Page 1

Equipment List, Electrical

Equipment List, Electrical

Applicable for W710 and Z710

Contents

General ................................................................................................................................................................ 2

1

2 Column Definitions............................................................................................................................................. 2

Description Columns ............................................................................................................................................ 2

Process Columns ................................................................................................................................................. 2

3 Repair Equipment............................................................................................................................................... 3

3.1 Repair Equipment orderable from Sony Ericsson...................................................................................3

3.2 Repair Equipment that should be obtained from local Suppliers............................................................ 7

3.3 Lead-free Solder Equipment................................................................................................................. 17

4 Revision History ............................................................................................................................................... 19

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

Page 2

Equipment List, Electrical

1 General

This document describes the equipment needed, in addition to the equipment listed in the Mechanical Equipment List, to upgrade

the applicable product(s)’s software, functional test and to repair the product(s) at an Electrical Repair Level. The first section is

equipment that can be purchased from a Sony Ericsson Parts and Tools warehouse. The second section is equipment that must be

purchased from other vendors.

2 Column Definitions

Description Columns

• Description = The name of the equipment.

• Part Number = The Sony Ericsson part number to use when ordering from a Sony Ericsson Parts and Tools warehouse.

• Comments = Additional information that helps to specify or clarify the equipment.

• Picture

Process Columns

These columns show which processes use the equipment. An “X” in a column indicates that the equipment must be used, and a “Z”

in a column indicates that the use of that equipment is optional.

Customization: Equipment necessary to perform a Customization/Activation.

Go/No Go test: Equipment necessary for Go/No Go testing.

Calibration with SERP: Equipment necessary to perform a calibration with SERP.

NOTE: Calibration can only be done by authorized repair centers.

Repair: Equipment necessary for replacing soldered components.

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

2(19)

Page 3

Equipment List, Electrical

3 Repair Equipment

Some of the required equipment will be orderable from Sony Ericsson and some equipment has to be sourced locally. The following

sections are structured based on whether equipment is obtained from Sony Ericsson or from a local supplier.

3.1 Repair Equipment orderable from Sony Ericsson

Go/No Go Test

Description Part Number Comments Picture

Sony Ericsson

Programming Interface

(SEPI)

LTN 214 1484 The Sony Ericsson

Programming Interface

(SEPI) is used in conjunction

with the SEPI interface cable,

the USB computer cable and

battery charger to perform

calibration on this product.

Customization

X

Calibration in

SERP

Repair

Sony Ericsson

Programming Interface

(SEPI) cable

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

KRY 101 1119 A battery charger needs to be

connected to this cable

during calibration.

X

3(19)

