Page 1

Pressure Switches for

connection

.

Fire Protective Signaling

General Instructions

These instructions cover installation, process connection, electrical connection

®

and calibration of the SOR

with Hermetically Sealed Electrical Switching Elements

The static-o-ring type Pressure Switch is suitable for a wide variety

of process applications.

NOTE: If you suspect that a product is defective, contact the factory

or the SOR Representative in your area for a return authorization

number (RMA).

Pressure Switches for Fire Protective Signaling

.

ignaling

Installation

This product should only be installed by trained and competent personnel.

The pressure switch may be line mounted to either rigid process piping or

electrical conduit. The body of the pressure switch should be clamped in

the area between the set point adjustment protrusion and the pressure

port to a suitable member on applications when rigid process piping or

electrical conduit is not available.

rsonnel

iping or

ped in

sure

Process Connection

Use two wrenches when connecting process pipe: an 1-1/8 inch open-end wrench to hold

the hex port while connecting the process pipe; the other wrench to tighten the process

pipe or tube fitting.

When rigid process piping is used, it is important that no bending or torsional

forces be imposed on the pressure switch.

Design and specifications are subject to change without notice.

For latest revision, go to sorinc.com

Form 1296 (05.13) ©SOR Inc.

Registered Quality System to ISO 9001

1/4

Page 2

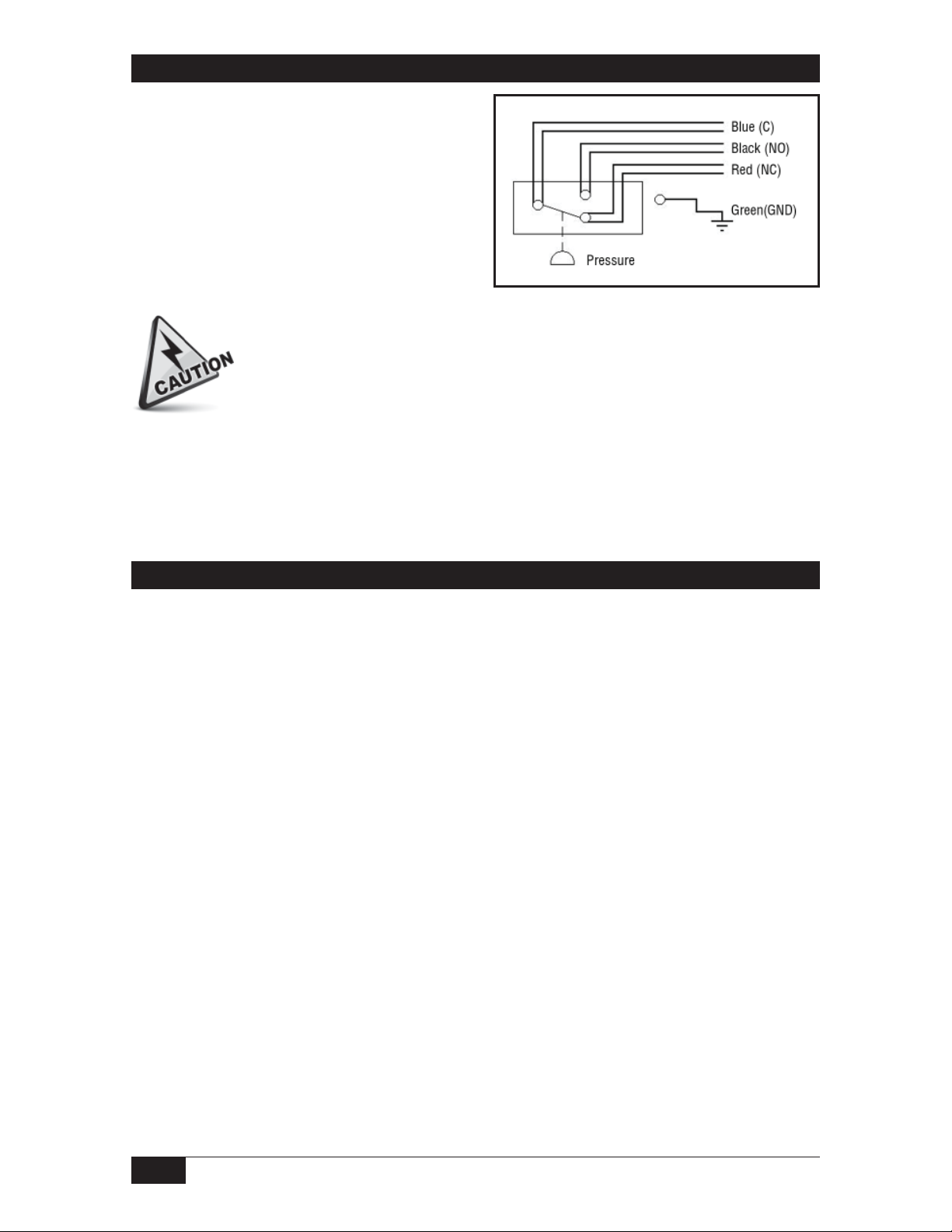

Electrical Connection

Ensure that wiring conforms to all applicable

local and national electrical codes and install

unit(s) according to relevant national and local

safety codes.

