Page 1

Dual Hi-Lo

Instructions

Pressure Switches

General Instructions

The pressure sensing elements are a pair of force-balanced,

piston-actuated assemblies sealed by flexible diaphragms and o-rings

that are static. The only wetted parts in this arrangement are the single

pressure port, two sensing assembly diaphragms and o-rings.

Media pressure on the area of the pistons counteracts the force of

the range spring (adjustable by the adjusting nuts),

which moves the piston shafts only a few

V1 Weathertight

Housing

thousandths of an inch to directly actuate

the electrical snap-action switching elements.

NOTE: If you suspect that a product is defective,

®

contact the factory or the SOR

your area for a return authorization number (RMA).

This product should only be installed by trained

and competent personnel.

Representative in

V2 Weathertight

Explosion Proof

Hermetically

Sealed

Installation

Dual Hi-Lo Pressure Switches may be secured to bulkheads, panels or pipe stanchions with

suitable bolts. When mounting the pressure switch to an irregular or uneven flat surface,

install rubber washers on the mounting bolts between the housing and the mounting surface.

Failure to place washers between the housing and the mounting surface may

result in torsional forces on the housing that could cause false trips or render

the pressure switch inoperative.

Failure to mount the housing on a at mounting surface may result in

torsional forces on the housing that could cause false trips or render the

pressure switch inoperative.

Line mounting by either the process connection or the electrical conduit connection is not

recommended.

Safety Integrity Level (SIL) Installation Requirements

The SOR pressure switches have been evaluated as Type-A safety related hardware.

To meet the necessary installation requirements for the SIL system, the following

information must be utilized:

Proof Test Interval shall be one year.

Units may only be installed for use in Low Demand Mode.

Products have a HFT (Hardware Fault Tolerance) of 0, and were evaluated in a

1oo1 (one out of one) configuration.

Design and specifications are subject to change without notice.

For latest revision, go to www.sorinc.com

Form 1538 (03.12) ©2012 SOR Inc.

Form 248 (04.13) ©SOR Inc.

Registered Quality System to ISO 9001

1/4

Page 2

Process Connection

Securely connect the process line to the pressure port using two wrenches; one to hold the

hexagonal flats on the pressure port, the other to tighten the process pipe or tube fitting.

Ensure that the process connection is tightened and positioned so that

bending and torsional forces imposed on the pressure switch are minimal. DO NOT loosen the pressure port from the body, because leakage

could result or the pressure switch could be rendered inoperative.

