Page 1

SORtrax Level Transmitter

General Instructions

SORtrax is a 4-20 mA continuous level transmitter. It produces a

4-20mA current superimposed on the 12-55 VDC loop supply lines. The

4-20mA current is proportional to the level sensed by the instrument.

SORtrax detects level based on process admittance. Bench or field

calibration is easily accomplished. Coarse and fine adjustments are

provided to allow the user full control over the zero and span settings,

and to insure the most accurate operation possible. Recalibration is

needed each time the content of the process changes, due to the

different dielectric constant of each material.

NOTE: If you suspect that a product is defective, contact the factory or the

®

Representative in your area for a return authorization number (RMA).

SOR

This product should only be installed by trained and competent personnel.

670K9

Probe Installation

Probes are mounted vertically from the top of a vessel. The probe must

be electrically isolated from the vessel; make no connection between the

probe and the vessel other than the process connection and (if applicable) the threaded

weight at the probe tip.

Do not weld any part of this instrument.

Make sure that the sensor can be fully inserted and tightened without interference from

obstructions inside the tank or vessel. The probe should be mounted away from inlet

fill paths. Spray from a fill path may cause false level indications.

Table of Contents

Probe Installation ...............................1

Design and

specifications are

subject to change

without notice.

For latest revision, go to

www.sorinc.com

Electrical Connection ...........................2

Empty and Fill Calibration .....................4

Bench Calibration ...............................5

Blind Calibration ................................6

Probe and Transmitter Performance Veri cation

..7

CE Mark Installation ............................7

RF Probe Grounding Scheme .................8

Control Drawings ...............................9

Troubleshooting ............................... 12

Dimensions .................................... 13

Form 837 (05.13) ©SOR Inc.

Registered Quality System to ISO 9001

1/16

Page 2

For pressurized vessels, seal the flanged or

threaded process connection to prevent leakage.

Do not use the sensor base as a handle to

tighten the process connection.

Use suitable mounting bolts to mount a flanged

probe on a flanged process connection.

Proper grounding is imperative for correct

operation of the unit.

Sensor

Base Hub

Apply thread

sealant

Apply wrench

to metal hex

or wrench

flats only!

Customer

Ground Lead

(optional)

Circuit Board

Ground Lead

SORtrax

Housing

Ground Screw

Open Sump or Basin

Do not suspend the unit by rigid conduit

installed in the electrical hub. When installing

the unit over an open sump or basin, use a

suitable bracket to support the instrument.

Condensation build-up inside the electronics

housing may damage the sensitive circuitry.

To prevent the ingress of moisture, use drip

loops or conduit runs which slope down from

the enclosure. (See

)

The unit can be grounded two ways. If

the tank is metallic, grounding is provided

by the tank. If the tank is not metallic, or

does not adequately make contact with

the sensor, a separate ground wire must

be provided by the customer. Run ground

wiring through the conduit and into the

electronics housing. Attach the ground

wire per

Bracket

.

Electrical Connection

Ensure that wiring conforms to all applicable local and national electrical codes and install

unit(s) according to relevant national and local safety codes.

Electrical power must be disconnected from explosion proof models before

the cover is removed. Failure to do so could result in severe personal injury

or substantial property damage.

2/16

Form 837 (05.13) ©SOR Inc.

