Page 1

Working Instruction, Electrical

Working Instruction, Electrical

Applicable for K200 and K220

CONTENTS

1 Lead-free soldering ................................................................................2

2 BGA equipment reflow profiles............................................................. 4

2.1

General.................................................................................................. 4

2.2

Temperature measurement...................................................................4

2.3

3 Replacement of components ................................................................6

3.1

3.2

3.3

J308: LCD Display continued .............................................................................. 9

3.4

3.5

3.6

3.7

3.8

3.9

3.10

3.11

3.12

3.13

3.14

3.15

4 Revision history ...................................................................................16

Reflow profiles.......................................................................................5

LED D317: Charge LED Red ................................................................ 7

D314, D316, D319, D360: Keypad Led Blue......................................... 7

J308: LCD Display................................................................................. 8

J402: Camera Socket.......................................................................... 10

J602: Antenna Connector.................................................................... 10

J302: SIM Connector........................................................................... 11

J305: Battery Connector...................................................................... 11

U604: IC Charger ................................................................................ 12

U606: FM Module (K220 Only)............................................................ 12

U702: Audio Power Amplifier (K220 Only) .......................................... 13

U605: IRDA Module ............................................................................ 13

U306: Melody IC.................................................................................. 14

U307: IC Charge Pump ....................................................................... 14

R201: NTC Resistor ............................................................................ 15

Shield can Lid Assy ............................................................................. 15

3/000 21-2/FEA 209 544/127 B

©

Company Internal

Sony Ericsson Mobile Communications AB

Page 2

Working Instruction, Electrical

1 Lead-free soldering

K

EEP ALL CONTACT SURFACES CLEAN OF DIRT AND HAND

GREASE

!

T

HIS PRODUCT IS MANUFACTURED WITH LEAD-FREE SOLDER

-

AND LEAD

FREE COMPONENTS!

During electrical repair, it is critical to make sure that no lead is

introduced.

This symbol indicates that the product is lead- free.

All lead-free PBA’s will be marked with this symbol.

A lead-free work area must be set up completely separated from

work areas that are used to make lead repairs.

The lead-free work area must also be clearly labeled with the lead

free symbol as shown in the adjacent picture.

The items on this desk must remain lead-free.

They must be adequately labeled to make their lead-free status

clearly and easily recognized.

3/000 21-2/FEA 209 544/127 B

©

Company Internal

Sony Ericsson Mobile Communications AB

2(16)

Page 3

Working Instruction, Electrical

LFS (lead-free solder paste) characteristics:

High melting point (typically 220°C)

Low wettability

High surface tension

Difficult to spread

Recommended tip temperature = 370°C

W

HEN SERVICING

LFS (

WITH

I

F NOT, THERE IS A HIGH RISK FOR UNRELIABLE SOLDERING

JOINTS

LEAD-FREE SOLDER PASTE),

.

PBA’

S THAT HAVE BEEN MANUFACTURED

LFS

MUST BE USED

.

Lead-free solder joints are more difficult to inspect because they

do not have shiny surfaces like leaded solder joints.

Also, lead-free solder does not flow as well as leaded solder, so

some of the solder pad areas may remain exposed.

3/000 21-2/FEA 209 544/127 B

©

Company Internal

Sony Ericsson Mobile Communications AB

3(16)

Page 4

Working Instruction, Electrical

2 BGA equipment reflow profiles

2.1 General

This document contains reflow profile recommendations for mobile phones and similar

products.

They are just general recommendations and considerations have to be taken for every single

product.

The solder paste is secondary but could also affect the parameters.

In this document one alloy is specified:

SnAgCu (Lead free) melting point 217°C

2.2 Temperature measurement

At least two probes should be used. Primary thermocouple should be attached from back side

of the board on a drilled hole under the middle of the component because that is usually the

coolest part of component during reflow. Second thermocouple should be attached on the top

of the component body.

It is recommended that the probes are soldered on the board, but glue and capton tape could

also be used, if necessary.

Nozzle type will be chosen after the outer size of the actual component.

Make sure the nozzle does not affect any nearby placed components.

These values are recommendations and may have to be changed depending on the type of

equipment.

The maximum temperature for any component must not exceed 260

°C.

3/000 21-2/FEA 209 544/127 B

©

Company Internal

Sony Ericsson Mobile Communications AB

4(16)

