Page 1

Trouble Shooting Guide, Mechanical

Trouble Shooting Guide, Mechanical

Applicable for S700i, S700c

Contents

1

Explanations ....................................................................................................................2

1.1 Service functions in the software.......................................................................2

1.2 Misuse and other no warranty issues.................................................................2

1.2.1 Action ................................................................................................................ 2

1.2.2 Water indicator label .........................................................................................4

1.2.3 Action ................................................................................................................ 5

2 Appearance Problem ...................................................................................................... 6

3 Alert Problem ..................................................................................................................9

3.1 Vibrator .............................................................................................................9

3.2 Speaker .............................................................................................................. 9

4 Audio Problem ..............................................................................................................11

4.1 Receiver...........................................................................................................11

4.2 Microphone......................................................................................................11

5 Charging/Capacity........................................................................................................13

5.1 Charging .......................................................................................................... 13

5.2 Capacity...........................................................................................................13

6 Data Communication Problem .................................................................................... 13

7 Key/Flip..........................................................................................................................14

7.1 Keyboard .........................................................................................................14

7.2 Side keys..........................................................................................................15

7.3 Hinge ............................................................................................................... 16

8 LCD/Illumination.......................................................................................................... 18

8.1 LCD .................................................................................................................18

8.2 Illumination .....................................................................................................18

8.2.1 Main keyboard................................................................................................. 18

8.2.2 Navigation keys ...............................................................................................19

9 Network..........................................................................................................................20

10 On/Off ............................................................................................................................21

10.1 Battery .............................................................................................................21

10.2 On/Off key....................................................................................................... 21

11 Other ..............................................................................................................................23

11.1 Camera Problem .............................................................................................. 23

11.2 Camera shutter................................................................................................. 23

12 Software Problem..........................................................................................................25

13 Revision History............................................................................................................ 26

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

Approved according to 000 21-LXE 107 42/1

Page 2

Trouble Shooting Guide, Mechanical

1 Explanations

1.1 Service functions in the software

The service menu will be accessed with the following key combination. Use the joystick.

⇒*⇐⇐*⇐*

They are as follows:

Service info

Service tests

Text labels

The phones software has a built in service functionality that allows you to test some of the

phones functions. (See point 2 above) It looks like this:

Main display

Camera

LED/illumination

Flash LED

Keyboard

Vibrator

Earphone

Speaker

Microphone

Real time clock

FM radio (You need a headset to test)

Total call time

1.2 Misuse and other no warranty issues

Misuse is not covered by warranty. This chapter will explain what’s not covered by warranty.

Phones that have been exposed to misuse will not be covered by warranty.

This means: if it is possible to repair the phone, the customer will have to pay for the repair.

SEMC will not allow any of these phones to be claimed into WCMS. Some local perspectives

may interfere with this. Please reference to local directives.

1.2.1 Action

Make a general visual inspection for misuse.

Below are some examples of what is not covered by warranty.

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

2(26)

Page 3

Trouble Shooting Guide, Mechanical

Front window broken due

to misuse.

LCD cracked due to

drop.

Clear scratches

Mark after drop Plugs are not covered by warranty.

Corrosion components on the

PCB.

System connector damaged by

liquid

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

Corrosion components on the

PCB.

Components around system

connector damaged by liquid

SIM reader damaged by

liquid.

System connector pad(s) damaged

by liquid

3(26)