Page 4

Equipment List, Electrical

Go/No Go Test

Customization

Calibration in

SERP

Repair

Description Part Number Comments Picture

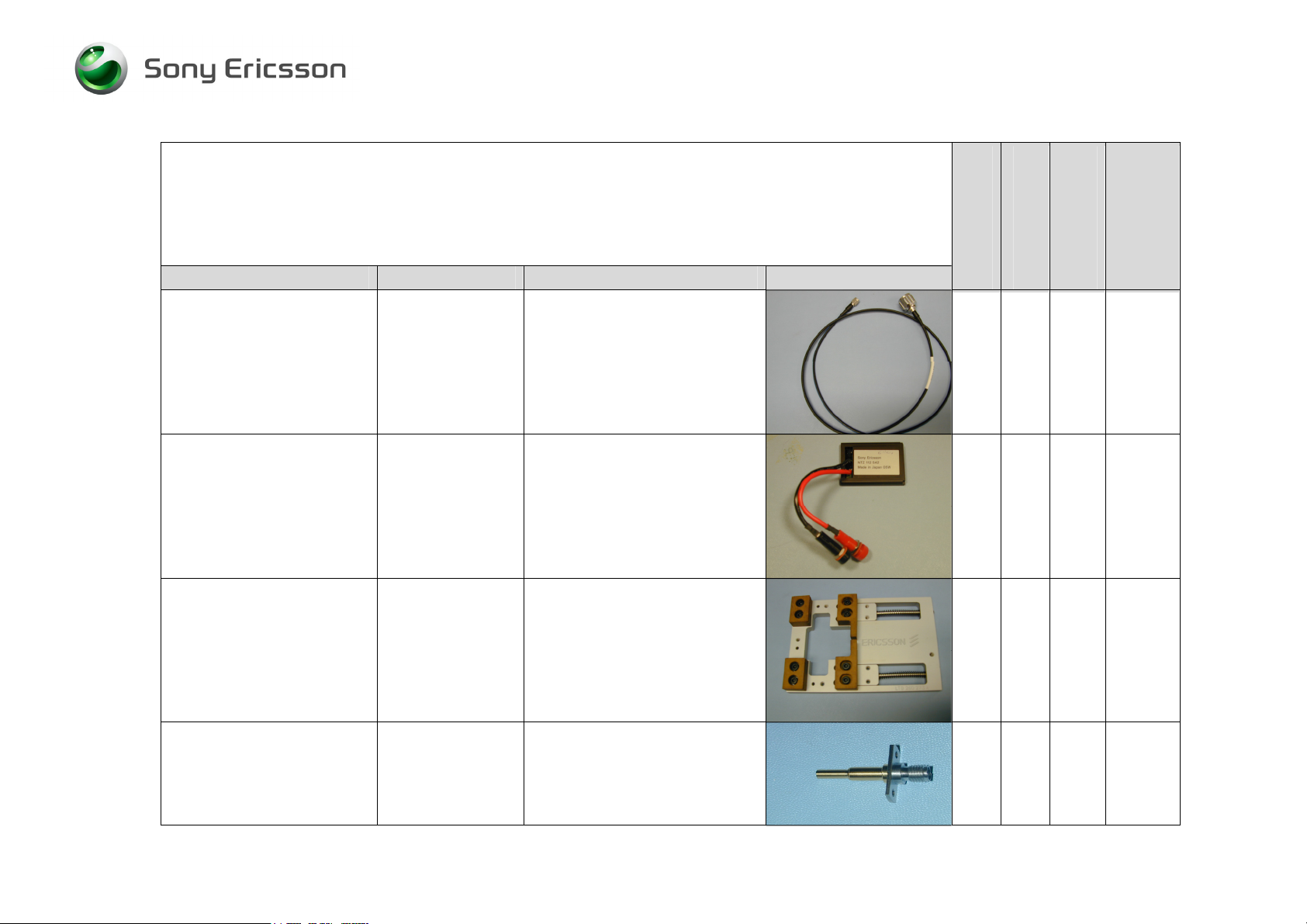

RF Cable RPM 119 855

X X

Battery Eliminator NTZ 112 542 If using the Battery Eliminator

to power the handset during

the GNG Test or Calibration

routine you must use a high

quality DC source.