Page 5

Working Instruction, Electrical

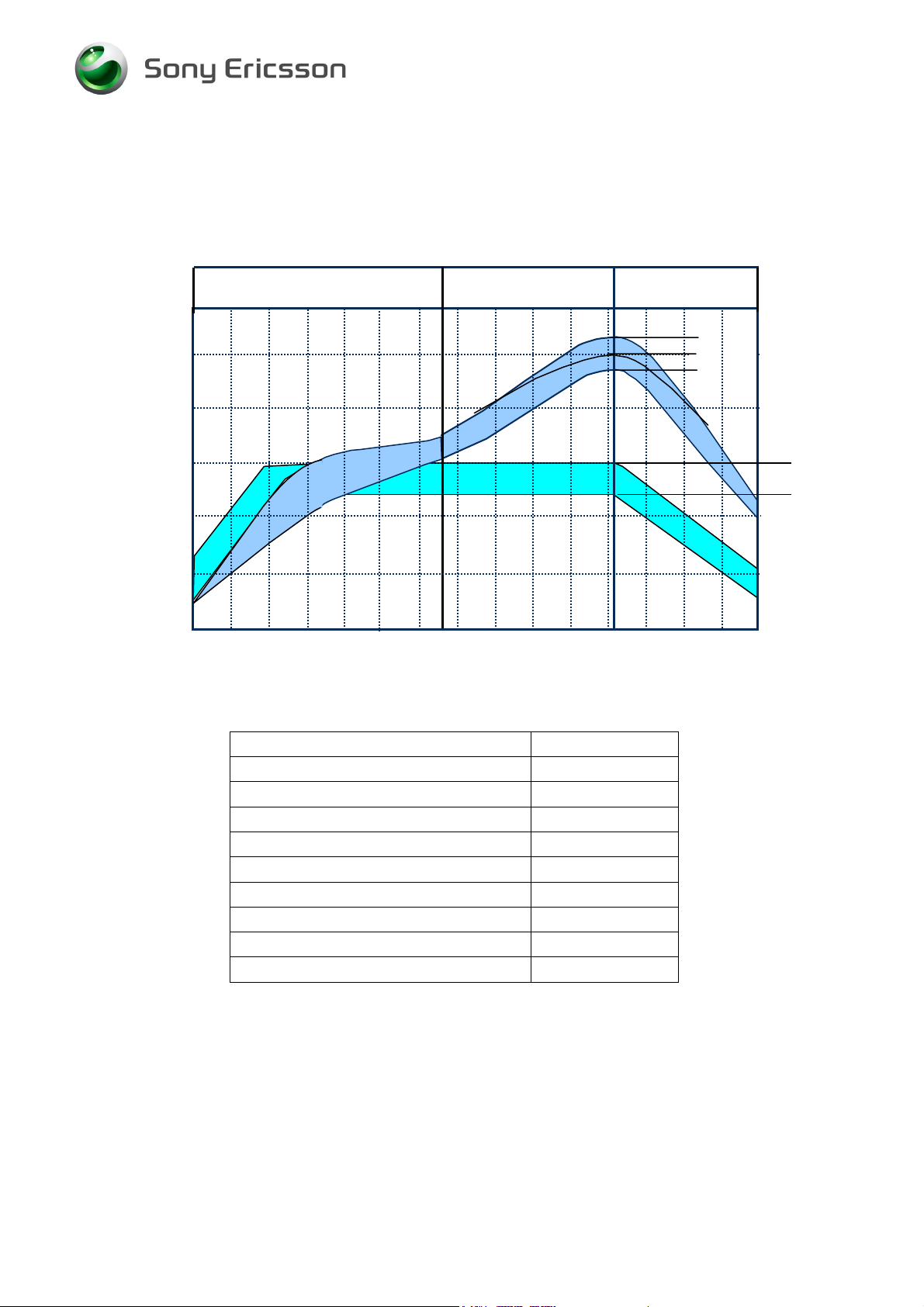

2.3 Reflow profiles

Sn/Ag/Cu (lead-free)

290

250

Reflow zone

260°C

245°C

230°C

200

150

Temperature [ºC]

100

150°C

125°C

50

0

40 80 120 160 200 240 280

Time [Seconds]

Ramp rate < 3°C/sec

Ramp rate cooling < 4°C/sec

Pre heating time 60-150 sec

Time above liquid 40-70 sec

Minimum temperature 230°C

Maximum temperature 245°C°

Maximum component temperature 260 °C

Time between 230 and 245 30 sec

Board temperature bottom side 160°C-185°C

Total time Approx. 3-5min

3/000 21-2/FEA 209 544/127 B

©

Company Internal

Sony Ericsson Mobile Communications AB

5(16)

Page 6

Working Instruction, Electrical

3 Replacement of components

EQUIPMENT

• Dentist hook

• ESD-gloves (cotton gloves)

• ESD-wristband

• Soldering tool

• Hot air soldering station

• Under Heat Equipment

• BGA Station

• Pair of tweezers

• Solder wick

• Solder paste lead-free (SN 96% Ag 3.5% Cu 0.5%)

• Flux, RMA no-clean flux

CAUTION

• Keep all contact surfaces clean of dirt and hand-grease!

• Remove the VGA Camera before starting repairing the board using hot air!

MECHANICAL INSTRUCTIONS

For all the following part replacements, disassemble and assemble the phone as described in

Working Instruction 3/00021-1/FEA 209 544/127.

3/000 21-2/FEA 209 544/127 B

©

Company Internal

Sony Ericsson Mobile Communications AB

6(16)

Page 7

Working Instruction, Electrical

3.1 LED D317: Charge LED Red

Remove the

Use the hot air soldering equipment.

