Page 1

Opposed Piston

Differential Pressure Switches

General Instructions

These instructions provide information for installation, electrical connection, process

®

connection and calibration of SOR

NOTE: If you suspect that a product is defective, contact the factory or the

SOR Representative in your area for a return authorization number (RMA).

This product should only be installed by trained and competent personnel.

Principles of Operation

Opposed Piston Differential Pressure Switches.

A = Hi Pressure Piston

B = Lo Pressure Piston

Fh = Force, Hi Pressure

Fl = Force, Lo Pressure

Fs = Force, Range Spring

Fd = Force Resultant Differential (Hi–Lo)

Basic construction is opposing diaphragm sealed pistons connected by a common shaft. Hi

side system pressure acts on Piston A to produce force Fh. It is counteracted by adjustable

range spring force Fs. Lo side system pressure acts on Piston B to produce force Fl. The

resultant force corresponds to the difference in pressure between the Hi and Lo system

pressures plus the force of the adjustable range spring, and moves the trip lever to actuate

and deactuate the SPDT electrical switching element.

Table of Contents

Design and

specifications are

subject to change

without notice.

For latest revision, go to

www.sorinc.com

Principles of Operation ....................... 1

Installation ...................................... 2

SIL Installation ................................. 2

Process Connection ........................... 3

Electrical Connection .......................... 3

Calibration ...................................... 3

Dimensions ..................................... 4

ATEX Marking Information ................... 10

Declaration of Conformity ................... 11

Form 279 (02.13) ©SOR Inc.

Registered Quality System to ISO 9001

1/12

Page 2

There are only three wetted parts on the Hi and Lo process connections: pressure port,

diaphragm and o-ring. A metal diaphragm may be welded to the pressure port for certain

applications, thereby eliminating the o-ring.

This force-balance system virtually eliminates friction and resultant wear while yielding

excellent repeatability.

These differential pressure switches are well suited for a variety of process applications.

They are not intended for high pressure, fluid power (hydraulic) applications where high

shock pressures and high cycle rates are expected.

Installation

This type of differential pressure switch can be installed in any position.

If a breather drain is installed, the device should be mounted with the

breather drain pointing downward (6 o’clock) so condensation will drain

from the housing.

WEATHERTIGHT HOUSING

Attach the device to a suitable surface or pipe stanchion bracket with two 1/4-inch diameter

bolts. Line mounting by either process or electrical connection is not recommended.

EXPLOSION PROOF HOUSING

Attach the device to a suitable surface or pipe stanchion bracket with two 1/4-inch diameter

bolts. The TA housing must be attached with 2-inch U-bolts over the housing hubs or

two 1/4 in. diameter bolts. Line mounting by either process or electrical connection is not

recommended.

NOTE: When mounting to an irregular or uneven surface, install rubber washers on the bolts

between the housing and the mounting surface to prevent housing deformation.

Failure to mount the housing on a at mounting surface may result in

torsional forces on the housing that could cause false trips or render the

pressure switch inoperative.

Safety Integrity Level (SIL) Installation Requirements

The SOR pressure switches have been evaluated as Type-A safety related hardware.

To meet the necessary installation requirements for the SIL system, the following

information must be utilized:

Proof Test Interval shall be one year.

Units may only be installed for use in Low Demand Mode.

Products have a HFT (Hardware Fault Tolerance) of 0, and were evaluated in a

1oo1 (one out of one) configuration.

2/12

Form 1538 (03.12) ©2012 SOR Inc.

Form 279 (02.13) ©SOR Inc.

Page 3

Process Connection

Pressure ports are marked Hi and Lo to indicate the high and low process pressure connections. Connect process piping accordingly. Use two wrenches-one to hold the hex pressure

port to prevent it from moving, the other to tighten the process pipe or tube fitting.

Care should be taken not to loosen the pressure port from the body or the

body from the housing.

Electrical Connection

Ensure that wiring conforms to all applicable local and national electrical codes and install

unit(s) according to relevant national and local safety codes.