Z Z Z

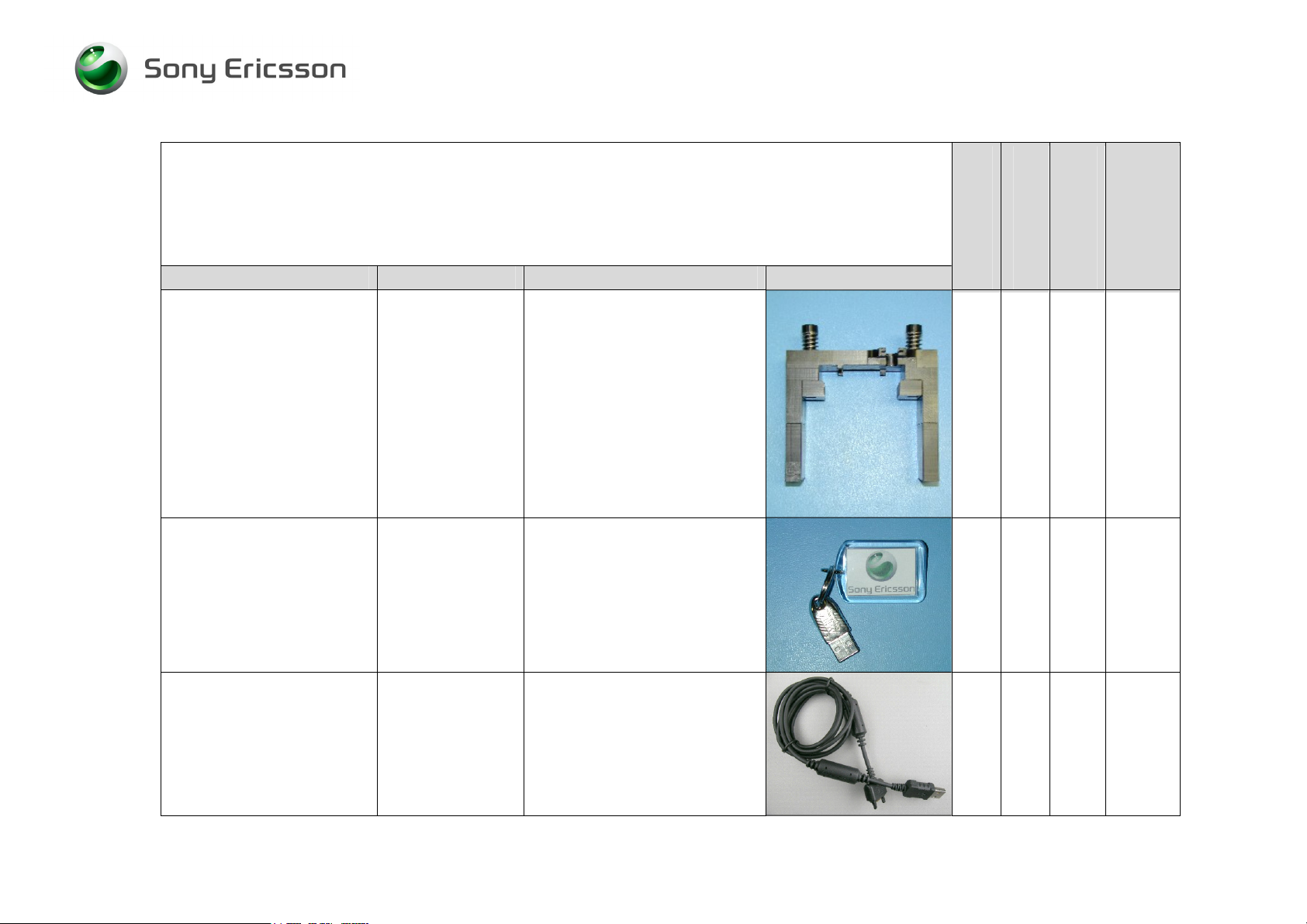

Rework Fixture for PCB LTD 260 273 Used to hold the PCB during

RF Probe RPM 119 0201 Used together with the RF

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

repair.

X

Holder and RF Cable.

Z X

4(19)

Page 5

Equipment List, Electrical

Go/No Go Test

Customization

Calibration in

SERP

Repair

Description Part Number Comments Picture

RF Holder NTZ 112 1072 Used together with RF probe

and RF cable.

Z X

USB Activation Dongle NTZ 112 1071 Used for Activation in EMMA

DCU-60/USB Cable KRY 101 1413 This cable is needed for

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

III

X

loading ITP software and

customization/activation.

X

5(19)