Page 4

Trouble Shooting Guide, Mechanical

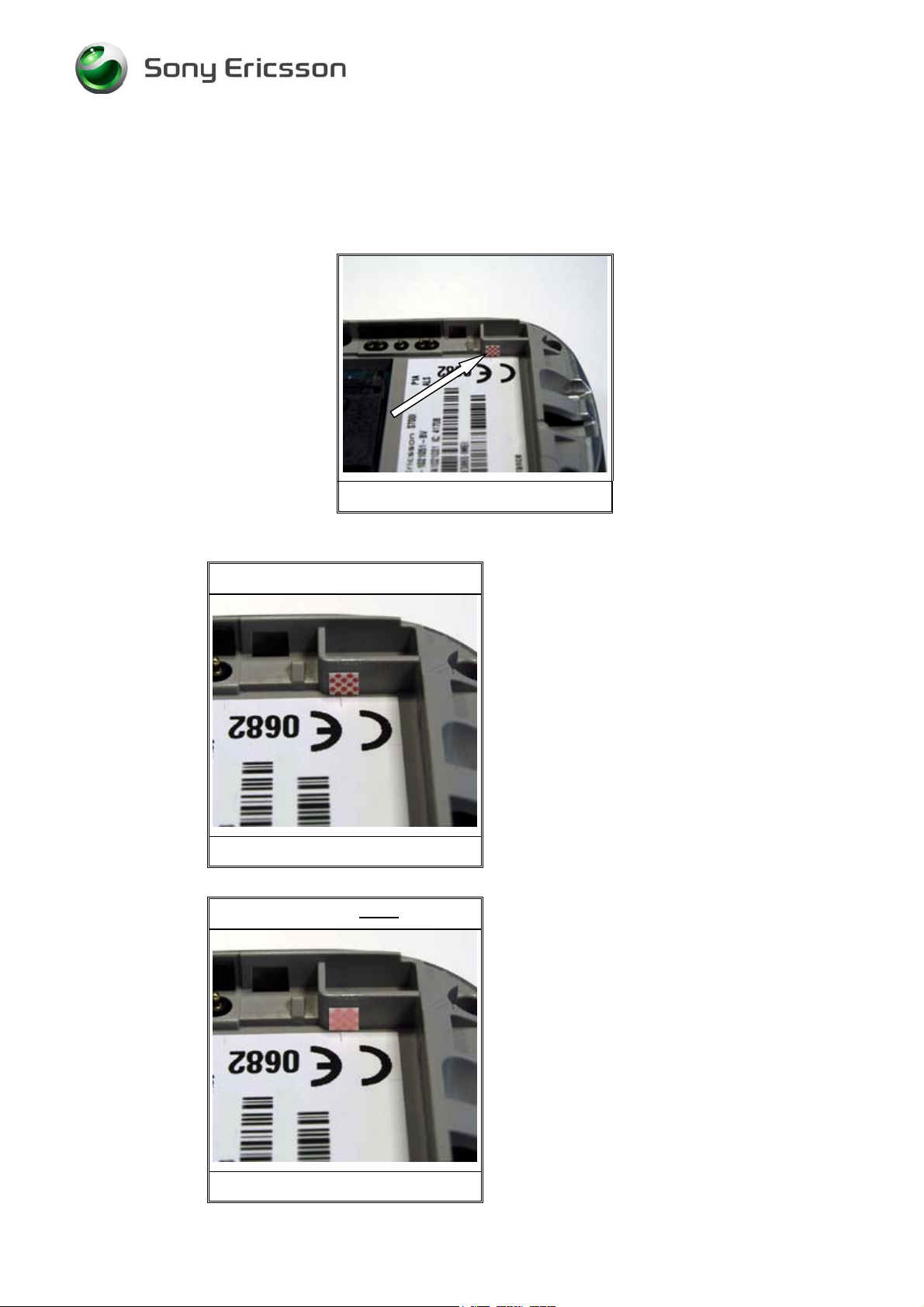

1.2.2 Water indicator label

In the phone there is placed a sticker that can give you a hint to see if the phone is damage by

liquid or not. This sticker is located near the type label (Fig. 1.2.1) and it is possible to see it

without disassemble the phone.

