Page 1

Working Instruction, Electrical

Working Instruction, Electrical

Applicable for Z770i

CONTENTS

1 Moisture Sensitivity and Component Baking ......................................3

2 Lead-free Rework...................................................................................4

2.1 Lead-free Symbol..................................................................................4

2.2 Bottom Heat ..........................................................................................4

2.3 Reflow Profile for BGA Rework Station.................................................5

2.4 Inspection..............................................................................................6

3 Replacement of components ................................................................7

3.1 X1200: Conn Antenna...........................................................................8

3.2 X1201: Coax Connector........................................................................8

3.3 X1202:ANT GND Connector Leaf Spring 1p .......................................9

X2200:Battery Connector......................................................................9

3.4

3.5 X2400:System connector.....................................................................10

3.6 X3100: Con X Keyboard connector ....................................................10

3.7 X4200:LCM Connector.......................................................................11

3.8 N1400:Module Bluetooth + FM STLC2592........................................11

3.9 B4200: SMD Vibrator.........................................................................12

3.10 X2403:SIM Card Connector................................................................12

3.11 X2405: MS-Micro Pico holder............................................................ 13

3.12 N3101:ASIC Tjatte3 CSP20................................................................13

3.13 D2105:IC Single bus buffer gate.........................................................14

3.14 D2400:IC IF ISP1508 ES3 (3.5*3.5*0.8)............................................14

3.15 L2401-L2404:Filter 0.0 Hz 0402.........................................................15

3.16 N2203: 2ch-LDO, Vout1=2.8V, Vout2=1.8V, WL-CSP6................... 15

3.17 N2400: IC............................................................................................ 16

3.18 N2402:IC ESD Prot UDFN 6 2x2 mm................................................16

3.19 Ear speaker:Ear Speaker 1107.0 Rectangular...................................... 17

3.20 Loudspeaker:Loudspeaker 1318.0 Oval..............................................18

3.21 V2420-V2422, V4209: Diode Zener 15, V SOD523........................... 18

3.22 E1000:Shield Can Closed small shielding...........................................19

E1001:Shield Can Fence.....................................................................20

3.23

3.24 N2202:IC Vreg SON-6........................................................................20

3.25 B4410:IC Lin,MR sensor....................................................................21

3.26 N2204: LDO1.2 V, 200mA, low noice, CS 5...................................... 21

3.27 B2102:Crystal 32,768 kHz..................................................................22

3.28 N1200: RF-Module Thor Pre-bumped.................................................22

3.29 N1210: RF-Module Squid Pre -bumped..............................................23

3.30 C3137,C3141: Capacitor Ceramic 220,0 nF +/-10% 6,3 V ..................23

3.31 L2200: Ind WW 4.7 uH K3012.............................................................24

3.32 V2202: TRANS V;DUAL_PMOSFET;BYX101603_A;REQ318.......24

3.33 V2431: Diode Protection 0.7 V SOD-882.............................................25

1208-5032 REV 4

Company Internal

© Sony Ericsson Mobile Communications

Page 2

Working Instruction, Electrical

3.34 Z4200,Z4201,Z4202: LC Filter Array 0805 22pF................................25

3.35 N2205: DC/DC Converter....................................................................26

3.36 N3100: IC Amp 9-Pin Flip-Chip...........................................................26

3.37 V4205,V4206: Trans Array..................................................................27

3.38 Z2400: Filter 100, MHz K1210...........................................................27

4 Revision history ...................................................................................28

1208-5032 REV 4

Company Internal

2(28)

© Sony Ericsson Mobile Communications

Page 3

Working Instruction, Electrical

1 Moisture Sensitivity and Component Baking

Some components in this product are moisture sensitive and must be baked prior to use if they

have been exposed to air. These components and their moisture sensitivity levels are

specified in the Electrical Component Placing document. Below is a brief description of

moisture sensitivity levels, but repair centers should visit the JEDEC website for more details

before reworking moisture sensitive components. Search for the most recent version of the

IPC/JEDEC J-STD-033A standard online at http://www.jedec.org/

Level 1 unlimited floor life; does not require dry pack or re-baking.

Level 2 1 year floor life; </=30° C; 60% relative humidity (rh); shipped in dry pack; must

be re-baked after being opened if floor life is exceeded.

Level 2A 4 weeks floor life; </=30° C; 60% rh; shipped in dry pack; must be re-baked after

being opened if floor life is exceeded.

Level 3 168 hours floor life; </=30° C; 60% rh; shipped in dry pack; must be re-baked

after being opened if floor life is exceeded.

Level 4 72 hours floor life; </=30° C; 60% rh; shipped in dry pack; must be re-baked after

being opened if floor life is exceeded.

Parts shipped from the Sony Ericsson Parts Warehouse are most likely NOT shipped in dry

pack. This means the time elapsed between placing the order and receiving the parts must be

considered as time exposed to the environment.

Different moisture sensitivity levels and exposure times create the need for different baking

temperatures and times. More detailed information may be found in the most recent version of

the IPC/JEDEC J-STD-033A standard. The standard is available online at

http://www.jedec.org/

.

1208-5032 REV 4

Company Internal

3(28)

© Sony Ericsson Mobile Communications

Page 4

Working Instruction, Electrical

2 Lead-free Rework

2.1 Lead-free Symbol

NOTE!

• This is a lead-free product!

• All solder wire or paste used with this product

must be lead-free.

• All rework tools that directly contact the solder

must remain lead-free. They must only be used

for lead-free repairs.