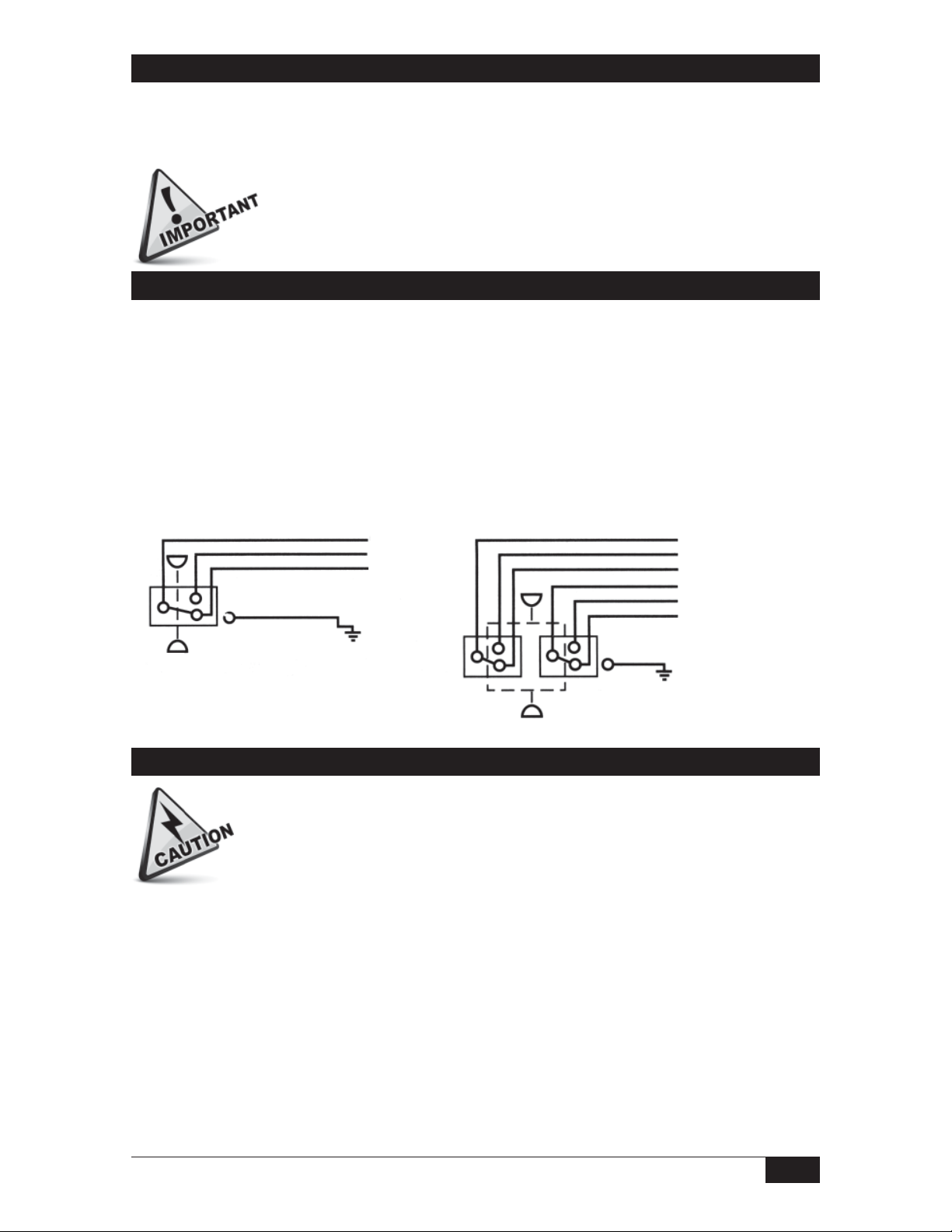

SOR Opposed Piston Differential Pressure Switches in RB and RH housings have terminal

blocks as standard. All other Opposed Piston Differential Pressure Switches have 18-inch

18 AWG color-coded wire leads. Storing excess wire or making wire lead splices inside the

switch housing will interfere with switch operation.

SPDT

Lo

Differential Pressure

Hi

Blue (C)

Black (NO)

Red (NC)

Green (GND)

No.1

2-SPDT

Lo

No.2

Differential Pressure

Hi

Blue (C)

Black (NO)

Red (NC)

Yellow (C2)

Brown (NO2)

Orange (NC2)

Green (GND)

Calibration

Units in Hazardous Locations – Prior to calibration, make sure that the work

area is declassi ed before removing the explosion proof cover to calibrate

the unit. Failure to do so could result in severe personal injury or substantial

property damage.

