Page 1

XR-C6093SP

SERVICE MANUAL

Dolby noise reduction manufactured under license

from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks of Dolby Laboratories Licensing Corporation.

SPECIFICATIONS

East European Model

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type MG-25E-136

MICROFILM

FM/MW/LW CASSET TE CAR STEREO

Page 2

TABLE OF CONTENTS

1. GENERAL ................................................................... 3

2. DISASSEMBLY ......................................................... 7

3. ASSEMBLY OF MECHANISM DECK........... 10

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

4. MECHANICAL ADJUSTMENTS....................... 13

5. ELECTRICAL ADJUSTMENTS

Tape Deck Section .......................................................... 13

Tuner Section .................................................................. 15

6. DIAGRAMS

6-1. IC Pin Function Description ........................................... 18

6-2. Printed Wiring Board – MAIN Section –...................... 21

6-3. Schematic Diagram – MAIN Section –.......................... 25

6-4. Printed Wiring Board – POWER Section –................... 30

6-5. Schematic Diagram – POWER Section – ...................... 33

6-6. Printed Wiring Board – PANEL Section – .................... 37

6-7. Schematic Diagram – PANEL Section – ........................ 39

7. EXPLODED VIEWS ................................................ 44

8. ELECTRICAL PARTS LIST ............................... 47

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the manufacturer.

Discard used batteries according to the manufacturer’ s instructions.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type

anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens

instruksjoner.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ som

rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande föreskrifter.

VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

V aihda paristo ainoastaan laite valmistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