Fig. 1.2.1

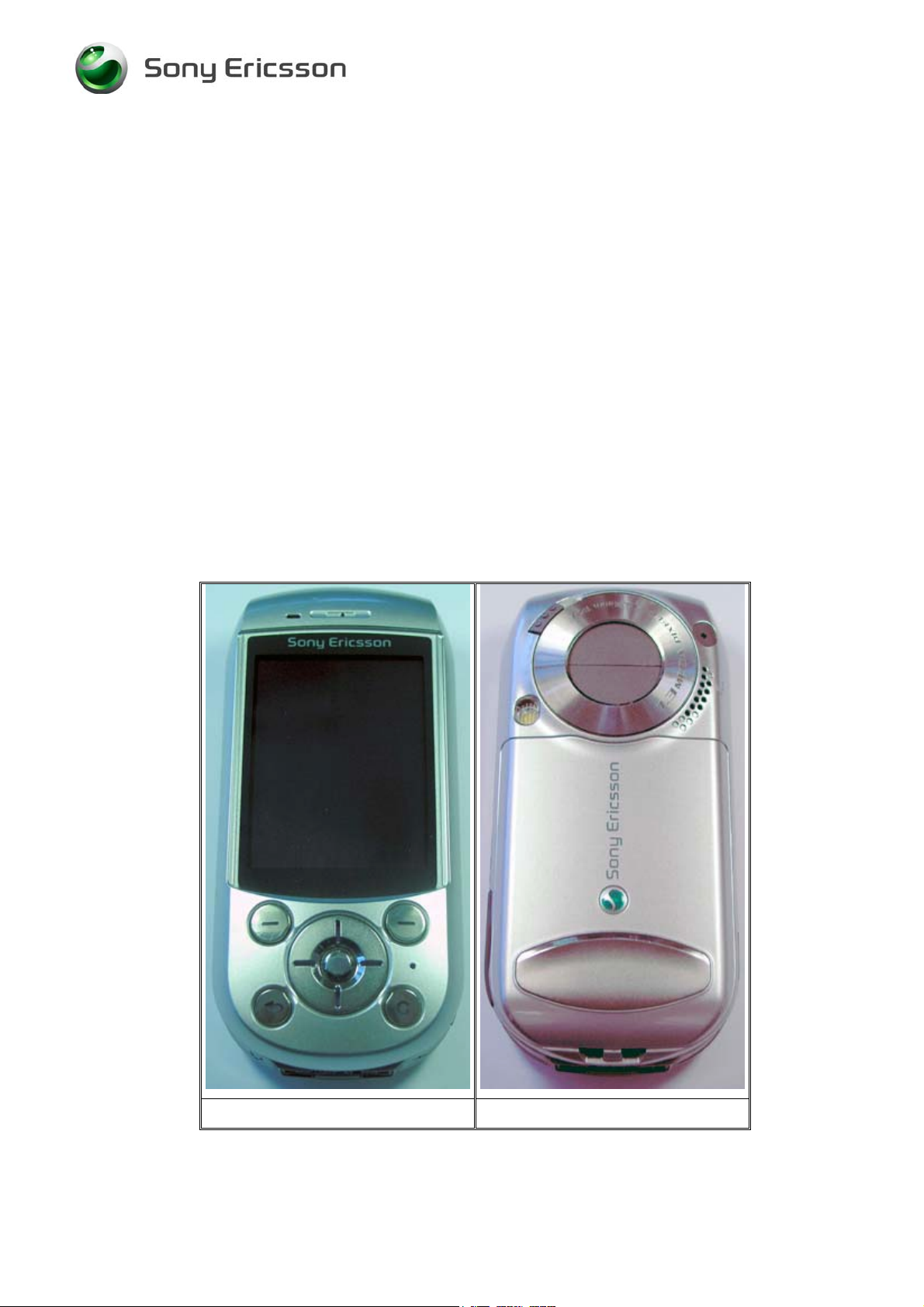

On the pictures below you will see the different between a sticker that has been in contact

with liquid (Fig. 1.2.3) and with one that hasn’t (Fig. 1.2.2).

This sticker is ok

This sticker has not been in contact with

liquid.

