Page 1

Working Instruction, Electrical

Working Instruction, Electrical

Applicable for F500 and K500 family

Contents

Lead free soldering .........................................................................................................2

1

2

BGA Equipment reflow profiles (lead free)..................................................................5

2.1

General ..............................................................................................................5

2.2

Temperature measurement ................................................................................ 5

3

BGA Equipment reflow profiles (lead free)..................................................................6

4

BGA Equipment reflow profiles (leaded) .....................................................................7

5

Replacement of parts......................................................................................................8

6

Replacement of parts......................................................................................................9

6.1

Battery connector...............................................................................................9

6.2

Board to board connector ................................................................................10

6.3

FPC connector.................................................................................................11

6.4

Form shield can fence......................................................................................12

6.5

PA shield can...................................................................................................14

6.6

Replacing shield can fence if damage at a repair center..................................14

7

Revision History............................................................................................................15

3/00021-2/FEA 209 544/86 E

Company Internal

©

Sony Ericsson Mobile Communications AB

Approved according to 000 21-LXE 107 42/1

Page 2

Working Instruction, Electrical

1 Lead free soldering

Instruction

Keep all contact surfaces clean of dirt and hand-grease

Step-by-Step Instructions

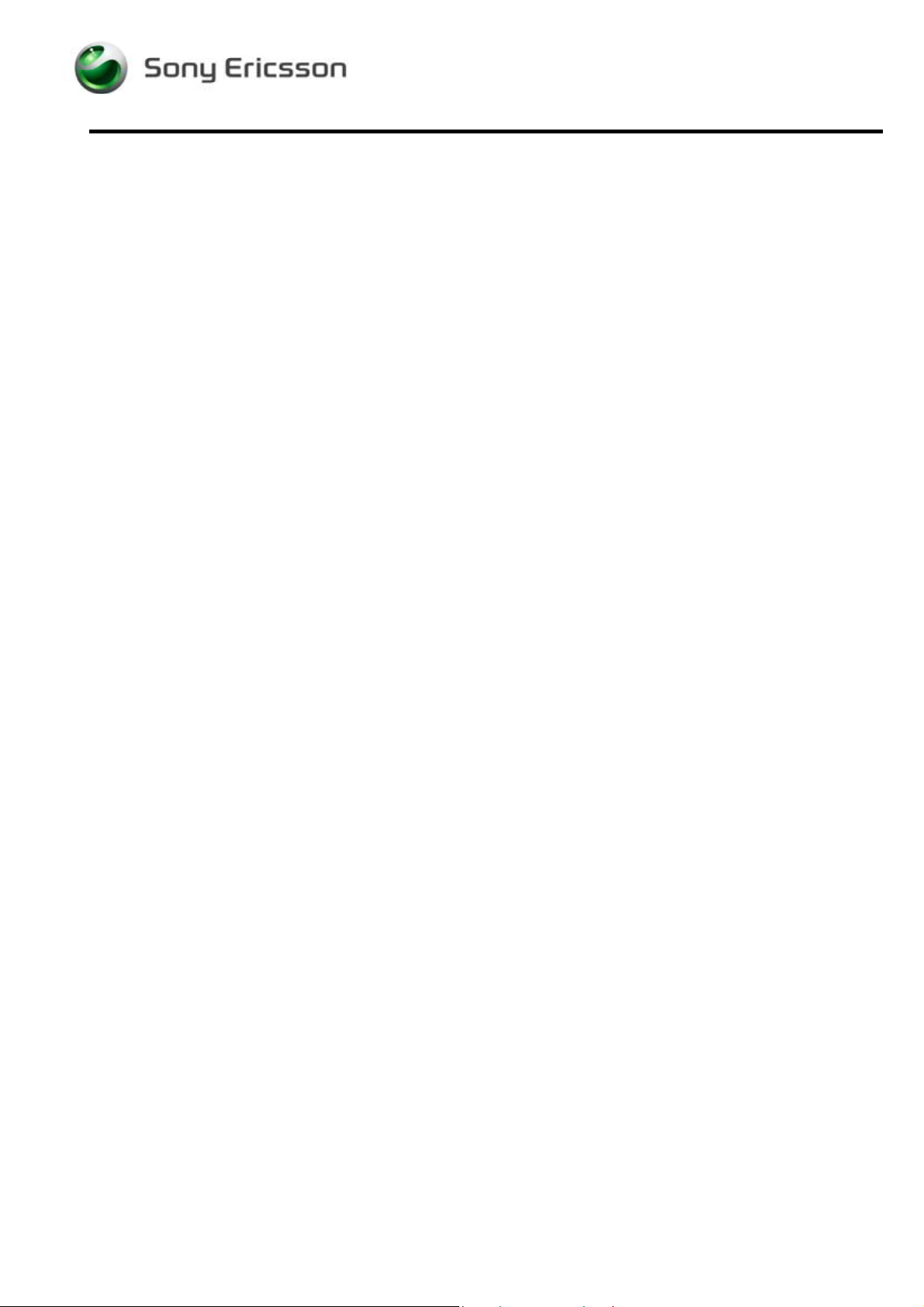

1 NOTE!

This product is manufactured with lead-free

solder and lead-free components.

During electrical repair, it is critical to make

sure that no lead is introduced.

The symbol indicates that the product is lead

free.

