Page 1

B & J

Pressure Switches

General Instructions

These instructions provide information for the installation and field calibration of SOR

®

B & J Pressure Switches.

The pressure sensing element of the SOR B & J pressure switch is a force-balanced

piston-actuated assembly sealed by a flexible diaphragm and an o-ring that is static. The

only wetted parts in this arrangement are: the pressure port, the diaphragm and o-ring.

An optional welded pressure port and diaphragm assembly eliminates the o-ring. A wide

selection of wetted parts materials is available for compatibility with the process media.

Media pressure on the piston counteracts the force of the adjustable range spring, which

moves the piston shaft only a few thousandths of an inch to directly actuate the electrical

switching element.

NOTE: If you suspect that a product is defective, contact the factory or the SOR Representative

in your area for a return authorization number (RMA). This product should only be installed by

trained and competent personnel.

Installation

B & J pressure switches may be secured to bulkheads, panels or pipe stanchions with

suitable bolts.

Failure to mount the housing on a at mounting surface may result in torsional

forces on the housing that could cause false trips or render the pressure switch

inoperative.

Line mounting by either the process connection or the electrical conduit connection is

NOT recommended.

Table of Contents

Design and

specifications are

subject to change

without notice.

For latest revision, go to

www.sorinc.com

Installation .......................................1

SIL Installation ..................................2

Process Connection ............................2

Electrical Connection ...........................3

Calibration .......................................4

ATEX Marking Details ..........................4

Operation...................................... 5-7

Declaration of Conformity .....................8

Form 316 (01.13) ©SOR Inc.

Registered Quality System to ISO 9001

1/8

Page 2

Safety Integrity Level (SIL) Installation Requirements

The SOR pressure switches have been evaluated as Type-A safety related hardware.

To meet the necessary installation requirements for the SIL system, the following

information must be utilized:

Proof Test Interval shall be one year.

Units may only be installed for use in Low Demand Mode.

Products have a HFT (Hardware Fault Tolerance) of 0, and were evaluated in a

1oo1 (one out of one) configuration.

Form 1538 (03.12) ©2012 SOR Inc.