– 2 –

Page 3

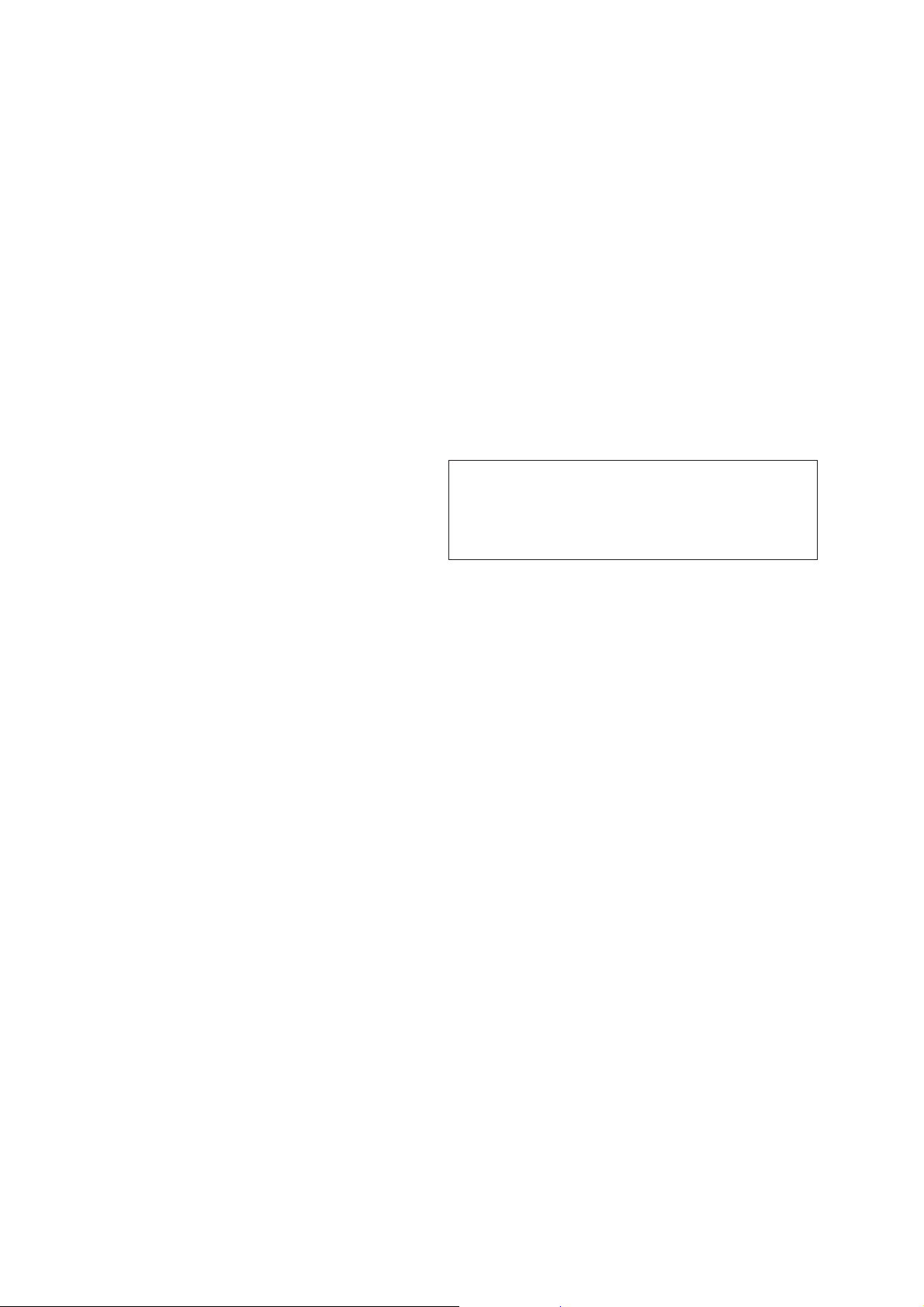

SECTION 1

GENERAL

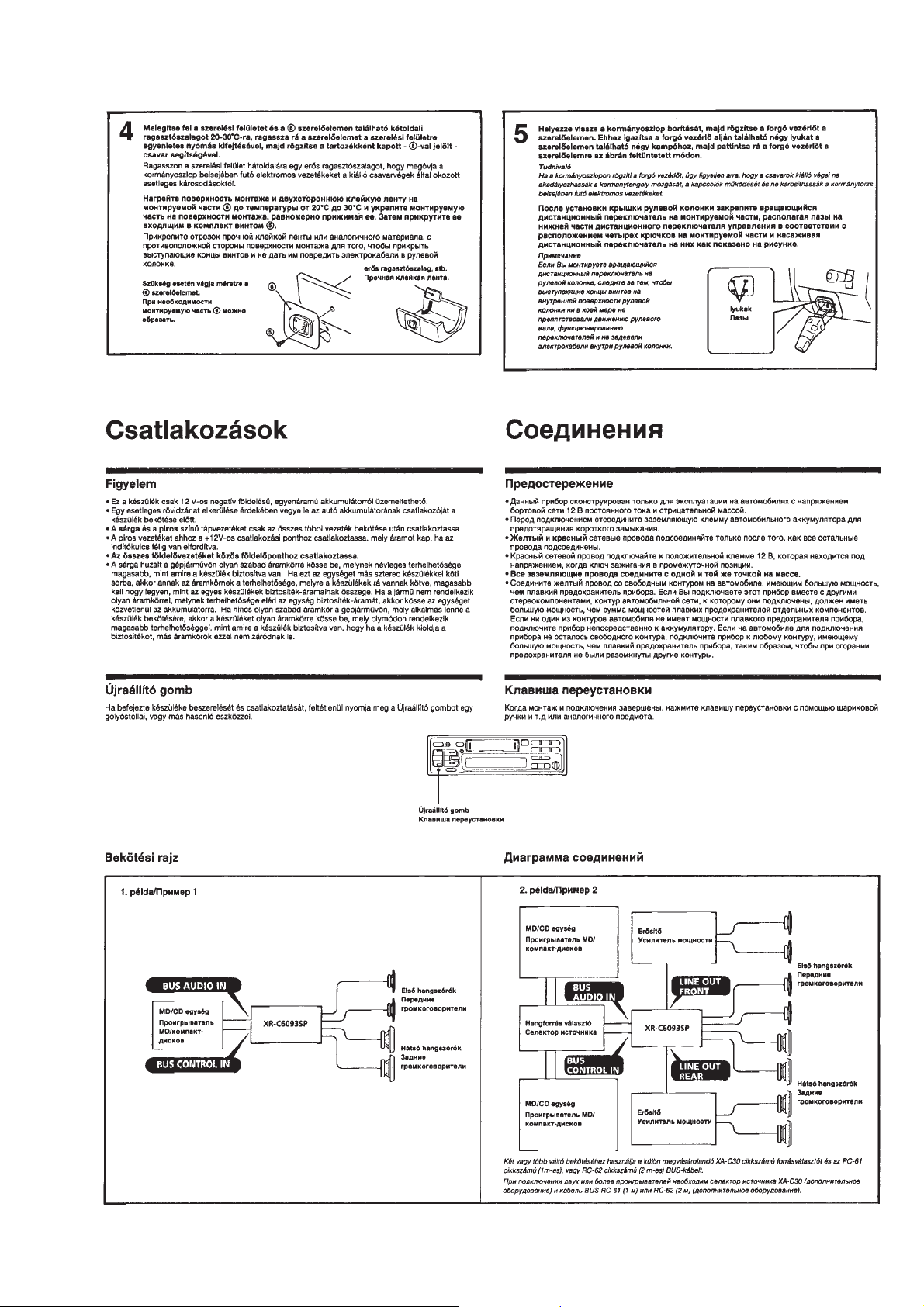

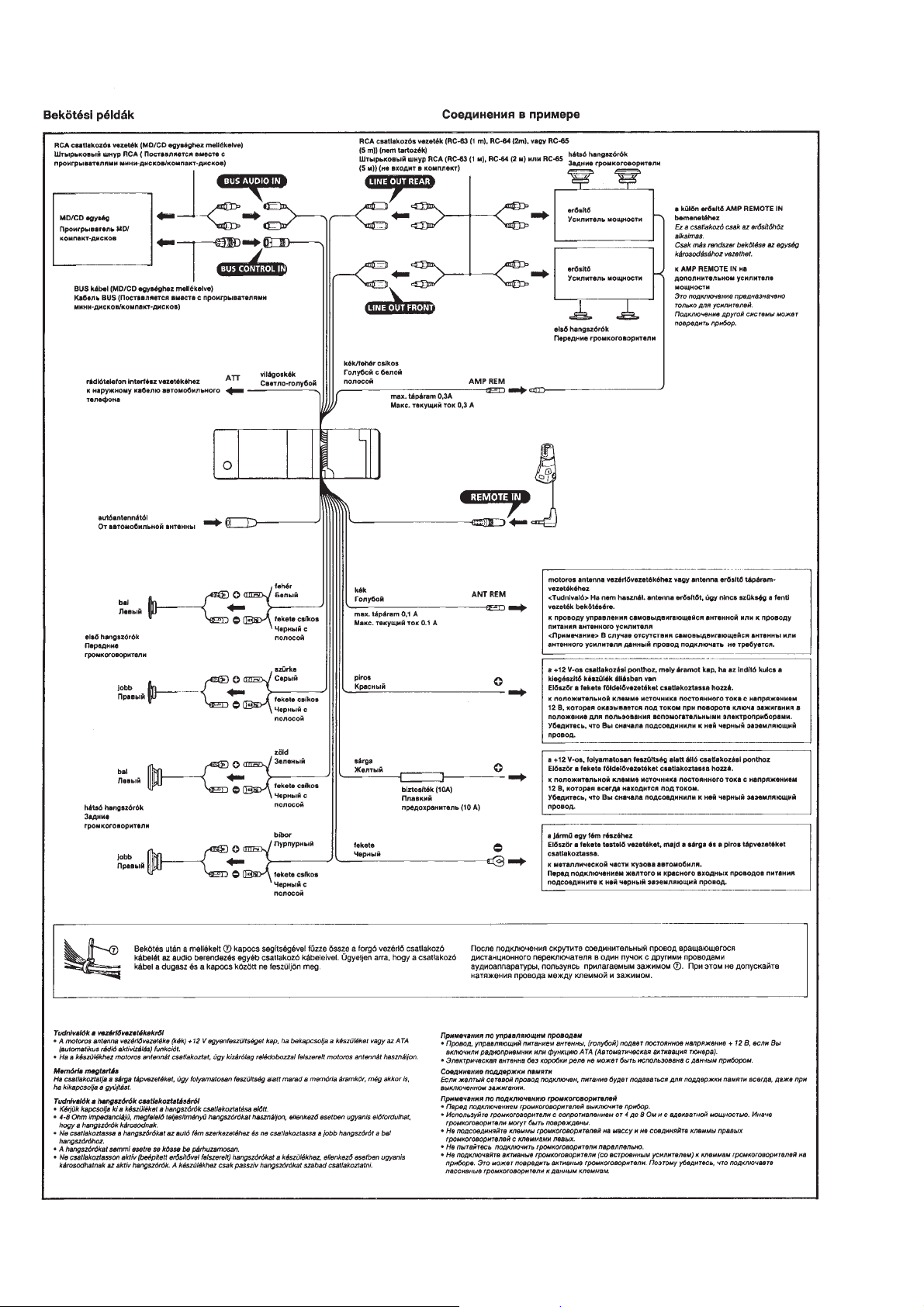

This section is extracted from

instruction manual.

– 3 –

Page 4

– 4 –

