Page 1

1530 Side Mounted

eat

c Level Switch provides a pneumatic output si

l

v

condition.

w

General Instruc

t

Pneumatic Level Switch

General Instructions

The side mounted SOR® 1530 Pneumatic Level Switch provides a pneumatic output signal

for either a high or low level condition.

The float moves a magnet into the field of a magnetically actuated pneumatic valve. The

pneumatic valve is pilot operated. An amplifying relay provides quick response.

The unit may be mounted for either high or low liquid level alarm by rotating the switch

body. Wrench flats provide ease of rotation.

High Level Pneumatic Output Signal (Direct Acting) Install with pneumatic connections

on the upper side of the body when the unit is tightened into the vessel.

Rising liquid level raises the float upward causing the float stem magnet to repel the

actuating lever magnet and seal the pilot nozzle. Resultant pilot pressure build-up triggers

the amplifying relay to pass pneumatic signal through the output port.

Low Level Pneumatic Output Signal (Reverse Acting) Install with pneumatic connections

on the lower side of the body when the unit is tightened into the vessel.

Falling liquid level lowers the float downward causing the float stem magnet to repel the

actuating lever magnet and seal the pilot nozzle. Resultant pilot pressure build-up

triggers the amplifying relay to pass pneumatic signal through the output port.

NOTE: If you suspect that a product is defective, contact the factory or the SOR Representative

in your area for a return authorization number (RMA). This product should only be installed by

trained and competent personnel.

Form 439 (04.13) ©SOR Inc.

Design and specifications are subject to change without notice.

For latest revision, go to www.sorinc.com

Registered Quality System to ISO 9001

1/4

Page 2

Before Installing the Level Switch

Inspect the unit for any shipment damage.

Check for mechanical clearance. The float must move freely throughout its stroke inside

the vessel.

Use an acceptable thread compound to ensure a leak free fit and avoid thread galling

when installing the unit into the vessel.

The unit may be mounted in any of the following installation arrangements:

2” NPT full or half coupling

3” NPT full coupling (Use in conjunction with 2 x 3” NPT bushing.)

Optional flanged mounting

Optional chamber mounting

Clean dry air or gas must be used as the supply media to avoid plugging critical internal

restrictions and nozzles.

SUPPLY PRESSURE RANGE: 20 TO 60 PSIG

Installation

Connect the supply line to the 1/8” NPT connection stamped Supply. Do not use pipe

compound on the first two threads on pneumatic fitting. The supply media must be

filtered and oil free. Air is the usual media; however, any dry filtered gas can be used.

Connect the output port stamped Output to the unit to be controlled.

NOTE: If the controlled device has a volume of less than 15 cubic inches, the small volume may

cause the output to uctuate. The addition of output volume will stop this uctuation.

VENTING CAUTION: Note the position of the vent connection on the body. It must

be positioned on a horizontal axis either on the right or the left side of the body.

This connection must not be plugged. It is used for either local atmospheric

venting or remote venting through a suitable line run to the designated venting

area. Supply or Output connections must not be connected to the Vent port.