Remove housing cover. First, calibrate the device as a gauge pressure switch, i.e. Lo

side vented to atmosphere. Turn the set point adjusting nut located on the Hi side piston

clockwise to increase the set point, or counterclockwise to decrease the set point.

Calibrate to simulated system operating pressure conditions for optimum performance,

i.e.: connect Hi and Lo sides to suitable pressure sources and raise pressures

simultaneously to expected system operating pressure at desired set point. Vary Lo

side pressure and fine tune the set point adjustment for actuation (deactuation) of the

electrical switching element on increasing or decreasing differential pressure at

simulated system operating pressure.

Replace the cover.

Form 279 (02.13) ©SOR Inc.

3/12

Page 4

Dimensions

Weathertight-NEMA 4, 4X, IP65

Linear = mm/inches

Drawing 0090262

Housing Designator: RB, RH, RE

Piston Number: 18

Dimensions are for reference only. Contact the factory for certified drawings for a particular model number.

Conventional Explosion Proof

Linear = mm/inches

Drawing 0090152

Housing Designator: S

Piston Number: 18

4/12

Form 279 (02.13) ©SOR Inc.

Page 5

G

O

W

7

7

9

A

1

Z

Weathertight-NEMA 4, 4X, IP65

Linear = mm/inches

Drawing 0090265

*230.6

9.08

Housing Designator: RB, RH, RE

107.3

4.22

52.0

2.05

69.9

2.75

33.3

1.31

A

CLEARANCE SLOTS

FOR

*57.4

2.26

A

1/4 OR 1/2 NPTM

PROCESS CONNECTION

OPTIONAL: HI, LO, OR BOTH

WITH

TO

MOUNTING CENTERS

76.2

3.00

6.4

0.25

63.5

2.50

MAX

PROCESS

CONNECTION

ELECTRICAL

CONNECTION

SEE CHART

HARDWARE

MIN

CONNECTION

LO

PROCESS

65.6

2.58

28.6

1.12

26.2

1.03

HI

Piston Number: 15, 17

DETAIL 1 NPTM

PROCESS CONNECTION

SCALE 0.38

40.5

1.59

PROCESS

* LEN

1/4 NPTM

1/2 NPTM

1 NPTM4ADD

LENGTH A

1/4 NPTM

SHOWN

1/2 NPTM

PER P

SHO

1

29.

1.1

38.

7.1

0.28

CONN SIZE

Dimensions are for reference only. Contact the factory for certified drawings for a particular model number.

Conventional Explosion Proof

Linear = mm/inches

Drawing 0090151

142.3

5.60

*230.6

9.08

*115.3

4.54

*74.9

2.95

A

1/4 OR 1/2 NPTM

PROCESS CONNECTION

OPTIONAL: HI, LO OR BOTH

Form 279 (02.13) ©SOR Inc.

71.1

2.80

OR PLUGGED OPT

40.4

1.59

TYP

7.9

4X

0.31

MOUNTING

HOLES

ELECTRICAL

CONNECTION

3/4 NPTF STD

1/2 NPTF OPT

2 PLACES

80.8

3.18

TYP

CONNECTION

PROCESS

CONNECTION

PROCESS

HI

79.4

3.12

LO

20.6

0.81

Housing Designator: S

Piston Number: 15, 17

6.7

0.26

322.3

12.69

161.1

6.34

120.7

4.75

PROCESS CONNECTION

6.4

0.25

PROCESS

CONN SIZE

1/4 NPTM

1/2 NPTM

1 NPTM

1/4 NPTM

SHOWN

1/2 NPTM

LENGTH A

* LENGTH

SHOWN

46.0

ADD

1.81

29.7

1.17

38.9

14685 W 105TH ST LENEXA, KS 66215 US

ISO-9001

PRODUCT CERTIFICATION DRAWING

ALL DIMENSIONS ARE ±1/16 IN

UNLESS OTHERWISE SPECIFIED

LINEAR =

THIS DRAWING IS THE EXCLUSIVE PROPERTY OF SOR.

NO USE WHATSOEVER OF THE INFORMATION CONTAINED

HEREON, NOR REPRODUCTION IN WHOLE OR PART MAY BE

MADE WITHOUT THE EXPRESS WRITTEN PERMISSION OF SOR.