Page 5

– 5 –

Page 6

– 6 –

Page 7

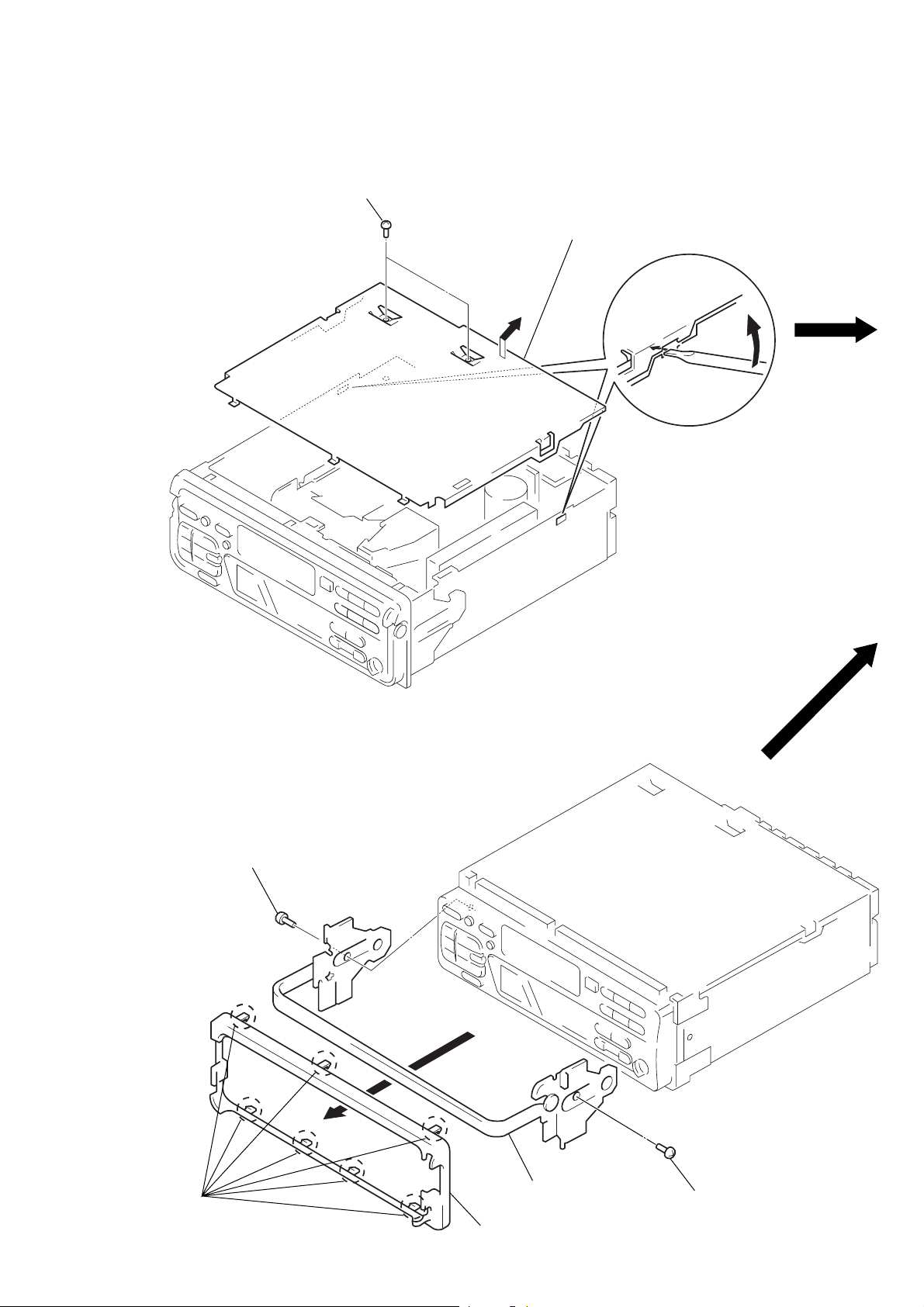

SECTION 2

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

COVER

1

two screws

(PTT2.6

×

6)

A

3

Remove the cover

toward direction

A

.