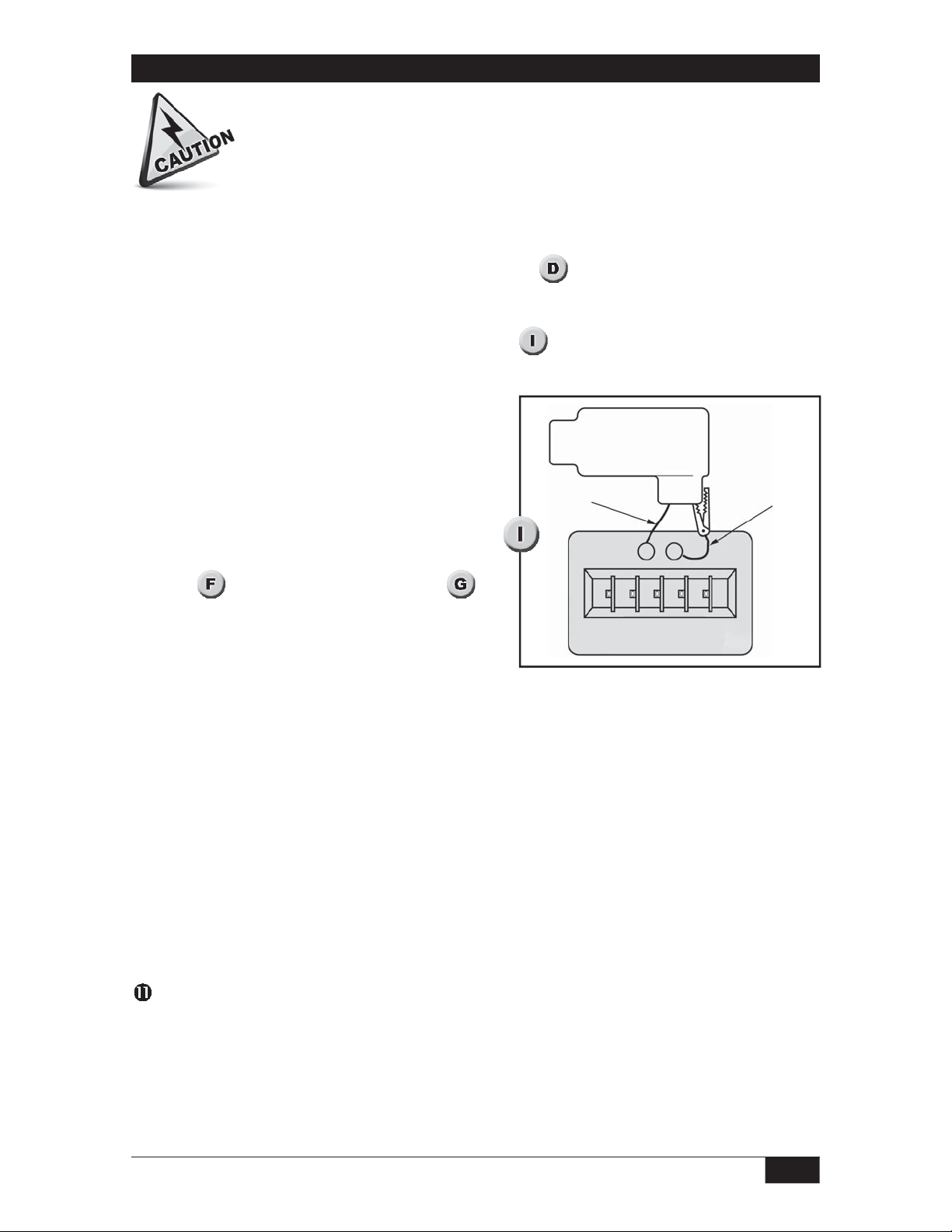

Page 3

This product must be installed with an explosion proof breather vent per

agency requirements and the Nationsl Electric Code - Article 501, Section F,

paragraph 3.

Use 18 - 22 AWG shielded twisted pair wire to make all signal and power connections.

Ensure that wiring conforms to all applicable local and national electrical codes and install

unit(s) according to relevant national and local safety codes.

Make sure the power source is

turned off.

Remove the housing cover.

Pull power and signal wire through

the conduit connection and into

the control housing.

Locate TB1 on the control board.

(See

) Terminals are labeled

Current Meter or Resistive

Load (optional)

+

+

-

DC Power

Supply

TB1 Loop Power

Terminal Block

+

Terminal

-

Terminal

Control

Board

“+” and “-”. Connect power leads

to the proper terminals.

Do not exceed the maximum loop resistance for the circuit. (See )

Use the following formula to determine the maximum loop resistance of your circuit:

R (ohms) = (input voltage - 12) ÷ 20.0 mA

Loop Resistance vs. Power Supply Voltage

2200

NOTE: Refer to the

individual device

speci cations of

user-supplied

equipment to

determine the

resistive load

(in ohms) and the

power requirements.

2100

2000

1900

1800

1700

1600

1500

1400

1300

1200

1100

1000

900

800

700

600

500

400

300

Maximum Loop Resistance (Ohms)

200

100

0

0 10 15 20 25 30 35 40 45 55

600 Ohms

at 24 VDC

1400 Ohms

at 40 VDC

1 Ohm

at 12 VDC

2150 Ohms

at 55 VDC

900 Ohms

at 30 VDC

-

Form 837 (05.13) ©SOR Inc.

Power Supply Voltage (Volts)

3/16

Page 4

Empty and FIll Calibration

Electrical power must be disconnected from explosion proof models before

the cover is removed. Failure to do so could result in severe personal injury

or substantial property damage.

Electrical power must be disconnected from explosion proof models before

the cover is removed. Failure to do so could result in severe personal injury

or substantial property damage.