Page 6

Equipment List, Electrical

Go/No Go Test

Customization

Calibration in

SERP

Repair

Description Part Number Comments Picture

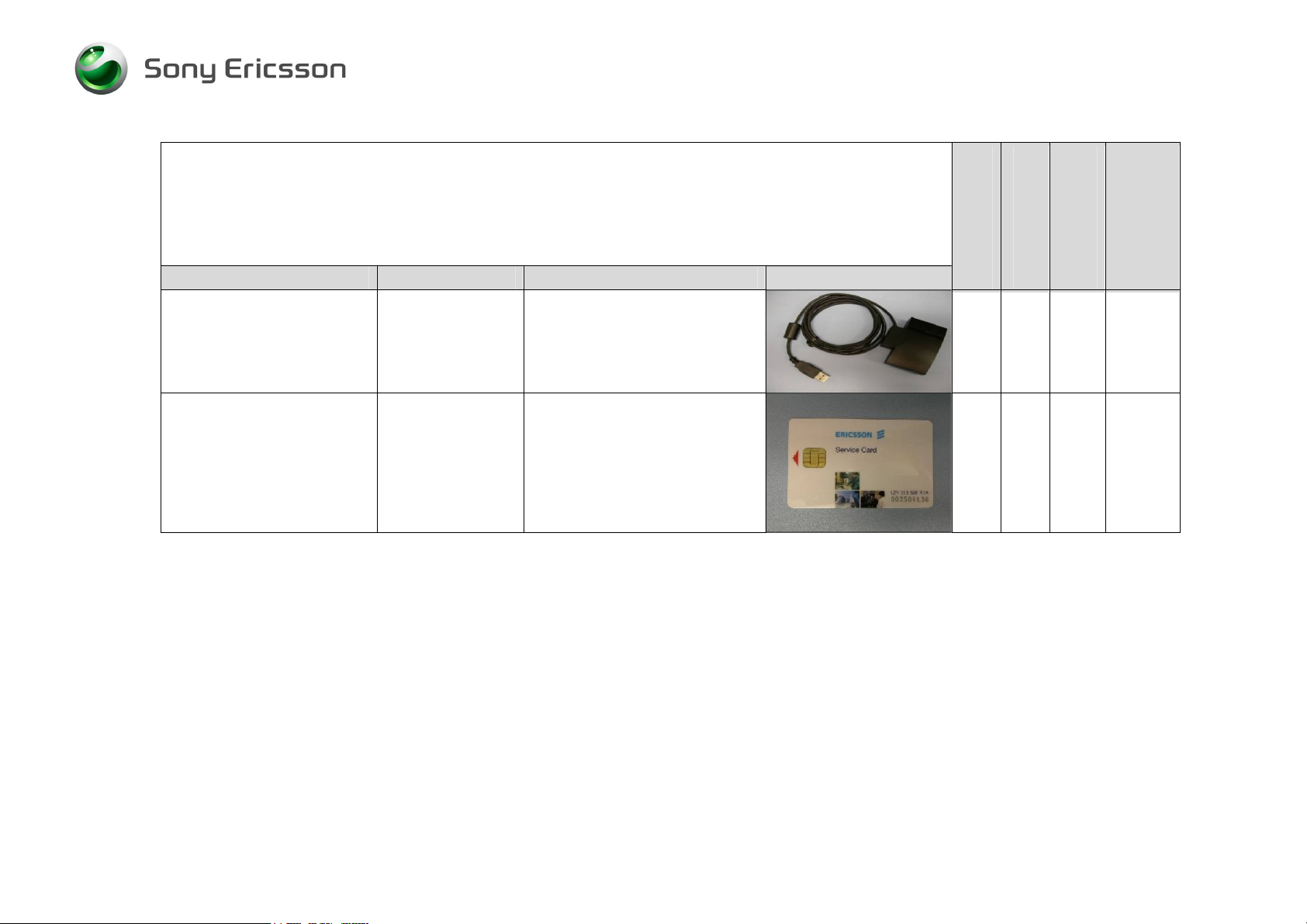

USB Smartcard Reader

and CD

Service Card LZY 213 595 The Service Card is required

LZY 213 1191 This USB Smartcard Reader

provides the means for

reading a Service Card. This

is required for Activation and

Flashing offline in EMMA III.

for Activation and Flashing

offline in EMMA III

X

X

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

6(19)

Page 7

Equipment List, Electrical

3.2 Repair Equipment that should be obtained from local Suppliers

Description Comments

RF Shield Package

Rohde&Schwarz RF Shield

Package

• CMU-Z10 – Antenna

Coupler

(Partnr: 1150.0801.10)

• CMU-Z11 – RF Shield Cover

(Partnr. 1150.1008.02)

Using an RF shield package is one of the options for testing

the applicable product(s). Testing of the applicable

product(s) can also be performed by using the combination

of an RF Probe and an RF cable.