2.2 Bottom Heat

Because of the higher temperatures required for lead-free solder, bottom heat is

strongly recommended for rework of all ASICs. This does not include small

transistors or chips, but it does include fine pitch components and BGA type

components.

1208-5032 REV 4

Company Internal

4(28)

© Sony Ericsson Mobile Communications

Page 5

Working Instruction, Electrical

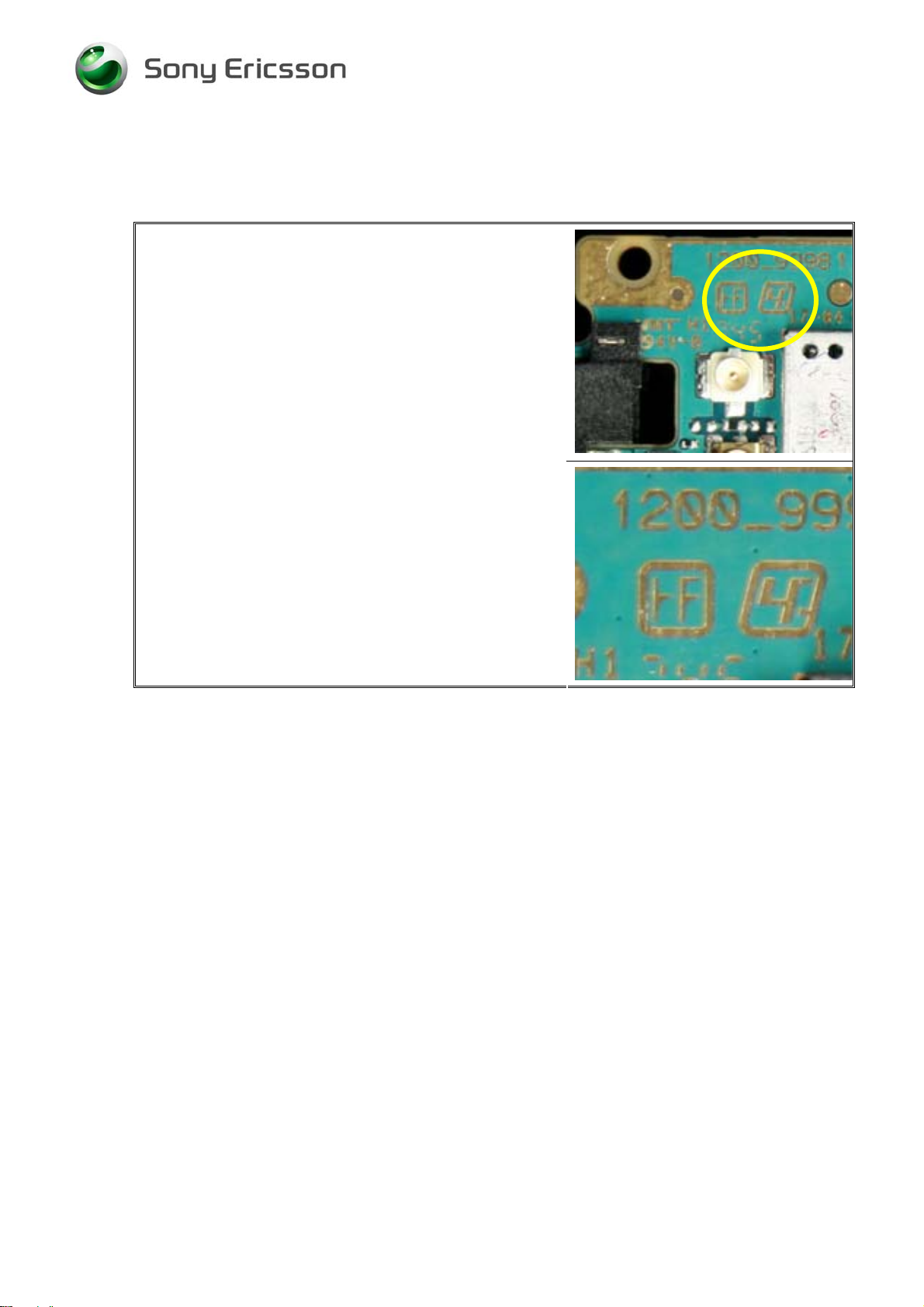

2.3 Reflow Profile for BGA Rework Station

The profile shall be according to SEMC profiling specification below.

Profile parameters are illustrated in table 2.3.

Reflow profile in this document always refers to the reflow profile which is measured

on the board/component with thermocouples and do not refer to the BGA Rework

Stations setting which can vary depending on the machine type and individual

machine. Verification of reflow profile shall be done on each set of equipment.

Table 2.3.1

Ramp rate < 3°C/sec

Ramp rate cooling < 6°C/sec

Time above liquidus 40-70 sec

Minimum temperature 235°C

Maximum component temperature 260 °C

Time above 235°C 10-40 sec

Recommended Total time Approx. 3-5min

The following graph, in table 2.3.2, shows an example of a lead-free profile including

bottom heat and top heat. The profile for specific parts and specific equipment will

vary, but the maximum temperature must not be exceeded.