Fig. 1.2.2

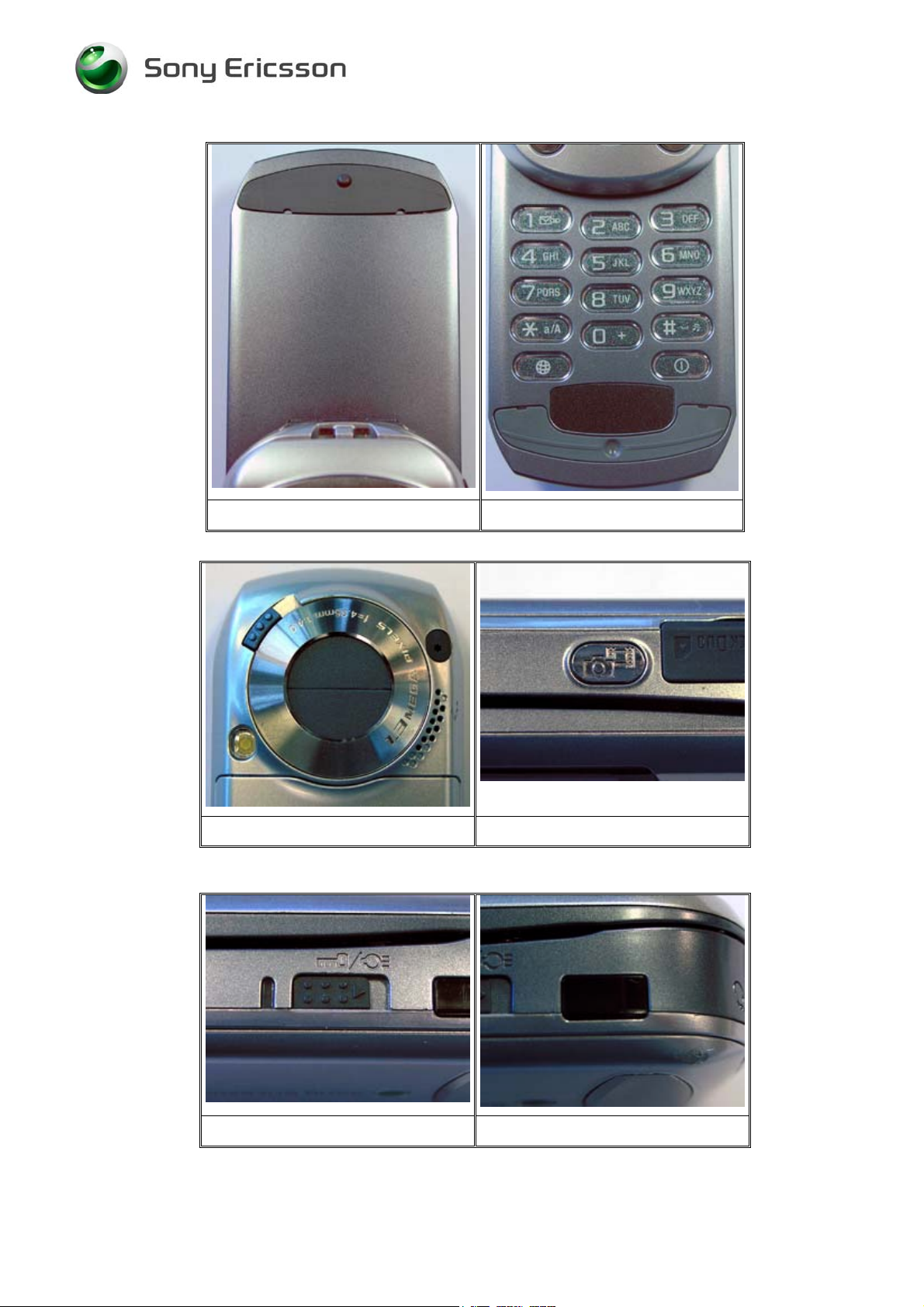

This sticker is not

ok

This sticker has been in contact with liquid. As you

can see it has turn into a red or pink label. In this

case you should check the phone for liquid damage

(See point 1.2.2).

Note: There must be clear marks after liquid on the

PCB before rejecting the phone for repair.

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

Fig. 1.2.3

4(26)

Page 5

Trouble Shooting Guide, Mechanical

1.2.3 Action

Make a general visual inspection for corrosion or oxidation from liquid damage. No further

action should be taken for a liquid damaged phone. Handle the unit according to local

directives.

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

5(26)