Install and connect power to the unit per previous pages. Install a current meter to the

unit per

Turn both potentiometers

(fine adjustments for

ZERO and SPAN) fully

counterclockwise.

(See

Zero Adjustment (4 mA)

.

ZERO AND SPAN

ADJUSTMENTS

Fine

)

Coarse

ZERO

Coarse

Fine

SPAN

Close switch #1 on coarse adjustment switches for ZERO and SPAN. (See )

Open switches #2, #3, and #4 on both coarse adjustment switches per .

With the tank at 0%, view the reading on

the current meter. If the output is less

than 4 mA, turn the fine ZERO adjustment

clockwise until 4 mA is reached.

NOTE: Only one ZERO switch may be in the

closed position at any time.

If the output is greater than 4 mA, close the other switches one at a time (opening

Coarse

Adjustment

switch #1 in

the closed

position, other

switches open

the previous switch) until a reading less than 4 mA is attained. Turn the fine ZERO

adjustment clockwise until 4 mA is reached.

NOTE: If 4 mA cannot be obtained, see the troubleshooting chart on page 14.

Span Adjustment (20 mA)

Set the process to desired high level. (See )

Ensure SPAN coarse adjust switch #1 is in the closed position,

100%

with all other switches open.

Rotate the SPAN fine adjustment pot clockwise until the meter

indicates 20 mA. If a 20 mA reading cannot be obtained,

proceed to step 10.

Open SPAN switch #1 (coarse) and close SPAN switch #2.

Repeat step 9. If a 20 mA reading cannot be obtained, repeat

the procedure closing switch #3 or #4 until 20 mA is indicated.

4/16

Form 837 (05.13) ©SOR Inc.

0%

Page 5

Bench Calibration

Electrical power must be disconnected from explosion proof models before

the cover is removed. Failure to do so could result in severe personal injury

or substantial property damage.

Remove the sensor. (Unscrew the sensor from the housing. Disconnect the ring

terminal or banana plug from the sensor end.)

Connect power and a current meter to the unit per . Connect a capacitor

substitution box (available from SOR) to the circuit to simulate the probe. Connect the

probe lead to one terminal of the capacitor substitution box, and connect the other

terminal of the box to the control housing. (See

eliminate any stray capacitance which may affect the calibration.

Set the capacitance box to desired zero level

capacitance.

Rotate ZERO and SPAN fine adjustment

potentiometers (pots) at least 22 turns

counter-clockwise.

) Use short connection wires to

Capacitance

SORtrax

Probe Wire

Substitution

Connection

Ground Wire

Zero Adjustment (4 mA)

Close ZERO switch #1 and SPAN switch #1.

(See

View the reading on the current meter. If the

output is less than 4 mA, turn the fine ZERO

) Open all other switches per .

Capacitor

Substitution Box

adjustment clockwise until 4 mA is reached.

NOTE: Only one ZERO switch may be in the closed position at any time.

If the output is greater than 4 mA, (opening the previous switch) close each coarse

adjustment switch, one at a time, until a reading less than 4 mA is reached. Turn the

fine ZERO adjustment clockwise until 4 mA is reached.

NOTE: If 4 mA cannot be obtained, please see the trouble shooting chart on page 14.

Span Adjustment (20 mA)

Set the capacitance box to the desired maximum capacitance value.

Ensure SPAN coarse adjust switch #1 is in the closed position, with all other switches open.

Rotate the SPAN fine adjustment pot clockwise until the meter indicates 20 mA. If a 20

mA reading cannot be obtained, proceed to step 11.

Open SPAN switch #1 (coarse) and close SPAN switch #2. Repeat step 10. If a 20 mA

reading cannot be obtained, repeat the procedure closing switch #3 or #4 until 20 mA

is indicated.

NOTE: Only one SPAN switch may be in the closed position at any time.

NOTE: If 20 mA cannot be obtained, please see the troubleshooting chart on page 14.

If the zero setting is changed, the span will change, and the unit must be recalibrated.

Form 837 (05.13) ©SOR Inc.