2

COLLAR (A), HANDLE ASS’Y

3

1

seven claws

screw

(PTT2.6

×

6)

2

collar (A)

4

handle ass’y

3

screw

(PTT2.6

×

6)

– 7 –

Page 8

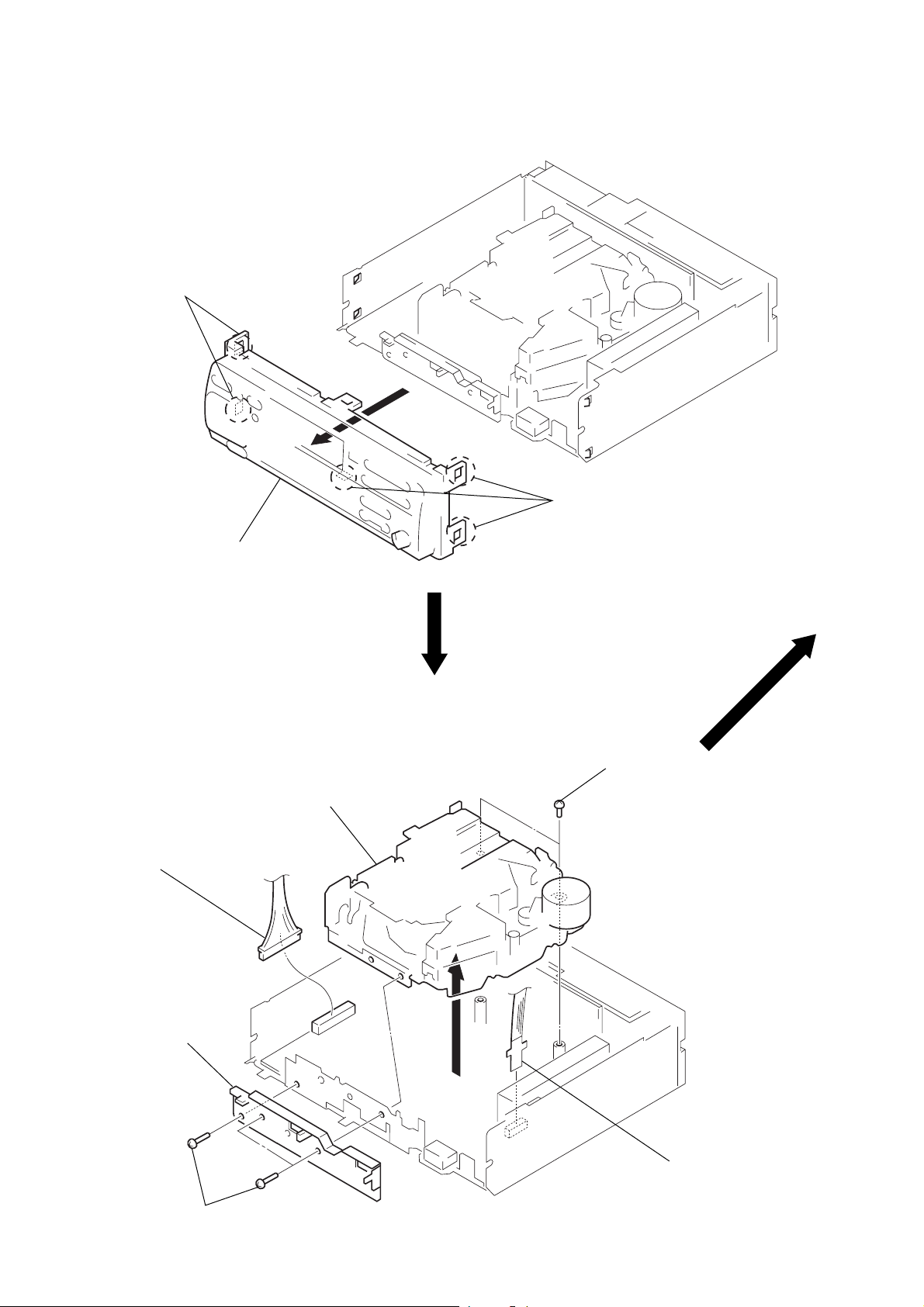

FRONT PANEL ASS’Y

1

two claws

2

front panel ass’y

1

three claws

MECHANISM DECK (MG-25E-136)

5

1

connector

(CNP331)

4

chassis (front)

mechanism deck

(MG-25E-136)

3

two screws

(PTT2.6

×

6)

2

flexible board

(CNP301)

3

three screws

(PTT2.6

×

6)