Spare parts for mobile phone fixation for R&S CMU-Z10 are

available for purchase from Rohde&Schwarz:

• Grid Positioning Plate – 1158.9789.00

• L-shaped bracket – 1158.9808.00

• Stabilizing pieces – 1158.9820.00

NOTE: The Rohde & Schwarz package will require the use

of a precision N-type male to SMA female RF adapter to

mate with the SEMC RF cable.

NOTE: If you are using a different RF Shield Package than

Rohde & Schwartz, special attenuation factors for Go/NoGo test are required.

Customization

Z

Go/No Go Test

Calibration in

SERP

Repair

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

7(19)

Page 8

Equipment List, Electrical

Customization

Go/No Go Test

Calibration in

SERP

Description Comments

RF adapter for RF shield box

• The adapter for a Rohde &

Schwarz Shield box must be a

precision N-type male to SMA

female adapter.

Battery Charger

(Standard SEMC charger

applicable for W710 or Z710)

USB Computer Cable Type A to Type B USB cable.

This adapter is used to connect the RF shield box to the RF

cable and is only required if a shield package is going to be

used for testing.

Recommended source:

• Pasternack Enterprises – (949) 261-1920 or

www.pasternack.com

Part number: PE9430

The battery charger needs to be connected to the Sony

Ericsson Programming Interface Cable during calibration.

Also used for Charger Test.

This is part of the hardware needed for performing

calibration. This cable connects the computer to the SEPI.

Z

X

X

Repair

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

8(19)

Page 9

Equipment List, Electrical

Customization

Go/No Go Test

Calibration in

SERP

Description Comments

Test and Calibration Instrument

(Chose one of the following.)

Anritsu MT 8801B

Required Components:

• MT8801B (Radio Com.

Analyser)

• MT8801B-02 (SG-local)

• MX880115A (GSM

Measurement Software)

Required Software:

• Main 4.02

• System 4.05

Anritsu MT 8801C

Required Components:

• MT8801C (Radio Com.

Analyser)

• MX880115A (GSM

Measurement Software)

Required Software:

• Main 4.02

• System 4.05

If it is preferred to use a test instrument for GNG that is not

specified, the test script must be written according to

2/1524-2/FEA 209 544/601 and approval of the test script

must be obtained from Sony Ericsson.

Note: This instrument does not support the calibration

routine for the W710 and Z710.

Note: It is strongly recommended that the instrument vendor

be contacted before ordering this setup to ensure that the

options stated are still valid or that no part numbers have

changed.

Note: This instrument does not support the calibration

routine for the W710 and Z710.

Note: It is strongly recommended that the instrument vendor

be contacted before ordering this setup to ensure that the

options stated are still valid or that no part numbers have

changed.

X

X

Repair

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

9(19)

Page 10

Equipment List, Electrical

Customization

Go/No Go Test

Calibration in

SERP

Description Comments

Anritsu MT 8802A

Required Components:

• MT8802A (Radio Com.

Analyser)

• MX880215A (GSM

Measurement Software)

Required Software:

• Main 1.11

• System 2.07

Agilent 8960

Required Components:

• E5515C (8960 Series 10

Mainframe)

• Option E5515C-002 (2nd RF

source)

Required Software

• E1968A-101 GSM and

E1968A-103 EGPRS Test

Application

or

• E1968A-202

GSM/GPRS/EGPRS Test

Application

Note: This instrument does not support the calibration

routine for the W710 and Z710.

Note: It is strongly recommended that the instrument vendor

be contacted before ordering this setup to ensure that the

options stated are still valid or that no part numbers have

changed.

Some older versions of the 8960 Series 10 mainframes may

need to have a hardware upgrade in order to have EDGE

capabilities. See your local Agilent representative for details

E1968A-103 is not necessary for Go/No Go testing only

Calibration.

