Page 1

Nuclear Qualified

thermal system.

y

Temperature Switches

General Instructions

The SOR® temperature switch utilizes a SAMA Class II thermal system.

NOTE: This type of system requires that the entire

length of the sensing bulb be exposed to the

temperature being measured.

II

Recommended Measurement Procedure

In considering the validity of a measurement,

remember that temperature-sensing devices respond

only to the temperature that they experience. It may

be considerably different from the temperature one

is attempting to measure if the sensor is of improper

size or configuration, or if the sensor is not adequately

coupled thermally to the media whose temperature is

being measured. The calibration procedures given below

will assure accurate and repeatable measurement of the

set points of SOR temperature switches. If the switch is

normally mounted in a thermowell, consideration should

be given to the effect this may have on the accuracy of

the switch. It is recommended that a heat transfer paste

or oil be used to thermally couple the sensing bulb to the

thermowell, both in service and during testing.

ond

a

e

per

ately

re is

n below

of the

itch is

should

cy of

r paste

lb to the

NOTE: If you suspect that a product is defective, contact the factory or the SOR Representative

in your area for a return authorization number (RMA). This product should only be installed by

trained and competent personnel.

Table of Contents

Design and

specifications are

subject to change

without notice.

For latest revision, go to

www.sorinc.com

Form 655 (04.13) ©SOR Inc.

Recommended Measurement Procedure ...1

N6 Housing ......................................3

TA Housing .......................................4

RT Housing ......................................5

Installation .......................................6

Site Storage .....................................6

Electrical Connection ...........................6

Calibration .......................................7

1/8

Page 2

Recommended temperature measurement procedure for switches used to sense

temperatures of liquids and steam with set points below 200°F:

Use a liquid bath (ethylene glycol, water, oil, etc.) with sufficient circulation to provide a

uniform bath temperature and efficient transfer of heat from the liquid to the sensing bulb.

Fully submerge the sensing bulb into the bath. Direct-mount sensing bulbs should be

submerged up to the bottom of the process connection threads.

Locate the tip of the temperature measuring standard (thermocouple, RTD, etc.) at the

mid point of, and adjacent to the sensing bulb.

Locate the sensing bulb and temperature measuring standard so that they do not touch

the sides or bottom of the bath or the heating and cooling coils.

When the bath temperature is within 3°F of the set points, it is recommended that the

temperature of the bath be changed at a rate of 0.1°F per 5 seconds or slower.

The minimum and maximum bath temperatures that the switch sees during testing

should be duplicated each time the switch is tested. It is recommended that the temperature of the bath be changed from the normal operating temperature to the critical

set point and back to the reset. Do not overshoot the critical set point if the switch is

going to be cycled more than once during the test.

Recommended temperature measurement procedures for switches used to sense temperatures of liquids and steam with set points above 200°F:

Recommended procedures for set points above 200°F are identical to those for set points

below 200°F with the exception of the bath used to test the switches. We recommend

either a circulated oil bath or a fluidized sand bath. The bath should be tested for uniformity

of temperature from top to bottom and side to side. If necessary, steps may be taken to

improve the uniformity of temperature, such as altering the air flow through a sand bath or

improving circulation or stirring.

Recommended temperature measurement procedures for switches used to sense air

or gas temperature:

Switches used to measure the temperature of air or gas should be tested in such a way that

it simulates the actual service conditions as closely as possible. Chances of measurement

error are much greater in air because of its poor thermal conductivity. Rate of change of

temperature, velocity of air flow, location of sensing bulb, and location of standard must

be duplicated as closely as possible for successive calibration checks to assure repeatable results. If the switch is being used as a room thermostat, the entire switch should be

placed in a test oven for calibration and testing. If only the sensing bulb is exposed to the

air or gas being measured, then only the sensing bulb should be inserted into the oven or

test apparatus for calibration and testing. In this case the switch housing should be kept at

room temperature.

2/8

Form 655 (04.13) ©SOR Inc.