– 8 –

Page 9

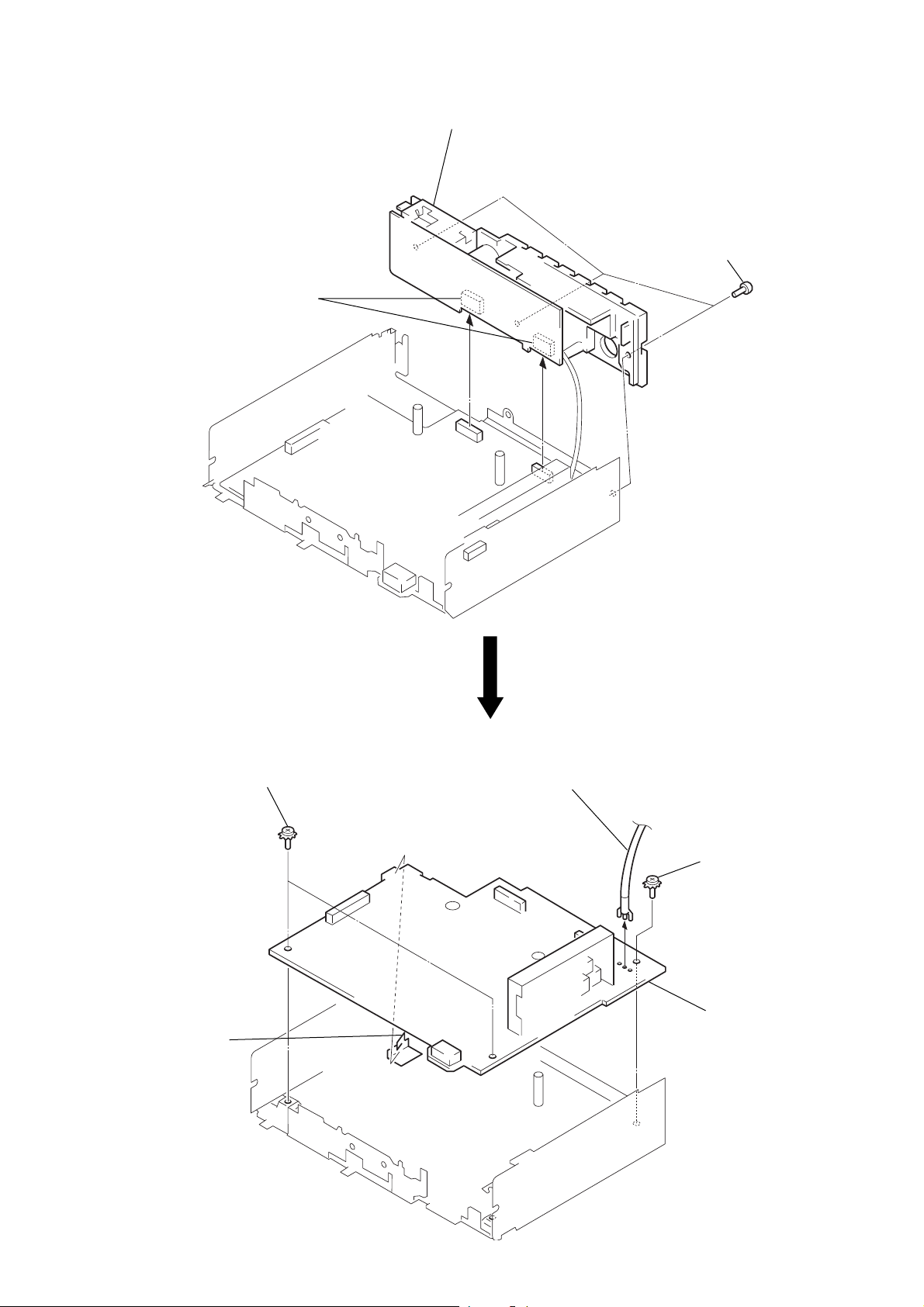

POWER BOARD

s

2

two connectors

(CNJ400, 401)

3

power board

1

three screw

(PTT2.6 × 8)

MAIN BOARD

2

claw

1

two ground point

screws

4

Break the soldering of

antenna cable.