Page 6

Trouble Shooting Guide, Mechanical

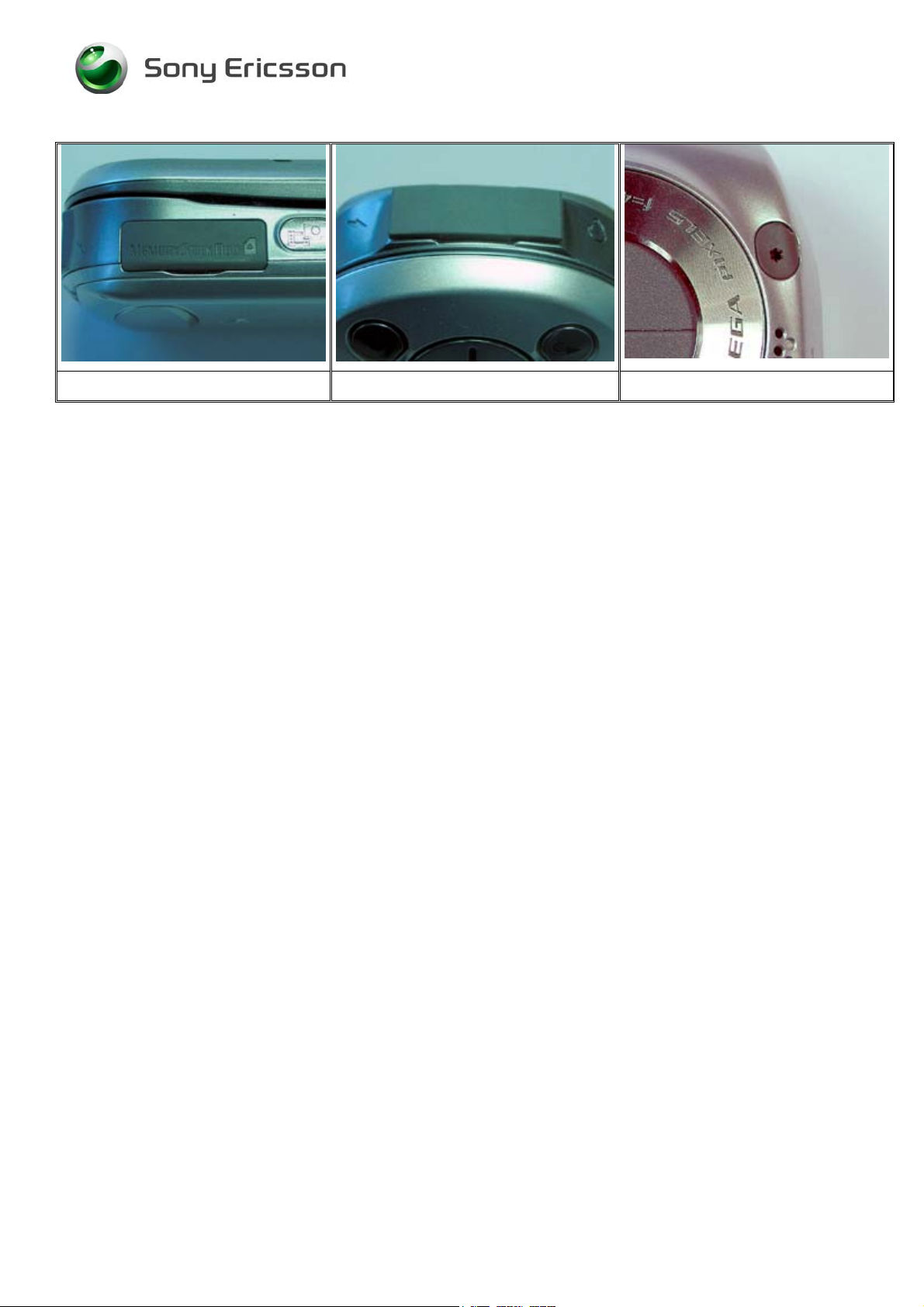

2 Appearance Problem

• Make a general visual inspection for misuse, corrosion or oxidation from liquid damage

according to point 1.2

• Check the Case LCD front (Fig. 2.1), the Case Key rear (Fig. 2.2), the Case LCD rear

(Fig. 2.3), the Case Key front (Fig. 2.4) The Panel LCD rear (Fig. 2.3), the Panel LCD

front (Fig. 2.4) and the battery cover (Fig. 2.2) for damage, scratches and if the parts fit

correct. Replace the faulty component(s) if necessary.

• Check the Panel Camera, (Fig. 2.5) and the Cover Camera left and right (Fig. 2.5) for

damage, scratches and if the parts fit correct. Replace the faulty component(s) if

necessary.

• Check the button key (Fig. 2.4), the button LCD top, side and centre (Fig. 2.1), the button

shutter (Fig. 2.6) and the button lock switch (Fig.2.7) for damage, scratches and if the

parts fit correct. Replace the faulty component(s) if necessary.

• Check the panel IRDA (Fig. 2.8), the light guide (Fig. 2.7), the cover MS (Fig. 2.9), the

cover system connector I/O (Fig. 2.10) and the cover R/F (Fig. 2.11) for damage, scratches

and if the parts fit correct. Replace the faulty component(s) if necessary.

If the failure still occurs, handle the unit according to the local directives.

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

Fig. 2.1 Fig. 2.2

6(26)

Page 7

Trouble Shooting Guide, Mechanical

Fig. 2.3 Fig. 2.4

Fig. 2.5 Fig.2.6

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

Fig. 2.7 Fig.2.8

7(26)

Page 8

Trouble Shooting Guide, Mechanical

Fig. 2.9 Fig. 2.10 Fig. 2.11

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

8(26)

Page 9

Trouble Shooting Guide, Mechanical

3 Alert Problem

• Make a general visual inspection for misuse, corrosion or oxidation from liquid damage

according to point 1.2

3.1 Vibrator

• Turn on the phone. Go to the service test menu; choose “Vibrator”. Press any key to check

the vibrator works properly.

• Check if the vibrator pads (Fig. 3.1) are dirty or oxidized. Clean them if necessary.

• Check if the vibrator (Fig. 3.2) is mechanical damaged, dirty or oxidized. Replace it if

necessary.

• Check if the Frame RF (Fig. 3.3) is mechanical damaged. Replace it if necessary.