Table 2.3.2

290

250

200

150

Temperature [ºC]

100

50

Reflow zone

260°C

245°C

230°C

150°C

125°C

0

1208-5032 REV 4

Company Internal

40 80 120 160 200 240 280

Time [Seconds]

© Sony Ericsson Mobile Communications

5(28)

Page 6

Working Instruction, Electrical

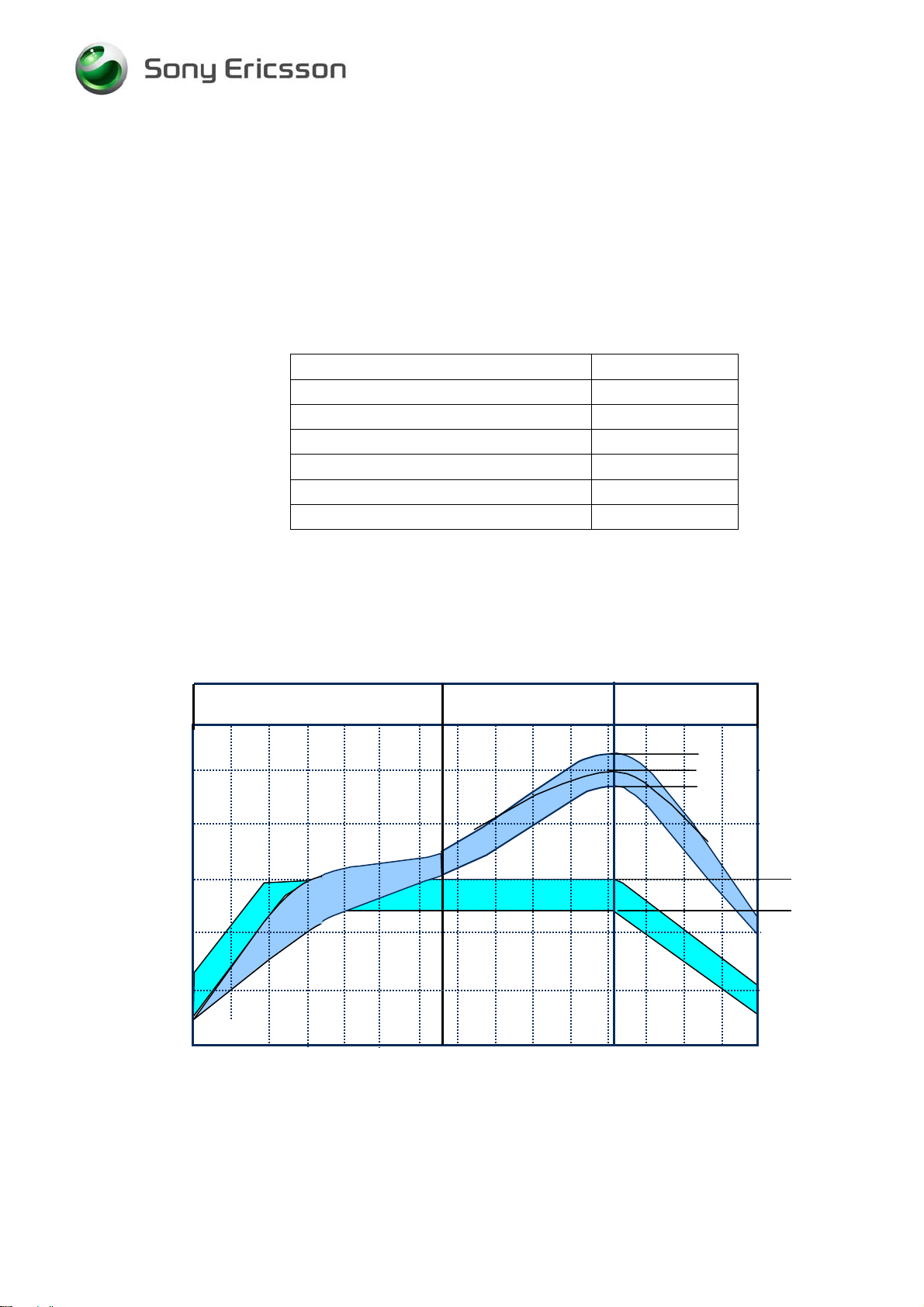

2.4 Inspection

Lead-free solder joints are more difficult to inspect because they do not have shiny

surfaces like leaded solder joints. Also, lead-free solder does not flow as well as

leaded solder, so some of the solder pad area may remain exposed.

Good Leaded Solder Joints

Good Lead-free Solder Joints

1208-5032 REV 4

Company Internal

© Sony Ericsson Mobile Communications

6(28)

Page 7

Working Instruction, Electrical

3 Replacement of components

EQUIPMENT

• Dentist hook

• ESD-gloves (cotton gloves)

• ESD-wristband

• Soldering tools

• Hot Air Station

• Bottom Heat

• BGA Rework Station

• Pair of tweezers

• Solder wick

• Solder paste lead-free (SN 96% Ag 3.5% Cu 0.5%)

• Flux, RMA no-clean flux

CAUTION

• Keep all contact surfaces clean of dirt and hand-grease!

• Remove Film and Labels on PCBA, BB shielding can, and Liquid intrusion indicators in

advance if necessary before repairing PCBA.

MECHANICAL INSTRUCTIONS

For all the following part replacements, disassemble and assemble the phone as described in

.

