Page 1

Ultrasonic Two-Wire

Point Level Control

General Instructions

The Ultrasonic Point Level Control indicates liquid presence/absence within a sensor cavity.

Two piezoelectric crystals face each other across the sensor cavity. One crystal transmits

an ultrasonic signal; the other crystal receives the signal.

When the sensor cavity is empty, the receiver detects a weak signal because air is a poor

conductor of ultrasonic waves. The yellow LED is lit, indicating 8 mA current output.

When process liquid fills the sensor cavity, the receiver detects a strong signal because

liquids are good conductors of ultrasonic waves. The red LED is lit, indicating 16 mA

current output.

The Ultrasonic Point Level Control constantly monitors sensor integrity and changes the

current output in the unlikely event of a sensor failure. The Failure Mode Switch located

inside the control housing can be field selected to either 5 mA or 19 mA to indicate

sensor failure.

Remote Self-Test is provided with non-intrinsically safe units only. Units equipped with

two terminal blocks feature the remote self-test. A dry contact may be used up to 50

feet/15 meters from the control to simulate a sensor failure.

Standard 316SS and Te on Notch-Type sensors, epoxy tip-sensitive, and 316SS viscous

sensors are available for use with the point level control. Extreme care must be taken when

®

installing units with Teflon

NOTE: If you suspect that a product is defective, contact the factory or the SOR® Representative

in your area for a return authorization number (RMA). This product should only be installed by

trained and competent personnel.

sensors. See installation instructions beginning on page 2.

Table of Contents

Installation .......................................3

Remote Cable Connection .....................4

Design and

specifications are

subject to change

without notice.

For latest revision,

go to sorinc.com

Remote Electrical Connection ................4

Electrical Connection ...........................5

Calibration and Function Test .................8

Sensor Replacement ...........................9

Circuit Board Replacement ....................9

CE Marked Units .............................. 10

Control Drawings ............................. 11

Troubleshooting ............................... 16

Dimensions ................................ 17-19

Form 771 (08.13) ©SOR Inc.

Registered Quality System to ISO 9001

1/20

Page 2

Installation

Notch-Type and Epoxy Sensors (Series 371-N and 371-E)

Ultrasonic Level Sensors can be mounted by inserting the sensor through a fitting in a vessel,

®

or over an open sump or basin. Special care must be taken when installing Teflon

Irreparable damage may be done to Te on sensors by turning metal hex

and Te on hex separately. Always rotate metal hex and Te on hex

simultaneously. Do not apply more than 10 in. lbs. of torque to either

hex during installation.

Keep the sensor cavity out of the direct flow of liquid fill to prevent false readings.

sensors.

Avoid installation of sensor in turbulent areas

such as pump discharge or suction. Air pockets

may be present in these areas which may cause

Always turn Teflon hex & metal hex

together when installing

sensor into process.

false indication.

DO NOT weld any part of

this instrument

Sensor

Tank or Vessel

Base Hub

No Obstructions

Make sure that the sensor can be fully inserted and

tightened without interference from obstructions

inside the tank or vessel. (See

)

Apply thread sealant

Apply suitable sealant to the process connection to prevent process leakage. (See )

Use an open end wrench to tighten the sensor into the process connection.

Do not use the sensor base as a handle to tighten the process connection.

Horizontal Mounting

Horizontal mounting is recommended for use in highly viscous liquids, or liquids

containing sludge and debris. When tightened securely, the sensor cavity must face

sideways for optimum drainage when process liquid level drops below the sensor cavity.

An alignment mark X stamped on a wrench flat (or on

the dry face of a flange below the housing) shows sensor

cavity orientation. (See

)

Notch Type Sensors – Optimum drainage occurs when the

X mark is located at 3 or 9 o’clock.

The sensor must project through a tank fitting so that the

sensor cavity is at least 1” (25.4mm) beyond the inner

wall of the tank. (See

2/20

)

Notch Sensor

Alignment mark shown

at 3 o’clock

Alternate position: 9 o’clock

1

inch minimum

Form 771 (08.13) ©SOR Inc.

Page 3

Open Sump or Basin

Do not suspend the unit by rigid conduit installed

in the electrical hub. When installing the unit over

an open sump or basin, use a suitable bracket to

Open Sump

Locally

Supplied

Bracket

support the instrument.

NOTE: The instrument must be positioned so that

over ow does not ood electrical housing. (See

)

CE Marking Sensor Installation (notch type sensors only, Series 371-N)

Shield Beads

Three beads are included with your CE marked unit.

