Page 1

1540 Side Mounted

®

Pneumatic Level Switch

General Instructions

The side mounted SOR® 1540 Pneumatic Level

Switch provides a pneumatic output signal for either

a high or low level condition.

The float moves a magnet

into the field of a

magnetically actuated

sensor. The unit may

be mounted for either

high or low liquid level alarm.

NOTE: If you suspect that a product is defective, contact the factory or the SOR Representative

in your area for a return authorization number (RMA). This product should only be installed by

trained and competent personnel.

1540 Pneumatic Level

matic output signal for either

ition.

et

alarm.

Before Installing the Level Switch

Inspect the unit for any shipment damage.

Check for mechanical clearance. The float must move freely throughout its stroke inside

the vessel.

Use an acceptable thread compound to ensure a leak-free fit and avoid thread

galling when installing the unit into the vessel.

Clean, dry air or gas must be used as the supply media to avoid plugging critical

internal restrictions.

MC or MD (manual check) option can be removed to allow supply fitting to be installed.

Reseal threads with acceptable thread compound and insert to dimension shown.

SUPPLY PRESSURE RANGE: J0 SWITCH – 0-30 psi (0-2 BAR)

J1 SWITCH – 0-80 psi (0-5.5 BAR)

Design and specifications are subject to change without notice.

For latest revision, go to www.sorinc.com

Form 1306 (04.13) ©SOR Inc.

