Page 1

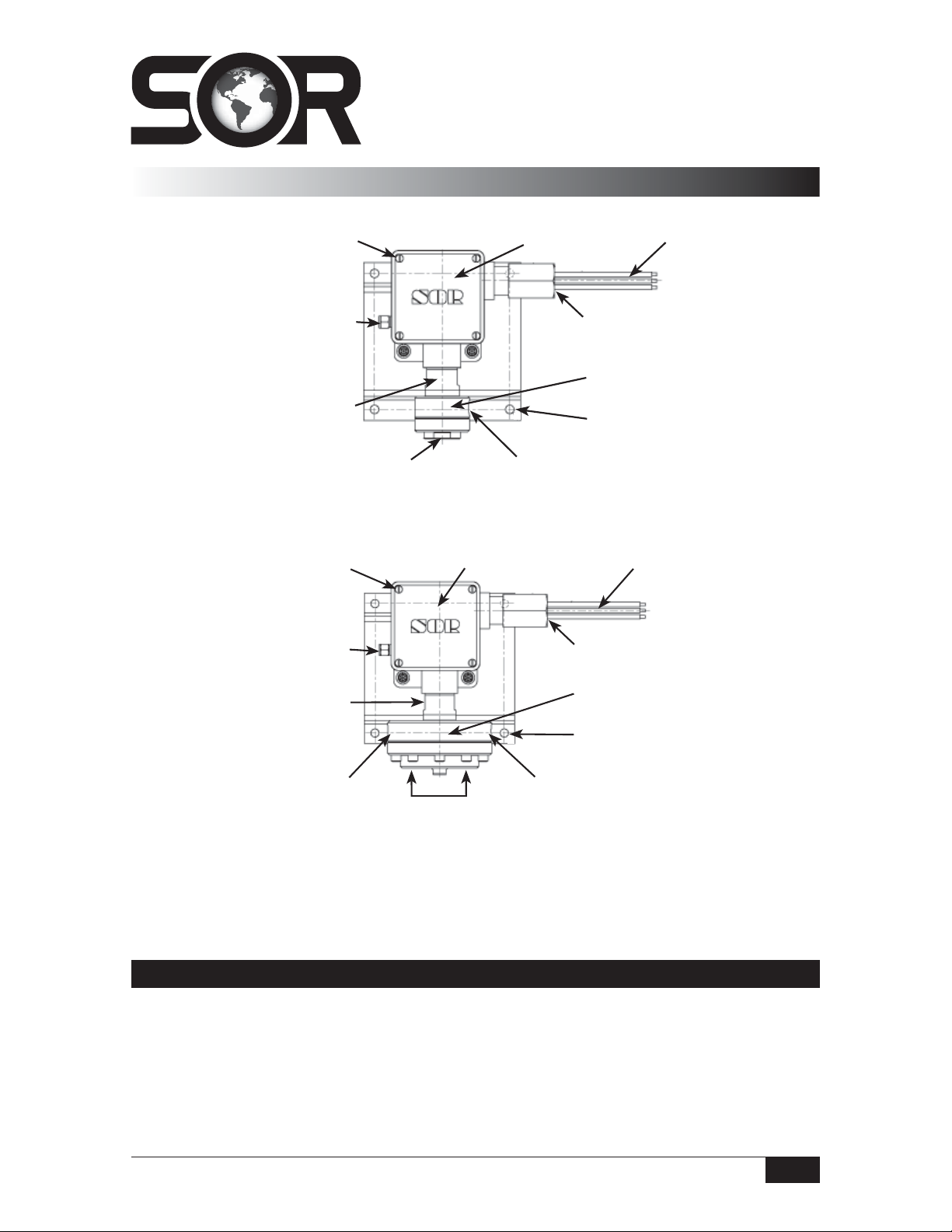

131/141 Nuclear-Qualified

Differential Pressure Switches

General Instructions

131

1/8” NPT(F) Vent Connection

High Side Process Connection

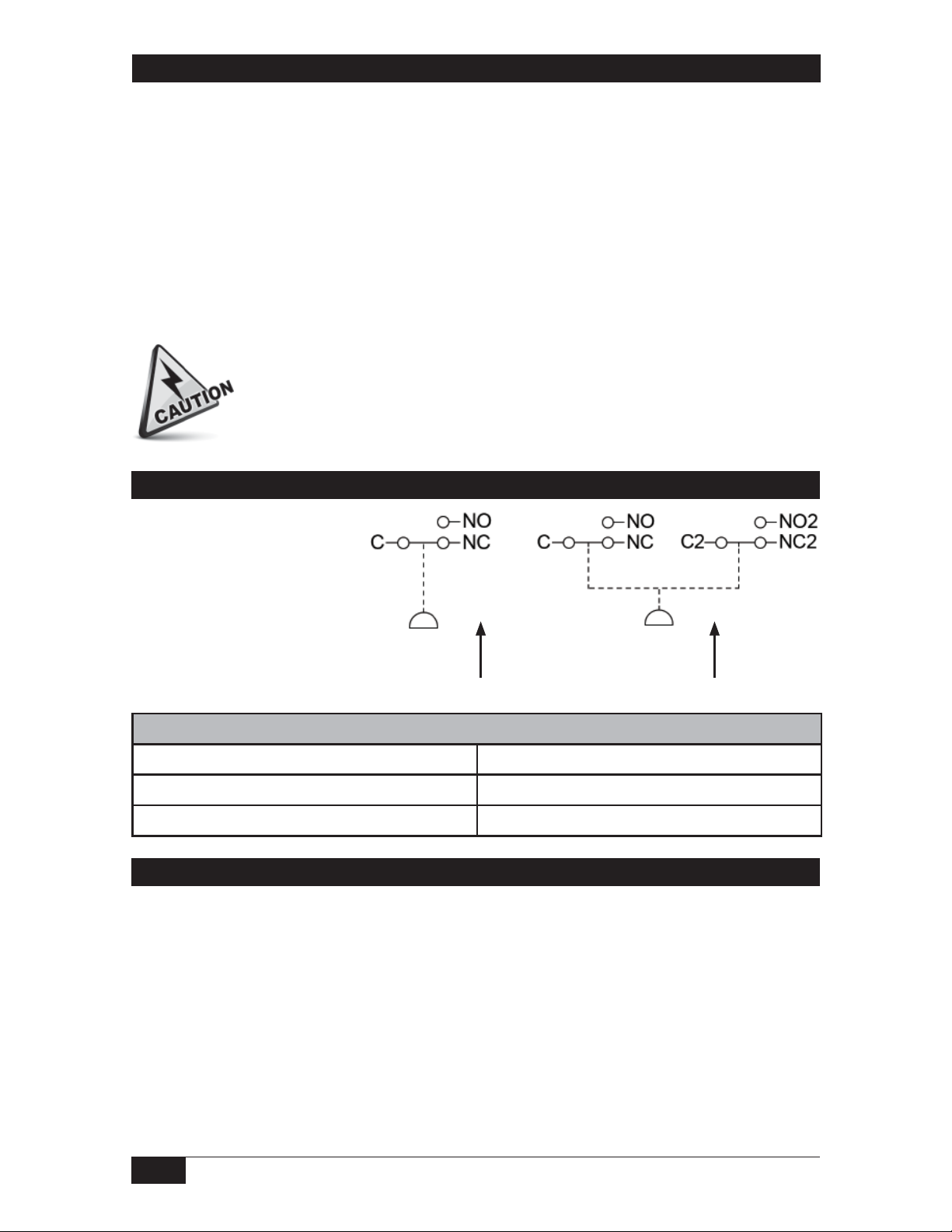

141

1/8” NPT(F) Vent Connection

Cover Screws

Cover Screws

Body

Housing

3/4” NPT(F) Conduit Connection

Sensor

Mounting Holes

Low Side Process Connection

3/4” NPT(F) Conduit Connection

Wire Leads

Wire LeadsHousing

Body

Low Side Process Connection

High Side Process Connection

NOTE: If you suspect that a product is defective, contact the factory or the SOR® Representative

in your area for a return authorization number (RMA). This product should only be installed by

trained and competent personnel.

Sensor

Mounting Holes

Low Side Process Connection

Installation

Mount pressure switch to rigid vertical mounting surface with four 1/4-20 Grade 5 screws

(not supplied). Torque screws to 70 - 85 in/lbs. The 141 must be oriented with the sensor

down (housing up).

Design and specifications are subject to change without notice.

For latest revision, go to www.sorinc.com

Form 1307 (04.13) ©SOR Inc.

1/4

Page 2

Process Connection

Be certain the process connection is tightened and positioned so bending and torsional

forces imposed on pressure switch are minimal. Use care not to loosen sensor assembly

from housing.