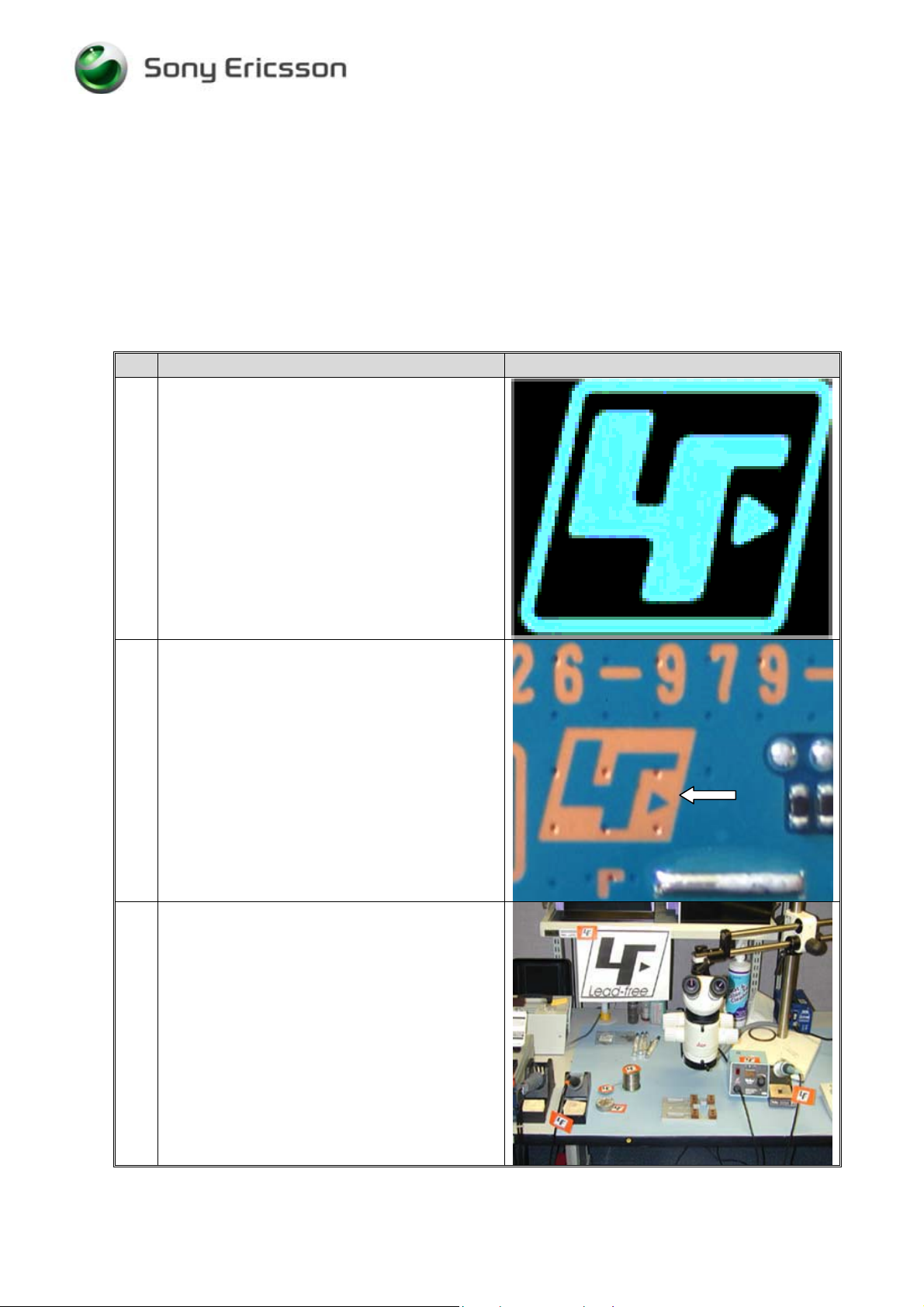

2 The first lead free PBA will not be marked with

this LF symbol; they are identified as lead free

by a new revision on the ROA label. All future

PBA is handled lead free

It’s important that from revision:

ROA 128 0768/3 R2A and onwards PBA is

handled with Lead Free process.

3 A lead-free work area must be set up that is

completely separated from work areas that are

used to make leaded repairs.

The lead free work area must also be clearly

labelled with the lead free symbol as shown in

the figure beside.

The items in this table must remain lead free.

They must be adequately labelled to make their

lead-free status clearly and easily recognized.

3/00021-2/FEA 209 544/86 E

Company Internal

©

Sony Ericsson Mobile Communications AB

2(15)

Page 3

Working Instruction, Electrical

Step-by-Step Instructions

4 LFS (Lead free solder paste) characteristics:

High melting point (Typically 220°C)

Low wet ability

High surface tension

Difficult to spread

Recommended tip temperature 370°C

NOTE!

When servicing PBA’s that is produced with

LFS (Lead free solder paste). LFS MUST be

used. If not, there is a high risk for unreliable

soldering joints.