5/16

Page 6

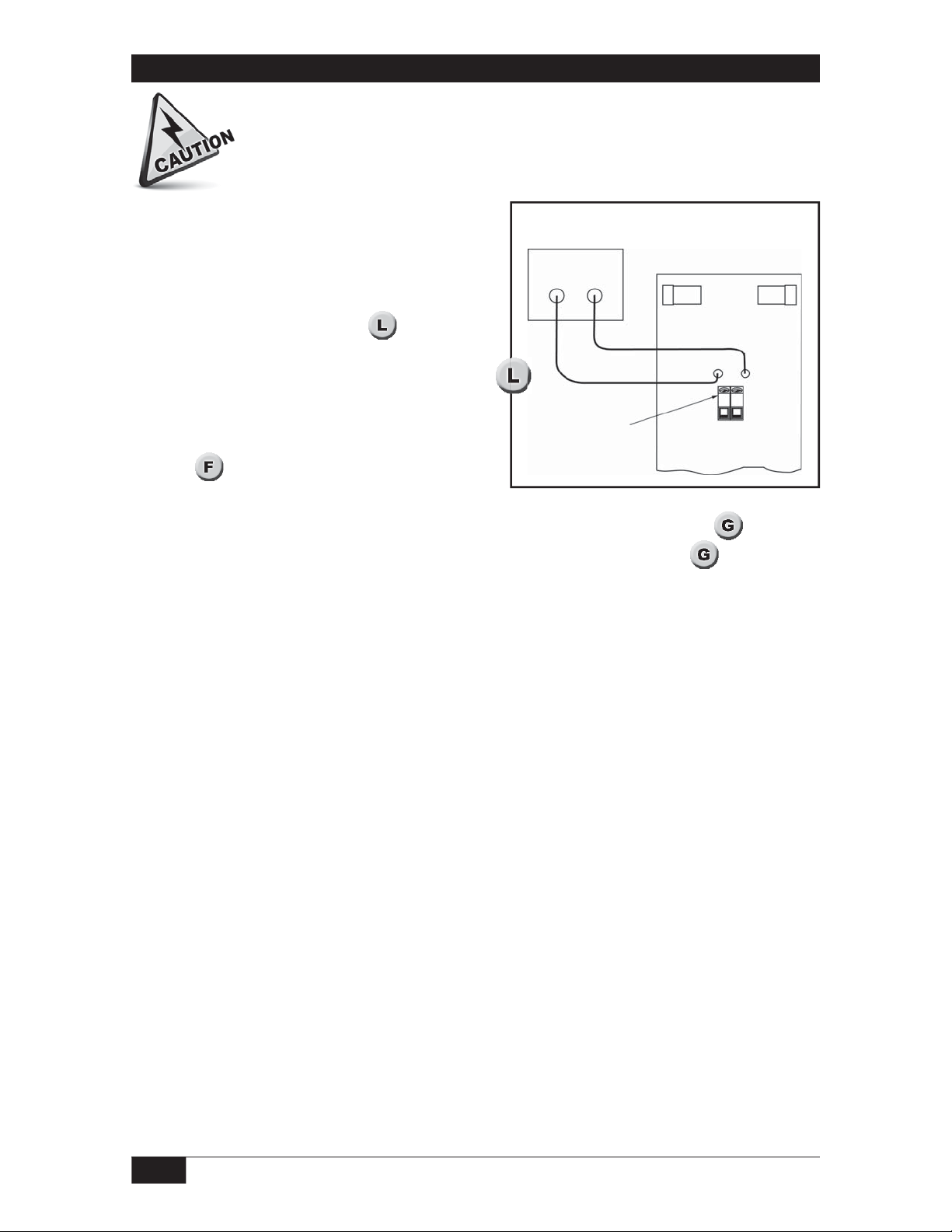

Blind Calibration

Electrical power must be disconnected from explosion proof models before

the cover is removed. Failure to do so could result in severe personal injury

or substantial property damage.

Use this calibration method when it is not possible

to raise or lower the level of the process in the

vessel or tank. Do not permanently install the unit

until after setting the ZERO (4 mA) point.

Current Meter

- +

M- and M+ optional

wiring diagram

Use the wiring configuration in when the

loop cannot be conveniently opened for current

monitoring. Attach a current meter as shown.

Turn both potentiometers (fine adjustments

for ZERO and SPAN) fully counterclockwise.

(See

)

TB1

Loop Power

Terminal Block

M- M+

Control

Board

Zero Adjustment (4 mA)

Close switch #1 on coarse adjustment switches for ZERO and SPAN. (See )

Open switches #2, #3, and #4 on both coarse adjustment switches per .

With the end of the probe just touching the process, view the output. If the output is

less than 4 mA, turn the fine ZERO adjustment clockwise until 4 mA is reached.

NOTE: Only one ZERO switch may be in the closed position at any time.

If the output is more than 4 mA, (opening the previous switch) close each coarse

adjustment switch individually until a reading less than 4 mA is attained. Turn the fine

ZERO adjustment clock-wise until 4 mA is reached.

NOTE: If 4 mA cannot be obtained, see the troubleshooting chart on page 14.