Use an 1-1/8 inch open-end wrench to hold

the hex on the electrical connection while

conduit or conduit fitting is being tightened.

Do not use a pipe wrench or strap wrench on the round body nor an open-end

wrench on the hex pressure port while tightening the conduit connection,

because the hermetically sealed switching element capsule has been precisely

positioned and locked during manufacture. Excessive force could overcome the

lock and cause movement which will adversely affect operation or render the

pressure switch inoperative. Should movement occur, factory calibration must

be performed in order to restore normal operation.

Electrical leads are in duplicate for wiring supervision and are marked NC (Normally Closed),

NO (Normally Open) and C (Common).

Calibration

The Pressure Switches are field adjustable across the entire cataloged range for a particular

piston/spring combination. Field adjustable models have a set point adjustment under the

removable weathertight cap.

It is not necessary to disconnect the electrical power, since the electrical switching element is

inside the hermetically sealed, explosion-proof capsule, thereby maintaining explosion-proof

integrity.

Remove the knurled weathertight cap.

Use an 1/8 inch hex (Allen type) wrench to turn the adjusting screw to achieve the

desired set point. Turn the adjusting screw clockwise (in) to increase set point; turn the

adjusting screw counterclockwise (out) to decrease set point. Use an external pressure

measuring device to accurately calibrate set points.

After the set point has been calibrated, replace the weathertight sealing cap tightly to

ensure the weathertight integrity of the device.

SOR discourages field modifications, change-out of wetted parts or repair. It is recommended

that products be returned to SOR for inspection and necessary repair work. Any field work

should be performed by a qualified instrument technician with formal SOR procedures.

2/4

Form 1296 (05.13) ©SOR Inc.

Page 3

Dimensions

*156.6

6.17

76.2

3.00

INSTALLATION

CLEARANCE MIN

FACTORY SEALED LEADS

COLOR CODED & MARKED

457.2

MIN LENGTH

18.00

ELECT CONN

1/2 NPTM

28.7

HEX

1.13

WEATHERTIGHT

COVER SCREW

FLEXIBLE SEAL

RETAINER

EXTERNAL GROUND

BG, BH, & JH HOUSING

** HEX

Linear = mm/inches

Drawing 0090119

PROCESS

CONN SIZE

1/4 NPTF SHOWN

1/2 NPTF

9/16 SAE SHOWN

3/4 NPTM

* LENGTH

ADD

ADD

1,5,6,9

13.2

0.52

23.1

0.91

34.9

1.38

** HEX

** HEX

PROCESS

CONNECTION

Dimensions are for reference only.

Contact the factory for certified drawings

for a particular model number.

* LENGTH

2,3

14.0

ADD

0.55

24.1

ADD

0.95

14.0

ADD

0.55

N/A N/A

* LENGTH

56

18.3

ADD

0.72

N/A

** HEX

1,5,6,9,56

28.7

1.13

** HEX

2,3

28.7

1.13

38.1

1.50

28.7

1.13

Form 1296 (05.13) ©SOR Inc.

3/4

Page 4

Ordering Information

Part

Number

9013-297

9013-298 125V (1A) 30V (1A)

9013-299

9013-300 125V (1A) 30V (1A)

9013-301

9013-302 125V (1A) 30V (1A)

9013-303

9013-304 125V (1A) 30V (1A)

Adjustable

Range psi

500 - 4000 5000

200 - 1750

100 - 500

25 - 240 1500 2500

Overrange

psi

2500

Proof

6000

psi

AC Rating DC Rating

250V (11A) 125V (0.5A), 30V (5A)

250V (11A) 125V (0.5A), 30V (5A)

250V (11A) 125V (0.5A), 30V (5A)

250V (11A) 125V (0.5A), 30V (5A)

Electrical Rating

Printed in USA sorinc.com

14685 West 105th Street, Lenexa, KS 66215 913-888-2630 800-676-6794 USA Fax 913-888-0767

4/4

Registered Quality System to ISO 9001

Form 1296 (05.13) ©SOR Inc.

Loading...

Loading...