131 - One process connection is provided for the high-pressure side of the device and one

for the low-pressure side.

141 - Two process connections are provided for the high-pressure side of the device and

two for the low-pressure side. On liquid service, the extra process connections should be

used to assist in bleeding the air out of the sensor. On gas service, they may be used to

drain condensate or accumulated liquid.

When the process could be considered dirty in terms of suspended particles,

it is recommended that 20-micron in-line lters be installed on the Hi and Lo

pressure ports.

Electrical Connection

Electrical connections are

marked on the insulation

of the wire leads. Conduit

should be installed without

applying strain to the

housing.

Differential

Pressure

Differential

Pressure

Minimum Bend Radius for Wire

Permanent Training 1/2”R

Pulling Tension 1”R

Terminating Junction 1/4”R

Site Storage

Store switch in a dry area in the original shipping package. Shelf life is 10 years for a

maximum ambient temperature of 80°F, based on aging data in SOR Test Report 9058-102.

2/4

Form 1307 (04.13) ©SOR Inc.

Page 3

Calibration

This instrument may be calibrated as a pressure switch (low side vented); however, for

best performance, calibrate under simulated operating conditions.

The 131 has a static shift of -1 psi per 100 psi applied static. If the unit is calibrated without

static pressure applied, the set point should be adjusted to counter the actual static pressure.

To check the set point of a switch, monitor either the common (C) and normally open (NO)

or the common (C) and normally closed (NC) contacts for change of state. Connect the

process connection to a regulated hydraulic or pneumatic pressure source. Monitor with

an accurate pressure measuring standard. Slowly increase or decrease the pressure to

accurately capture the precise moment that the switch changes state. To assure the most

accurate and repeatable results, the switch must be tested in an identical manner each time

the calibration is checked.

Increasing Set Points

If the normal operating pressure is below the set point, then the pressure should be increased from 0

PSI up to the increasing set point and then back down to the reset point. Repeat this cycle

as necessary.

Decreasing Set Points

If the normal operating pressure is above the set point, then the calibration should be checked by first

pressurizing to the normal operating pressure, then reducing the pressure to the decreasing set point,

and then increasing the pressure to the reset point. Repeat this cycle as necessary.

To adjust pressure at which switch will operate, remove cover and tighten the hex head adjusting nut

with a 3/4” wrench to increase pressure; loosen to reduce pressure.

After calibration is complete, reinstall the cover with new gaskets as required by the

Maintenance instructions.

The switching element has been

positioned with a dial indicator to

a tolerance of ±.002 inches. Do

not move this switching element!

Its position has nothing to do with

the set point adjustment. Any

movement can either render the

switch inoperative or cause the

switching element to be damaged

with overpressure.

Switching Element

Do not apply more than 300 psi

positive differential to the switch.

Do not apply a negative differential

of more than 10 psi.

Form 1307 (04.13) ©SOR Inc.

Adjusting Nut

Calibration Scale

3/4

Page 4

Maintenance

Cover Gasket Replacement

SOR provides one new replacement gasket (SOR P/N 8923-180) for each new switch. It

is recommended that the new gasket be installed upon installation of a new switch and

the old gasket be discarded. After that time, the gaskets must be replaced based on the

following schedule:

If Cover Is Not Removed

If the cover is not removed at any time, the gasket need not be replaced for up to five

years. Replace the cover gasket on or before five years from the installation date of a

new gasket.

If Cover Is Removed

The cover may be removed and reinstalled any number of times within a two-year

window without replacing the cover gasket. If the cover is removed within this two-year

window, the cover and gasket assembly must be reinstalled onto the same switch and it

must be oriented in the same way. After two years, the cover gasket must be replaced if

the cover is removed.

NOTE: When removing the cover, if the cover gasket is going to be reused, do not remove the

captive screws. Remove the cover, gasket, and captive screws as one assembly. Reinstall per the

above guidelines (same switch- same orientation).

Instructions For Replacement

Remove the four cover screws. Remove the old gasket. Place new gasket between housing

and cover. Line up holes in cover, gasket and housing. Insert the four screws and torque

each to 7-10 in-lbs.

Printed in USA sorinc.com

14685 West 105th Street, Lenexa, KS 66215 913-888-2630 800-676-6794 USA Fax 913-888-0767

4/4

Form 1307 (04.13) ©SOR Inc.

Loading...

Loading...