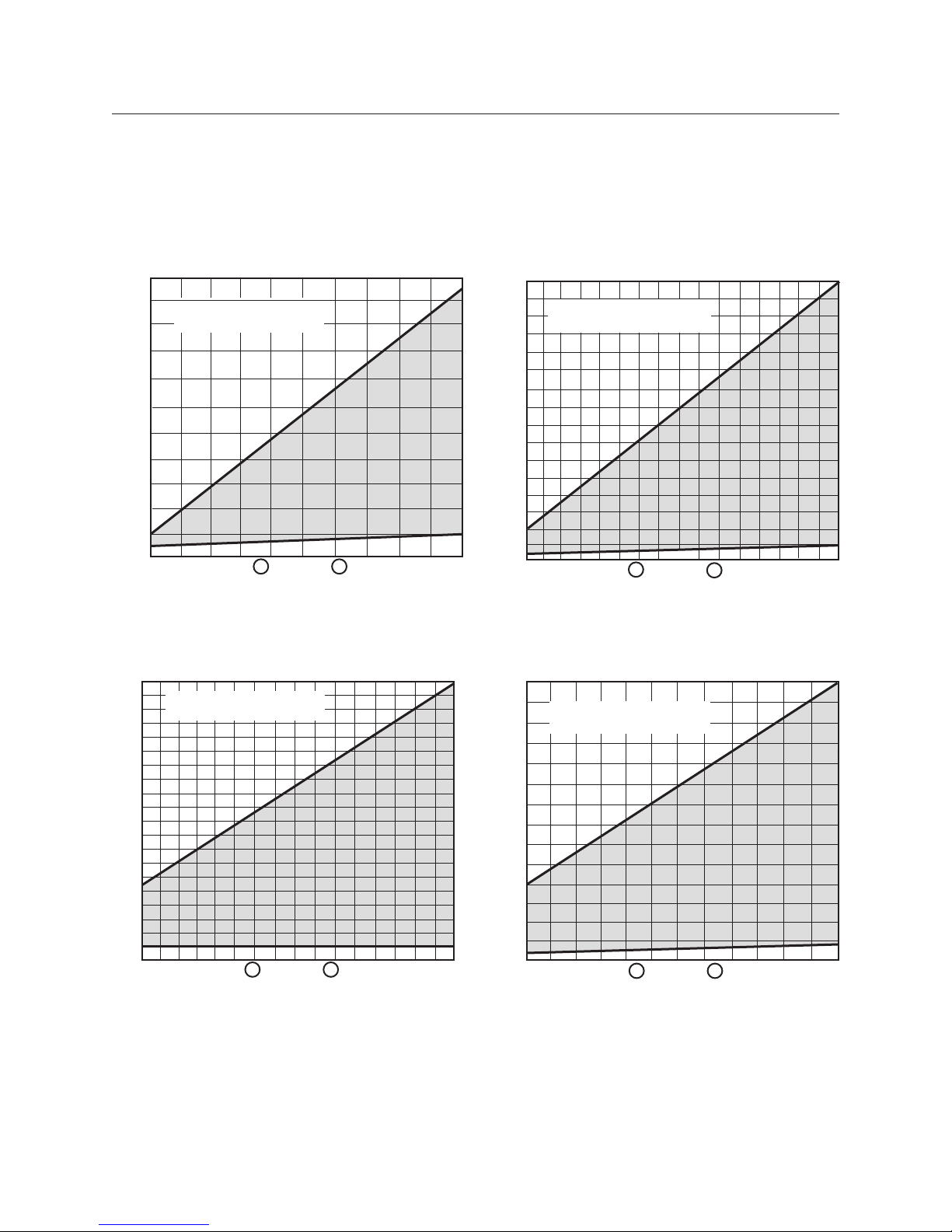

Six adjustable dead band ranges are available. Each adjustable range is displayed on a grid

(pages 5 and 6). Determine the correct adjustable range for the application by checking

increasing and decreasing Set Point requirements against the tables. In the example below,

a contact closure is required when pressure increases to 160 psi. The same contact must

open when pressure decreases to 60 psi. Since 60 psi is within the blue field, the example

grid range is correct for the application.

When the correct range grid is selected, insert range designators and from that grid into the

model number.

Step 1

Find the specified increasing Set Point at the top of the graph.