1

ground point screw

3

main board

– 9 –

Page 10

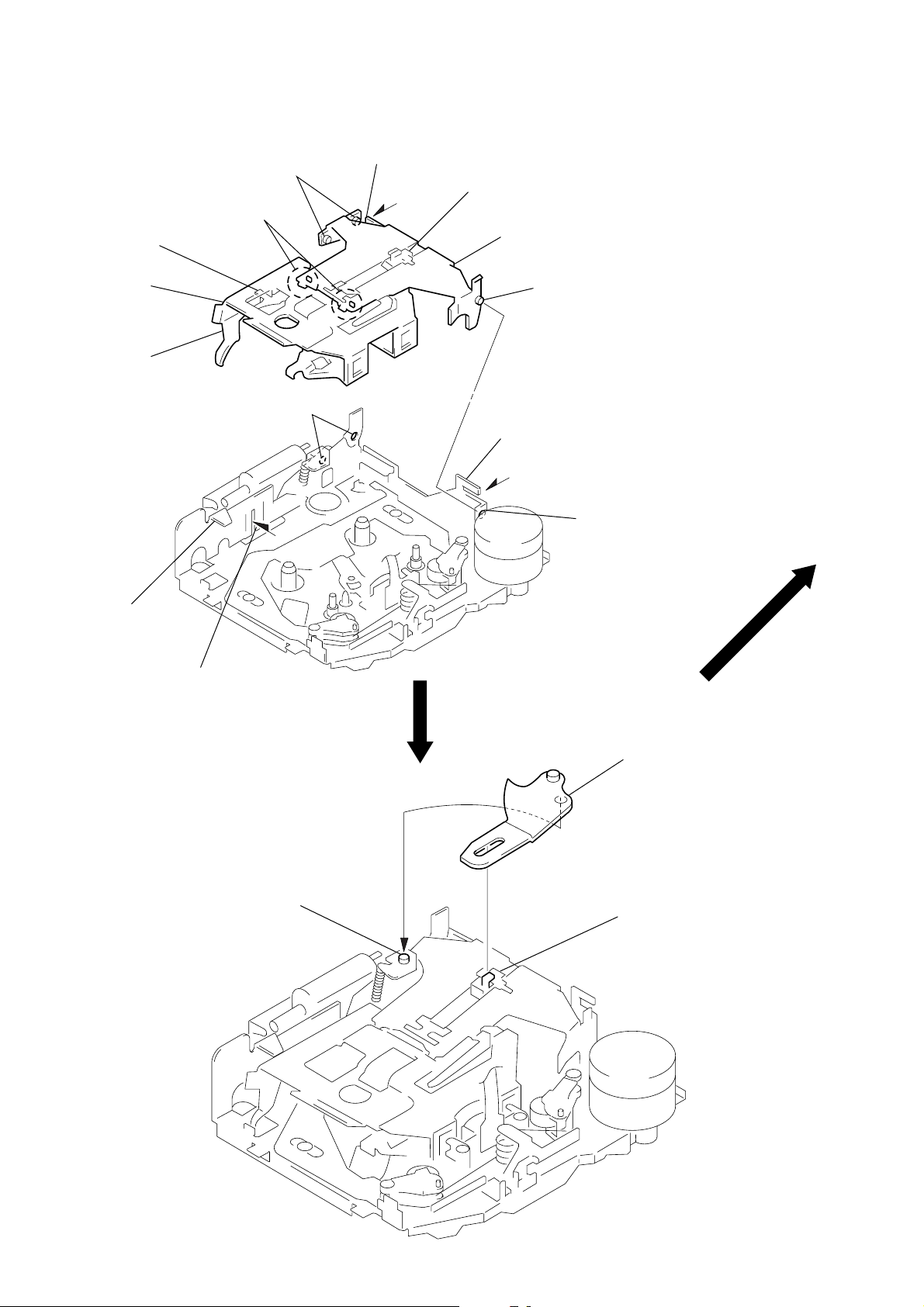

SECTION 3

2

Move the arm (suction) in the arrow

direction and fit on projection.

1

Fit the arm (suction) on the shaft.

projection

ASSEMBLY OF MECHANISM DECK

Note: Follow the assembly procedure in the numerical order given.

HOUSING

4

Fit claw on B part.

3

Put the housing

under A part.

5

Fit projection on C part.

2

Install the hanger onto

two claws of the housing.

housing

C

part

7

Holder the hanger by bending the claw.

1

Install the catch to the hanger.

hanger

6

Fit projection on D part.

8

Hold the hanger by

bending the claw.

A

part

ARM (SUCTION)

B

part

D

part

– 10 –

Page 11

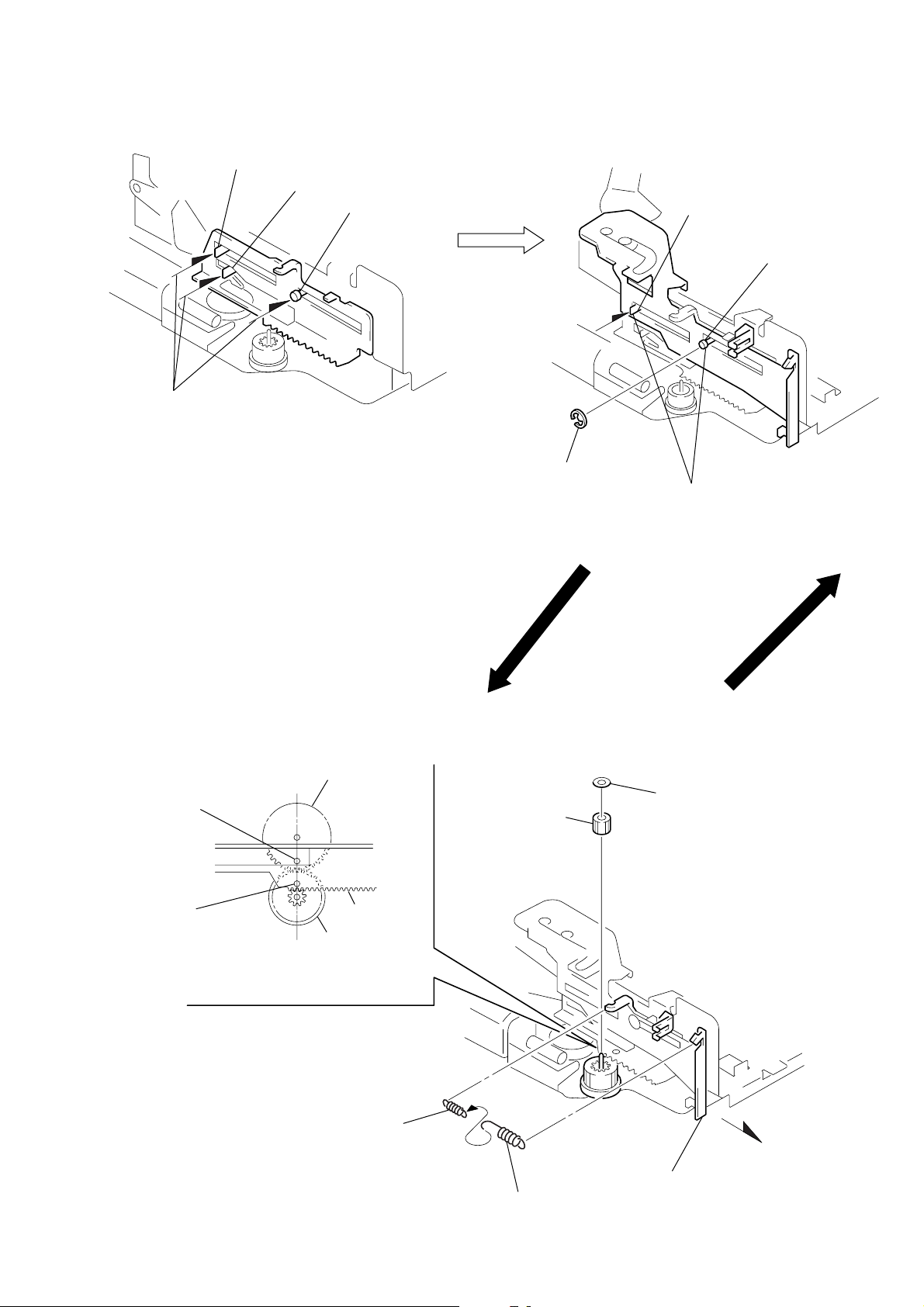

LEVER (LDG-A) / (LDG-B)

shaft

A

shaft

1

Fit the lever (LDG-A) on

shafts A – C and install it.