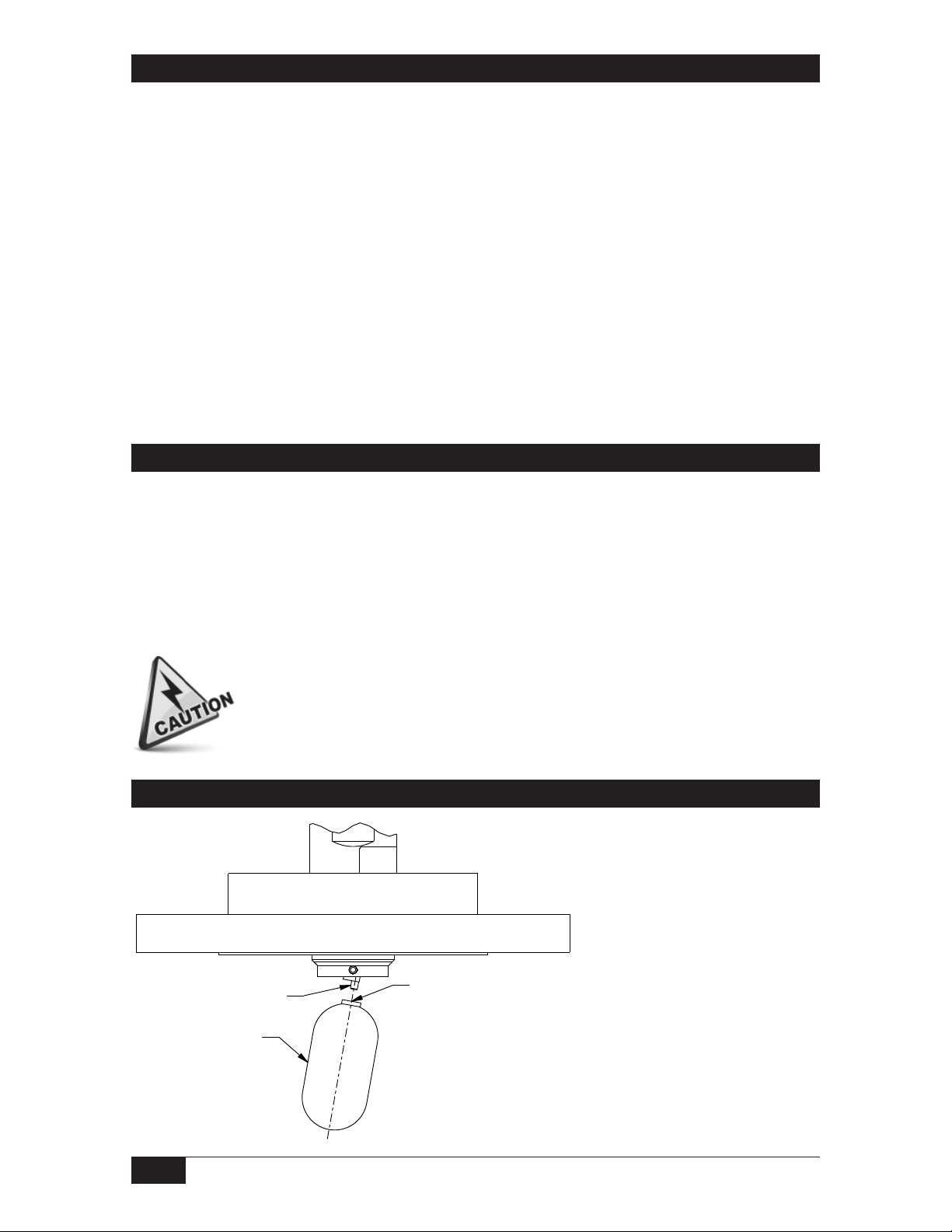

Float Attachment

Place two drops of Loctite

271 inside the threaded

hole of the float.

Thread the float onto the set

screw and hand-tighten.

APPLY TWO DROPS

SET SCREW

FLOAT

LOCTITE 271 INSIDE

THREADED HOLE

OF FLOAT

Linear = mm/inches

Drawing 0390747

NOTE: Do not remove the set

screw as it secures the pivot

arm to the shaft.

2/4

Form 439 (04.13) ©SOR Inc.

Page 3

Dimensions

T

L

98.4

3.88

BODY FLOAT

60.3

2.38

WRENCH

FLATS

50.8

2.00

168.3

CONNECTION

1530 Operating Principle Schematic

Pilot Nozzle

Pilot Pressure

Diaphragm

Vent

PROCESS

2" NPTM

Actuating Lever

Magnet

78.6 REF

Actuator Arm

Float

Magnet

Restriction (0.015”)

59.8

2.35

FLOA

TRAVE

35.6

1.40

MAX

Linear = mm/inches

Drawing 0390026

Output

Form 439 (04.13) ©SOR Inc.

Supply

Restriction Filter

3/4

Page 4

Troubleshooting

Symptom Probable Cause

Float in actuated position

but no output signal.

a. Pilot nozzle-seat worn or damaged. (No seating of

flapper.) Return to the factory or replace the switch.

b.

Actuating lever bound up or dirty. Clean or return to the factory.

c. Damaged relay diaphragm. Replace the relay assembly.

d. Relay orifice plugged. Clean.

e. Insufficient supply pressure adjust to 20-60 psi.

f. Output line clogged. Clean.

Float in de-actuated position

but still receiving an output

signal.

Control will not function

when installed but operates

when removed from vessel.

Liquid in vessel at the

actuation level but unit does

not respond.

Slow response.

Fluttering output. a. Inadequate volume in the output leg.

a. Pilot nozzle plugged. Clean the pilot nozzle.

b. Actuating lever bound up or dirty. (Flapper remains seated.)

Clean or return to factory.

c. Vent screen clogged. Clean.

a. Inadequate float travel. Float travel restricted by the

process connection.

a. Leaky or collapsed float. Replace.

b. Liquid specific gravity too low.

c. Float stem bound up or dirty. Clean.

d. Float travel is obstructed. Verify float can move freely and is

not obstructed when installed.

a. Excessive volume in the output leg.

b. Leaky output line.

Replacement Parts

Part Number Description

3130-052 316SS Float & Actuator Arm Assembly

3130-114 Pneumatic Relay Assembly

sorinc.com

14685 West 105th Street, Lenexa, KS 66215 913-888-2630 800-676-6794 USA Fax 913-888-0767

4/4

Registered Quality System to ISO 9001

Form 439 (04.13) ©SOR Inc.

Loading...

Loading...