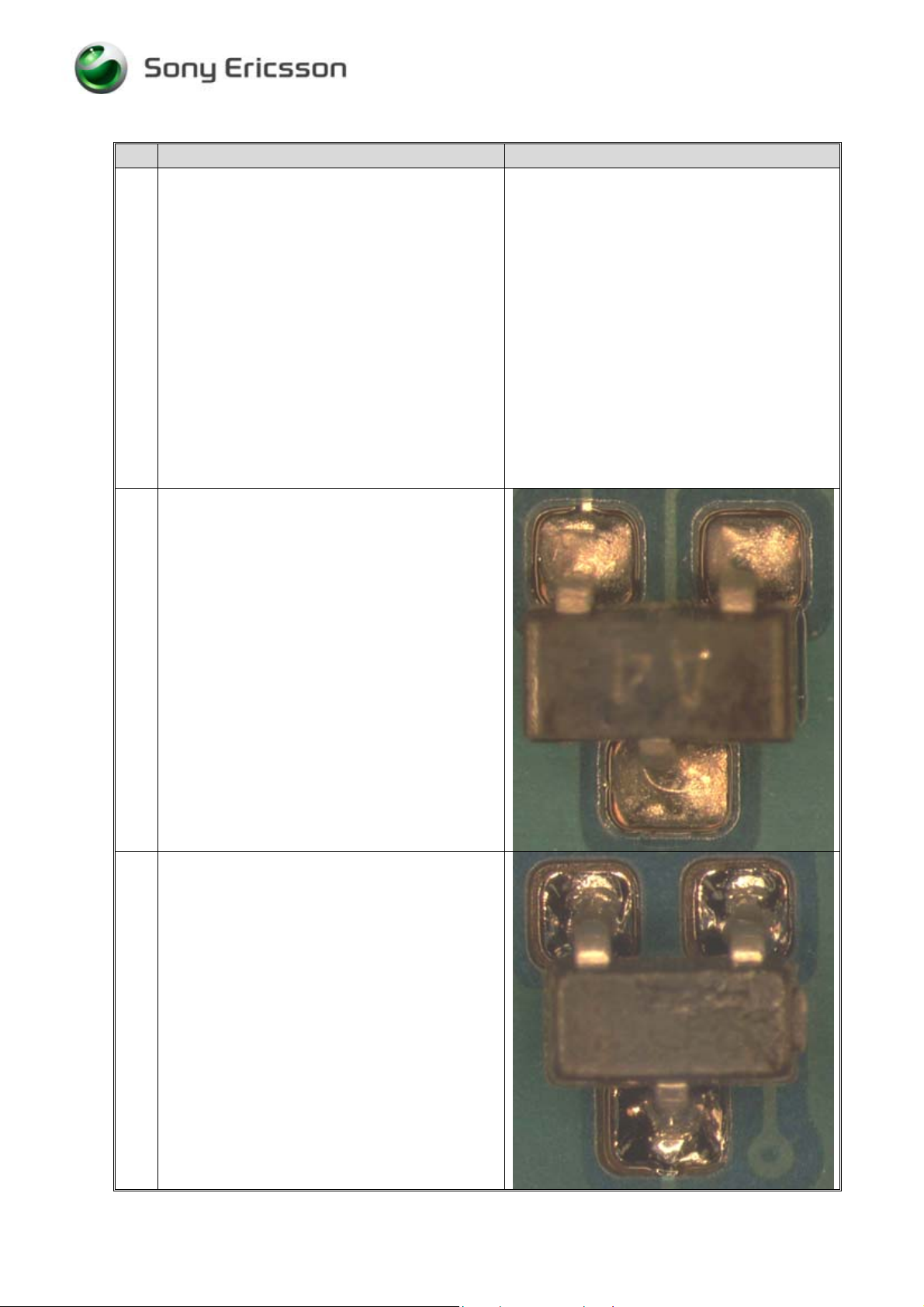

5 Lead-free solder joints are more difficult to

inspect because they do not have shiny surfaces

like leaded solder joints.

Also, lead-free solder does not flow as well as

leaded solder, so some of the solder pad area

may remain exposed.

Example of lead free solders joints.

6 Example of solder joints with lead.

3/00021-2/FEA 209 544/86 E

Company Internal

©

Sony Ericsson Mobile Communications AB

3(15)

Page 4

Working Instruction, Electrical

Step-by-Step Instructions

7 Example of lead free solders joints.

8 Example of solder joints with lead.

3/00021-2/FEA 209 544/86 E

Company Internal

©

Sony Ericsson Mobile Communications AB

4(15)

Page 5

Working Instruction, Electrical

2 BGA Equipment reflow profiles (lead free)

2.1 General

This document contains recommendations for reflow profile for mobile phones and similar

products. This is only general recommendation and considerations have to be taken for every

single product. The solder paste is secondary but could also affect the parameters.

In this document one alloy is specified:

SnAgCu (Lead free) melting point 217°C

2.2 Temperature measurement

At least 4 probes should be used; they should be placed on components with the highest and

lowest thermal mass.

The probes shall be located in the beginning, in the middle and at the end of the board/panel.

The probes are recommended to be soldered on the board but glue and capton tape could also

be used if necessary.

At least one probe shall be placed in the air or on top of a component.

These values are strongly depending on the BGA replacement equipment.

Nozzle type will be chosen after the outer size of the actual component. Make sure the nozzle

does not affect any near placed components.

NOTE:

These values are recommendations and may have to be changed depending on the type of

equipment.

The maximum temperature for any component must not exceed 250C.

3/00021-2/FEA 209 544/86 E

Company Internal

©

Sony Ericsson Mobile Communications AB

5(15)

Page 6

Working Instruction, Electrical

3 BGA Equipment reflow profiles (lead free)

These values are strongly depending on the BGA replacement equipment.

Nozzle type will be chosen after the outer size of the actual component. Make sure the nozzle

does not affect any near placed components.

NOTE:

These values are recommendations and may have to be changed depending on the type of

equipment.