If the fault still occurs, try to update the phone to the latest available software version. If this

doesn’t solve the problem, handle the unit according to the local directives.

Fig. 3.1 Fig. 3.2 Fig. 3.3

3.2 Speaker

• Turn on the phone. Go to the service test menu; choose “Speaker”. Press any key to check

the speaker works properly.

• Check if the keyboard flex-film is fitting correct into the FPC connector (Fig. 3.4) and

check if the FPC connector is closed.

• Check if the key FPC (Fig. 3.5) is mechanical damage, dirty or oxidized. Replace it if

necessary.

If the fault still occurs, try to update the phone to the latest available software version. If this

doesn’t solve the problem, handle the unit according to the local directives.

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

9(26)

Page 10

Trouble Shooting Guide, Mechanical

Fig. 3.4 Fig. 3.5

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

10(26)

Page 11

Trouble Shooting Guide, Mechanical

4 Audio Problem

• Make a general visual inspection for misuse, corrosion or oxidation from liquid damage

according to point 1.2

4.1 Receiver

• Turn on the phone. Go to the service test menu; choose “Earphone” press any key to check

the speaker works properly.

• Check if the receiver pads (Fig. 4.1) is dirty or oxidized. Clean or replace the FPC hinge if

necessary.

• Check if the receiver (Fig. 4.2) is mechanical damaged, dirty or oxidized. Replace it if

necessary.

If the fault still occurs, try to update the phone to the latest available software version. If this

doesn’t solve the problem, handle the unit according to the local directives.

Fig. 4.1 Fig. 4.2

4.2 Microphone

• Turn on the phone. Go to the service test menu; choose “Microphone”. Check if the

microphone works properly.

• Check if the microphone pads (Fig. 4.3) are dirty or oxidized. Clean or replace the FPC

hinge if necessary.

• Check if the microphone (Fig. 4.4) is mechanical damaged, dirty or oxidized. Replace it if

necessary.

If the fault still occurs, try to update the phone to the latest available software version. If this

doesn’t solve the problem, handle the unit according to the local directives.

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

11(26)

Page 12

Trouble Shooting Guide, Mechanical

Fig. 4.3 Fig. 4.4

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

12(26)

Page 13

Trouble Shooting Guide, Mechanical

5 Charging/Capacity

• Make a general visual inspection for misuse, corrosion or oxidation from liquid damage

according to point 1.2

5.1 Charging

• Insert a working battery and connect a working charger to the phone. If the battery voltage

is too low the phone will charge the battery without turning on the phone (this will usually

take less than 10 minutes) and when the battery voltage is high enough the phone will be

able to turn on and show charging in the LCD.

• Check if the system connector (Fig 6.1) is mechanical damaged, dirty or oxidized. Replace

it if necessary.

If the fault still occurs, try to update the phone to the latest available software version. If this

doesn’t solve the problem, handle the unit according to the local directives.

5.2 Capacity

• The standby time will be reduced if, the light is turned on all the time, the bluetooth is

turned on, or if the infrared is turned on.

6 Data Communication Problem

• Make a general visual inspection for misuse, corrosion or oxidation from liquid damage

according to point 1.2

• If there is a problem with the communication through the system connector, e.g. if it is not

possible to synchronizing with MS Outlook, check if the system connector (Fig. 6.1) is

mechanical damaged, dirty or oxidized. Replace it if necessary.

• Check if there is a problem with bluetooth communication. Replace the BT Antenna (Fig.

6.2) if necessary.

If the fault still occurs, try to update the phone to the latest available software version. If this

doesn’t solve the problem, handle the unit according to the local directives.

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

Fig. 6.1 Fig. 6.2

13(26)

Page 14

Trouble Shooting Guide, Mechanical

7 Key/Flip

• Make a general visual inspection for misuse, corrosion or oxidation from liquid damage

according to point 1.2

7.1 Keyboard

• Turn on the phone. Go to the service test menu; choose “Keyboard”. Press all the keys.

The pressed key will be indicated in the LCD and a DTMF tone is heard.

• Check if the mechanically response feels normal and that all the keys have been showed in

the LCD.

• Check if the button LCD top, side, base and centre (Fig. 7.1) or the button key (Fig. 7.2) is

mechanical damaged or dirty. Replace the faulty necessary.

• Check if the key flex sheet (Fig. 7.3) or the LCD flex sheet (Fig.7.4) is mechanical

damaged, dirty or oxidized. Replace the faulty component if necessary.