Note: It is strongly recommended that the instrument vendor

be contacted before ordering this setup to ensure that the

options stated are still valid or that no part numbers have

changed.

X

X X

Repair

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

10(19)

Page 11

Equipment List, Electrical

Customization

Go/No Go Test

Calibration in

SERP

Description Comments

Willtek 4403/4405/4407

Required Components:

• Option 4460 (GSM System)

• Option 4468 (EDGE

System)

• Option 4477 (OCXO)

• Firmware 4.24 or greater

• The 4403 instrument needs

to have option # M897163

installed.

Willtek 4202

Required Components:

• M101302 - 4202S

Mainframe

• M 248 418 - GSM 850

option

• Firmware 5.50 or greater

Note: It is strongly recommended that the instrument vendor

be contacted before ordering this setup to ensure that the

options stated are still valid or that no part numbers have

changed.

This instrument is only capable of running a stand alone

Go/No Go test. (SERP not required.)

Note: This instrument does not support the calibration

routine.

Note: It is strongly recommended that the instrument vendor

be contacted before ordering this setup to ensure that the

options stated are still valid or that no part numbers have

changed.

X X

X

Repair

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

11(19)

Page 12

Equipment List, Electrical

Customization

Go/No Go Test

Calibration in

SERP

Description Comments

Rohde & Schwarz CMU200

Required Components

• CMU200 mainframe

(Base Unit)

• Options CMU-B11,

CMU-B21, CMU-B52,

CMU-B54

• Required SW package:

CMU-PK20

Power Supply

(w/digital readout)

NOTE!

If using the Power Supply in

conjunction with the Battery

Eliminator (Dummy Battery) to

power the phone during the GNG

test or Calibration routine a high

quality DC source that meets the

following requirements must be

used.

Note: It is strongly recommended that the instrument vendor

be contacted before ordering this setup to ensure that the

options stated are still valid or that no part numbers have

changed.

Device Requirements:

• Output Voltage: 0-5 volt minimum.

• Output Current: 0-2 amps minimum.

• Transient response time: < 100 µs

Some examples of Power Supplies that meet these

requirements are as follows:

• Agilent 66xx ser

• Agilent 663x series

X X

Z Z Z

Repair

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

12(19)

Page 13

Equipment List, Electrical

Customization

Go/No Go Test

Calibration in

SERP

Description Comments

Small Convection (Hot Air) Device

Large Convection (Hot Air) Device

Nozzles for Large Convection (Hot

Air) Device

Digital Multi-meter

Microscope

Device Requirements:

• The device should allow variable adjustment over a

temperature range.

• The device should be capable of reaching an upper

temperature of 426.7oC (800oF) or more.

The range of airflow the device is capable of generating

should fall under 20 litre/minute.

Certain components on the parts list can only be

replaced using this device. These parts are specified in

the parts list.

• The device should allow variable temperature

adjustment and be capable of reaching an upper

temperature of 426.7oC (800oF) or more.

The range of airflow the device is capable of generating

should be above 20 litre/minute.

NOTE: Only necessary if you have a large convection

device.

Used for troubleshooting failures.

Minimum magnification required is 10x.

X

X

X

Z

X

Repair

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

13(19)

Page 14

Equipment List, Electrical

Customization

Go/No Go Test

Calibration in

SERP

Description Comments

GPIB Card National Instruments or Keithley

NOTES:

GPIB Cable

Power cable – Red

NOTE: Only necessary if using the

Battery Eliminator (Dummy

Battery).

• Drivers are required and should be supplied with a

card.

A GPIB card is not required if testing is being performed

using the Willtek 420x instrument.

This cable is only required if a GPIB card is used.

Cable Requirements:

• Minimum cross sectional area of conductor = 1.2mm2

• Maximum length = 1.5 m

• One end of cable must have a male banana-type

connector to be able to interface with the battery

eliminator.

The other end of the cable needs whatever connection is

necessary to connect to the power supply that you have.

