Page 1

1780 Wireless

Level Switch

General Instructions

The SOR® 1780 Level Switch is a horizontally mounted, float-operated level switch. The

1780 is suitable for plant and OEM applications to detect presence or absence of liquid at a

discrete level.

When the liquid rises, the float extension arm moves a magnet that repels an internal

magnet de-actuating the wireless unit. When the liquid level falls, the float extension arm

moves in the opposite direction, actuating the wireless unit. The 1780 is recommended for

use in clean liquids only.

NOTE: If you suspect that a product is

defective, contact the factory or the SOR

Representative in your area for a return

authorization number (RMA).

This product should only be

installed by trained and

competent personnel.

Mounting

Verify that obstructions are not present in the application that would prevent free float

movement throughout the entire range of motion.

Assure that the mounting provides a horizontal alignment of the switch.

Counterbalance area must be free from metallic particles that may attract to

magnetic components in the 1780 model.

Use a 2” open end wrench on the two flats next to the process connection. Tighten the unit

onto the process connection by rotating clockwise.

To ensure proper operation, the unit must be mounted with either wrench flat horizontal ±1°.

(See

Mount the wireless unit using the two supplied M6X10 screws. Tighten using a 5mm

hex wrench.

Setup and calibrate the wireless unit according to the separtely supplied instructions.

Test the units action by varying the liquid level in the tank.

).

The unit can be mounted with either wrench flat horizontal ±180°

Design and specifications are subject to change without notice.

Form 1564 (09.14) ©SOR Inc.

For latest revision, go to sorinc.com

Registered Quality System to ISO 9001

1/4

Page 2

Wireless Con guration

The following configuration guide is provided as a reference tool only. For the most

complete and up-to-date information regarding configuration, calibration and set up

please refer to the general instructions provided by the manufacturer and included in

the original packaging.

Configuration consists of two parts: Configuration via a HART calibration device and

configuration via the integrated display

Hart Handheld Guided Setup

Open hart on field communicator

Press “right arrow” after finding the device

(2) Configure press “right arrow”

(1) Guided Setup press “right arrow”

(1) Device Setup press “right arrow”

Enter tag # press enter

Enter long tag # press enter

Enter Date press enter

Enter optional description press enter

Enter optional message press enter

Enter optional polling address press enter

Set High Trip Point to 80%

Set Low Trip Point to 20%

Set Dead band to 5%

Select no to configure power source

Configuration is finished

High and Low indication can be switched on the integrated display.

Output -> “Left Button”

If “In Service” -> “Left Button – Toggle Mode”, Else “right Button – Next”

Calibrate -> “Left Button“

Calibrate -> “Left Button – Feedback”

Select first point – High or Low

When sensor is in correct position select “left button to mark” then hit next

When sensor is in opposite position select “left button to mark” then hit next

Then apply

Again, these steps are provided for reference only and are not guaranteed to

reflect periodic software changes. If you have further questions please visit the

manufacturer’s website for the most up to date general instructions.

2/4

Form 1564 (09.14) ©SOR Inc.