Working Instruction 1208-3142

1208-5032 REV 4

Company Internal

7(28)

© Sony Ericsson Mobile Communications

Page 8

Working Instruction, Electrical

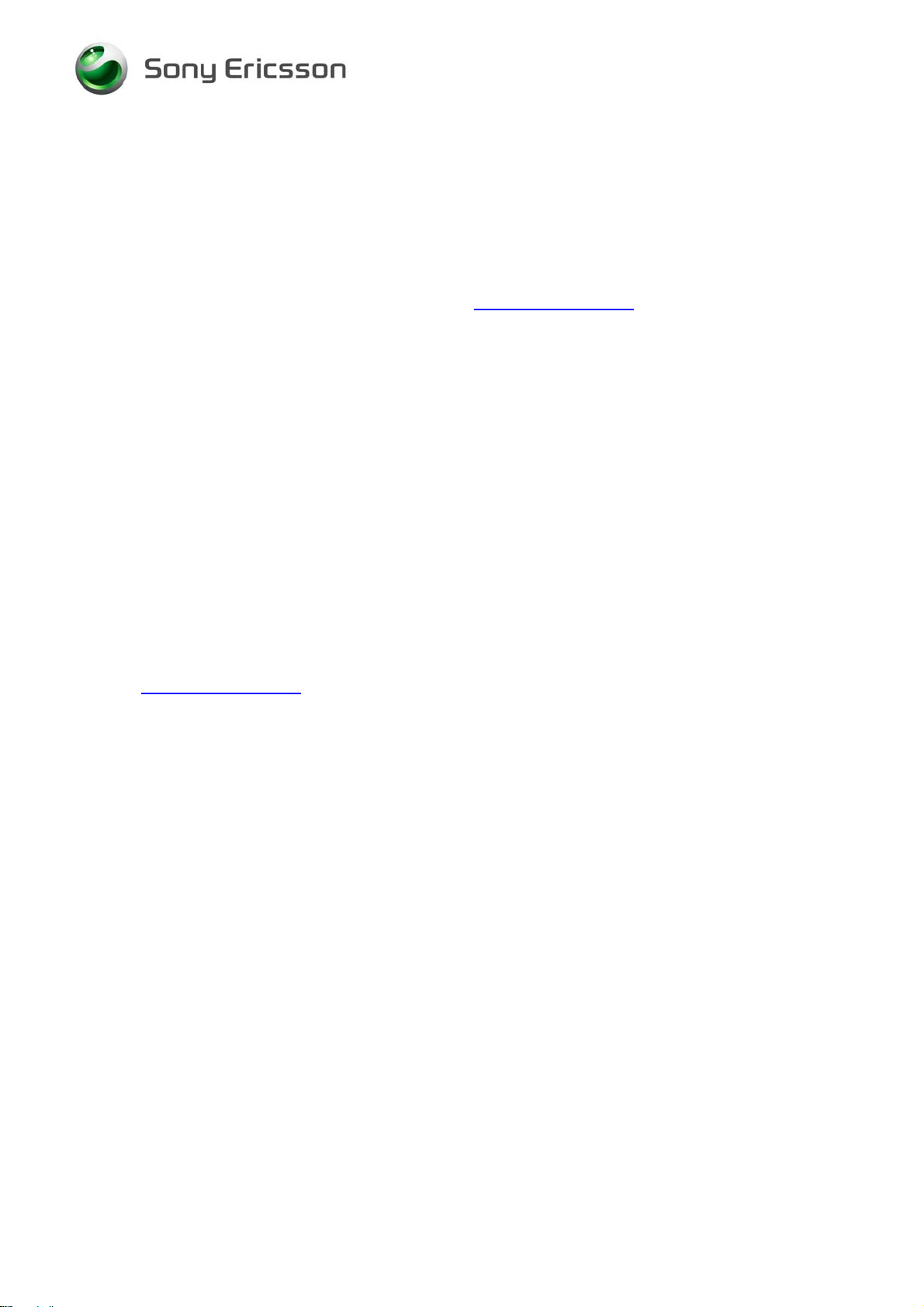

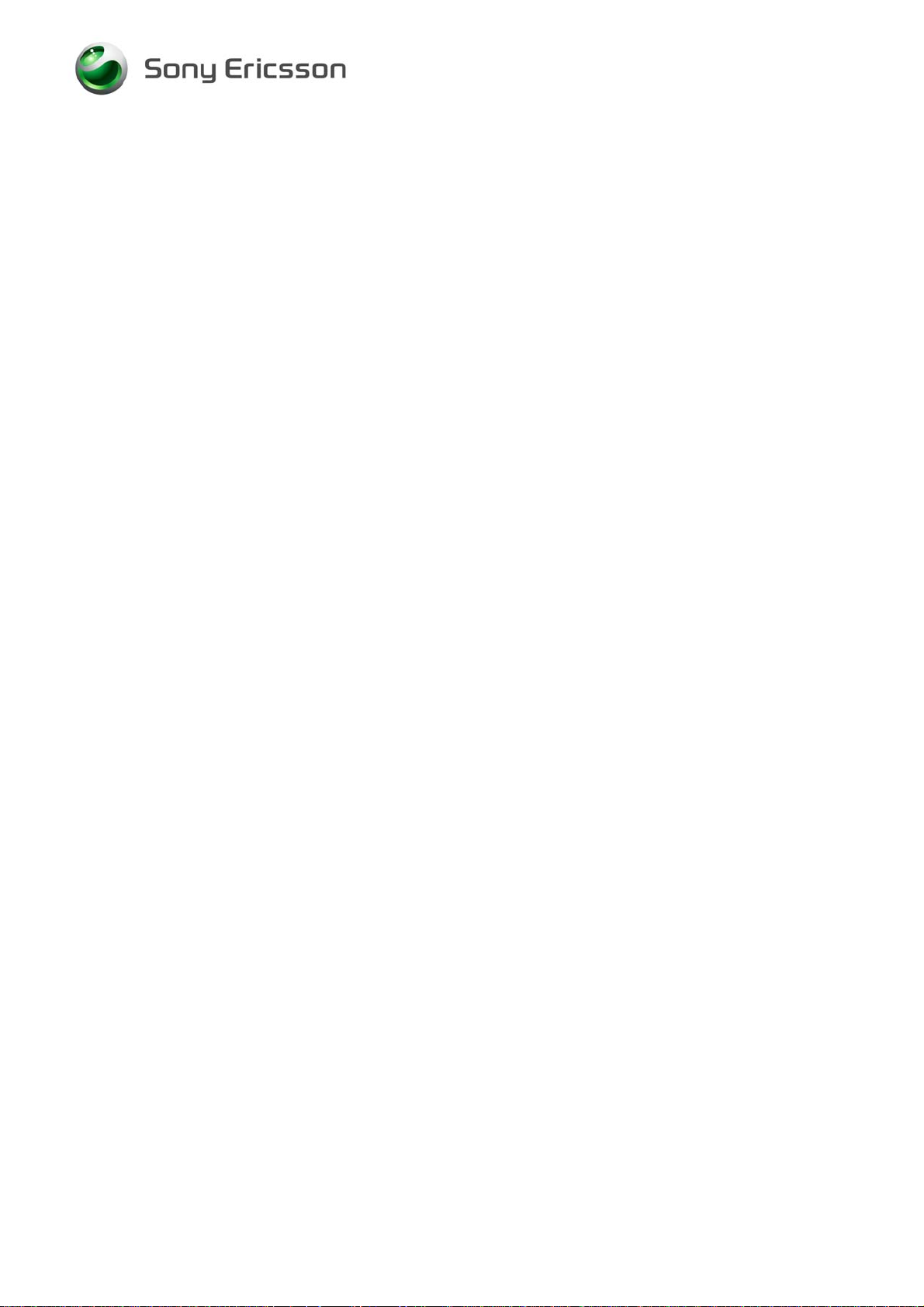

3.1 X1200: Conn Antenna

REMOVE FILM AND LIQUID INTRUSION INDICATORS IN

ADVANCE!

PROTECT THE SYSTEM CONNECTOR AND SIM CONNECTOR WITH

HEAT RESISTANT TAPE

Use BGA Station to replace the Conn Antenna.

!

3.2 X1201: Coax Connector

REMOVE FILM AND LIQUID INTRUSION INDICATORS IN

ADVANCE!

PROTECT THE SYSTEM CONNECTOR AND SIM CONNECTOR WITH

HEAT RESISTANT TAPE

Use BGA Station to replace the Coax Connector.

!

1208-5032 REV 4

Company Internal

8(28)

© Sony Ericsson Mobile Communications

Page 9

Working Instruction, Electrical

3.3 X1202: ANT GND Connector Leaf Spring 1p

Use Hot Air Station to replace the ANT GND Connector

Leaf Spring 1p

3.4 X2200: Battery Connector

REMOVE FILM AND LIQUID INTRUSION INDICATORS IN

ADVANCE!

PROTECT THE M2 CARD CONNECTOR AND SIM CONNECTOR WITH

HEAT RESISTANT TAPE

Use BGA Station to replace the Battery Connector.

!

1208-5032 REV 4

Company Internal

9(28)