Z X

Z X

Z Z Z

Repair

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

14(19)

Page 15

Equipment List, Electrical

Customization

Go/No Go Test

Calibration in

SERP

Description Comments

Power cable – Black

NOTE: Only necessary if using the

Battery Eliminator (Dummy

Battery).

Component baking oven

Cable Requirements:

• Minimum cross sectional area of conductor = 1.2mm2

• Maximum length = 1.5 m

• One end of cable must have a male banana-type

connector to be able to interface with the battery

eliminator.

The other end of the cable needs whatever connection is

necessary to connect to the power supply that you have.

Temperature requirements: 125°C +5°C/-0°C

Required for drying moisture sensitive components.

Below are links to several companies that sell convection

ovens.

http://www.cascadetek.com/forcedlist.php

http://www.wisoven.com/lab1.htm

http://www.shellab.com/products.html

http://www.terrauniversal.com/products/ovens/imperiaivmec

hcon.php

http://www.labsynergy.com/products_laboratoryovens.asp?k

eyword=*laboratoryovens

Z Z Z

X

Repair

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

15(19)

Page 16

Equipment List, Electrical

Customization

Go/No Go Test

Calibration in

SERP

Description Comments

FLUX Lead-free solder does not require a special flux. The “No

Clean” flux used with leaded products is acceptable.

Although some manufacturers are developing fluxes

specially made for use with lead-free solder (higher

evaporation temperatures, less smoke, etc.), these are not

required.

Low Static Heat Protection Tape This tape is required to protect adjacent components from

hot air.

Computer One of the following operating systems must be used:

• Windows 2000 with service pack 2 or higher

• Windows XP

Minimum Requirements:

• One unused PCI slot for GPIB card

• 2 USB Ports

The processor and RAM of the computer should at least

meet the the minimum requirements specified by the

operating system’s manufacturer.

Test SIM According to your Instrument supplier X

Printer

Optional, but recommended

X

X

X Z X

Z

Repair

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

16(19)

Page 17

Equipment List, Electrical

3.3 Lead-free Solder Equipment

The items in this table, and any other soldering tools or material that make physical contact with the solder, must remain lead-free.

They must be adequately labelled to make their lead-free status clearly and easily recognized.

Test

Pos Description Comments Picture

Lead-free Solder

Note: The solder must be composed of

Tin, Silver, and Copper, and nothing else.

The exact composition ratio may vary, but

it must be Tin, Silver, and Copper only.

This composition may also be known as

SnAgCu or SAC.

Lead-free Soldering paste To be used when replacing the RF

Lead-free labels

(sheet of 24)

SEMC Part # SVF9301379

(These labels are available from the Sony

Ericsson Parts and Tools Warehouse.)

Manufacturers of LF Solder:

- Tamura (www.tamura-kaken.co.jp)

Part # TLF-206-93F

- Multicore (www.multicore.com)

Part # 96SC

- Senju (www.senju-

m.co.jp)

Part # M705

module.

Required for labeling all soldering tools

and materials that contact the solder.

Repair

X

X

X

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

17(19)

Page 18

Equipment List, Electrical

Test

Repair

Pos Description Comments Picture

Soldering Tips

X

Soldering Iron

If one work bench is divided to

accommodate both leaded and lead-free

solder, then each side of the bench should

have its own iron.

Wicking Tape

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

• The device should allow variable

temperature adjustment and be

capable of reaching an upper

temperature of 426.7oC (800oF) or

more.

X

X

18(19)

Page 19

Equipment List, Electrical

Test

Repair

Pos Description Comments Picture

Tip Tinner

Z

Tip Cleaner (steel wool)

Z

4 Revision History

Rev. Date Changes / Comments

A 2006-08-25 Initial release

B 2006-09-18 New Firmware for the Willtek 4202 to support Quad Band testing.

Added USB Activation Dongle, Service Card Reader and Service Card.

Adjusted format issues

131 30-2/FEA 209 544/601 B

Company Internal

© Sony Ericsson Mobile Communications AB

19(19)

Loading...

Loading...