Step 2

Find the specified

decreasing Set

Point along the left

edge of the graph.

80

200

160

120

80

40

Decreasing Set Point (psi)

20

0

Increasing Set Point (psi)

100 120 160 200

5 - 3

1

5 3

2

5V1-LA3-N6-C1A-YY

1st and 4th places in model number

240

Step 3

Following the vertical line

down from the increasing

Set Point.

Follow the horizontal line

across from the

decreasing Set Point.

Any point within the blue

field is acceptable.

4/16

Registered Quality System to ISO 9001 | 913-888-2630 | SORInc.com

Form 281 (05.18) ©SOR Inc.

Page 5

Adjustable Dead Band

Pressure Switches

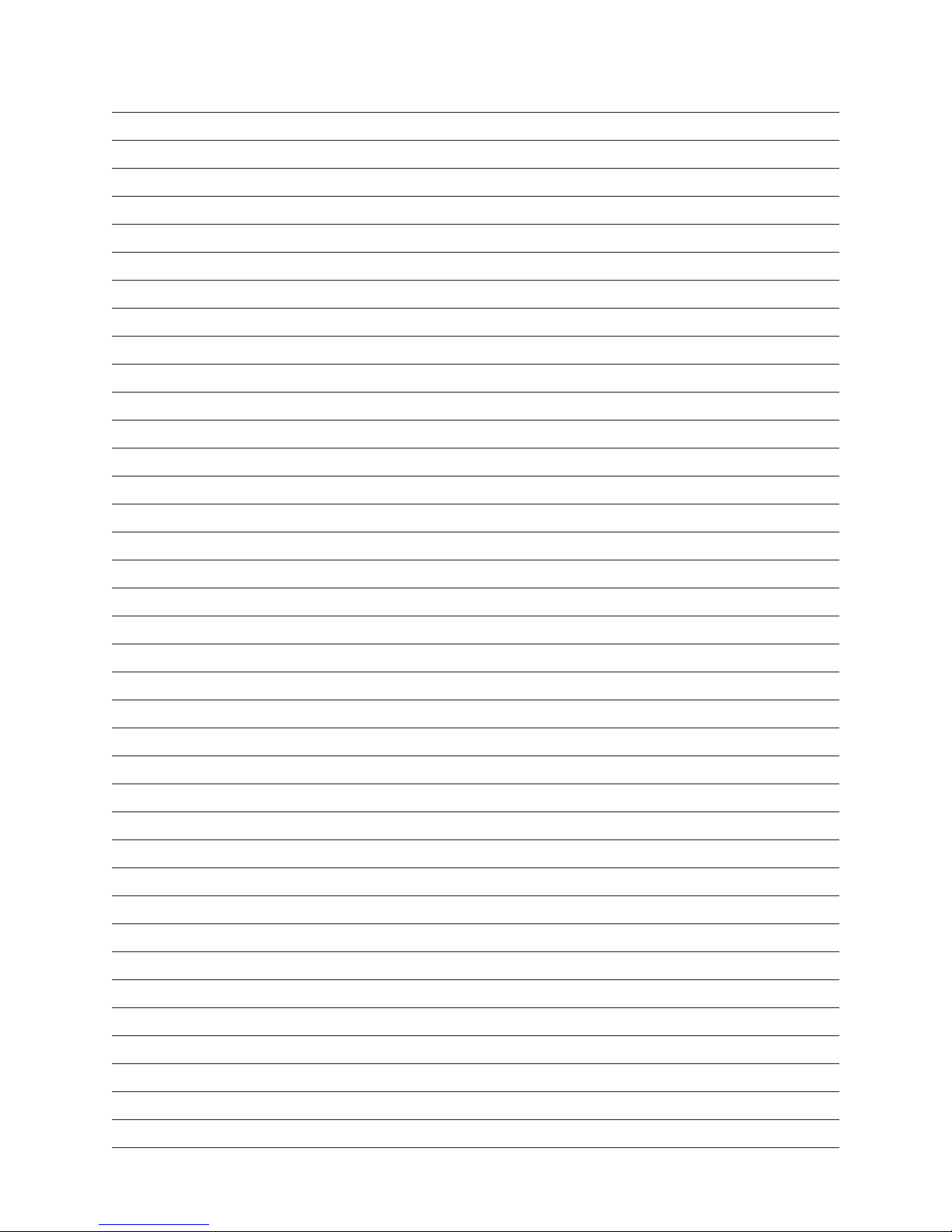

Increasing Set Point (psi)