TITLE

DIM DWG 15 & 17 S DP

EO NUMBER: 5090

SCALE: 0.75

DETAIL

1 NPTM

SCALE 0.38

913-888-2630

SORINC.COM

DRAWN BY

K MITCHELL

CHECKED BY

M SMITH

MM

IN

ENGINEER APPROVAL

S BOAL

DATE

28 MAR 201

DRAWING NUMBER REV

0090151 6

SHEET 1 OF 1

5/12

DWG SI

Page 6

Weathertight-NEMA 4, 4X, IP65

N

S

Z

D

L

N

O

R

D

S

&

M

R

N

4

2

4

Linear = mm/inches

Drawing 0090263

225.3

8.87

*54.7

2.15

A

107.3

4.22

69.9

2.75

33.3

1.31

52.0

2.05

CONNECTION

ELECTRICAL

CONNECTION

SEE CHART

CLEARANCE SLOTS

6.4

FOR

HARDWARE

0.25

63.5

WITH

MIN

2.5

76.2

TO

MAX

3.00

MOUNTING HOLES

1/4 OR 1/2 NPTM

PROCESS CONNECTION

OPTIONAL: HI, LO OR BOTH

PROCESS

LO

CONNECTION

Housing Designator: RB, RH, RE

Piston Number: 13, 14, 16

64.9

2.56

28.6

1.12

26.2

1.03

40.5

1.59

7.1

0.28

CON

1

PROCESS

HI

PROCES

CONN SI

1

Dimensions are for reference only. Contact the factory for certified drawings for a particular model number.

Conventional Explosion Proof

Linear = mm/inches

Drawing 0090150

*225.3

8.87

*112.6

4.43

*72.2

2.84

142.3

5.60

71.1

2.80

80.8

3.18

TYP

40.4

1.59

TYP

4X

MOUNTING

HOLES

7.9

0.31

PROCESS

CONNECTION

Housing Designator: S

Piston Number: 13, 14, 16

79.4

3.12

20.6

LO

0.81

2X ELECTRICAL

CONNECTION

3/4 NPTF STD

1/2 NPTF OPT

OR PLUGGED OPT

6.4

0.25

P

CO

1/

1/

3/

PRO

AL

U

6/12

A

1/4 OR 1/2 NPTM

PROCESS CONNECTION

OPTIONAL: HI, LO OR BOTH

PROCESS

CONNECTION

HI

Form 279 (02.13) ©SOR Inc.

TITLE

DIMEN

13, 14

EO NU

N

HE

MA

Page 7

Conventional Explosion Proof

Linear = mm/inches

Drawing 0090109

*240.2

9.46

*121.7

4.79

*67.7

2.67

A

108.0

4.25

(TYP)

147.1

5.79

73.7

2.90

54.0

2.13

(TYP)

HOLE (TYP 4)

1/4 OR 1/2 NPT

MALE PROCESS CONNECTION

(OPTIONAL: HI, LO OR BOTH)

MOUNTING

7.1

0.28

PROCESS

CONNECTION

(LOW)

ELECTRICAL

CONNECTION

3/4 NPT(F)(STD)

1/2 NPT(OPT)

OR PLUGGED(OPT)

(TYP 2)

PROCESS

CONNECTION

(HIGH)

Housing Designator: SC

Piston Number: 18

119.6

4.71

34.0

1.34

8.7

0.34

LENGTH A

1/4 NPT(M) = (SHOWN)

1/2 NPT(M) =

13.2

0.52

29.7

1.17

38.9

1.53

Dimensions are for reference only. Contact the factory for certified drawings for a particular model number.

Conventional Explosion Proof

Linear = mm/inches

Drawing 0090248

Housing Designator: TA

Piston Number: 18

Form 279 (02.13) ©SOR Inc.