Span Adjustment (20 mA)

Calibrate for span by determining the present level in the tank, and setting the span

proportionally. For best results, the level should be at 50% or greater.

Determine the level present in the tank. Complete the unit installation, except for the

housing cover.

Calculate the expected current output using the following formula: 20mA x (% of tank

fill) 20mA = output.

For example: Tank level is at 50%, set SPAN coarse and fine for 20mA reading (16mA x

50% + 4mA, If the material level is at 90%, set the span adjustment for 18.4 mA (16mA

x 90% + 4mA, The 100% fill level should be verified at the earliest opportunity.

If the zero setting is changed, the span will change, and the unit must be recalibrated.

6/16

Form 837 (05.13) ©SOR Inc.

Page 7

Probe and Transmitter Performance Veri cation

Probe Check Remove the transmitter from the probe. With no process on the probe, check

the resistance from the probe to ground. Resistance less than 1MΩ indicates leakage in the

probe. With process touching the probe, check the resistance from the probe to ground.

Resistance of 100KΩ or less in the case of a bare probe with conductive material indicates

that an insulated probe is required. In any other case, a defect in the probe is indicated.

Transmitter Drift Check If the output of the transmitter is drifting, it is important to verify

if the drift is due to the probe or the transmitter. If the probe is connected and installed

properly, it will not drift.

Remove the probe from the transmitter. Without touching the calibration settings, connect

a capacitance across the probe to ground input. See Figure 9 on page 5. Change the

capacitance until the transmitter output is 4.00 mA. Observe the zero point reading for

twenty four hours. If the reading is stable, then the probe or the application is the source

of the drift.

CE Mark Installation

When subjected to an RF interference, the 670K9

will maintain the +/-1% accuracy in all frequency

ranges with the following exception:

The unit is susceptible to a conducted RF

interference in the range of 31-40MHz, reducing

the accuracy to +/-1.3%. The +/-1% accuracy is

maintained above and below this range.

In order to achieve the stated accuracy for 670K9,

a shielded cable, cable gland, shield beads, and

the probe should be mounted in a metallic vessel.

SOR recommends using a shielded cable made

of PVC insulation around a tinned copper braid

shield (Olflex CY cable or equivalent). Refer to

illustrations for installation of shield beads.

Install end of bead

as close to cable

gland as possible

2 Loops

POSITIVE

NEGATIVE

1 Loop

POWER WIRE

SHIELD BEAD

2 Loops

Long/Slender

bead

PROBE WIRE

SHIELD BEAD

Short/Fat bead

Form 837 (05.13) ©SOR Inc.

7/16

Page 8

SOR RF Probe Grounding Scheme

Power Supply

Do not provide separate earth grounding

for the process connection. This can

create a parallel grounding circuit

that will impair operation and calibration.

IMPORTANT! Do not

provide separate earth

grounding for the process

connection. This can create

a parallel grounding circuit

that will impair operation

and calibration.

SOR RF Probe Grounding Scheme

Critical Grounding Path =

Circuit

Board

Line

Neutral

Ground

Line

Neutral

Ground

Electronics

Housing

Connection

Process

SOR Supplied

Stilling Well

(optional)

Probe Center

Conductive Element

8/16

Form 837 (05.13) ©SOR Inc.

Page 9

Control Drawing

Form 837 (05.13) ©SOR Inc.

9/16

Page 10

Control Drawing

10/16

Form 837 (05.13) ©SOR Inc.

Page 11

Control Drawing

Form 837 (05.13) ©SOR Inc.