B

shaft

C

3

type-E stop ring 2.0

shaft

A

Fit the lever (LDG-B) on

2

shafts

install it.

A

and B and

shaft

B

GEAR (LDG-FT)

hole

hole

gear (LDG-D)

lever (LDG-A)

gear (LDG-FB)

4

Align hole in the gear (LDG-D)

with hole the lever (LDG-A).

2

tension spring (LD-2)

5

gear (LDG-FT)

1

6

polyethylene washer

2

tension spring (LD-1)

– 11 –

3

Move the lever (LDG-B)

in the arrow direction.

Page 12

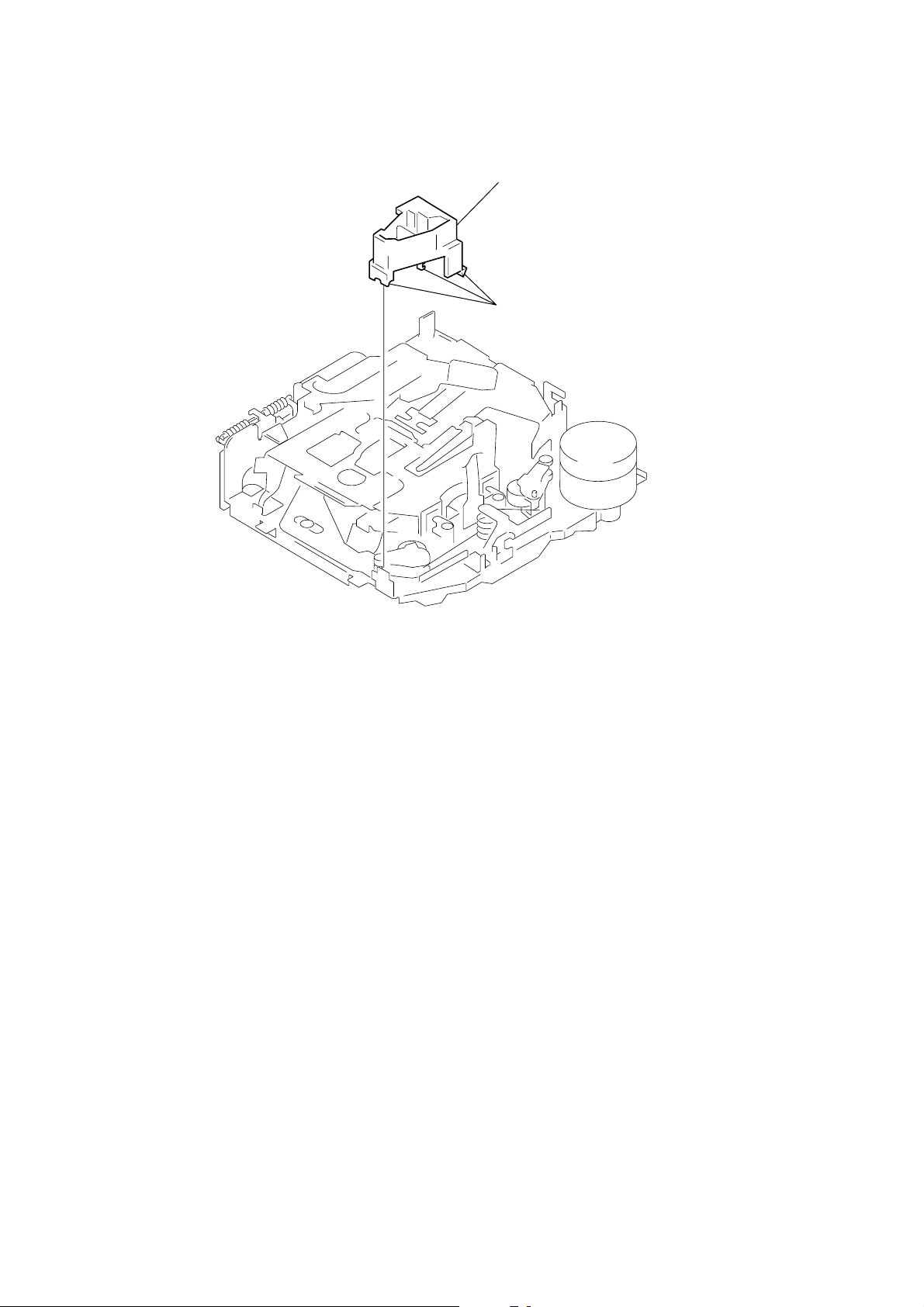

GUIDE (C)

2

guide (C)

1

three claws

– 12 –

Page 13

SECTION 4

e

MECHANICAL ADJUSTMENTS

SECTION 5

ELECTRICAL ADJUSTMENTS

1. Clean the following parts with a denatured-alcohol-moistened

swab:

playback head pinch roller

rubber belt capstan

idlers

2. Demagnetize the playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the power supply

voltage unless otherwise noted.