© Sony Ericsson Mobile Communications

Page 10

Working Instruction, Electrical

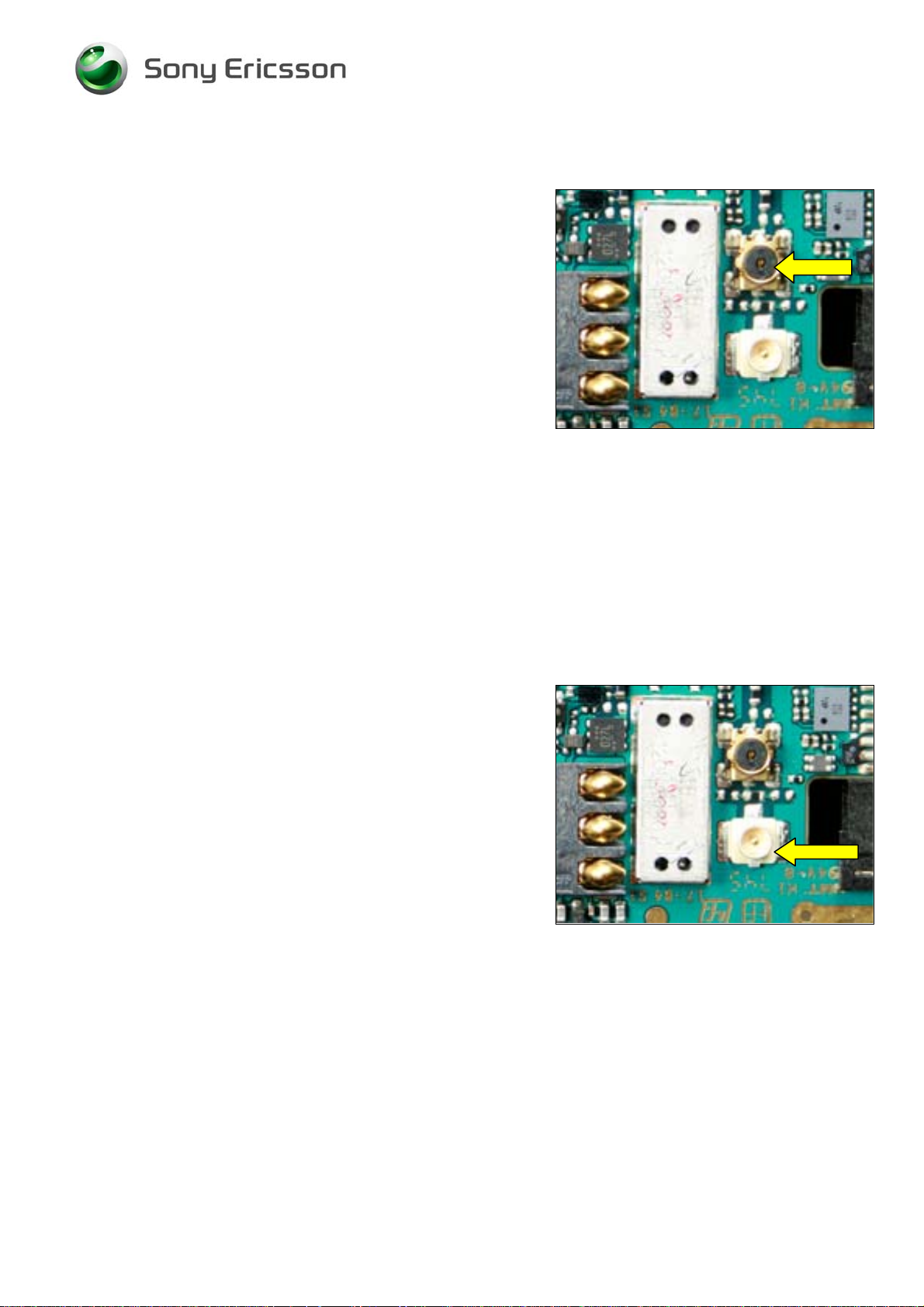

3.5 X2400: System connector

REMOVE FILM AND PCBA LABELS IN ADVANCE!

PROTECT RF CONNECTOR WITH HEAT RESISTANT TAPE!

Use BGA Station to replace the System connector.

3.6 X3100: Con X Keyboard connector

REMOVE FILM IN ADVANCE!

PROTECT M2 CARD CONNECTOR WITH HEAT RESISTANT TAPE!

Use BGA Station to replace the Con X Keyboard connector.

1208-5032 REV 4

Company Internal

10(28)

© Sony Ericsson Mobile Communications

Page 11

Working Instruction, Electrical

3.7 X4200: LCM Connector

Use BGA Station to replace the LCM Connector.

3.8 N1400: Module Bluetooth + FM STLC2592

Cut the pickup area firstly.

Use BGA Station to replace the BT/FM Module.

1208-5032 REV 4

Company Internal

11(28)

© Sony Ericsson Mobile Communications

Page 12

Working Instruction, Electrical

3.9 B4200: SMD Vibrator

Use Hot Air Station to replace the SMD Vibrator.

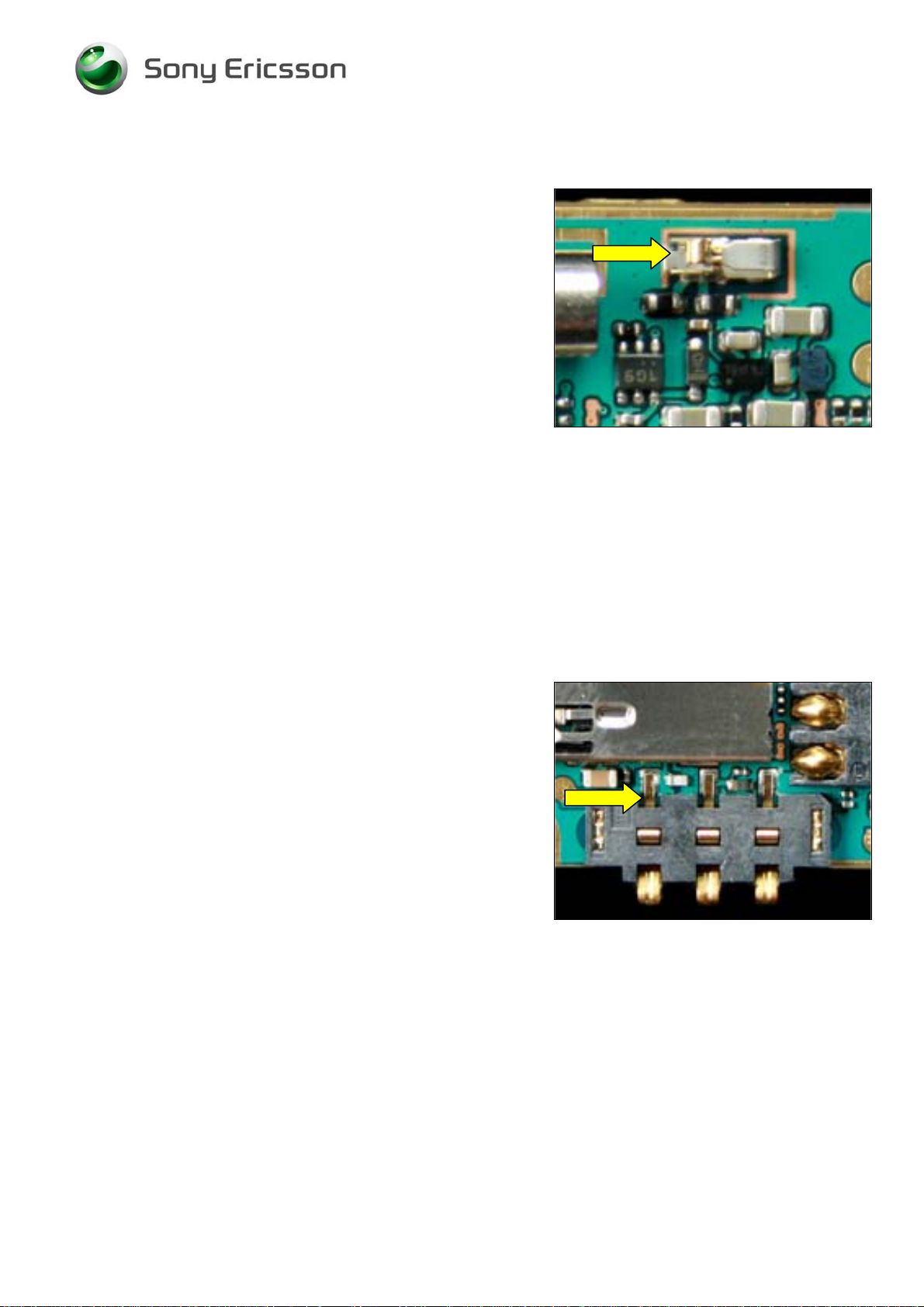

3.10 X2403: SIM Card Connector

REMOVE FILM IN ADVANCE!