11/16

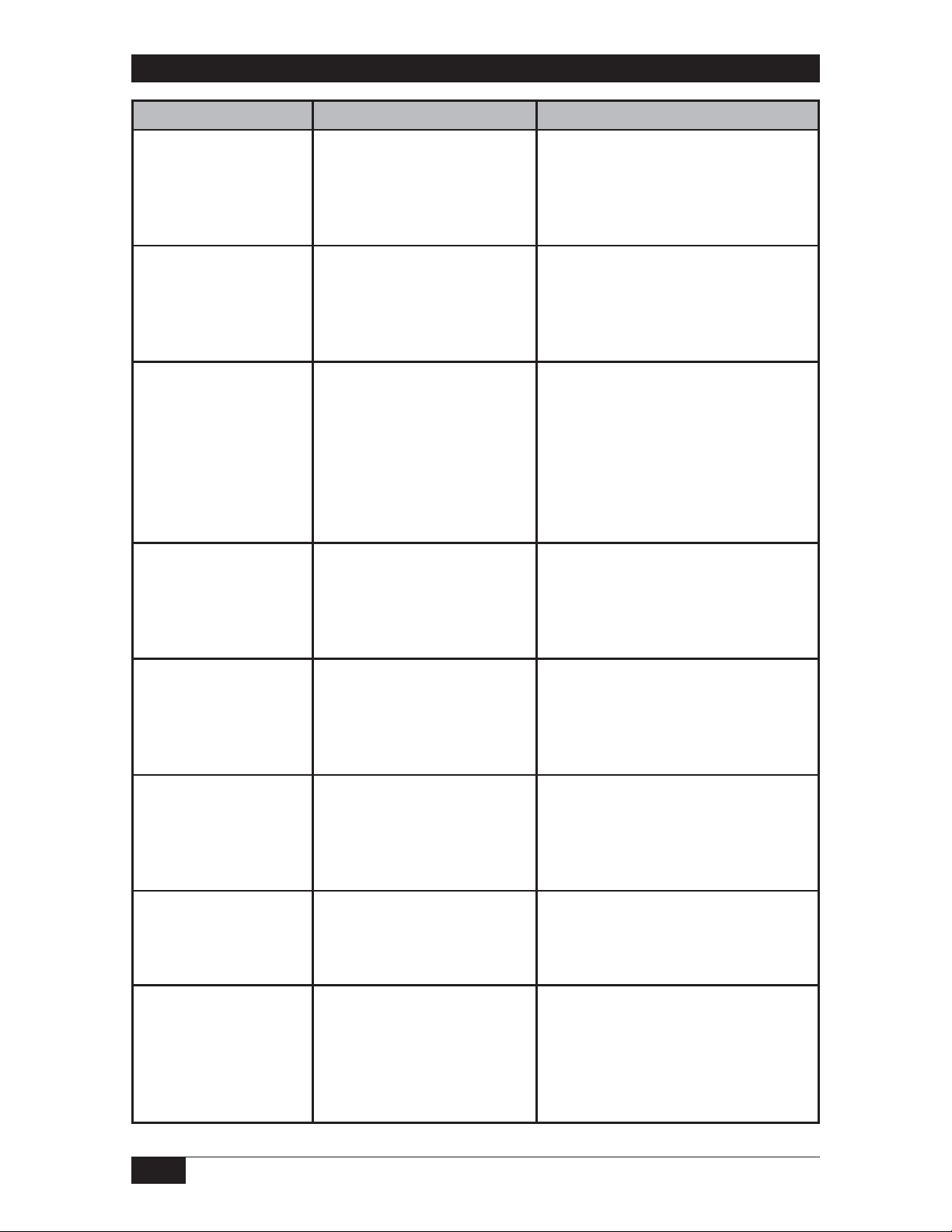

Page 12

Troubleshooting

Symptom/Problem Possible Cause Corrective Action

Not current in the loop 1. Power supply turned off

2. Improper wiring at TB1

3. Excessive loop resistance

Zero point cannot be

set to 4.00mA at low

level

Span point cannot be

increased to 20mA at

high level

Span point cannot be

decreased to 20mA at

high level

1. Fine zero incorrect

2. Probe capacitance greater

than 500pF when coarse

ZERO switch #4 is closed (all

other switches open)

1. Insufficient probe

capacitance

2. Excessive loop resistance

3. Incorrect calibration

1. Low probe resistance to

ground

2. Probe capacitance greater

than 2,000pF

1. Check power supply

2. Check electrical connections,

figure 4

3. Reduce loop resistance or adjust

power supply

1. Check calibration

2. Use smaller diameter probe or

replace bare probe w/insulated probe

or locate probe farther from the

vessel wall or consult the factory

1. Increase probe diameter or use

probe w/higher dielectric insulation

or locate probe closer to vessel wall

or install a stilling well or consult the

factory

2. Reduce loop resistance or adjust

power supply

3. Check calibration

1. Consult the factory

2. Use a smaller diameter probe or

replace bare probe w/insulated probe

or locate the probe farther from the

vessel wall

Transmitter output is

20mA or greater when

the vessel is not full

Erratic transmitter

output

Drifting transmitter

output

Non-linear output 1. Extreme material build-up

1. Incorrect calibration

2. Probe shorted to ground

3. Material build-up on probe

1. Turbulent process

2. Radio frequency

interference

3. Probe moving within the

vessel

1. Process material

properties are changing

2. Probe insulation is eroded

3. Transmitter malfunction

2. Non-parallel surfaces near

the probe

3. Conducting liquid in an

ungrounded vessel, eg:

fiberglass tank

1. Recalibrate

2. Replace the probe

3. Clean probe and replace or

possible misapplication, consult

the factory

1. Install a stilling well

2. Install RFI/EMI filters

3. Improve probe anchoring

1. Consult the factory

2. Verify probe integrity

3. Consult the factory

1. Consult the factory

2. Mount the probe in a better

location or install a stilling well, or

install a probe with a ground rod

3. Connect earth ground to

instrument ground

12/16

Form 837 (05.13) ©SOR Inc.