5

22

18

14

10

80

6

40

Decreasing Set Point (psi)

2

0

9

Overrange 750 psi 50 bar

Proof 1000 psi 70 bar

13

1 2

4 4

17

21

25

20

80

60

40

20

Decreasing Set Point (psi)

10

0

Step 1: Adjustable Range

5V1-LA3-N6-C1A-YY

Increasing Set Point (psi)

30 40

Overrange 1500 psi 100 bar

Proof 2500 psi 170 bar

60

1

6 3

80

2

100

80

200

160

120

80

40

Decreasing Set Point (psi)

20

0

Increasing Set Point (psi)

100 120 160 200

Overrange 1500 psi 100 bar

5 - 3

Proof 2500 psi 170 bar

1

5 3

2

240

Increasing Set Point (psi)

150 200 250 350

350

Overrange 2500 psi 170 bar

300

200

100

Decreasing Set Point (psi)

Proof 3875 psi 267 bar

50

0

1

9 4

450

2

Form 281 (05.18) ©SOR Inc.

SORInc.com | 913-888-2630 | Registered Quality System to ISO 9001

5/16

Page 6

Adjustable Dead Band

Pressure Switches

Increasing Set Point (psi)

300 400 600 800

800

Overrange 2500 psi 170 bar

Proof 3875 psi 267 bar

600

400

200

Decreasing Set Point (psi)

100

0

1

9

2

5

1000

Step 1: Adjustable Range

5V1-LA3-N6-C1A-YY

Increasing Set Point (psi)

600 900 1200 1500

1500

Overrange 2500 psi 170 bar

Proof 3875 psi 267 bar

1200

900

600

300

Decreasing Set Point (psi)

200

100

0

1

9

1750

2

45

Service Description Designator

Non-Hazardous

Locations

Hazardous

Locations

(UL Listed/CSA Certified,

ATEX and SAA Approved

Snap Switch)

Weathertight for non-hazardous service.

NEMA 4, 4X & IP65

Electrical conduit connection: 3/4” NPT(F)

Material: 356 aluminum

Use LA or SA switching element and terminal

block.

Shipping weight: 4 pounds (2 kgs)

See cutaway view on page 2; dimensions on

page 14.

Explosion proof and weathertight. NEMA 4, 4X &

IP65. Class I, Group A, B, C, D;

Class II, Group E, F, G; Division 1 & 2

Electrical conduit connection: 3/4” NPT(F)

Material: 356 aluminum

Use AG switching element; hermetically sealed SS

capsule

Shipping weight: 5 pounds (2.5 kgs)

Step 2: Housing

5V1-LA3-N6-C1A-YY

V1

V3

6/16

Registered Quality System to ISO 9001 | 913-888-2630 | SORInc.com

Form 281 (05.18) ©SOR Inc.

Page 7

Adjustable Dead Band

Pressure Switches

Switching

Element

Service

Normal

Service AC

Very High

Capacity

DC

Magnetic

Blow-out

AC or DC DPDT

Contact

Form

SPDT

Electrical

Connection

Type

Screw

Terminal

Block

18” 18 AWG

color-coded

wire leads

3/4” NPT(M)

conduit

connection

AC Rating DC Rating Resistive

Volts Amps Volts Amps Volts Amps Deg F

250 15 125 .5 30 10* 180 80 LA N/A

125 10 125

250 11 125 .5* 30 5.0 160 70 N/A AG

Step 3: Switching Elements

5V1-LA3-N6-C1A-YY

Maximum

1.5

Min.

10.0

Max.

Ambient

Temperature

Deg C

- - 180 80 SA N/A

Designator

SPDT DPDT

1. The switching elements shown

above are UL Listed and CSA

Certified. The DC current rating

marked (*) is not UL Listed but has

been verified by testing and/or

experienced.

2. The hermetically sealed switching

element capsule is UL Listed, CSA

Certified and SAA Approved as a

snap switch in accordance with the

following table.

3. Consult the factory for availability of

SAA Approved units.