Sn/Ag/Cu (Lead free)

290

250

Preheat zone

Reflow zone

Cooling zone

260°C

245°C

235°C

200

150

Temperature [ºC]

100

50

0

40 80 120 160 200 240 280

Time [Seconds]

Ramp rate < 4°C/sec

Ramp rate cooling zone < 6°C/sec

Time above liquidus 60-150 sec

Minimum temperature 235°C

Maximum temperature 245°C or 260°C* for 10 sec

Total time Appr. 4-7 min

• The higher temperature in case the board has extremely high ∆T.

3/00021-2/FEA 209 544/86 E

Company Internal

©

Sony Ericsson Mobile Communications AB

6(15)

Page 7

Working Instruction, Electrical

4 BGA Equipment reflow profiles (leaded)

These values are strongly depending on the BGA replacement equipment.

Nozzle type will be chosen after the outer size of the actual component. Make sure the nozzle

does not affect any near placed components.

NOTE:

These values are recommendations and may have to be changed depending on the type of

equipment.

General reflow profile sn/pb (leaded)

Preheat zone

250

200

150

Temperature [ºC]

10

0

50

0

040 80120 160 200 240 280

Time [Seconds]

Reflow

zone

Cooling

zone

Ramp rate < 3°C/sec

Ramp rate cooling zone < 6°C/sec

Time above liquidus 60-150 sec

Minimum temperature 215°C

Maximum temperature 225°C or 235°C for 10-20 sec

Total time Appr. 4-7 min

*

3/00021-2/FEA 209 544/86 E

Company Internal

©

Sony Ericsson Mobile Communications AB

The higher temperature in case the board has extremely high ∆T.

7(15)

Page 8

Working Instruction, Electrical

5 Replacement of parts

• Equipment

• Dentist hook

• ESD-gloves (cotton gloves)

• ESD-wristband

• Soldering tool

• Hot air soldering station

• BGA replacement equipment

• Pair of tweezers

• Solder cleaning wiper (Tin wick)

• Solder paste, for Lead free use (SN 96% Ag 3.5% Cu 0.5%)

• Flux, RMA No-clean flux

• Cutting pliers

• Shield fence pliers NTZ 112 537

Instruction

• Keep all contact surfaces clean of dirt and hand-grease

3/00021-2/FEA 209 544/86 E

Company Internal

©

Sony Ericsson Mobile Communications AB

8(15)

Page 9

Working Instruction, Electrical

6 Replacement of parts

6.1 Battery connector

Process tools

• BGA replacement equipment

• Pair of tweezers

• Solder cleaning wiper (Tin wick)

• Solder paste

• Gel flux

Equipment

• ESD-gloves (cotton gloves)

• ESD-wristband

Instruction

• Disassemble the phone as described in Working Instruction 3/00021-1/FEA 209 544/86

Step-by-Step Instructions

1 Replace the component.

Use BGA repair equipment.

No special treatment due to through pins.

• Reassemble the phone as described in Working Instruction 3/00021-1/FEA 209 544/86

3/00021-2/FEA 209 544/86 E

Company Internal

©

Sony Ericsson Mobile Communications AB

9(15)

Page 10

Working Instruction, Electrical

6.2 Board to board connector

Process tools

• BGA replacement equipment

• Pair of tweezers

• Solder cleaning wiper (Tin wick)

• Solder paste

• Gel flux

Equipment

• ESD-gloves (cotton gloves)

• ESD-wristband

Instruction

• Disassemble the phone as described in Working Instruction 3/00021-1/FEA 209 544/86

Step-by-Step Instructions

1 Replace the component.

Use BGA repair equipment.

After soldering check for solder bridges between

solder joints.

• Reassemble the phone as described in Working Instruction 3/00021-1/FEA 209 544/86

3/00021-2/FEA 209 544/86 E

Company Internal

©

Sony Ericsson Mobile Communications AB

10(15)

Page 11

Working Instruction, Electrical

6.3 FPC connector

Process tools

• Dentist hook

• BGA replacement

• Pair of tweezers

• Solder cleaning wiper (Tin wick)

• Solder paste

• Gel flux

Equipment

• ESD-gloves (cotton gloves)

• ESD-wristband

Instruction

• Disassemble the phone as described in Working Instruction 3/00021-1/FEA 209 544/86

Step-by-Step Instructions

1 Replace the component.

Use BGA repair equipment.