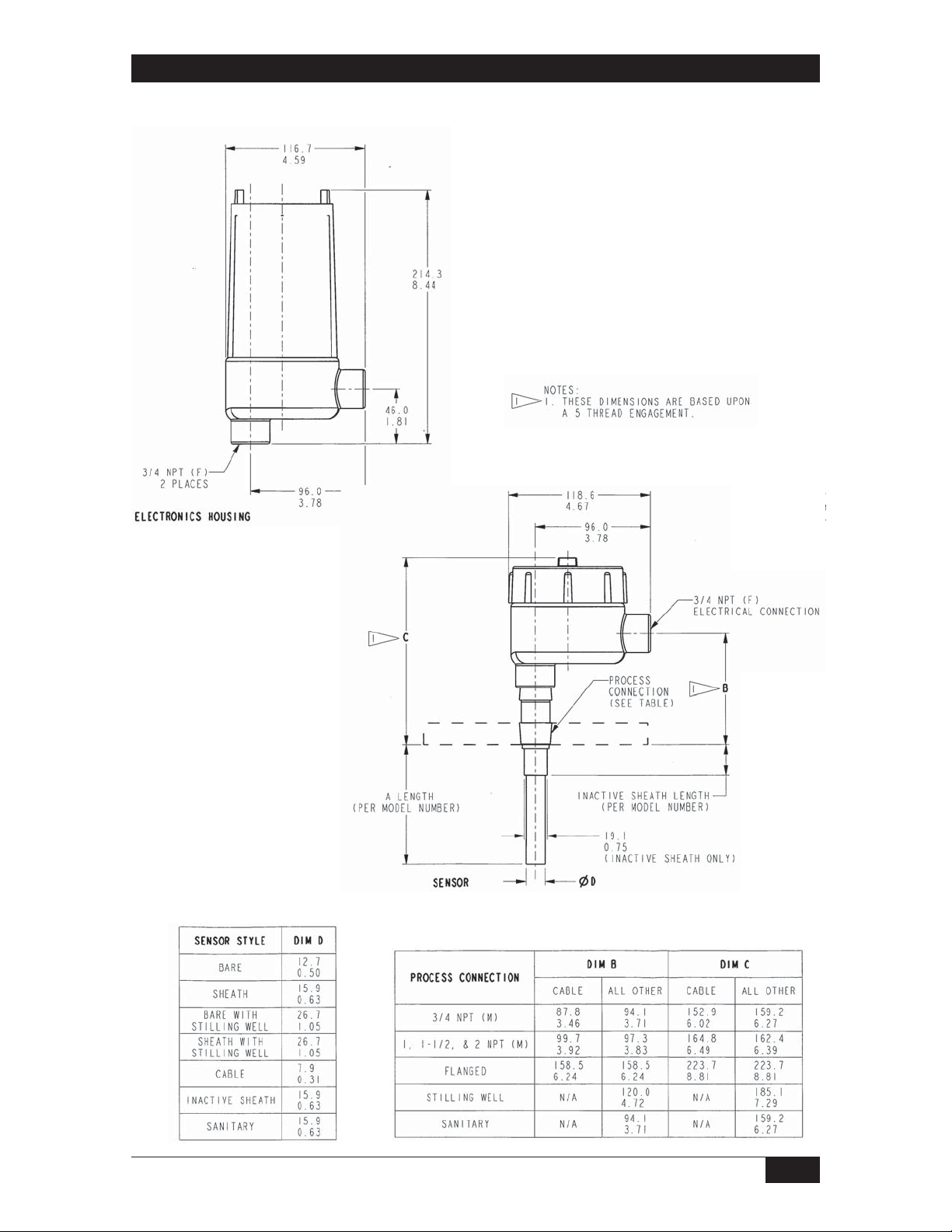

Page 13

Dimensions

R Housing Con guration (Explosion Proof Remote)

Dimensions are for

reference only.

Contact the factory

for certified drawings

for a particular model

number.

Linear = mm/inches

Drawing 0390653

Form 837 (05.13) ©SOR Inc.