Agency

UL Listed

Hazardous Location

Conditions

Class I,

Group A, B, C, D;

Class II,

Group E, F, G;

CSA Certified

SAA Note 3

Approved

Division 1 & 2

Ex s Zone 2 IIC T4 IP65

Ex tD A22 T105 °C IP65

ATEX Approved II 2 G EEx m II

Designator

AG

Form 281 (05.18) ©SOR Inc.

SORInc.com | 913-888-2630 | Registered Quality System to ISO 9001

7/16

Page 8

Adjustable Dead Band

Pressure Switches

Notes

1. N4 diaphragm system is standard. It is

normally suitable for air, oil, water and noncorrosive processes.

2. Other diaphragm and o-ring combinations

may be available. Consult the factory or the

SOR representative in your area for more

information.

3. Wetted parts have been selected as representing the most suitable commercially

available material for use in the service

intended. However, they do not constitute a

guarantee against corrosion or permeation,

since processes vary form plant to plant and

concentration of harmful fluids, gases or

solids vary from time to time in a given

process. Emperical experience by users

should be the final guide. Alternate materials

based on this are generally available.

4. Specify N3 diaphragm system for high cycle

rate, high shock applications where Buna-N

and TCP are compatible with the process.

5. This table shows allowable minimum and

maximum temperature for o-rings.

Step 4: Diaphragm and O-Ring

5V1-LA3-N6-C1A-YY

O-Ring

(Wetted)

Viton

Kalrez A6

Viton

Kalrez H6

Viton

Kalrez J6

Viton

Kalrez L6

Viton GLT

Buna-N M2

Viton M4

Neoprene M5

Kalrez M7

Aflas M8

EPR M9 Note 6

Viton

Diaphragm

(Wetted)

Monel

Hastelloy-B

Hastelloy-C

Carpenter-20

316L SS

Designator

A4

H4

J4

L4

M1

N1

O-Ring Material ° F ° C

Viton 32 to 400 0 to 204

Viton GLT -20 to 400 -29 to 204

Kalrez* 5 to 400 -15 to 204

Aflas 25 to 400 -4 to 204

Buna-N

Neoprene EPR

TCP Teflon Coated

Polyimide

Diaphragm

*Kalrez or equivalent

Perfluoroelastomer (FFKM) o-rings

-30 to 200 -34 to 93

-30 to 400 -34 to 204

6. M9 diaphragm system is suggested for

steam applications up to 400oF.

7. Dead bands are slightly higher when using

H, J, W, N3, or N6 series diaphragm options.

Consult the factory.

Buna-N N3 Note 4

Buna-N

Kalrez N5

Kalrez Kalrez N6

EPR

Aflas N8

Buna-N Buna-N P1

Neoprene Neoprene R1

Viton

Viton GLT S2

Buna-N

Viton W4

Neoprene W5

Kalrez W6

EPR

Ethylene

Propylene

Ethylene Propylene

TCP

Teflon-Coated

Polyimide

TCP

Teflon-Coated

Polyimide

Viton

Tantalum

EPR

N4 Standard

Note 1

N7

S1

W2

Y1

8/16

Registered Quality System to ISO 9001 | 913-888-2630 | SORInc.com

Form 281 (05.18) ©SOR Inc.

Page 9

Adjustable Dead Band

Pressure Switches

Step 5: Pressure Port

5V1-LA3-N6-C1A-YY

Material Connection Designator

Aluminum Alloy 356

copper-free casting

316SS CF-8M Casting

1/4” NPT(F) B1A

1/2” NPT(F) B2A

1/4” NPT(F) C1A

1/2” NPT(F) C2A

Step 6: Accessories

5V1-LA3-N6-C1A-YY

Accessory / Option & Description Designator

Wetted parts are cleaned for industrial oxygen service. BB

CSA Certified pressure switch. Available with V1 housing. Housing has earth (ground) lug.

See agency listings on page 10 for details.

Cemented cover gasket on weathertight housing. GC

Universal terminal box, 1/2” NPT(F). 316SS. Explosion proof. FM Approved; CSA Certified.

See form 657 (Catalog GI-30).

Vacuum protector plate retains diaphragm system in the pressure switch if subjected to

intermittent vacuum greater than 10 in Hg. If a pressure switch is subjected to continuous, rapid changes of vacuum, other protection may be available (consult factory). Material

matches or exceeds pressure port material.