Two of the beads are 5/8” dia x 1/2” long. The other

bead is 3/8” dia x 3/4” long (save this bead for the

electrical connection beginning on page 5).

Disconnect the sensor leads from the circuit board.

Slide one 5/8” dia. bead onto each lead.

Reinstall the sensor leads into the circuit board.

Push the beads to the bottom of the housing. (See )

Shield

Beads

Electronics

Housing

Sensor

Wires

Sensor

Viscous Sensor Installation (Series 371-V)

Vertical or horizontal (flange only) mounting is supported for the viscous sensor. A 3”

(76.2mm) minimum opening is required for insertion.

76.2

minimum opening required (typ.)

An alignment mark X stamped on

the dry face of the flange below

the housing shows sensor cavity orientation. (See

) When

mounting the viscous

sensor horizontally, optimum

drainage occurs when the X mark

is located in the 6 o’clock position.

Take care during installation to

prevent damage to the sensor

62.1

2.44

(typ.)

Bottom View Viscous

Sensor with 4-Hole Flange

3.00

5.9

0.23

of fl ange

Alignment mark, (other side)

position at 6 o’clock (typ.)

Bottom View Viscous

Sensor with 8-Hole Flange

5.9

0.23

C

L

end. Slight bending of the sensor may result in loss of sensitivity due to misalignment of

the ultrasonic crystals.

Form 771 (08.13) ©SOR Inc.

3/20

Page 4

Remote Cable Connection

Conduit must be installed between the sensor base and the electronics housing to provide

a raceway for sensor extension cables. (See

housing are suitable for use in Class I Group C & D; Class II Groups E, F & G; Division 1

& 2 Hazardous Locations. All conduit and fittings used for the installation must equal or

exceed this rating to maintain the explosion proof integrity of the assembly.

) The sensor base and the electronics

Ensure that wiring conforms to

all applicable local and national

electrical codes and install unit(s)

according to relevant national and

local safety codes.

Fishing the Sensor Extension

Cables Two sensor extension cables

are supplied. Both ends of the cables

are terminated and labeled at the

Electronics

Housing

Control Board

See Figures 12 and 14

Remote

Interconnect

Board

See Figure 8

Protect factory

installed

plugs

factory.

Use care to avoid damaging the

factory installed mini-phono

Conduit must meet

Class I Group C & D;

Class II Groups E, F & G;

Division 1 & 2

Sensor Base

connectors while fishing the sensor

extension cables through the conduit. Pull cables from the sensor base so that the free

ends follow the fish through the conduit. (See

)

Remote Electrical Connection

Electrical power must be disconnected from explosion proof models before

the cover is removed. Failure to do so could result in severe personal injury

or substantial property damage.

Sensor Coax Connections Inside Sensor Base

Inside the sensor base, a remote interconnect board rests in a plastic holder. Slide the

interconnect board up. Attach the sensor coax connectors to the interconnect board as follows:

Connect the long sensor* (A) cable to IN 1.

Connect the short sensor (T) cable to IN 2.

*Viscous probe sensor cables are the same length. Refer to the cable markings to make correct

electrical connections.

Attach the extension cables to the interconnect board as follows:

Connect cable A to OUT 1. (See )

Connect cable T to OUT 2.

4/20

Form 771 (08.13) ©SOR Inc.

Page 5

Connect extension

lead T to OUT 2

Remote Interconnect Board

located inside sensor base

Connect extension lead A to OUT 1

OUT connections are located

on the opposite side of the

board from the IN connections.

Do not use positions 3 & 4 to

connect wires.

