Page 1

These instructions provide information for

installation, process connection, electrical

connection and calibration of Nuclear Qualified

Pressure Switch with Terminal Block.

NOTE: If you suspect that a product is defective,

contact the factory or the SOR

your area for a return authorization number (RMA).

This product should only be installed by trained

and competent personnel.

®

Representative in

.

Installation

Nuclear Qualified

Pressure Switch

with Terminal Block

General Instructions

The vent connection must be plugged or vented to dry atmosphere as required by

application requirements. Test Data Sheet SOR form #716 is supplied for each serial

number and provides switch performance data in the vented and plugged condition.

Failure to mount the housing on a at mounting surface may result in

torsional forces on the housing that could cause false trips or render the

pressure switch inoperative.

Process Connection

Securely connect process line to pressure port using two wrenches: one to hold hex flats

on pressure port, the other to tighten process pipe or tube fitting.

Be certain the process connection is tightened and positioned so bending

and torsional forces imposed on pressure switch are minimal. Use care

not to loosen pressure port from body or body from housing.

Design and specifications are subject to change without notice.

Form 1472 (05.13) ©SOR Inc.

For latest revision, go to sorinc.com

1/4

Page 2

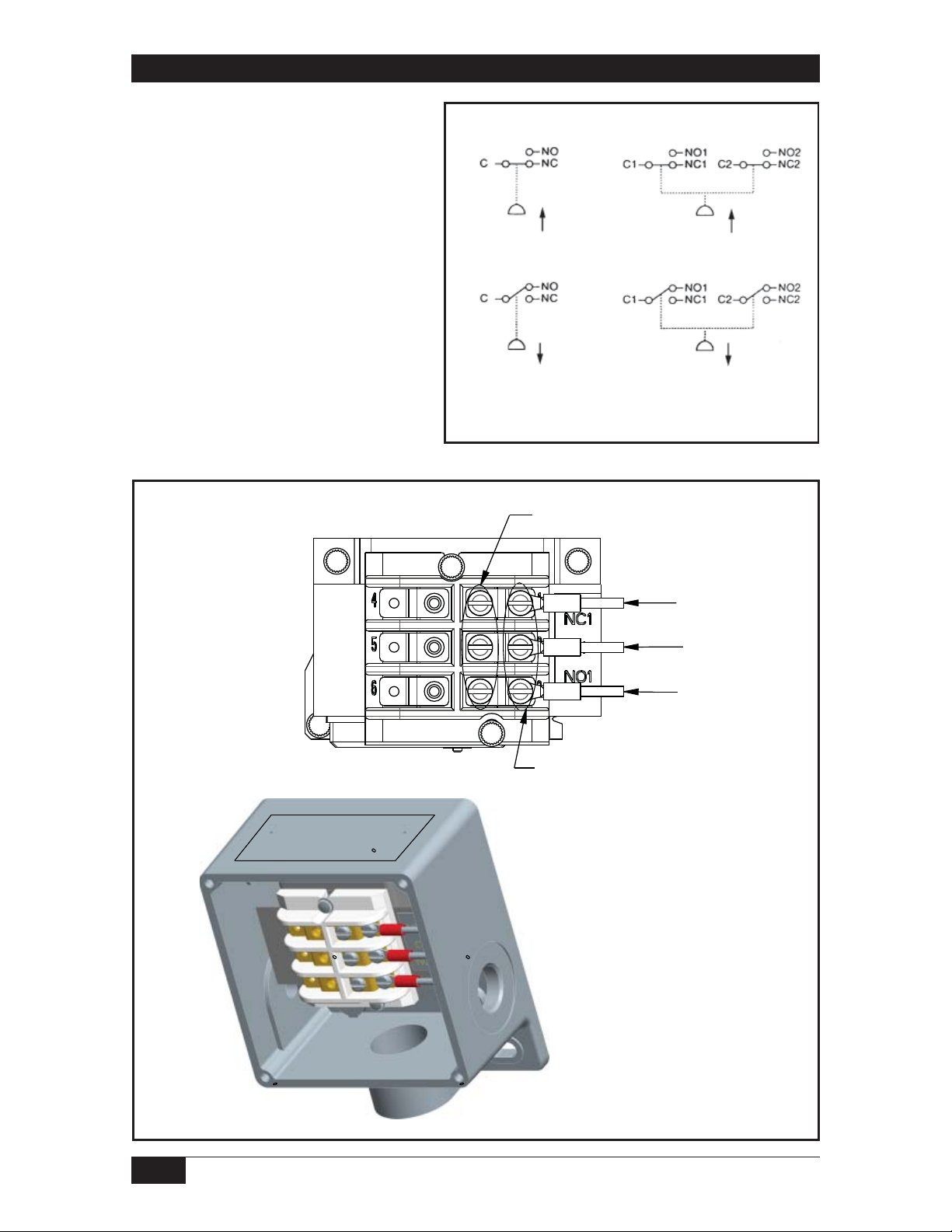

Electrical Connection

Conduit should be

installed without

applying strain to the

housing. Screw terminal

block is provided with

marked insulation as

denoted below. Tighten

screw terminals to

10 in-lbs. (1.1 N-m)

SPDT DPDT

Pressure

Vacuum

Pressure

Vacuum

Vacuum switches only

Drawing 9013747

INSTALL WIRING ON TOP ROW ONLY.

NC TERMINAL

C TERMINAL

NO TERMINAL

SOR INSTALLED WIRING, DO NOT REMOVE.

2/4

Form 1472 (05.13) ©SOR Inc.

Page 3

Site Storage

Store switch in a dry area in the original shipping package. Shelf life is 10 years for a

maximum ambient temperature of 80°F, based on aging data in SOR Test Report 9058-102.

Calibration

To check the set point of a switch, monitor either the common (C) and normally open (NO)

or the common (C) and normally closed (NC) contacts for change of state. Connect the

process connection to a regulated hydraulic or pneumatic pressure source. Monitor with