• Check if the key FPC (Fig. 7.5) or the FPC hinge (Fig.7.6) is mechanical damaged, dirty

or oxidized. Replace the faulty component if necessary.

• Check if the keyboard flex-film is fitting correct into the FPC connector (Fig. 7.7) and

check if the FPC connector is closed.

If the fault still occurs, try to update the phone to the latest available software version. If this

doesn’t solve the problem, handle the unit according to the local directives.

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

Fig. 7.1 Fig. 7.2

14(26)

Page 15

Trouble Shooting Guide, Mechanical

Fig. 7.3 Fig. 7.4 Fig. 7.5

Fig. 7.6 Fig. 7.7

7.2 Side keys

• Turn on the phone. Go to the service test menu; choose “Keyboard”. Press all the side

keys. The pressed key will be indicated in the LCD and a DTMF tone is heard.

• Check if the Button lock switch (Fig. 7.8) and the button shutter (Fig.7.9) is working

properly and if the mechanical response feels normal. Replace the faulty component if

necessary.

• Check if the key flex sheet (Fig. 7.10) is mechanical damaged, dirty or oxidized. Replace

it if necessary.

• Check if the key FPC (Fig. 7.11) is mechanical damaged, dirty or oxidized. Replace it if

necessary.

• Check if the FPC Connectors (Fig. 7.12) are closed properly and if the flex films are

mounted right in the FPC connectors.

If the fault still occurs, try to update the phone to the latest available software version. If this

doesn’t solve the problem, handle the unit according to the local directives.

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

15(26)

Page 16

Trouble Shooting Guide, Mechanical

Fig. 7.8 Fig. 7.9

Fig. 7.10 Fig. 7.11 Fig. 7.12

7.3 Hinge

• Check if the mechanically response feels normal and if the hinge is loose. Replace the

hinge (Fig. 7.13), the panel LCD rear (Fig. 7.14) or the panel LCD front (Fig. 7.15) if

necessary.

• Check if the electrical response when opening the flip works. Replace the magnet (Fig.

7.16) if necessary. If the fault still occurs replace the key FPC (Fig. 7.17).

If the fault still occurs, try to update the phone to the latest available software version. If this

doesn’t solve the problem, handle the unit according to the local directives.

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

Fig. 7.13 Fig. 7.14

16(26)

Page 17

Trouble Shooting Guide, Mechanical

Fig. 7.15 Fig. 7.16 Fig. 7.17

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

17(26)

Page 18

Trouble Shooting Guide, Mechanical

8 LCD/Illumination

• Make a general visual inspection for misuse, corrosion or oxidation from liquid damage

according to point 1.2

8.1 LCD

• Turn on the phone. Go to service test menu; choose “Display”. You should see a colour

pattern.

• Check if the LCD unit (Fig. 8.1) works properly and if there are missing lines or

discolours. Replace it if necessary.

• Check if the LCD flex-film is fitting correct into the FPC connector (Fig. 8.2) and check if

the FPC connector is closed.

• Check if the harness (Fig. 8.3) is mechanical damaged, dirty or oxidized. Replace it if

necessary.

If the fault still occurs, try to update the phone to the latest available software version. If this

doesn’t solve the problem, handle the unit according to the local directives.

Fig. 8.1 Fig. 8.2 Fig. 8.3

8.2 Illumination

• Turn on the phone. Go to service test menu; choose “LED/Illumination”. The illumination

should start blinking ~1Hz.

• Check if the LCD unit (Fig. 8.1) is lighting up properly. Replace it if necessary.

• Check if the harness (Fig. 8.3) is mechanical damaged, dirty or oxidized. Replace it if

necessary.

8.2.1 Main keyboard

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

18(26)

Page 19

Trouble Shooting Guide, Mechanical

• Check if the entire 10 key LED’s (Fig. 8.5) is lighting in the same strength. Replace the

key FPC if necessary.

• Check if the key FPC is fitting correct into the FPC connector (Fig. 8.4) and check if the

FPC connector is closed.

8.2.2 Navigation keys

• Check if the entire 4 key LED’s (Fig. 8.6) is lighting in the same strength. Replace the

FPC hinge if necessary.

• Check if the harness (Fig. 8.3) is mechanical damaged, dirty or oxidized. Replace it if

necessary.

If the fault still occurs, try to update the phone to the latest available software version. If this

doesn’t solve the problem, handle the unit according to the local directives.