Registered Quality System to ISO 9001

1/4

Page 2

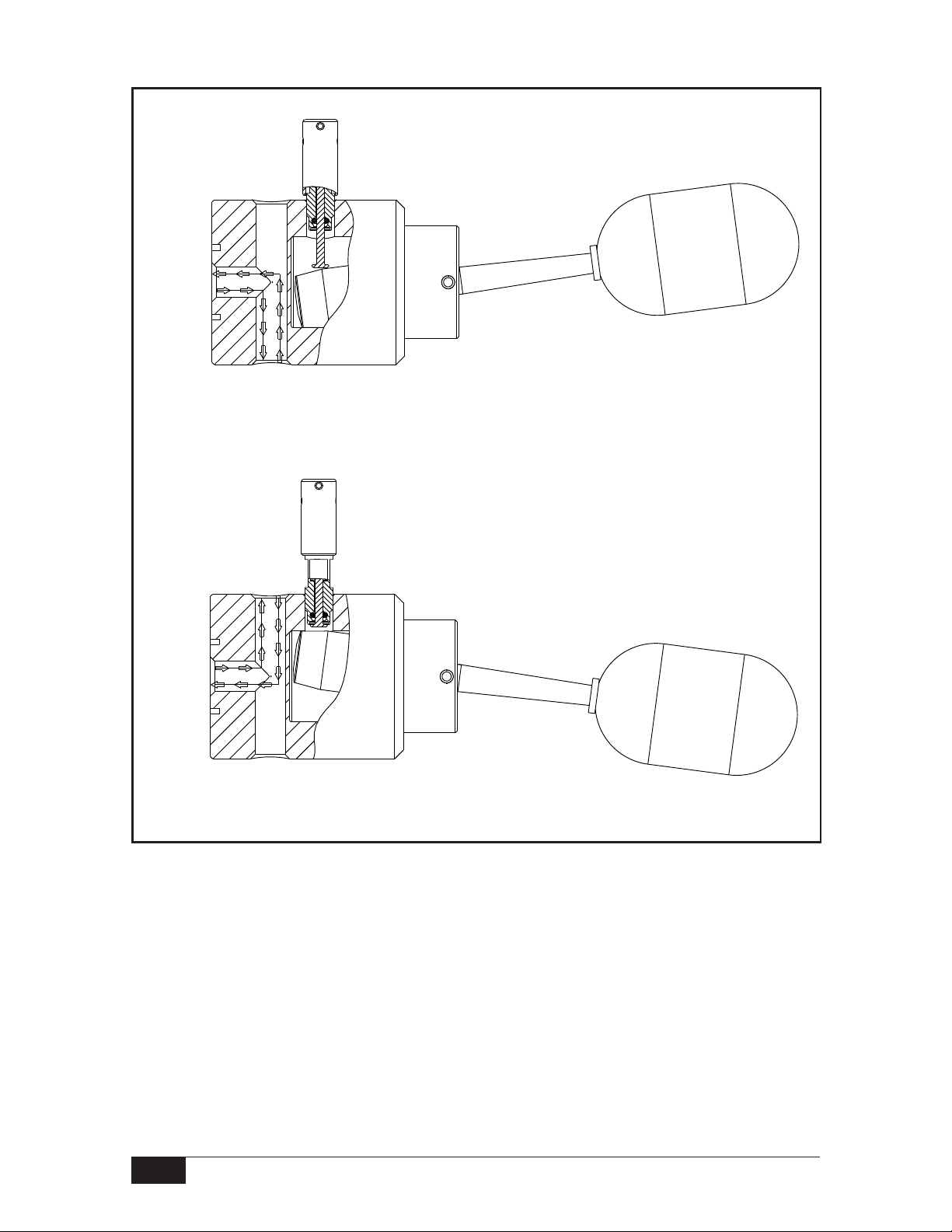

The following drawings show the manual check (MC or MD) option.

* CLOSED

AIR

FLOW

HIGH LEVEL

HIGH LEVEL

AIR

FLOW

* DO NOT PLUG THIS PORT. DURING ACTUATION AND RESET,

TRAPPED AIR IN THE SENSOR MUST ESCAPE FOR THE UNIT

TO OPERATE PROPERLY.

Linear = mm/inches

Drawing 0091448

AIR

FLOW

AIR

FLOW

* CLOSED

LOW LEVEL

LOW LEVEL

2/4

Form 1306 (04.13) ©SOR Inc.

Page 3

Installation

The unit may be mounted using the standard 2” NPT process connection.

MD Remote Option (includes plunger, 20 foot cable and two crimps.)

– Screw plunger to the top of unit.

– Thread the 20’ cable through the hole in plunger and create a 14 inch top loop as

shown below.

– At the bottom of the cable, a second loop can be created as a handle for actuation at

the desired length.

Linear = mm/inches

Drawing 0098626 p.2

PLUNGER

TOP 14” LOOP

CRIMP

REMOTE MANUAL CHECK

MD OPTION

REMOTE CABLE

REMOTE MANUAL CHECK

MD OPTION

CREATE HANDLE AT DESIRED LENGTH

Form 1306 (04.13) ©SOR Inc.

3/4

Page 4

Dimensions

MANUAL CHECK

MC or MD OPTION

32.5

1.28

WRENCH

FLATS

MOUNT THIS AXIS

HORIZONTAL ±5°

MOUNT THIS SURFACE

VERTICAL ±5°

Dimensions are for reference only. Contact the factory for

72.2

2.84

18.4

0.72

1/4"NPTF

INLET

1/4"NPTF

INLET

72.8

2.87

31.0

1.22

12.7

0.50

MANUAL CHECK CABLE

20 FT LONG

MD OPTION ONLY

19.8

0.78

14.3

0.56

2" NPTM PROCESS

CONNECTION

145.3

5.72

certified drawings for a particular model number.

FLOAT

TRAVEL

71

2.8

ACTUATION

56

2.2

36

1.4

ACTUATION

28

1.1

Linear = mm/inches

Drawing 0091448

Replacement Parts

Designator Description

3130040 20’ Remote Cable with two cable crimps*

3100152 Float

9227012 Float & Arm Assembly

9227024 Manual Check Accessory (uses Viton GLT O-ring) (MC)*

9227025 Manual Check Accessory with remote 20’ cable (MD)*

* Unit must have originally been supplied with MC or MD option.

Printed in USA sorinc.com

14685 West 105th Street, Lenexa, KS 66215 913-888-2630 800-676-6794 USA Fax 913-888-0767

4/4

Registered Quality System to ISO 9001

Form 1306 (04.13) ©SOR Inc.

Loading...

Loading...