an accurate pressure measuring standard. Slowly increase or decrease the pressure to

accurately capture the precise moment that the switch changes state. To assure the most

accurate and repeatable results, the switch must be tested in an identical manner each time

the calibration is checked.

Increasing Set Points

If the normal operating pressure is below the

set point, then the pressure should be increased

from 0 PSI up to the increasing set point and

then back down to the reset point. Repeat this

cycle as necessary.

Switching Element

Decreasing Set Points

If the normal operating pressure is above

the set point, then the calibration should be

checked by first pressurizing to the normal

operating pressure, then reducing the pressure

to the decreasing set point, and then increasing

the pressure to the reset point. Repeat this cycle

as necessary.

To adjust pressure at which switch will operate, remove cover and tighten the hex head

adjusting nut with a 3/4” wrench to increase pressure; loosen to reduce pressure. Sighting

across the top of the 3/4-inch hex adjusting nut to the scale gives approximate set point

pressure.

After calibration is complete, reinstall the cover with new gaskets or o-rings as required by

the Maintenance instructions.

The Switching element has been positioned with a dial indicator to a

tolerance of

nothing to do with the set point adjustment. Any movement can either render

the switch inoperative or cause the switching element to be damaged with

overpressure.

±.002 inches. Do not move this switching element! Its position has

Adjusting Nut

Calibration Scale

Form 1472 (05.13) ©SOR Inc.

3/4

Page 4

RT Housing

Mounting Hardware

Cover Screws

Fasteners per SOR Test

Report 9058-102 consist of

two 1/4-20, Grade 5 screws

(not supplied). Torque screws

1/8 NPT(F)

Vent Connection

Conduit

Connection

to 70 to 85 in-lbs.

(7.9-9.6 N-m)

Maintenance

Body

Replace cover gasket (SOR

P/N 8923-181) whenever

cover is removed or minimum

Process Connection

(Pressure Port)

Mounting Holes

of once every 5 years,

whichever comes first. Remove the four cover screws. Remove old gasket. Place new

gasket between housing and cover. Line up holes in cover, gasket and housing. Insert the

4 screws and torque each to 7 to 10 in-lbs. (0.8-1.1 N-m)

Printed in USA sorinc.com

14685 West 105th Street, Lenexa, KS 66215 913-888-2630 800-676-6794 USA Fax 913-888-0767

4/4

Form 1472 (05.13) ©SOR Inc.

Loading...

Loading...