Connect

long sensor lead (A) to IN 1

Connect short sensor lead

(T) to IN 2

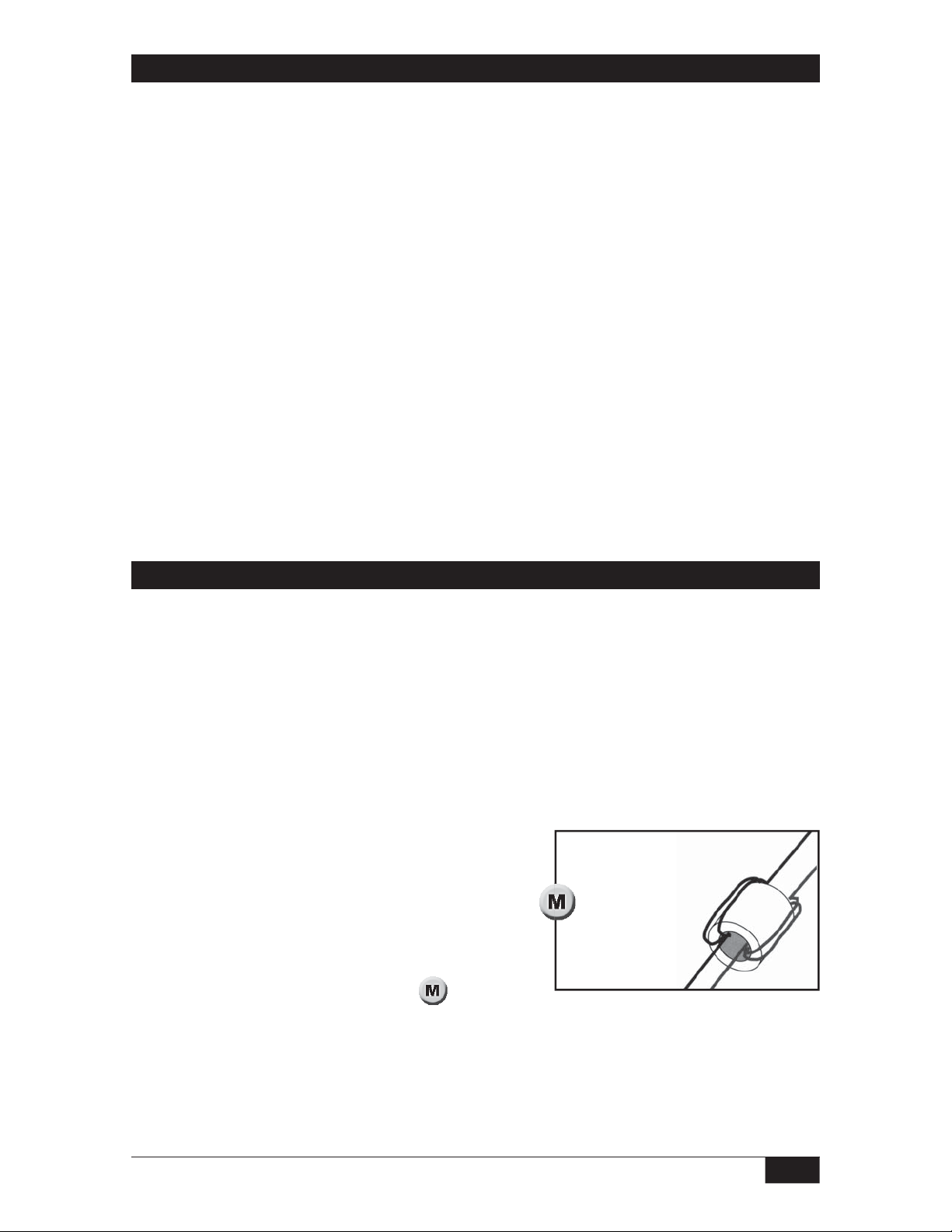

Discharge the Sensor

Temperature changes which occur during shipment may result in a small electrical charge

inside the sensor crystals. This charge is harmless to humans, but may result in damage to

the electronics if the sensor is plugged in before it is discharged. To discharge the sensor,

touch a wire to each sensor connector so that the center conductor

and outside shell make contact. (See

)

Plug in Connections Inside Electronics Housing

Plug sensor extension cables onto the PC board as follows:

Short each center

Connect cable A to J1.

Connect cable T to J2. (See to locate J1 and J2.)

conductor to the

shell to discharge

sensor crystals.

Electrical Connection

Explosion Proof and Non-Agency Listed model

Electrical power must be disconnected from explosion proof models before

the cover is removed. Failure to do so could result in severe personal injury

or substantial property damage.

Ensure that wiring comforms to

all applicable local and national

electrical codes and install unit(s)

according to relevant national and

local safety codes.

Make sure the power source

is turned off.

Remove the housing cover.

Pull power and signal wires

Loop Power

Terminal Block

(Non-Intrinsically Safe Units Only)

TB1

Remote Self-Test Terminal Block

through the conduit connection and into the control housing.

Locate TB1 on the control board. (See )Terminals are labeled “+” and “-”. Connect

power leads to the proper terminals.