After soldering check for solder bridges between

solder joints.

• Reassemble the phone as described in Working Instruction 3/00021-1/FEA 209 544/86

3/00021-2/FEA 209 544/86 E

Company Internal

©

Sony Ericsson Mobile Communications AB

11(15)

Page 12

Working Instruction, Electrical

6.4 Form shield can fence

Process tools

• Dentist hook

• Cutting pliers

• Shield fence pliers NTZ 112 537

Equipment

• ESD-gloves (cotton gloves)

• ESD-wristband

Instruction

• Disassemble the phone as described in Working Instruction 3/00021-1/FEA 209 544/86

3/00021-2/FEA 209 544/86 E

Company Internal

©

Sony Ericsson Mobile Communications AB

12(15)

Page 13

Working Instruction, Electrical

Step-by-Step Instructions

1 Remove the shield can lid.

If needed it is allowed to remove the pick up

area with a cutting pliers (1). This pick up area is

only used when machine mounting the can and

there is no need to put it back again.

NOTE!

Assure that the cutting pliers is sharp-edged to

prevent damaging the shield can fence.

Cut the fence according to the red lines in the

picture.

Form the frame carefully without bending the

shield can fence wall. Use Shield fence pliers

NTZ 112 537.

Replace the component and gently fold back the

fence. Be very cautious with the shield can fence

wall.

Put back a new shield can lid. Press on all sides

of the lid until you hear a “click” sound.

• Reassemble the phone as described in Working Instruction 3/00021-1/FEA 209 544/86

3/00021-2/FEA 209 544/86 E

Company Internal

©

Sony Ericsson Mobile Communications AB

13(15)

Page 14

Working Instruction, Electrical

6.5 PA shield can

Instruction

• Disassemble the phone as described in Working Instruction 3/00021-1/FEA 209 544/83