Fig. 8.4 Fig. 8.5 Fig. 8.6

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

19(26)

Page 20

Trouble Shooting Guide, Mechanical

9 Network

• Make a general visual inspection for misuse, corrosion or oxidation from liquid damage

according to point 1.2

• Insert a correct working SIM-card in the phone and turn it on. Check if the phone gets

service and if the signal strength indicator shows a correct value at the display. Compare

the value with a working phone.

• Check if the antenna flex (Fig. 9.1-9.2) is mechanical damaged, dirty or oxidized. Replace

it if necessary.

If the fault still occurs, try to update the phone to the latest available software version. If this

doesn’t solve the problem, handle the unit according to the local directives.

Fig. 9.1 Fig. 9.2

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

20(26)

Page 21

Trouble Shooting Guide, Mechanical

10 On/Off

• Make a general visual inspection for misuse, corrosion or oxidation from liquid damage

according to point 1.2

10.1 Battery

• Insert a working battery and connect a working charger to the phone. If the battery voltage

is too low the phone will charge the battery without turning on the phone (this will usually

take less than 10 minutes) and when the battery voltage is high enough the phone will be

able to turn on and show charging in the LCD.

If the fault still occurs, try to update the phone to the latest available software version. If this

doesn’t solve the problem, handle the unit according to the local directives.

10.2 On/Off key

• Insert a fully charged battery and turn the phone on. If it fails;

• Check if the button key (Fig. 10.1) is mechanical damaged or dirty. Replace it if

necessary.

• Check if the key flex sheet (Fig. 10.2) is mechanical damaged, dirty or oxidized. Replace

it if necessary.

• Check if the key FPC (Fig. 10.3) is mechanical damaged, dirty or oxidized. Replace it if

necessary.

• Check if the keyboard flex-film is fitting correct into the FPC connector (Fig. 10.5) and

check if the FPC connector is closed.

If the fault still occurs, try to update the phone to the latest available software version. If this

doesn’t solve the problem, handle the unit according to the local directives.

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

Fig. 10.1 Fig. 10.2

21(26)

Page 22

Trouble Shooting Guide, Mechanical

Fig. 10.3 Fig. 10.4

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

22(26)

Page 23

Trouble Shooting Guide, Mechanical

11 Other

11.1 Camera Problem

• Make a general visual inspection for misuse, corrosion or oxidation from liquid damage

according to point 1.2

• Turn on the phone. Go to the service test menu; choose “Camera” and open the shutter.

The viewfinder will be visible in the LCD.

Note: if the flip is open the picture will be upside down

• Check if the 1.3M CCD camera (Fig. 11.1) is working properly; verify the viewfinder

functionality in the LCD.

• Check if the camera flex film is fitting correct into the FPC connector (Fig. 11.2) and

check if the connector is closed.

• Check if there are black spots and if the picture is in focus. Replace the camera module if

necessary.

If the fault still occurs, try to update the phone to the latest available software version. If this

doesn’t solve the problem, handle the unit according to the local directives.

Fig. 11.1 Fig. 11.2

11.2 Camera shutter

• Make a general visual inspection for misuse, corrosion or oxidation from liquid damage

according to point 1.2

• Check if the camera shutter works properly. Check if it loose and if it will close tight.

Replace the frame camera cover (Fig. 11.3) and the cover camera right & left (Fig. 11.4) if

necessary.

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

23(26)

Page 24

Trouble Shooting Guide, Mechanical

Fig. 11.3 Fig. 11.4

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

24(26)

Page 25

Trouble Shooting Guide, Mechanical

12 Software Problem

• If there are problems with the response of the keypad commands, or spelling errors in the

menu, if they are not related to mechanical damage, make a master reset and flash the

phone with the latest software from EMMA II.

• Checking the software revision can be done in the Service info, see chapter Service

functions in the software.

Choose: Service info / SW information.

The Software revision and date will be shown in the display.

• If a flash upgrade is interrupted for some reason, EMMA II will prompt "Error in

sequence". After which the phone will not start up. In order to restore functionality you

need to run "S700x Flash Recovery". The script can be found under "Flash" in EMMA II.

After a successful recovery you need to re-flash the phone with correct signalling software

before start up.

Note: Do a SW upgrade before sending the unit to a higher level. Do not

hasn’t been upgraded.

If the failure still occurs, handle the unit according to the local directives.

scrap a phone that

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

25(26)

Page 26

Trouble Shooting Guide, Mechanical

13 Revision History

Rev. Date Changes / Comments

A 2004-09-24 Initial Release

4/00021-1/FEA 209 544/89 A

Company Internal

Sony Ericsson Mobile Communications AB

26(26)

Loading...

Loading...