- Terminal

+ Terminal

TB2

Do not exceed the maximum loop resistance for the circuit. (See )

Form 771 (08.13) ©SOR Inc.

5/20

Page 6

Loop Resistance vs. Power Supply Voltage

1800

1700

1600

1500

1400

1300

1200

1100

1000

900

800

700

600

500

400

(including Barrier Resistance)

Maximum Loop Resistance (Ohms)

300

200

100

0

5 10 15 20 25 30 35 40

650 Ohms

at 24 VDC

1 Ohm at

11 VDC

Power Supply Voltage (Volts)

1450 Ohms

at 40 VDC

950 Ohms

at 30 VDC

850 Ohms

at 28 VDC

Electrical Connection (Remote Self-Test)

Explosion Proof and Non-Agency Listed models:

Electrical power must be disconnected from explosion proof models before

the cover is removed. Failure to do so could result in severe personal injury

or substantial property damage.

Ensure that wiring comforms to all

applicable local and national

electrical codes and install unit(s)

Loop Power Terminal Block

according to relevant national and

local safety codes.

Make sure the power source is

turned off.

Remove the housing cover.

Pull twisted pair cable through the conduit connection and into the control housing.

Connect dry contact wires to TB2 on the control board. (See ) Terminals are

Remote Dry Contact Ground Twisted Pair Shield

labeled “RMT COM” and “RMT TST*”. Attach the twisted pair shield to the ground

screw inside the housing. Ground only one end of the twisted pair shield.

TB2 Remote Self-Test Terminal Block

(Non-Intrinsically Safe Units Only)

TB1

to Housing Ground Screw

Do not apply power to the remote test terminals.

Connect the open end of the wires to a dry (unpowered) contact designed for small

loads. There is no polarity required for this connection.

6/20

Form 771 (08.13) ©SOR Inc.

Page 7

Electrical Connection (Intrinsically Safe)

Intrinsically Safe Models (does not apply to viscous or epoxy controls and sensors):

Any model numbers containing the designators “AI”, “CI” or “FI” are listed Intrinsically

Safe with CSA (AI), CENELEC (CI) or FM (FI). Please note the housing nameplate to determine the Agency Approval of your instrument. Connections must be as shown on the SOR

Control Drawings shown on pages 8-12.

AI CSA Intrinsically Safe... ................ Class I, Div. 1, Groups C, & D; Class II, III, Div. 1,

Groups E, F, & G; Class I, Div. 2, Groups A, B, C, D; Class II, III, Div. 2, Groups F, G;

Type 4X; T4

Connections must be as shown on the SOR Control Drawing 9065-136.

CI CENELEC Intrinsically Safe...... .................................................... EEx ia IIB T4, IP65

Connections must be as shown on the SOR Control Drawing 9065-146.

FI FM Intrinsically Safe....... ............................................Class I, Div. 1, Groups C, & D;

Class II, III, Div. 1, Groups E, F, & G; Class I, Div. 2, Groups A, B, C, D;

Class II, III, Div. 2, Groups F, G; NEMA 4X; T4

Connections must be as shown on the SOR Control Drawing 9065-135.

Electrical Connection (CE Marking)

Shield Beads

Three beads are included with your CE marked unit. Two of the beads are 5/8” dia. x 1/2”

long; they are used in the sensor installation. (See page 3.) The other bead is 3/8” dia. x

3/4” long. Use this bead for the following electrical connection.

In order to achieve the stated accuracy of ±1mA, a customer supplied shielded cable and

cable gland are used with the furnished 3/8” dia. x 3/4” bead. SOR recommends using a

shielded cable made of PVC insulation around a tinned copper braid shield (Olflex CY or

equivalent). Install the bead as close as possible to the cable gland.

Strip outer cable insulation and shield approx.

10 inches.

Separate the positive and negative wires.

Slide the bead over both wires.

Wrap each wire around opposite sides of the bead

to make two complete loops. (See

Make internal power connections as shown on page 4.

)

Install bead as close as

possible to cable gland

Install the cable gland per manufacturer’s instructions. The cable gland will provide

necessary grounding for the cable shield.

Form 771 (08.13) ©SOR Inc.

7/20

Page 8

Calibration and Function Test

No calibration is needed. Units are calibrated at the factory. No user adjustments are

required.

TB2 Remote

Self-Test

Electrical power

must be

disconnected

from explosion

proof models

before the cover is

removed. Failure to

do so could result

in severe personal

injury or substantial

property damage.