Compliance to NACE Certification MR0175/ISO 15156* NC

Pipe (stanchion) mounting kit for (1-1/2” to 2” pipe). Order as a separate line item for CSA

Certified pressure switches.

Tag, fiber. Attached with plastic wire to housing. Stamped with customer-specified tagging

information.

Powder coat epoxy coating. No coating on stainless steel parts or plated screws.

(500 hours-salt spray)

Tag, stainless steel. Attached with stainless steel wire to housing. Stamped with customer

specified tagging information. (2 lines, 18 characters and spaces per line.)

Stainless steel piston and cylinder disc for corrosion resistance. SP

Explosion proof and weathertight electrical junction box with screw terminals. Aluminum

3/4” NPT(F) top or right conduit connections as required. UL Listed and CSA Certified

Class I, Groups A, B, C & D; Class II, Group E, F & G; Division 1 & 2. Includes cover o-ring

for weathertight applications. (V3 housing only.)

Oversize stainless steel nameplate. Permanently attached to housing. Stamped with

customer specified tagging information

Fungicidal varnish. Covers exterior and interior except working parts. VV

Epoxy coating. Exterior only. Polyimide epoxy with 316SS pigment. (200 hours-salt spray) YY

Chained cover with captive screws to conform to former JIC specification ZZ

“X” is used as a suffix to the model number for special requirements not keyed elsewhere in

the model number by an “X”. Each “X” must be completely identified in the text of the order

or inquiry. When more than one “X” is required, use “X” followed by the number of such

items. For example, “X3” means three separate, otherwise unidentifiable requirements.

CS

HT

MM

PK

PP

PY

RR

TB

TT

X

Form 281 (05.18) ©SOR Inc.

SORInc.com | 913-888-2630 | Registered Quality System to ISO 9001

9/16

Page 10

Adjustable Dead Band

Pressure Switches

Certificates C1 C2 C3 C4 C5 C6 C8 B1 B4 B5 B6 B7 A1 A2 A3 A4 A5 A6 A7 A8

Calibration

Hydrostatic Pressure Test

Inspection Report

Compliance / Conformance

Dielectric Test

Insulation Resistance

Typical Material of

Wetted Parts

¿ ¿ ¿ ¿ ¿ ¿ ¿ ¿ ¿ ¿ ¿ ¿ ¿ ¿

¿ ¿ ¿ ¿ ¿ ¿ ¿ ¿ ¿ ¿

¿ ¿ ¿ ¿ ¿ ¿ ¿ ¿ ¿ ¿ ¿

¿ ¿ ¿ ¿ ¿ ¿ ¿

¿ ¿ ¿ ¿

¿ ¿ ¿ ¿ ¿ ¿ ¿

¿ ¿ ¿ ¿ ¿ ¿

Test Certificates

Agency Listings

The following combinations only are available as approved, certified or listed by the agencies shown. Some

components are for products not offered in this catalog. Certain components or combinations may acquire

additional approval, certification or listing between print dates of this catalog. Contact the factory for the most

current information.

CSA Enclosure 4 (Weathertight)

Piston Housing

Switching

Element

All V1 LA, SA All All All

Spring

Diaphragm

& O-Ring

Pressure Port

Material &

Connection Size

Accessories/

Option

CS Required

All except TB

10/16

Registered Quality System to ISO 9001 | 913-888-2630 | SORInc.com

Form 281 (05.18) ©SOR Inc.

Page 11

Adjustable Dead Band

Pressure Switches

SOR recognizes that there is no industry convention with respect to terminology and definitions

pertinent to pressure switches. This glossary applies to SOR Pressure Switches.

Adjustable Range

The span of pressure between upper and lower

limits within which the pressure switch may be

adjusted to actuate/deactuate.

Dead Band

The difference in pressure between the

increasing Set Point and decreasing Set Point.

Decreasing Set Point

That discrete pressure at which the pressure

switch is adjusted to deactuate on falling

pressure. It must fall within the adjustable range.

Hermetically Sealed

A welded steel capsule with glass-to-metal,

factory-sealed, electrical leads that isolates

the electrical switching element(s) from the

environment.

Increasing Set Point

That discrete pressure at which the pressure

switch is adjusted to actuate on rising pressure.

It must fall within the adjustable range.