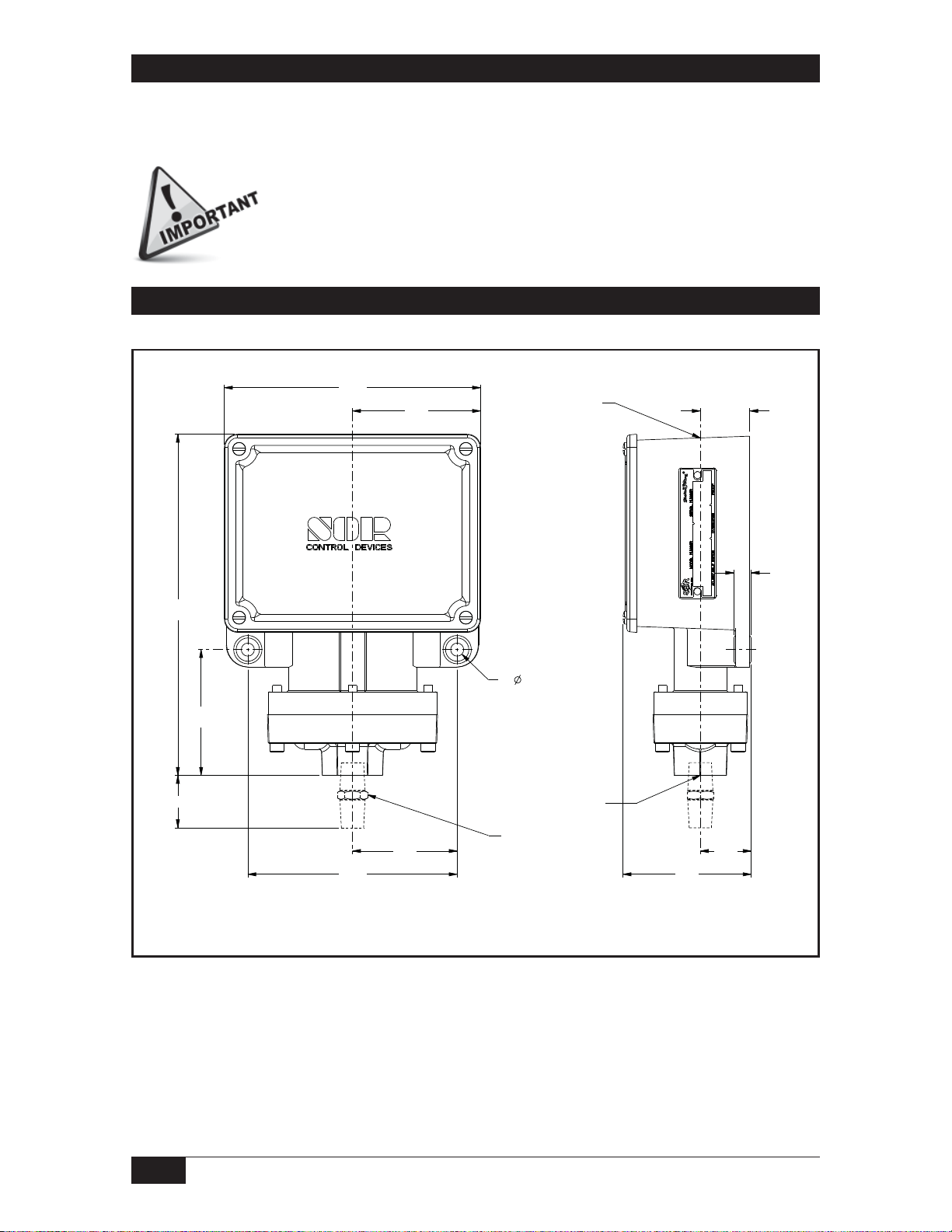

Dimensions

V1 WEATHERTIGHT

139.9

5.51

70.0

2.75

ELECTRICAL

CONNECTION

3/4 NPTF STD

1/2 NPTF OPT

M20 X 1.5 F OPT

27.0

1.06

*186.2

7.33

*68.6

2.70

A

Linear = mm/inches

Drawing 0090236

114.3

4.50

57.2

2.25

2X

7.1

0.28

MOUNTING

HOLES

PROCESS

CONNECTION

1/4 OR 1/2 NPTM

PROCESS CONNECTION

OPTIONAL

70.0

2.76

27.8

1.09

9.5

0.38

2/4

Form 248 (04.13) ©SOR Inc.