Terminal Block

(Optional)

Yellow LED (Dry)

Red LED (Wet)

TB1 Loop Power

Terminal Block

SW1 Failure

Mode Switch

J1 Receive Jack

J2 Transmit Jack

Functional test can be done with or without a current meter. See for wiring

configuration. See

Connect power to the circuit board as shown in . If the sensor is dry, the yellow LED

for component location.

will light. If using a current meter, the display should read 8 mA (± 1 mA).

Apply process liquid to the sensor. The yellow LED will turn off, and the red LED will

light. Current meter will read 16 mA (±1 mA).

With Failure Mode Switch (SW1) in the 5 mA position, disconnect one probe lead wire (J1

or J2). Both LED’s will turn off and the current meter will read 5 mA (±1 mA). Reconnect

the probe lead wire.

With Failure Mode Switch (SW1) in the 19 mA position, disconnect one probe lead wire

(J1 or J2). Both LEDs will light and the current meter will read 19 mA (±1 mA).

Reconnect the probe lead wire.

To test Remote Self-Test switch connections (non-intrinsically safe units only), use the

dry contact to simulate a probe failure for steps 3 and 4 instead of disconnecting the

probe lead wire.

8/20

Form 771 (08.13) ©SOR Inc.

Page 9

Current Output Chart

LED on

LED off

Yellow LED

(Dry)

Red LED

(Wet)

Current Meter

(+ 1mA)

8 mA Dry

16 mA Wet

5 mA

19 mA

Sensor

Status

__

__

Failure Mode

__

__

5 mA

19 mA

Sensor Replacement

Disconnect power to the unit.

Remove the housing cover.

Remove two mounting screws and slide out PC board to expose the sensor connections

J1 and J2. (See

Disconnect the sensor wires from J1 and J2.

)

Unscrew the sensor from the housing.

Apply thread sealant to the male threads of the new sensor.

Thread the new sensor into the bottom of the housing.

Discharge the sensor. Connect the center conductor and shell of sensor wire end as

shown on page 4. (See

Connect the sensor wire (T) into the J2 mini-phono jack on the circuit board. (See )

Connect the sensor wire (A) into the J1 miniphono jack on the circuit board.

)

Slide the PC board into the grooves in the plastic ring inside the housing.

Replace the two mounting screws into the plastic ring: these screws are self-tapping.

Do not overtighten.

Reconnect power and replace the housing cover.

Replacement Sensors

See Form #973, Ultrasonic Catalog for replacement sensor model numbers.

Circuit Board Replacement

Disconnect power to the unit.

Remove the housing cover.

Remove two mounting screws and slide out PC board.

Disconnect sensor plugs J1 and J2. (See )

Slide the new board into the control housing.

Form 771 (08.13) ©SOR Inc.

9/20

Page 10

Discharge the sensor. Connect the center conductor and shell of sensor wire end as

shown on page 5. (See

Connect the sensor plugs to the new board. The sensor wire (T) plugs into J2

)

(transmit). The sensor wire (A) plugs into J1 (receive).

Replace the two mounting screws into the plastic ring. These screws are self-tapping.

Do not overtighten.

Replacement Circuit Boards Match the characters of your model number with those

shown below to select the proper replacement board part number. Accessory

designators are located at the end of the model number in no particular order.

Accessory Designator

Model Number

I.S. CI, FI or AI Expf FM or CS

Non-Agency (no match)

721 2-N-P9-G

721 2-N-P9-C

721 2-V-P9-C

721 2-E-P9-C

NOTE: When ordering replacements for remote units (R in the 4th position of the model

number), supply cable length information and serial number. Circuit boards are tuned

to remote cable length for optimum circuit performance.

5003-009 5003-010 5003-010

5003-011 5003-012 5003-012

__ __ 5003-028

__ __ 5003-042

CE Marked Units

In order to achieve the stated accuracy of +/-1mA, a shielded cable, cable gland and shield

beads must be used. SOR recommends using a shielded cable made of PVC insulation

around a tinned copper braid shield. (Olflex CY cable or equivalent.) Refer to illustrations

below for installation of shield beads.

Probe Wire Shield Bead

Probe Wire Shield Bead

10/20

Short/Fat Bead

Install end of bead as close

to cable gland as possible

2 Loops

Positive

Negative

Form 771 (08.13) ©SOR Inc.