7/12

Page 8

Conventional Explosion Proof

Linear = mm/inches

Drawing 0090111

*240.2

9.46

*121.7

4.79

*67.7

2.67

Housing Designator: SC

142.9

5.63

108.0

4.25

(TYP)

A

71.4

2.81

54.0

2.13

(TYP)

7.1

0.28

HOLE (TYP 4)

1/4 OR 1/2 NPT

MALE PROCESS CONNECTION

(OPTIONAL: HI, LO OR BOTH)

3/4 NPT(F)(STD)

1/2 NPT(F)(OPT)

OR PLUGGED(OPT)

MOUNTING

PROCESS

CONNECTION

(LOW)

ELECTRICAL

CONNECTION

(TYP 2)

CONNECTION

Piston Number: 15, 17

106.4

4.19

34.0

1.34

8.7

0.34

PROCESS

(HIGH)

LENGTH A

1/4 NPT(M) = (SHOWN)

1/2 NPT(M) =

29.7

1.17

38.9

1.53

Dimensions are for reference only. Contact the factory for certified drawings for a particular model number.

Conventional Explosion Proof

Linear = mm/inches

Drawing 0090157

Housing Designator: TA

Piston Number: 15, 17

8/12

Form 279 (02.13) ©SOR Inc.

Page 9

Conventional Explosion Proof

Linear = mm/inches

Drawing 0090112

LENGTH A

1/4 NPT(M) = (SHOWN)

1/2 NPT(M) =

29.7

1.17

38.9

1.53

*234.8

9.24

*119.0

4.68

*65.0

2.56

Housing Designator: SC

142.9

5.63

108.0

4.25

(TYP)

A

71.4

2.81

54.0

2.13

(TYP)

HOLE (TYP 4)

1/4 OR 1/2 NPT

MALE PROCESS CONNECTION

(OPTIONAL: HI, LO OR BOTH)

MOUNTING

7.1

0.28

CONNECTION

ELECTRICAL

CONNECTION

3/4 NPT(F)(STD)

1/2 NPT(F)(OPT)

OR PLUGGED(OPT)

Piston Number: 13, 14, 16

106.4

4.19

34.0

PROCESS

(LOW)

(TYP 2)

PROCESS

CONNECTION

(HIGH)

1.34

8.7

0.34

Dimensions are for reference only. Contact the factory for certified drawings for a particular model number.

Conventional Explosion Proof

Linear = mm/inches

Drawing 0090156

Housing Designator: TA

Piston Number: 13, 14, 16

Form 279 (02.13) ©SOR Inc.

9/12

Page 10

ATEX Marking Information

Sample Nameplate

Manufacturer’s

Registered

Drawing 072004x

ATEX Listing

Information

Trademark

Serial Number

Product

Model

Identification

NOTE: The unit conforms to the requirements of clause 6.3.12, EN 60079-11: 2007. The unit

is capable of withstanding a 500 Vrms isolation test between circuit and enclosure.

Numbers Indicate

Year of Manufacture)

(First Two

10/12

Form 279 (02.13) ©SOR Inc.

Page 11

Declaration of Conformity

R Series Pressure Switches

SOR Inc.

14685 West 105

th

Street

Lenexa, Kansas 66215-2003

United States of America

November 12, 2012

ATEX Directive (94/9/EC) Equipment Intended for use

in Potentially Explosive Atmospheres

EN 60079-0: 2009

EN 60079-11: 2007

II 2 G Ex ia IIC T6...T4 Gb

T6

(-40°CTa 75°C)

T5

(-40°CTa 90°C)

T4

(-40°CTa 125°C)

EC-Type Examination Certificate

Baseefa11ATEX0125

Issued February 16, 2012

Baseefa Ltd. (Notified Body No. 1180)

Rockhead Business Park, Staden Lane,

Buxton, Derbyshire SK17 9RZ

United Kingdom

Baseefa Customer Reference No. 1021

John J. Fortino (VP of Engineering)

Form 1539 (11.12) SOR Inc.

Product

Manufacturer

Date of Issue

We declare that the above

products conform to

the following specifications

and directives

Carries the marking

Reference document

ATEX Notified Body

Person responsible

John J. Fortino

EC Declaration

of Conformity

14685 West 105th Street, Lenexa, KS 66215-2003

s53!s&!8

Engineered to Order with Off-the-Shelf Speed

For ATEX Certi ed Models

Form 279 (02.13) ©SOR Inc.

11/12

Page 12

Printed in USA sorinc.com

14685 West 105th Street, Lenexa, KS 66215 913-888-2630 800-676-6794 USA Fax 913-888-0767

12/12

Registered Quality System to ISO 9001

Form 279 (02.13) ©SOR Inc.

Loading...

Loading...