Page 3

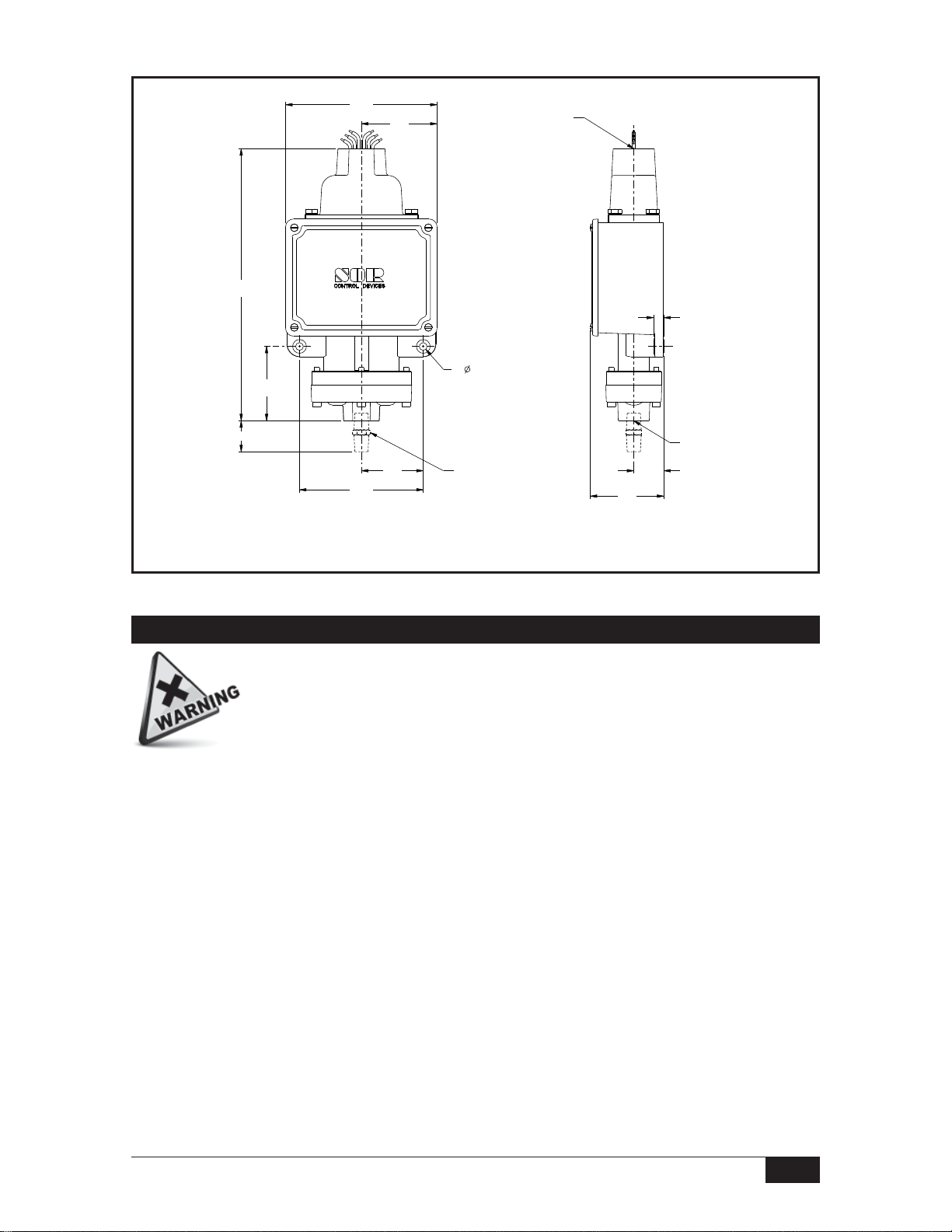

F

V2 EXPLOSION PROOF, HERMETICALLY SEALED

139.9

*251.2

9.89

*68.6

2.70

5.51

69.5

2.74

2X

7.1

0.28

MOUNTING

HOLES

ELECTRICAL

CONNECTION

3/4 NPTF STD

1/2 NPTF OPT

FACTORY SEALED

WIRE LEADS

9.5

0.38

A

Linear = mm/inches

Drawing 0090281

114.3

4.50

57.2

2.25

1/4 OR 1/2 NPTM

PROCESS CONNECTION

OPTIONAL

69.9

2.75

Dimensions are for reference only. Contact the factory for

certified drawings for a particular model number.

27.8

1.09

1/4 OR 1/2 NPT

PROCESS

CONNECTION

Electrical Connection

Units in hazardous locations— Prior to removal from service, make sure

that the work area is declassi ed. Failure to do so could result in severe

personal injury or substantial property damage.

Ensure that wiring conforms to all applicable local and national electrical codes and install

unit(s) according to relevant national and local safety codes.

V1 WEATHERTIGHT Common Normally Open Normally Closed

SPDT: Screw terminal block with marked insulation. Left and right positions.

No. 1 (Left side) C1 NO1 NC1

No. 2 (Right side) C2 NO2 NC2

2-SPDT (DPDT): Left and right positions

Nos. 1 & 2 (Left side) C1 NO1 NC1

C2 NO2 NC2

Nos. 3 & 4 (Right side) C3 NO3 NC3

C4 NO4 NC4

Form 248 (04.13) ©SOR Inc.

3/4

Page 4

“V2 EXPLOSION PROOF 18” 18 AWG color-coded and marked wire leads

with 3/4” NPT (F) conduit connection.

Common Normally Open Normally Closed

SPDT

No. 1 (Left side) C1 Blue NO1 Black NC1 Red

No. 2 (Right side) C2 Blue NO2 Black NC2 Red

2-SPDT (DPDT)

Nos. 1 & 2 (Left side) C1 Blue NO1 Black NC1 Red

C2 Yellow NO2 Brown NC2 Orange

Nos. 3 & 4 (Right side) C3 Blue NO3 Black NC3 Red

C4 Yellow NO4 Brown NC4 Orange

GR - Ground (Earth) Green wire connected to each hermetically sealed switching

element capsule.

NOTE: Transpose NO and NC on vacuum switches when set points are in the vacuum range.

Overtravel has been preset at the factory, i.e. the switching element assembly has

been precisely positioned in the housing for optimum performance. It normally

should not be changed in the eld. Should adjustment be necessary, factory

approved procedures must be closely followed. Any inadvertent movement or

replacement in the eld will degrade performance, void the warranty and could

render the device inoperative.

Calibration

Remove the housing cover.

To increase the set point at which the No. 1 (left side) switching element(s) actuates,

turn the hex adjusting nut clockwise with a 3/4-inch open-end wrench.

Sight across the flat top of the adjusting nut to the calibration scale at the bottom of

the housing for an approximate set point. Use a 1/4% external pressure gauge to more

precisely calibrate the pressure switch.

Repeat steps and for the No. 2 (right side) set point. There is no interaction, so it

is not critical whether the left or right side is set first.

Replace the housing cover. The pressure switch can be placed in service.

Printed in USA www.sorinc.com

14685 West 105th Street, Lenexa, KS 66215 913-888-2630 800-676-6794 USA Fax 913-888-0767

4/4

Registered Quality System to ISO 9001

Form 248 (04.13) ©SOR Inc.

Loading...

Loading...