PROTECT THE M2 CARD CONNECTOR AND BATTERY

CONNECTOR WITH HEAT RESISTANT TAPE

Use BGA Station to replace the SIM Card Connector.

!

1208-5032 REV 4

Company Internal

12(28)

© Sony Ericsson Mobile Communications

Page 13

Working Instruction, Electrical

3.11 X2405: MS-Micro Pico holder

PROTECT THE SIM CONNECTOR, KEYBOARD CONNECTOR,

BATTERY CONNECTOR WITH HEAT RESISTANT TAPE

Use BGA Station to replace the MS-Micro Pico holder.

!

3.12 N3101: ASIC Tjatte3 CSP20

REMOVE PCBA LABELS AND FILM IN ADVANCE!

PROTECT THE RF CONNECTOR AND SYSTEM CONNECTOR WITH

HEAT RESISTANT TAPE

Use BGA Station to replace the ASIC Tjatte3 CSP20.

!

1208-5032 REV 4

Company Internal

13(28)

© Sony Ericsson Mobile Communications

Page 14

Working Instruction, Electrical

3.13 D2105: IC Single bus buffer gate

Cut the pickup area firstly.

Use BGA Station to replace the IC Single bus buffer gate.

3.14 D2400: IC IF ISP1508 ES3 (3.5*3.5*0.8)

Use BGA Station to replace the IC IF ISP1508 ES3

(3.5*3.5*0.8)

1208-5032 REV 4

Company Internal

© Sony Ericsson Mobile Communications

14(28)

Page 15

Working Instruction, Electrical

3.15 L2401-L2404: Filter 0.0 Hz 0402

PROTECT THE SYSTEM CONNECTOR WITH HEAT RESISTANT

!

TAPE

Use Hot Air Station to replace the Filter 0.0 Hz 0402.

3.16 N2203: 2ch-LDO, Vout1=2.8V, Vout2=1.8V, WL-CSP6

PROTECT THE LCM CONNECTOR WITH HEAT RESISTANT TAPE!

Use BGA Repair Station to replace the 2ch-LDO,

Vout1=2.8V, Vout2=1.8V, WL-CSP6.

1208-5032 REV 4

Company Internal

15(28)

© Sony Ericsson Mobile Communications

Page 16

Working Instruction, Electrical

3.17 N2400: IC

REMOVE PCBA LABELS AND FILM IN ADVANCE!

PROTECT THE SIM CONNECTOR AND M2 CONNECTOR WITH

HEAT RESISTANT TAPE

Use BGA Repair Station to replace IC.

!

3.18 N2402:IC ESD Prot UDFN 6 2x2 mm

REMOVE PCBA LABELS IN ADVANCE!

PROTECT THE SYSTEM CONNECTOR AND RF CONNECTOR WITH

HEAT RESISTANT TAPE

Use BGA Station to replace the IC ESD Prot UDFN 6 2x2

mm.

!

1208-5032 REV 4

Company Internal

16(28)

© Sony Ericsson Mobile Communications

Page 17

Working Instruction, Electrical

3.19 Ear speaker: Ear Speaker 1107.0 Rectangular

Use Hot Iron to replace the Ear Speaker 1107.0

Rectangular.

1208-5032 REV 4

Company Internal

© Sony Ericsson Mobile Communications

17(28)

Page 18

Working Instruction, Electrical

3.20 Loudspeaker: Loudspeaker 1318.0 Oval

Use Hot Iron to replace the Loudspeaker 1318.0 Oval

3.21 V2420-V2422, V4209: Diode Zener 15, V SOD523

PROTECT THESYSTEM CONNECTOR WITH HEAT RESISTANT

!

TAPE

PAY MORE ATTENTION ABOUT THE PART DIRECTION!

Use Hot Air Station to replace the Diode Zener 15, V

SOD523

V2420—Left, V2421--Right

V2422:

1208-5032 REV 4

Company Internal

18(28)

© Sony Ericsson Mobile Communications

Page 19

Working Instruction, Electrical

V4209:

3.22 E1000: Shield Can Closed small shielding

REMOVE FILM AND PCBA LABELS IN ADVANCE!

PROTECT THE SIM CONNECTOR AND RF CONNECTOR WITH HEAT

RESISTANT TAPE!

Use BGA Repair Station to remove the Shield Can Closed

small shielding.

1208-5032 REV 4

Company Internal

19(28)

© Sony Ericsson Mobile Communications

Page 20

Working Instruction, Electrical

3.23 E1001: Shield Can Fence

REMOVE BB SHEILDING CAN IN ADVANCE!

PROTECT THE BATTERY CONNECTOR AND LCM CONNECTOR,

SYSTEM CONNECTOR WITH HEAT RESISTANT TAPE

Use BGA Station to replace the Shield Can Fence.

!

3.24 N2202: IC Vreg SON-6

REMOVE FILM IN ADVANCE!