13/16

Page 14

Dimensions

K Housing Con guration (Explosion Proof Remote)

Dimensions are for reference only.

Contact the factory

for certified drawings

for a particular model number.

Linear = mm/inches

Drawing 0390654

14/16

Form 837 (05.13) ©SOR Inc.

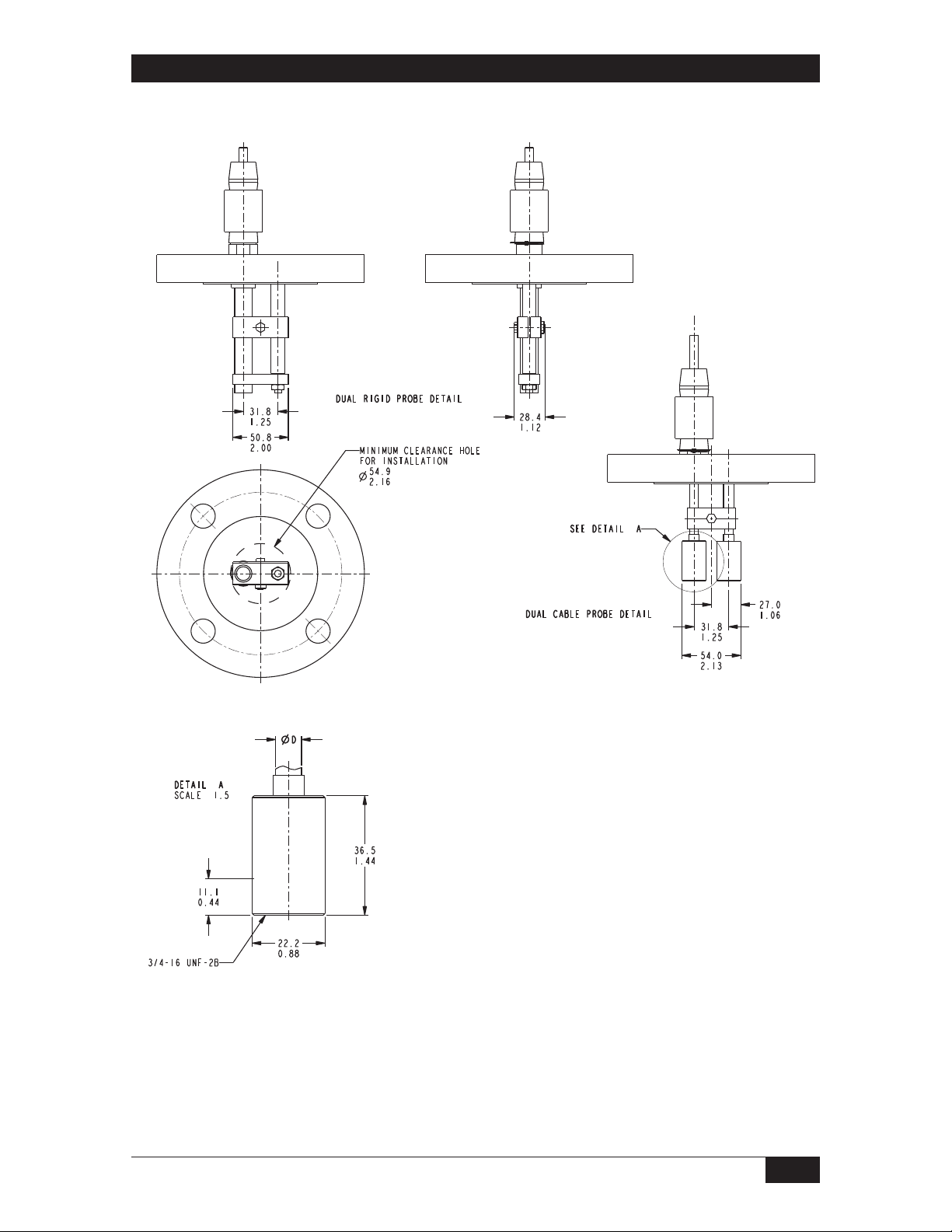

Page 15

Dimensions

Other Sensors

Form 837 (05.13) ©SOR Inc.

Dimensions are for reference only.

Contact the factory for certified drawings

for a particular model number.

Linear = mm/inches

Drawing 0390654

15/16

Page 16

Printed in USA www.sorinc.com

14685 West 105th Street, Lenexa, KS 66215 913-888-2630 800-676-6794 USA Fax 913-888-0767

16/16

Registered Quality System to ISO 9001

Form 837 (05.13) ©SOR Inc.

Loading...

Loading...