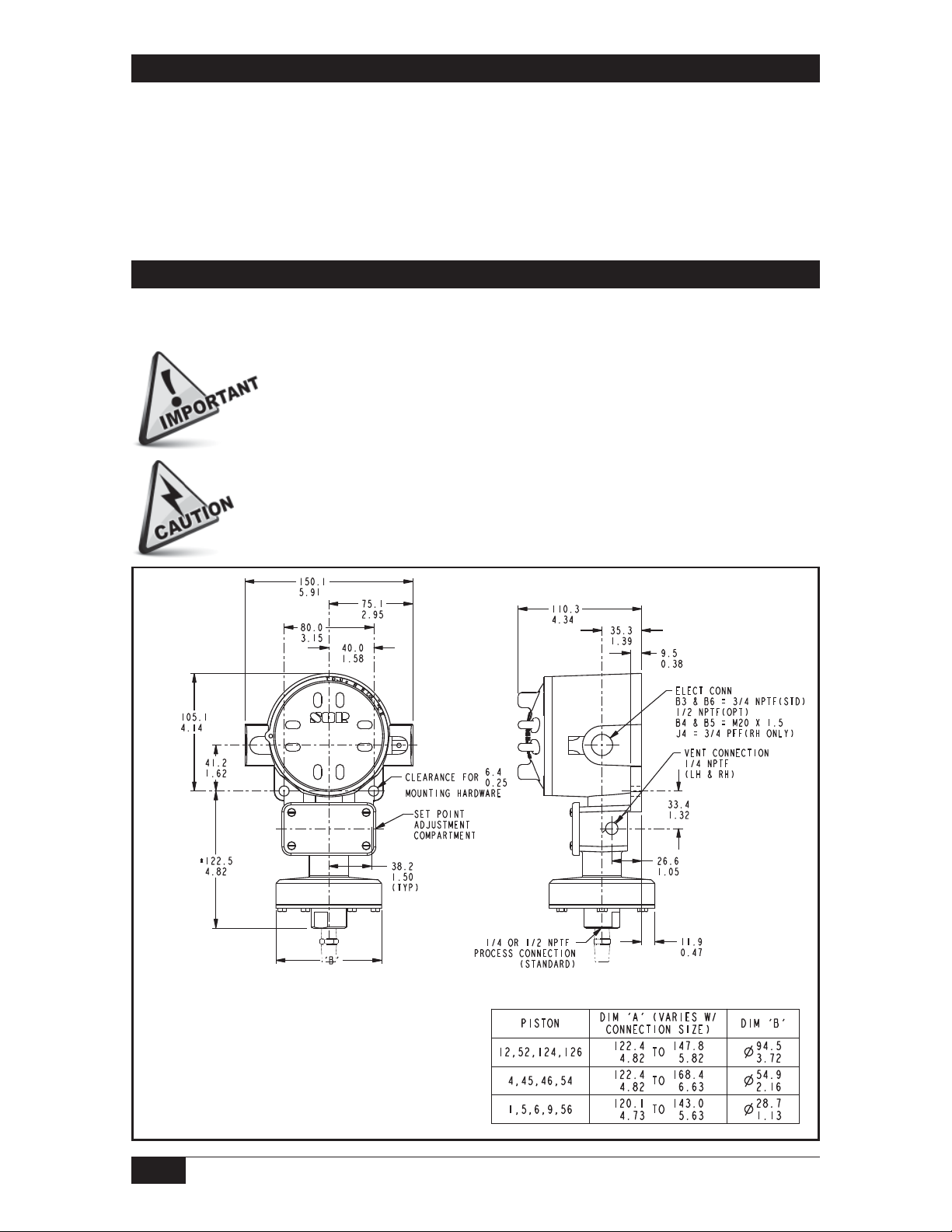

Process Connection

Securely connect the process line to the pressure connection using two wrenches; one to hold

the wrench flats on the pressure port, the other to tighten the process pipe or tube fitting.

Ensure that the process connection is tightened and positioned so

that bending and torsional forces imposed on the pressure switch are

minimal. Do not loosen the pressure port from the body or the body from

the housing, because leakage could result or the pressure switch could

be rendered inoperative.

One vent connection should be tted with a suitable breather to maintain

weathertight rating NEMA 4, 4X, IP65 or vented to a safe area. Piping

should be minimum 1/4” diameter and maximum 5 meters long (based

on process uid SG 1.0). The other vent connection may be plugged.

Linear = mm/inches

Drawing 0091417

Dimensions are for reference only.

Contact the factory

for certified drawings

for a particular model number.

2/8

Form 316 (01.13) ©SOR Inc.

Page 3

Electrical Connection

Ensure that wiring conforms to all applicable local and national electrical codes and install

unit(s) according to relevant national and local safety codes.

NOTE: For ATEX Certi ed Models: Electrical conduit connection threads may be of non-ISO thread

form. Check the product nametag for relevant thread form information before attempting to

connect to the electrical conduit connection. In the event a tting is used, check the adapter body

for thread size information.