PROTECT SIM CONNECTOR WITH HEAT RESISTANT TAPE!

Use BGA Station to replace the IC Vreg SON-6.

1208-5032 REV 4

Company Internal

20(28)

© Sony Ericsson Mobile Communications

Page 21

Working Instruction, Electrical

3.25 B4410: IC Lin, MR sensor

PROTECT THE LCM CONNECTOR WITH HEAT RESISTANT TAPE!

Use BGA Station to replace the IC Lin, MR sensor.

3.26 N2204: LDO1.2 V, 200mA, low noice, CS 5

PROTECT THE LCM CONNECTOR WITH HEAT RESISTANT TAPE!

Use BGA Station to replace the LDO1.2 V, 200mA, low

noice, CS 5.

1208-5032 REV 4

Company Internal

21(28)

© Sony Ericsson Mobile Communications

Page 22

Working Instruction, Electrical

3.27 B2102: Crystal 32,768 kHz

REMOVE BB SHEILDING CAN IN ADVANCE!

PROTECT BATTERY CONNECTOR WITH HEAT RESISTANT TAPE!

Use BGA Station to replace the Crystal 32,768 kHz.

3.28 N1200: RF-Module Thor Pre-bumped

REMOVE PCBA LABELS IN ADVANCE!

PROTECT SYSTEM CONNECTOR WITH HEAT RESISTANT TAPE!

Use BGA Station to replace the pre-bumped Mod Radio

Thor GSM/EDGE.

.

1208-5032 REV 4

Company Internal

22(28)

© Sony Ericsson Mobile Communications

Page 23

Working Instruction, Electrical

3.29 N1210: RF-Module Squid Pre -bumped

REMOVE PCBA LABELS IN ADVANCE!

PROTECT M2 CONNECTOR AND KEYBOARD CONNECTOR WITH

HEAT RESISTANT TAPE

Use BGA Station to replace the pre-bumped Mod Radio

WCDMA Squid.

!

3.30 C3137, C3141: Capacitor Ceramic 220,0 nF +/-10% 6,3 V

REMOVE BB SHEILDING CAN LID IN ADVANCE!

Cut the pickup area firstly.

Use Hot Air Station to replace the Capacitor Ceramic 220,0

nF +/-10% 6,3 V

.

1208-5032 REV 4

Company Internal

23(28)

© Sony Ericsson Mobile Communications

Page 24

Working Instruction, Electrical

3.31 L2200: Ind WW 4.7 uH K3012

REMOVE BB SHEILDING CAN LID IN ADVANCE!

Use Hot Air Station to replace the Ind WW 4.7 uH K3012.

3.32 V2202: TRANS V;DUAL_PMOSFET;BYX101603_A;REQ318

REMOVE SHEILDING FILM IN ADVANCE!

PROTECT SIM CARD CONNECTOR WITH HEAT RESISTANT TAPE!

Use BGA Station to replace the TRANS

V;DUAL_PMOSFET;BYX101603_A;REQ318.

.

1208-5032 REV 4

Company Internal

24(28)

© Sony Ericsson Mobile Communications

Page 25

Working Instruction, Electrical

3.33 V2431: Diode Protection 0.7 V SOD-882

PROTECT SYSTEM CONNECTOR WITH HEAT RESISTANT TAPE!

Use BGA Station to replace the Diode Protection 0.7 V

SOD-882.

3.34 Z4200, Z4201, Z4202: LC Filter Array 0805 22pF

PROTECT LCM CONNECTOR WITH HEAT RESISTANT TAPE!

Use BGA Station to replace the LC Filter Array 0805 22pF.

Note: From left to right, their positions are Z4200, Z4201,

and Z4202.

.

1208-5032 REV 4

Company Internal

25(28)

© Sony Ericsson Mobile Communications

Page 26

Working Instruction, Electrical

3.35 N2205: DC/DC Converter

REMOVE SHEILDING FILM IN ADVANCE!

PROTECT SIM CARD CONNECTOR AND RF CONNECTOR WITH

HEAT RESISTANT TAPE

Use BGA Station to remove the small shielding firstly.

Use BGA Station to replace the DC/DC Converter.

Use BGA Station to re-solder the small shielding.

!

3.36 N3100: IC Amp 9-Pin Flip-Chip

REMOVE BB SHEILDING CAN LID IN ADVANCE!

Use BGA Station to replace the IC Amp 9-Pin Flip-Chip .

.

1208-5032 REV 4

Company Internal

26(28)

© Sony Ericsson Mobile Communications

Page 27

Working Instruction, Electrical

3.37 V4205,V4206: Trans Array

PROTECT LCM CONNECTOR WITH HEAT RESISTANT TAPE!

Use BGA Station to replace the Trans Array.

Left: V4206 Right: V4205

3.38 Z2400: Filter 100, MHz K1210

PROTECT LCM CONNECTOR AND RF CONNECTOR WITH

HEAT RESISTANT TAPE

Use BGA Station to replace the Filter 100, MHz K1210.

.

!

1208-5032 REV 4

Company Internal

27(28)

© Sony Ericsson Mobile Communications

Page 28

Working Instruction, Electrical

4 Revision history

Rev. Date Changes / Comments

1 2008-03-17 First release

2 2008-04-01 Delete N3100

3 2008-04-03 Add C3137, C3141, L2200, V2202, V2431,

Z4200,Z4201,Z4202, N2205

4 2008-04-07 Add N3100,V4205,V4206,Z2400

1208-5032 REV 4

Company Internal

28(28)

© Sony Ericsson Mobile Communications

Loading...

Loading...