Page 1

107

tallation, electrical connection, p

oes

Pressure Switches.

m

to

at actuates

nt. Low

ge spring

accomplished by

oint adjustment screw.

, contact the

for a retur

n

d only be

Differential Pressure Switch

General Instructions

These instructions provide information for installation, electrical connection, process

connection and calibration of 107 Differential Pressure Switches.

NOTE: If you suspect that a product is defective, contact the

®

factory or the SOR

authorization number (RMA). This product should only be

installed by trained and competent personnel.

Principle of Operation

Process pressure is sensed by a diaphragm

and piston assembly. The piston responds to

differential pressure and moves a shaft that actuates

(deactuates) an electrical switching element. Low

side pressure and a wetted adjustable range spring

oppose high side pressure. Calibration is accomplished by

adjusting the range spring with the set point adjustment screw.

Representative in your area for a return

107EL

Application

The 107 Differential Pressure Switch is suited for draft range service as well as industrial air and

gas services which are compatible with the wetted parts and within nameplate specifications.

Contact the SOR representative in your area or the factory in Lenexa, Kansas for details.

Use care during installation not to inadvertently move the electrical switching

element or its housing. Movement of either could disturb the relative positions of

internal working parts and alter calibration or render the device inoperative.

Installation

The 107 is position sensitive. Mount the 107 so that the diaphragm is vertical (as shown

above). Non-vertical mounting positions will cause calibration scale error.

If condensation is expected within process piping, pressure ports should be located at 6

o’clock to prevent moisture accumulation within the instrument. If condensation is not

expected, the pressure ports can be positioned to any location as long as the diaphragm

remains vertical.

Securely mount the base plate bracket to flat surface using suitable bolts.

Design and specifications are subject to change without notice.

Form 492 (11.13) ©SOR Inc.

For latest revision, go to sorinc.com

Registered Quality System to ISO 9001

1/4

Page 2

Safety Integrity Level (SIL) Installation Requirements

The SOR pressure switches have been evaluated as Type-A safety related hardware.

To meet the necessary installation requirements for the SIL system, the following

information must be utilized:

Proof Test Interval shall be one year.

Units may only be installed for use in Low Demand Mode.

Products have a HFT (Hardware Fault Tolerance) of 0, and were evaluated in a

1oo1 (one out of one) configuration.

Form 1538 (03.12) ©2012 SOR Inc.

Process Connection

The high-pressure side (marked HIGH) and the low pressure

side (marked LOW) have 1/8” NPT(F) process connections

unless 1/4” NPT(F) adapters were specified.