Page 3

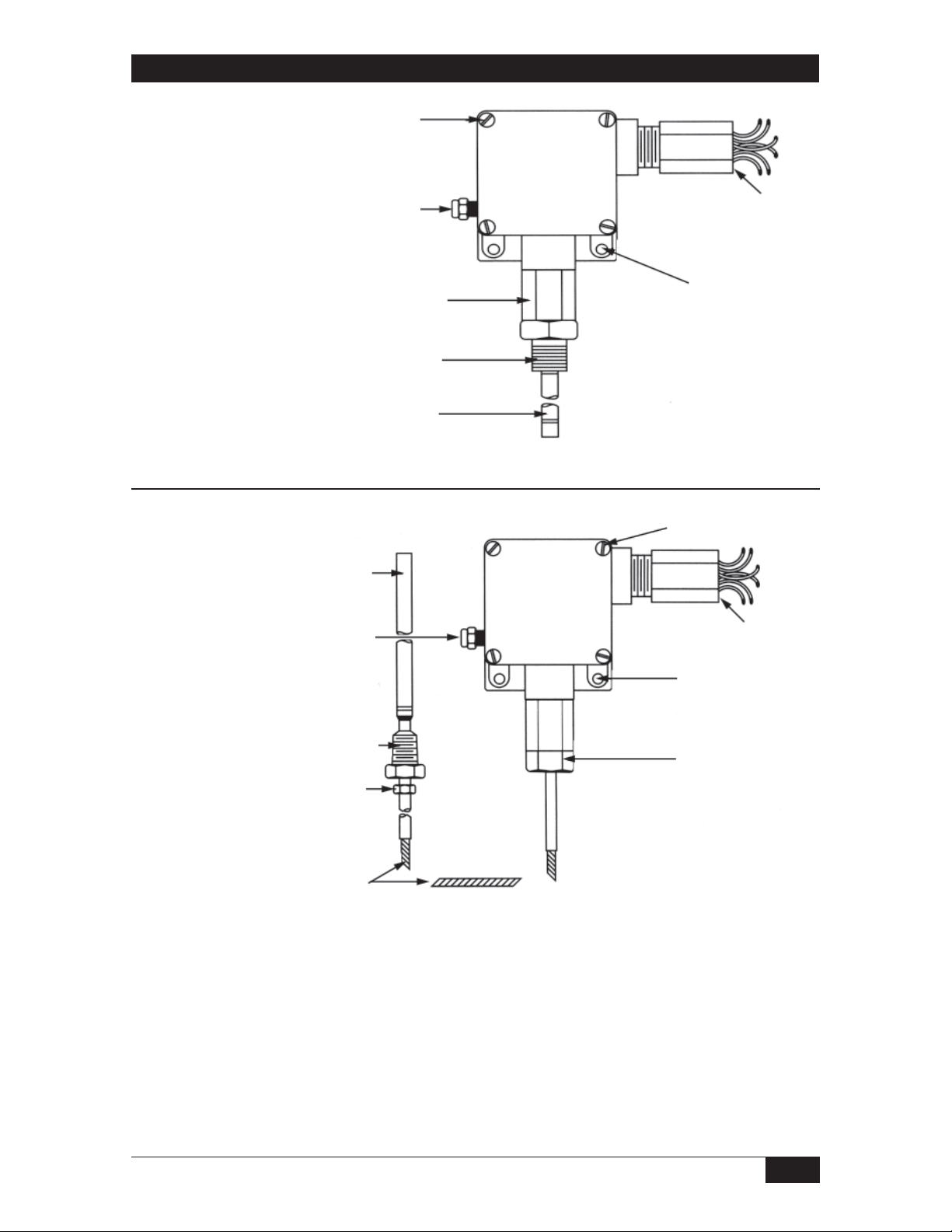

N6 Housing

Direct Mount

Remote Mount

Cover

Screws

1/8” NPT(F)

Vent

Connection

Body

Process

Connection

Sensing Bulb

3/4” NPT(F)

Conduit Connection

Mounting

Holes

Cover Screws

Sensing

Bulb

1/8” NPT(F)

Vent

Connection

Process

Connection

Gland

Nut

Capillary

Conduit Connection

3/4” NPT(F)

Mounting

Holes

Retainer

Mounting Hardware Fasteners per SOR Test Report 9058-102 consist of two 1/4-20,

Grade 5 screws (not supplied). Torque screws to 70 to 85 in-lbs.

Maintenance Replace cover gasket (SOR P/N 8923-180) whenever cover is removed or

minimum of once every 5 years, whichever comes first. Remove the four cover screws.

Remove the old gasket. Place new gasket between housing and cover. Line up holes in

cover, gasket and housing. Insert the 4 screws and torque each to 7 to 10 in-lbs.

Form 655 (04.13) ©SOR Inc.