Place the

Use the soldering iron equipment.

LED Red

LED Red

.

.

3.2 D314, D316, D319, D360: Keypad Led Blue

Remove the

Use the hot air soldering equipment.

Place the

Use the soldering iron equipment.

LED Blue

LED Blue

.

.

3/000 21-2/FEA 209 544/127 B

©

Company Internal

Sony Ericsson Mobile Communications AB

7(16)

Page 8

Working Instruction, Electrical

3.3 J308: LCD Display

R

EMOVE THE

Place the PBA in the Fixture

VGA

CAMERA FIRST

Loosen the snaps on the side of the board to release the

LCD Display from the PBA

A PART OF THE FLEXFILM IS ATACHED WITH ADESIVE TO THE

BOARD

BE CAREFULL TO NOT REMOVE THE SOLDERING PADS

Separate the Flex film from board

Lift the LCD Display and cut the Flex film

3/000 21-2/FEA 209 544/127 B

©

Company Internal

Sony Ericsson Mobile Communications AB

8(16)

Page 9

Working Instruction, Electrical

J308: LCD Display continued

Use under heat station to support the soldering process

Use Hot Air Station to remove the rest of Flex film

K

EEP THE UNDER HEAT STATION ON

Add Flux and remove the solder residual

Use Soldering Iron and Solder wick

Clean the pads with alcohol

P

LEASE NOTICE THAT THE SPARE PART

FROM THE ORIGINAL

THE SPARE PART

OF THE FLEX FILM

LCD

HAS SOLDERING PADS ON BOTH SIDES

LCD

IS DIFFERENT

Align the new Flex film with the board pads

Apply flux and solder with Soldering Iron

Start by applying heat on the pads of the board and then

slide the tip on top of the flex film

Clean the pads with alcohol

Use microscope to inspect the repair result

3/000 21-2/FEA 209 544/127 B

©

Company Internal

Sony Ericsson Mobile Communications AB

9(16)

Page 10

Working Instruction, Electrical

3.4 J402: Camera Socket

P

ROTECT THE BATTERY CONNECTOR WITH CAPTON TAPE

R

EMOVE THE

PCB

SPONGE FIRST

Use BGA Station to change the Camera Socket

!

3.5 J602: Antenna Connector

R

EMOVE THE

Use Hot Air Station to remove the Antenna Connector

Use BGA Repair Station to mount the Antenna Connector

PCB

SPONGE FIRST

3/000 21-2/FEA 209 544/127 B

©

Company Internal

Sony Ericsson Mobile Communications AB

10(16)

Page 11

Working Instruction, Electrical

3.6 J302: SIM Connector

Use BGA Station to replace the SIM Connector

3.7 J305: Battery Connector

PROTECT THE CAMERA SOCKET WITH CAPTON TAPE

Use BGA station to replace the Battery Connector

3/000 21-2/FEA 209 544/127 B

©

Company Internal

Sony Ericsson Mobile Communications AB

11(16)

Page 12

Working Instruction, Electrical

3.8 U604: IC Charger

Use BGA Station to replace the IC Charger

3.9 U606: FM Module (K220 Only)

Use BGA Station to replace the FM Module

3/000 21-2/FEA 209 544/127 B

©

Company Internal

Sony Ericsson Mobile Communications AB

12(16)

Page 13

Working Instruction, Electrical

3.10 U702: Audio Power Amplifier (K220 Only)

Use BGA Station to replace the Audio Power Amplifier

3.11 U605: IRDA Module

R

EMOVE THE

Use Hot Air Station to remove the IRDA Module

Use Soldering Iron to replace the IRDA Module

PCB

SPONGE FIRST

3/000 21-2/FEA 209 544/127 B

©

Company Internal

Sony Ericsson Mobile Communications AB

13(16)

Page 14

Working Instruction, Electrical

3.12 U306: Melody IC

Use BGA Station to replace the Melody IC

3.13 U307: IC Charge Pump

Use Hot Air Station to replace the IC Charge Pump

3/000 21-2/FEA 209 544/127 B

©

Company Internal

Sony Ericsson Mobile Communications AB

14(16)

Page 15

Working Instruction, Electrical

3.14 R201: NTC Resistor

P

ROTECT THE BATTERY CONNECTOR WITH CAPTON TAPE

Use Hot Air Station to replace the NTC Resistor

!

3.15 Shield can Lid Assy

D

O NOT REUSE THE SHIELDCAN LID

!

3/000 21-2/FEA 209 544/127 B

©

Company Internal

Sony Ericsson Mobile Communications AB

15(16)

Page 16

Working Instruction, Electrical

4 Revision history

Rev. Date Changes / Comments

A 2007-05-04 First release

B 2007-09-21 New component added, R201 NTC Resistor

3/000 21-2/FEA 209 544/127 B

©

Company Internal

Sony Ericsson Mobile Communications AB

16(16)

Loading...

Loading...