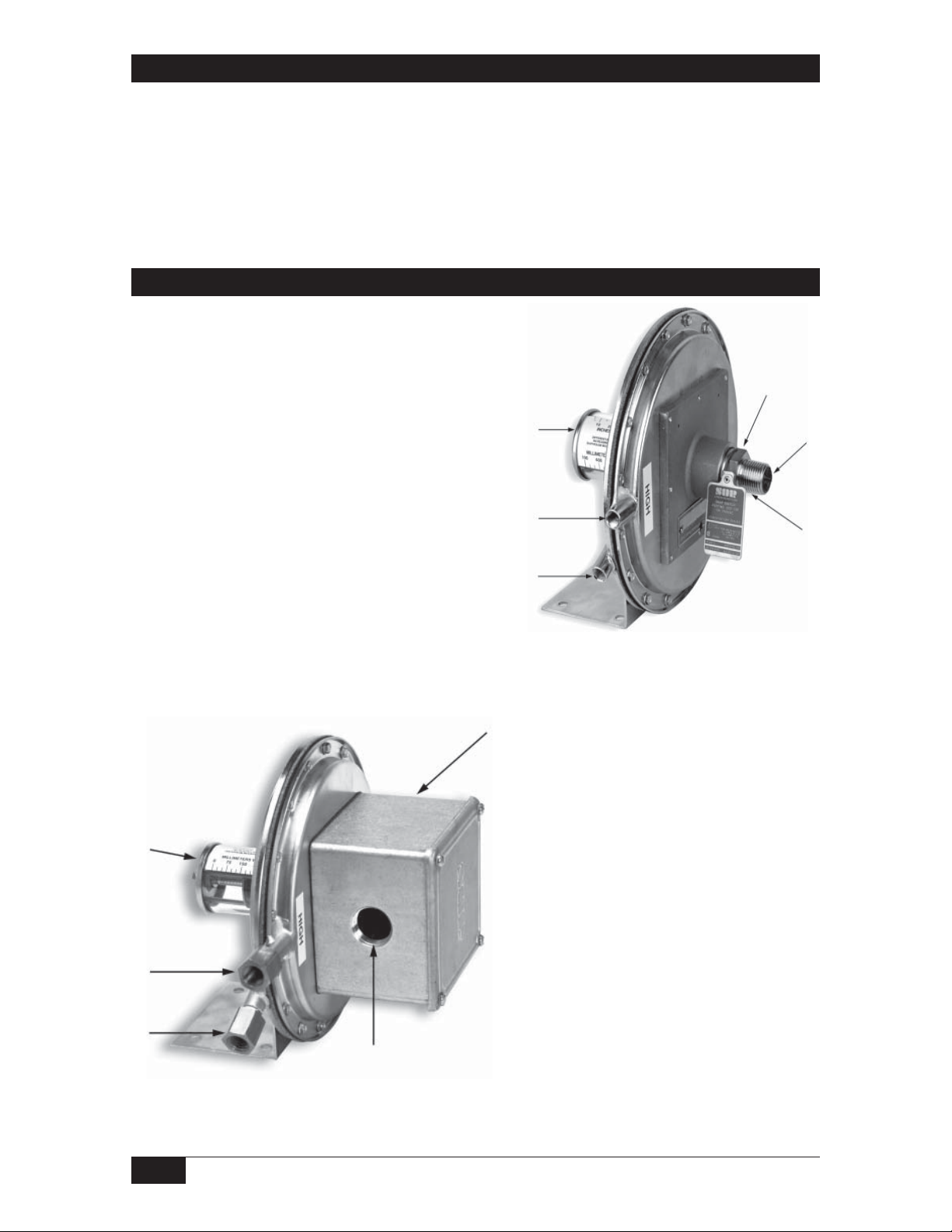

Set point adjustment screw (not shown)

High side process connection

Low side process connection

Hermetically sealed switching element capsule

18 AWG wire leads (not shown)

1/2” NPT(M) electrical conduit connection

3/4” NPT(F) electrcial conduit connection

Weatherproof switching element housing

Hazardous Locations - 107EL

Ensure that wiring conforms to

all applicable local and national

electrical codes and install unit(s)

according to relevant national and

local safety codes.

Non-Hazardous Locations - 107AL

2/4

Form 492 (11.13) ©SOR Inc.

Page 3

Electrical Connection

107AL (weatherproof): Interrupt electrical power. Remove top cover plate.

Screw terminals are standard. Terminals are identified

C - Common, NO - Normally Open and NC - Normally Closed.

(Use terminal identification on sticker located on the floor of

the housing. Do not use identification on microswitch.)

107EL (explosion proof): Hermetically sealed switching element capsule has

”

18

C - Common, NO - Normally Open, NC - Normally Closed

and G - Ground (earth). (See below.)

Wire Lead Color Code

Units in hazardous locations-prior to removal from service, make sure

that the work area is declassi ed. Failure to do so could result in severe

personal injury or substantial property damage.

- 18 AWG wire leads color coded and marked

DPDT (2 SPDT)

SPDT

NO 1

LO

Differential Pressure

HI

LO

Differential Pressure

HI

Blue (C)

Red (NO)

Black (NC)

Yellow (C2)

Orange (NO2)

Brown (NC2)

Green (GND)

NO 2

Blue (C)

Red (NO)

Black (NC)

Green (GND)

See SOR Catalog 459 for reference dimension drawings. For certified dimension

drawings, contact the factory.

Form 492 (11.13) ©SOR Inc.

3/4

Page 4

Calibration

Normal Calibration: Turn set point adjustment screw to move spring guide plate

into alignment with desired set point on calibration scale.

Precise Calibration: Device calibrated without reference to calibration scale

and low side vented.

Test apparatus: Manometer

Variable pressure source

Test light or ohmmeter

Connect variable pressure source to manometer and high side pressure port.

Connect test light or ohmmeter to C-Common and NO - Normally Open switching

element contacts.

Raise pressure and note manometer reading when circuit closes.

Slowly drop pressure and note manometer reading when circuit opens.

Use a screwdriver to turn set point adjusting screw: counterclockwise to increase set

point, or clockwise to decrease set point.

Repeat steps 3, 4 and 5 until contacts change at desired increasing or decreasing

differential pressure set point.

Do not remove other covers or attempt to adjust other parts of the

mechanism. All have been precisely positioned at the factory and

should not be moved in the eld.

Printed in USA sorinc.com

14685 West 105th Street, Lenexa, KS 66215 913-888-2630 800-676-6794 USA Fax 913-888-0767

4/4

Registered Quality System to ISO 9001

Form 492 (11.13) ©SOR Inc.

Loading...

Loading...