Page 3

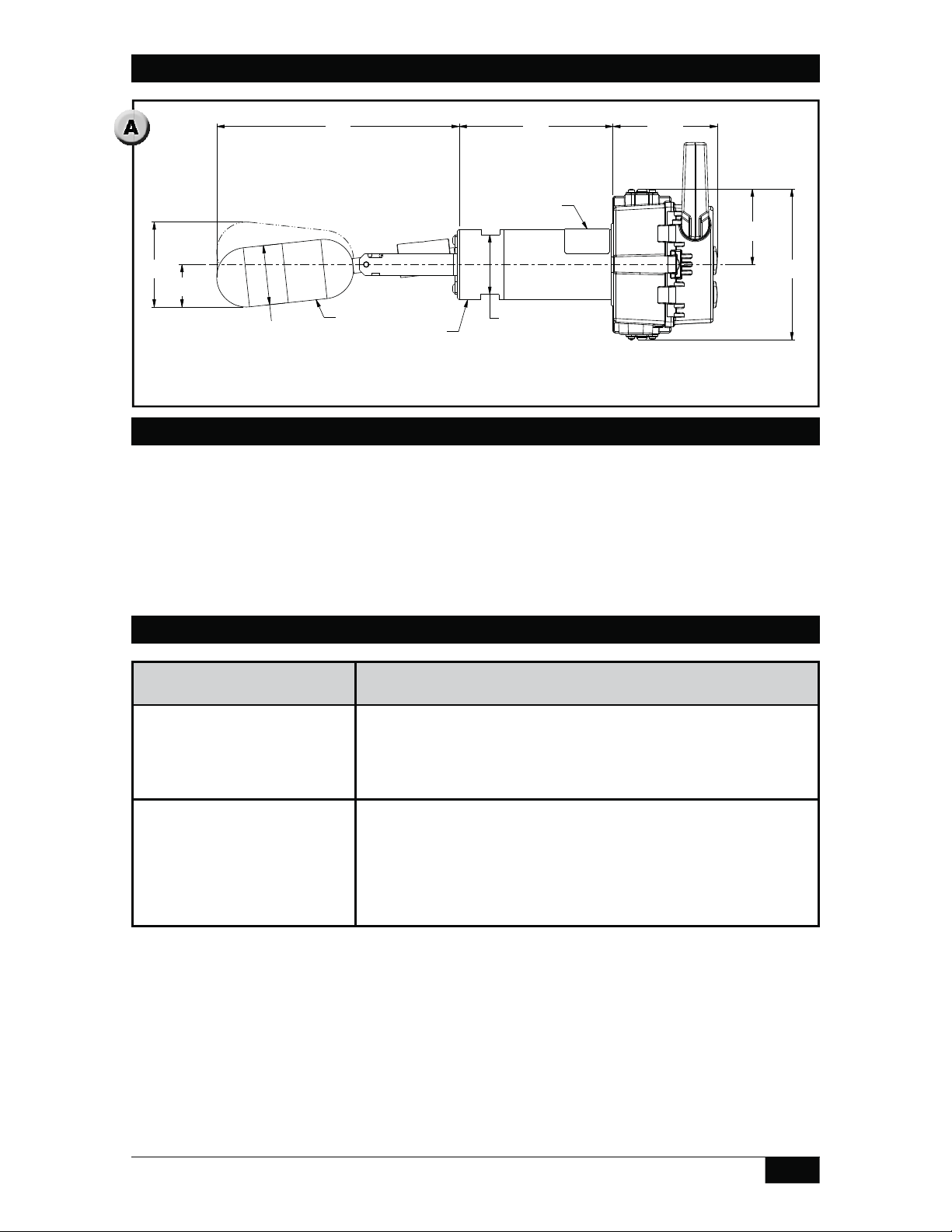

Dimensions

131.4

5.17

207.3

8.16

36.3

1.43

72.7

2.86

50.8

2.00

50.8

2.00

WRENCH

FLATS

64.5 REF

2.54

128.9 REF

5.08

89.3 REF

3.52

NAMEPLATE

2" NPTM

PROCESS

CONNECTION

FLOAT

Linear = mm/inches

Drawing 0390759

Maintenance

Clean the float and counterweight mechanism periodically to assure continued free

movement.

Make no adjustments to the float or counterweight mechanism. They are factory

calibrated for optimum performance.

Troubleshooting

Symptom Probable Cause

The control will not function

when installed but operates

when removed from process

connection.

Liquid is in the vessel at the

actuation level but the unit

does not respond.

a. Float travel is inadequate. Check for internal

vessel obstructions. See Mounting Requirements.

a. The float pivot pin is bound up or dirty. Clean the

float pivot pin.

b. The specific gravity of the liquid is not sufficient

to lift the float.

c.

The float is leaky or collapsed. Contact the factory.

Form 1564 (09.14) ©SOR Inc.

3/4

Page 4

Printed in USA sorinc.com

14685 West 105th Street, Lenexa, KS 66215 913-888-2630 800-676-6794 USA Fax 913-888-0767

4/4

Registered Quality System to ISO 9001

Form 1564 (09.14) ©SOR Inc.

Loading...

Loading...