3/8

Page 4

TA Housing

Direct Mount

Remote Mount

Cover

1/4” NPT(F)

Vent Connection

Body

Process Connection

Sensing Bulb

U-Bolts

3/4” NPT(F)

Conduit

Connection

Cover

Sensing

Bulb

Process

Connection

Gland Nut

Capillary

1/4” NPT(F)

Vent

Connection

U-Bolts

3/4” NPT(F)

Conduit Connection

Retainer

Mounting Hardware Fasteners per SOR Test Report 9058-102 consist of three standardgrade 1/4-inch U bolts (not supplied).

Maintenance Replace cover o-rings (SOR P/N 8923-206 and 8923-207) whenever cover

is removed or minimum of once every 5 years, whichever comes first. Unscrew the cover.

Remove the old o-rings. Place new o-rings in grooves of cover. Lubricate o-rings with

light film of Krytox 240AC grease (or equivalent fluorinated grease). Tighten cover until the

flange of the cover makes contact with the housing.

4/8

Form 655 (04.13) ©SOR Inc.

Page 5

RT Housing

Direct Mount

Remote Mount

1/8” NPT(F)

Vent

Connection

Cover

Screws

Body

Process Connection

Sensing Bulb

Sensing

Bulb

3/4” NPT(F)

Conduit

Connection

Mounting Holes

Cover Screws

3/4” NPT(F)

Conduit Connection

1/8” NPT(F)

Vent

Connection

Process

Connection

Gland

Nut

Capillary

Mounting

Holes

Retainer

Mounting Hardware Fasteners per SOR Test Report 9058-102 consist of two 1/4-20,

Grade 5 screws (not supplied). Torque screws to 70 to 85 in-lbs.

Maintenance Replace cover gasket (SOR P/N 8923-181) whenever cover is removed or

minimum of once every 5 years, whichever comes first. Remove the four cover screws.

Remove old gasket. Place new gasket between housing and cover. Line up holes in cover,

gasket and housing. Insert the 4 screws and torque each to 7 to 10 in-lbs.

Form 655 (04.13) ©SOR Inc.

5/8

Page 6

Installation

Refer to applicable drawing for mounting dimensions of specific model number. The

vent connection must be plugged or vented to dry atmosphere as required by application

requirements.

Direct Mount Line mount or mount to a rigid mounting surface with process connection

down (6 o’clock). If the switch must be removed from a thermowell, loosen the process

connection by placing a 1-1/4” wrench on the hex adjacent to the process threads. Do not

use wrench on the sensing body. (See drawings.)

Remote Mount Mount to a rigid mounting surface with retainer down (6 o’clock). Secure

capillary every two feet. To install sensing bulb, loosen gland nut so that the process connection turns freely. Re-tighten gland nut after process connection is installed.

Site Storage

Store switch in a dry area in the original shipping package. Shelf life is 10 years for a

maximum ambient temperature of 80°F, based on aging data in SOR Test Report 9058-102.

Electrical Connection

Electrical connections are marked on the insulation of the wire leads. Conduit should be

installed without applying strain to the housing.

Temperature Temperature

Minimum Bend Radius for Wire

Permanent Training 1/2” R

Pulling Tension 1” R

Terminating Junction 1/4” R

6/8

Form 655 (04.13) ©SOR Inc.

Page 7

Calibration

To adjust temperature at which switch will operate, remove cover and tighten the hex head

adjusting nut with a 3/4-inch wrench to increase temperature; loosen to reduce temperature.

Sighting across the top of the 3/4-inch hex adjusting nut to the scale gives approximate

set point temperature. Use accurate test gear external to the temperature switch to set or

check set points. See recommended measurement procedure on Page 1. After calibration

is complete, reinstall the cover with new gaskets or o-rings as required by the maintenance

instructions.

The switching element has been positioned with a dial indicator to a

tolerance of +/-.002 inches. Do not move this switching element! Its position

has nothing to do with the set point adjustment. Any movement can either

render the switch inoperative or cause the switching element to be damaged

with over-temperature.

Switching Element

Adjusting Nut

Form 655 (04.13) ©SOR Inc.

Calibration Scale

7/8

Page 8

Printed in USA www.sorinc.com

14685 West 105th Street, Lenexa, KS 66215 913-888-2630 800-676-6794 USA Fax 913-888-0767

8/8

Form 655 (04.13) ©SOR Inc.

Loading...

Loading...