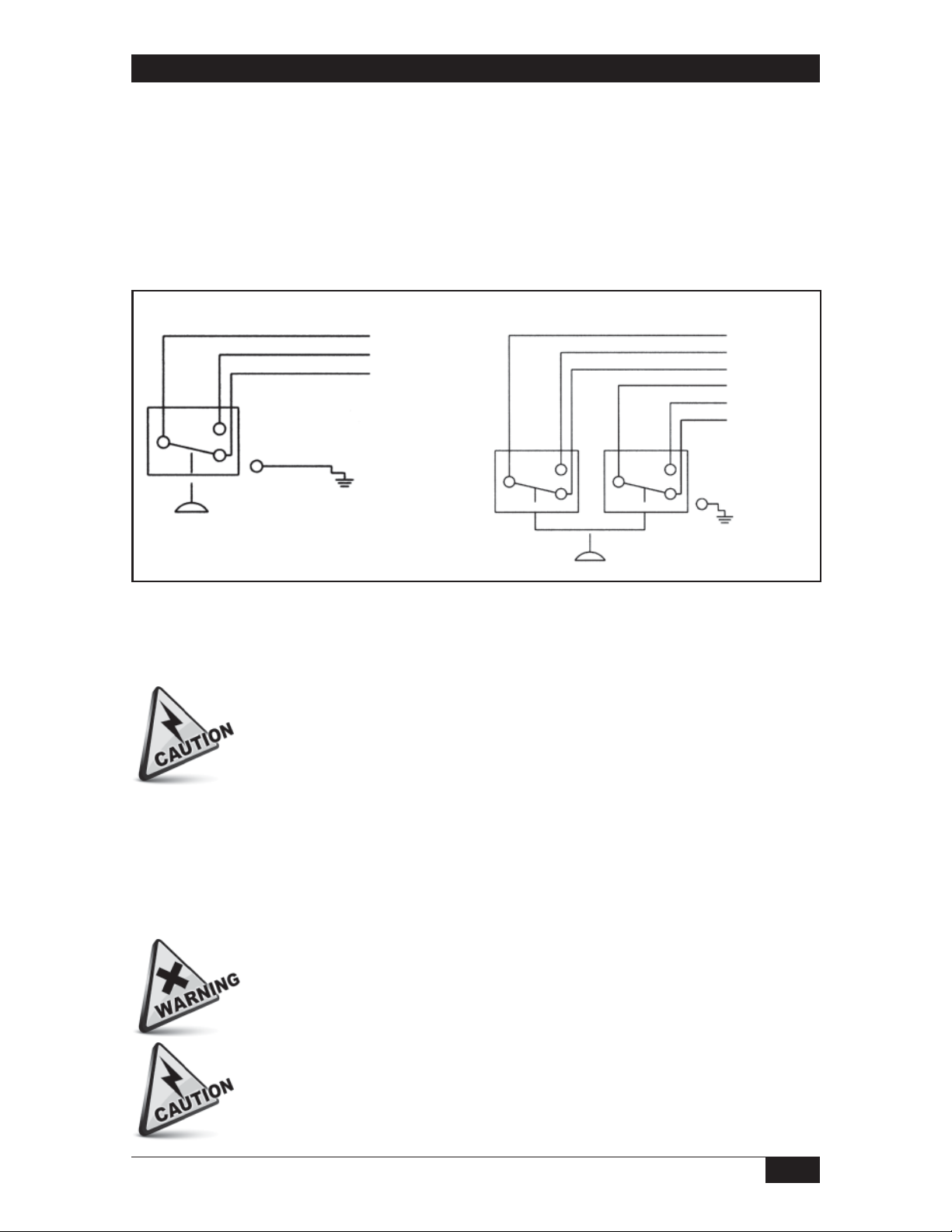

Standard electrical connection is a terminal block.

SPDT

Pressure

Blue (C)

Black (NO)

Red (NC)

Green (GND)

Blue (C)

DPDT (2-SPDT)

Pressure

Blue (C)

Black (NO)

Red (NC)

Yellow (C2)

Brown (NO2)

Orange (NC2)

NO2NO1

Green (GND)

B-series is 6-place compression type; J4 is 6-place screw type. The terminal block is marked:

Common (C), Normally Open (NO), Normally Closed (NC). If DPDT is specified, additional

markings are: Common 2 (C-2), Normally Open 2 (NO-2), and Normally Closed 2 (NC-2).

Overtravel has been preset at the factory, i.e. the switching element

assembly has been precisely positioned in the housing for optimum

performance. It normally should not be changed in the eld. Should

adjustment be necessary, factory approved procedures must be closely

followed. Any inadvertent movement or replacement in the eld will degrade

performance, void the warranty and could render the device inoperative,

unless factory approved procedures are followed.

NOTE: Internal primary equipment ground (earth) screw must be used for the equipment ground

connection and the external supplemental ground screw is provided for safety and compliance

with speci c code requirements.

The electrical compartment cover must remain sealed and the Allen locking

screw tightened at all times to prevent removal of the cover while the

pressure switch is in service.

Electrical power must be disconnected from explosion proof models before

the cover is removed. Failure to do so could result in severe personal injury

or substantial property damage.

Form 316 (01.13) ©SOR Inc.

3/8

Page 4

Calibration

Remove the set point adjustment compartment cover.

To increase the set point at which the switching element actuates, turn the hex adjusting

nut clockwise with a 3/4-inch open-end wrench.

Sight across the flat top of the adjusting nut to the calibration scale at the bottom of

the housing for an approximate set point. Use a 1/4% external pressure gauge to more

precisely calibrate the pressure switch.

Replace the set point adjustment compartment cover. The pressure switch can be

placed in service.

NOTE: The set point adjustment compartment is separate from the electrical compartment. The

set point may be changed without disconnecting electrical power.

ATEX Marking Information

For ATEX Certi ed Models

Manufacturer’s

Registered Trademark

Drawing 8513025

ATEX Listing

Information

Product Model

Identification

Thread Form

Information

Serial Number

(First Two Numbers

Indicate Year of Manufacture)

Special Conditions for Safe Use

To minimize the risk of electrostatic discharge, clean only with a damp cloth.

4/8

Form 316 (01.13) ©SOR Inc.