2 Loops

Long/Slender

Bead

Page 11

Control Drawing

Form 771 (08.13) ©SOR Inc.

11/20

Page 12

Control Drawing

12/20

Form 771 (08.13) ©SOR Inc.

Page 13

Control Drawing

Form 771 (08.13) ©SOR Inc.

13/20

Page 14

Control Drawing

14/20

Form 771 (08.13) ©SOR Inc.

Page 15

Control Drawing

Form 771 (08.13) ©SOR Inc.

15/20

Page 16

Troubleshooting

Symptom/Problem

No current in the loop

No LEDs lit.

Current 5 or 19 mA.

No LEDs lit or both

LEDs lit.

Current stays at 8 mA

when liquid is in the

gap.

Yellow LED remains lit.

Current stays at 16 mA

when the gap is empty

Red LED remains lit.

Current is greater than

20 mA.

Possible Cause Corrective Action

1. Power supply turned off.

2. Improperly wired terminal block TB1.

3. Broken power supply wire.

1. Sensor lead unplugged.

2. Sensor integrity is compromised.

3. Remote Self-Test activated.

1. Process is highly aerated liquid.

2. There is no liquid in the gap.

3. Remote cable length has been changed*.

4. Circuit integrity is compromised.

1. Process is clogging the sensor.

2. There is liquid in the gap.

3. Remote cable length has been changed*.

4. Circuit integrity is compromised.

1. Incorrectly wired circuit.

2. Circuit integrity is compromised.

1. Check power supply source.

Check terminal block wiring per

2.

(page 5)

3. Check loop wire integrity.

1. Check sensor cable connections.

2. Replace the sensor.

3. Check dry contact & TB2 wiring.

1. Install baffle or stilling well, or use

a 651K9 RF Point Level Control.

2. Unit is operting properly.

3. Replace circuit board.

4. Replace circuit board.

1. Clean the sensor.

2. Unit is operating properly.

3. Replace circuit board.

4. Replace circuit board.

1. Check current loop wiring per

(page 5)

2. Replace circuit board.

Remote Self-Test does

not switch to 5 or 19 mA.

Current intermittently

switching to 5 or 19 mA.

1. Open signal wire.

2. Wires hooked to the wrong terminal block.

1. Improperly grounded shield of TB2

twisted pair.

1. Check twisted pair wire integrity.

2. Verify dry contact wired to TB2.

1. Ground one end only of the twisted

pair shield.

*Circuit boards for remote units are tuned at the factory for optimum performance with specified

cable length. If the remote cable length is changed, circuit operation will be adversely affected.

NOTE: Agency certi ed units, (FM, CSA, IEC) must be returned to SOR for repairs.

16/20

Form 771 (08.13) ©SOR Inc.

Page 17

Dimensions

Metal Sensor

ELECTRICAL

CONNECTION

3/4 NPTF STD

1/2 NPTF OPT

95.3

3.75

50.8

2.00

ADD FOR

K2 HSG

K1 HSG

210.8 *

8.30

93.3 *

3.67

A

15.9

0.63

116.7

4.59

96.0

3.78

SENSOR

CAVITY

15/16 WRENCH

FLATS

PROCESS

CONNECTION

SEE CHART

Linear = mm/inches

Drawing 0390000

Dimensions are for reference only.

Contact the factory for certified drawings

for a particular model number.

20.6

0.81

CONNECTION

SIZE

3/4 NPT(M) SHOWN

1 NPT(M)

1-1/2 NPT(M)

2 NPT(M)

PROBE LENGTH

A

* LENGTH

ADD

ADD

ADD

8.0

0.31

9.5

0.38

9.5

0.38

22.2

0.88

Form 771 (08.13) ©SOR Inc.

17/20

Page 18

Te on Sensor

Linear = mm/inches

Drawing 0390002

18/20

Dimensions are for reference only.

Contact the factory for certified drawings

for a particular model number.

Form 771 (08.13) ©SOR Inc.

Page 19

Viscous Sensor

Linear = mm/inches

Drawing 0390439

Dimensions are for

reference only.

Contact the factory for

certified drawings

for a particular model

number.

Form 771 (08.13) ©SOR Inc.

19/20

Page 20

Printed in USA sorinc.com

14685 West 105th Street, Lenexa, KS 66215 913-888-2630 800-676-6794 USA Fax 913-888-0767

20/20

Registered Quality System to ISO 9001

Form 771 (08.13) ©SOR Inc.

Loading...

Loading...