Step-by-Step Instructions

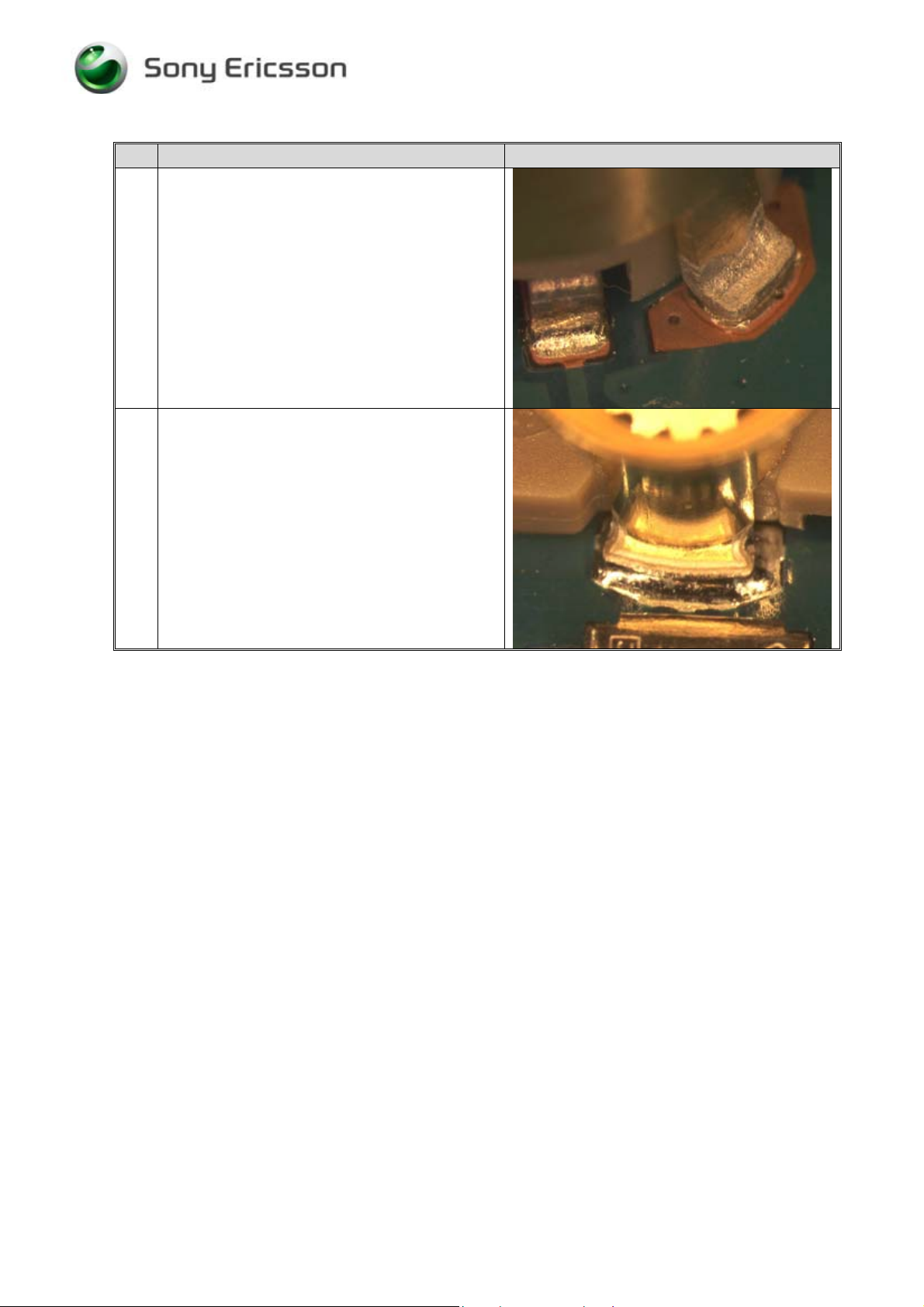

1 NOTE!

This operation is very time consuming and must

be performed by very skilled repair operators.

1) Remove the battery connector X2600 (1)

using hot air

2) Remove the shield can S0102 (2) using

BGA repair equipment or hot air

(temperature profile for lead-free

soldering)

3) Rework the components inside the shield

can

4) Clean pad and add solder

5) Replace the shield can using BGA repair

equipment with a suited nozzle

6)

Replace the battery connector using a

BGA repair equipment

• Reassemble the phone as described in Working Instruction 3/00021-1/FEA 209 544/83

6.6 Replacing shield can fence if damage at a repair center

Process tools

• Dentist hook

• BGA repair equipment

• Hot air soldering station

• Pair of tweezers

• Solder cleaning wiper (Tin wick)

• Solder paste

• Solder wire

• Gel flux

• Cutting pliers

Equipment

• ESD-gloves (cotton gloves)

• ESD-wristband

3/00021-2/FEA 209 544/86 E

Company Internal

©

Sony Ericsson Mobile Communications AB

14(15)

Page 15

Working Instruction, Electrical

Instruction

• Disassemble the phone as described in Working Instruction 3/00021-1/FEA 209 544/86

Step-by-Step Instructions

1 NOTE!

Replacing shield can fence is only done at repair

centers when a shield can fence is damaged after

bending the frame.

This operation is very time consuming and must

be performed by very skilled repair operators.

Remove the shield can fence by using hot air (or

preferrably with BGA repair equipment).

Most often it is necessary to remove the shield

can fence in pieces by using cutting pliers.

Assemble a new shield can fence with BGA

repair equipment.

• Reassemble the phone as described in Working Instruction 3/00021-1/FEA 209 544/86

7 Revision History

Rev. Date Changes / Comments

A 2004-06-30 Initial release

B 2004-07-13 Revision update due to publishing problems

C 2004-08-19 K500 Added

D 2004-12-21 Lead Free information added

E 2005-07-13 Corrected fields, added instructions for Shielding Can PA SXA

109 5603

3/00021-2/FEA 209 544/86 E

Company Internal

©

Sony Ericsson Mobile Communications AB

15(15)

Loading...

Loading...