Page 5

Operation

For ATEX Certified Models

Maximum Surface Temperature

T6 Rating - 85

T5 Rating - 100

o

C

o

C

Regular Pressure

Piston-

Adjustable Range Overrange Proof

Spring

Designators

12 - 66 (0.6 to 2.5) [1.5 to 6.2]

12 - 614 (2.5 to 45) [6.2 to 110]

12 - 2 0.4 to 2.0 [30 to 140]

12 - 4 0.5 to 6.0 [35 to 415]

12 - 5 0.75 to 12 [50 to 830]

12 - 45 1 to 16 [70 to 1100]

4 - 2 2 to 8 [140 to 550]

4 - 4 2 to 25 0.14 to 1.7

4 - 5 3 to 50 0.2 to 3.5

4 - 45 4 to 75 0.3 to 5

6 - 2 7 to 30 0.5 to 2

psi (in. wc) bar [mbar] psi bar psi bar

200 14 400 28

750 50 1000 70

6 - 3 12 to 100 0.8 to 7

6 - 5 20 to 180 1.4 to 12

6 - 45 25 to 275 1.7 to 19

5 - 3 25 to 240 1.7 to 16

5 - 5 35 to 375 2.4 to 26

5 - 45 45 to 550 3.1 to 38

9 - 4 100 to 500 7 to 35

9 - 45 200 to 1750 14 to 120

1 - 45 500 to 4000 35 to 275 5000 340 6000 410

Form 316 (01.13) ©SOR Inc.

1500 100 2500 170

2500 170 6000 4109 - 5 200 to 1000 14 to 70

5/8

Page 6

Vacuum

Adjustable Range

Piston-

(Vacuum - 0 - Pressure)

Spring

Designators

52 - 116 (20 - 0 - 20) [50 - 0 - 50]

52 - 117 (40 - 0 - 40)

54 - 117 15 - 0 - 15 0.5 - 0 - 0.5

54 - 118 30 - 0 1.0 - 0

56 - 216 30 - 0 - 20 1.0 - 0 - 0.7

56 - 316 30 - 0 - 160 1.0 - 0 - 5.4

in. Hg (in.

wc)

bar [mbar] psi bar psi bar

Pivot Seal

[100 - 0 -

100]

Overrange Proof

200 14 400 28

750 50 1000 70

1500 100 2500 170

Piston-

Adjustable Range Overrange Proof

Spring

Designators

2 - 3 100 to 1900 7 to 130

3 - 45 1000 to 7000 70 to 480

psi bar psi bar psi bar

8000 550 10,000 7002 - 5 500 to 3000 35 to 210

6/8

Form 316 (01.13) ©SOR Inc.

Page 7

Designator AC Rating DC Rating Resistive

SPDT DPDT Volts Amps Volts Amps Volts Amps

K KK 250 15 - - - -

KA - 125 1 - - - -

J JJ 125 1 - - 30 1

G GG 250 15 125 0.5 - -

A AA 250 11 - - 30 5

L LL 250 15 125 0.5 - -

E EE 250 5 - - - -

C - 250 15 125 0.5 - -

S - 125 10 125

B BB 250 5 125 0.3 - -

Y YY 250 5 - - - -

W - 250 5 - - - -

N - 250 10 - - - -

T - 250 15 - - - -

H - 250 15 - - - -

AF AG 250 11 - - 30 5

EF EG 250 5 - - - -

JF JG 125 1 - - 30 1

1.5 min.

10.0 max.

--

Form 316 (01.13) ©SOR Inc.

7/8

Page 8

Declaration of Conformity

Form 1380 (08.12) ©2012 SOR Inc. (Printed in USA)

Product

Manufacturer

Date of Issue

We declare that the above

products conform to

the following specifications

and directives

Carries the marking

Reference document

ATEX Notified Body

Persons responsible

B Series Pressure and Temperature Switches

SOR Inc.

14685 West 105

th

Street

Lenexa, Kansas 66215-2003

United States of America

July 16, 2012

ATEX Directive (94/9/EC) Equipment Intended for use

in Potentially Explosive Atmospheres

EN 60079-0:2009

EN 60079-1:2007

II 2 G Ex d IIC T6 Gb

(Tamb = -40°C to +65°C) or T5 (Tamb = -40°C to +80°C)

EC-Type Examination Certificate

Baseefa02ATEX0252X

Issued May 7, 2003

Baseefa Ltd. (Notified Body No. 1180)

Rockhead Business Park, Staden Lane,

Buxton, Derbyshire SK17 9RZ

United Kingdom

Baseefa Customer Reference No. 1021

John J. Fortino (VP of Engineering)

John J. Fortino

14685 West 105th Street, Lenexa, KS 66215-2003

s53!s&!8

Engineered to Order with Off-the-Shelf Speed

EC Declaration

of Conformity

For ATEX Certi ed Models

Printed in USA sorinc.com

14685 West 105th Street, Lenexa, KS 66215 913-888-2630 800-676-6794 USA Fax 913-888-0767

8/8

Registered Quality System to ISO 9001

Form 316 (01.13) ©SOR Inc.

Loading...

Loading...