Proof Pressure

The maximum input pressure that may be

continuously applied to the pressure switch

without causing leakage or catastrophic

material failure. Permanent change of Set

Point may occur, or destruction of the device

may be rendered inoperative.

Repeatability

The ability of a pressure switch to successively

operate at a Set Point that is approached from a

starting point in the same direction and

returns to the starting point over three

consecutive cycles to establish a pressure

profile. The closeness of the measured Set Point

values is normally expressed as a percentage of

full scale (maximum adjustable range pressure).

SPDT Switching Element

Single-Pole, Double Throw (SPDT) has three

connections: C — Common, NO — Normally

Open and NC — Normally Closed, which allows

the switching element to be electrically

connected to the circuit in either NO or

NC state.

Glossary of Terms

Overrange

The maximum input pressure that may be

continuously applied to the pressure switch

without causing permanent change of Set Point,

leakage or material failure.

Pressure Switch

A bi-stable electromechanical device that

actuates/deactuates one or more electrical

switching element(s) at a predetermined discrete

pressure/vacuum (Set Point) upon rising or

falling pressure/vacuum.

Form 281 (05.18) ©SOR Inc.

DPDT Switching Element

DPDT is two synchronized SPDT switching

elements which actuate together at increasing

Set Point and deactuate together at decreasing

Set Point. Discrete SPDT switching elements

allow two independent circuits to be switched;

i.e., one AC and one DC.

The synchronization linkage is factory set, and is

not field adjustable. Synchronization is verified by

connecting test lamps to the switching elements

and observing them go “On” simultaneously at

actuation and “Off” simultaneously at deactuation.

SORInc.com | 913-888-2630 | Registered Quality System to ISO 9001

11/16

Page 12

Adjustable Dead Band

Pressure Switches

Dimensions in this catalog are for reference only. They may be changed without notice. Contact the

factory for certified drawings for a particular model number. Dimensions are expressed as millimeters

over inches (Linear = mm/in.).

Dimensions

Drawing 0090300

Pipe Mounting Kit: PK

Drawing 0091353

Junction Box with Terminal Block: TB

12/16

Registered Quality System to ISO 9001 | 913-888-2630 | SORInc.com

Form 281 (05.18) ©SOR Inc.

Page 13

Adjustable Dead Band

Pressure Switches

Dimensions

Drawing 0090763

Junction Box with Terminal Block: HT

Weights

V1 Housing V3 Housing

4 lbs (2 kgs) 5 lbs (2.5 kgs)

Pk Pipe Kit 1.5 0.7

TB Junction box with

Terminal Block

Actual shipping weights may vary from the charted values because of product material,

configuration and packaging requirements.

Accessory Add lbs kgs

5 2.25

Form 281 (05.18) ©SOR Inc.

SORInc.com | 913-888-2630 | Registered Quality System to ISO 9001

13/16

Page 14

Adjustable Dead Band

Pressure Switches

Dimensions in this catalog are for reference only. They may be changed without notice. Contact the

factory for certified drawings for a particular model number. Dimensions are expressed as millimeters

over inches (Linear = mm/in.).

Housing Dimensions

Drawing 0090236

Non-Hazardous Locations

Weathertight NEMA 4, 4X, IP65

Housing Designator: V1

Drawing 0090325

Hazardous Locations

Contains Explosion Proof, Hermetically Sealed Switching Element Capsule: UL Listed, CSA Certified, ATEX and SAA Approved

Housing Designator: V3

14/16

Registered Quality System to ISO 9001 | 913-888-2630 | SORInc.com

Form 281 (05.18) ©SOR Inc.

Page 15

Notes

Form 281 (05.18) ©SOR Inc.

SORInc.com | 913-888-2630 | Registered Quality System to ISO 9001

15/16

Page 16

SOR Inc. | Lenexa, KS USA | 913-888-2630 | Fax 913-888-0767 | SORInc.com

REGIONAL OFFICES

China

SOR China | Beijing, China

+86 (10) 5820 8767 | Fax +86 (10) 58 20 8770

Middle East

SOR Measurement & Control Equipment Trading DMCC | Dubai, UAE

+971 4 278 9632 | Fax +971 4 279 8399

16/16

Registered Quality System to ISO 9001 | 913-888-2630 | SORInc.com

Form 281 (05.18) ©SOR Inc.

Loading...

Loading...