• Torque Measurement

Mode Torque Meter Meter Reading

Forward CQ-102C

Forward

Back Tension (0.01 - 0.06 oz•inch)

Reverse CQ-102RC

Reverse

Back Tension (0.01 - 0.06 oz•inch)

FF, REW CQ-201B

CQ-102C

CQ-102RC

30 - 65 g•cm

(0.42 - 0.90 oz•inch)

0.5 - 4.5g•cm

30 - 65 g•cm

(0.42 - 0.90 oz•inch)

0.5 - 4.5g•cm

60 - 200 g•cm

(0.83 - 2.78 oz•inch)

• Tape T ension Measurement

Mode Tension Meter Meter Reading

Forward CQ-403A

Reverse CQ-403R

more than 90 g

(more than 3.18 oz)

more than 90 g

(more than 3.18 oz)

T APE DECK SECTION

0 dB= 0.775 V

1. The adjustments should be performed in the order given in

this service manual.

2. The adjustments should be performed for both L-CH and

R-CH.

Test T ape

Type Signal Used for

P-4-A100 10 kHz, –10 dB head azimuth adjustment

WS-48A 3 kHz, 0 db tape speed adjustment

PB Head Azimuth Adjustment

Procedure:

1. Put the set into the FWD PB mode.

test tape

P-4-A100

(10 kHz, –10 dB)

set

Ω

4

speaker out terminal

level meter

+

–

2. Turn the screw and check the output peak value. Adjust the

screw so that the peak value in channels L and R coincides

within 2 dB.

output

level

within

2 dB

within

2 dB

L-CH

peak

R-CH

screw

position

peak

L-CH

peak

R-CH

peak

3. Check the phase in the FWD PB mode.

test tape

P-4-A100

(10 kHz, –10 dB)

4

L-CH

set

R-CH

in phase

Ω

4

Ω

speaker out terminal

Screen pattern

°

45

good wrong

90

°

135 °180

oscilloscope

V

H

+

+

–

–

°

angl

– 13 –

Page 14

4. Repeat the above adjustment for the REV PB mode.

5. Check that output level difference between FWD PB mode

and REV PB mode is within 4 dB.

Adjustment Location: PB head

See the adjustment location from on page 17 for the

adjustment.

Tape Speed Adjustment

Setting:

speed checker

or

test tape

WS-48A

(3 kHz, 0 dB)

frequency counter

Ω

4

REV FWD

adjustment screws

set

speaker out terminal

+–

Procedure:

1. Put the set into the FWD PB mode.

2. Adjust adjustment resistor for inside capstan motor so that the

reading on the speed checker or frequency counter becomes in

specification.

Specification: Constant speed

Speed checker Frequency counter

–2 to +3% 2,940 to 3,090 Hz

Adjustment Location: See page 17.

DOLBY Level Adjustment

Setting:

Preset [3] (DOLBY) button : NR OFF

SEL (BAS) button : Center

SEL (TRE) button : Center

SEL (BAL) button : Center

SEL (FAD) button : Center

SEL (VOL) button : Maximum

D-BASS control : OFF

L-CH: TP101 (DOLBY-L)

test tape

P-4-D400

(400 Hz, 0 dB)

MAIN board

R-CH: TP201 (DOLBY-R)

level meter

set

+

–

Procedure:

1. Put the set into the FWD PB mode.

2. Adjust RV121 (L-CH) and RV221 (R-CH) so that the level

meter reading is –6 ± 0.5 dB (0.37 to 0.41 V).

Adjustment Location: See page 17.

– 14 –

Page 15

TUNER SECTION

)

l

0 dB=1 µV

Cautions during repair

When the tuner unit is defective, replace it by a new one because its internal block is difficult to repair.

Note: Adjust the tuner section in the sequence shown below.

1. FM Auto Scan/Stop Level Adjustment.

2. FM Stereo Separation Adjustment.

3. MW Auto Scan/Stop Level Adjustment.

4. FM Polar VCO Adjustment.

5. FM Polar Pilot Adjustment.

FM Auto Scan/Stop Level Adjustment

Setting:

[SOURCE] button: FM 1

FM RF signal

generator

Carrier frequency : 98.00MHz

Output leve : 20 dB (10.0

Mode : mono

Modulation : 1 kHz, 22.5 kHz deviation (30 %

MAIN board

Procedure:

1. Tune the set to 98.0 MHz.

2. Connect the digital voltmeter to TP (SD) on MAIN board.

3. Adjust RV2 on TU1 so that the reading on the digital voltmeter changes point from low to high.

TP (SD)

dummy

antenna

50

Ω

50

Ω

antenna

terminal

µ

V)

digital

voltmeter

+

–

set

FM Stereo Separation Adjustment

Setting:

[SOURCE] button: FM 1

FM RF signal

generator

Carrier frequency

Output level

Mode

Modulation

Procedure:

FM Stereo

signal generator

output channel

L-CH L-CH A

R-CH L-CH Adjust RV4 on TU1

R-CH R-CH C

L-CH R-CH Adjust RV4 on TU1

L-CH Stereo separation: A-B

R-CH Stereo separation: C-D

The separations of both channels should be equal.

Specification: Separation more than 26 dB

Adjustment Location: See page 17.

dummy

antenna

50

50

: 98.00MHz

: 70 dB (3.2 mV)

: stereo

: main : 1 kHz, 20 kHz deviation (26.7 %)

sub : 1 kHz, 20 kHz deviation (26.7 %)

pilot : 19 kHz, 7.5 kHz deviation (10 %)

Level meter Level meter

connection reading (dB)

antenna

terminal

Ω

Ω

set

4

speaker out termina

for minimum reading.

for minimum reading.

level

meter

Ω

+

–

B

D

Adjustment Location: See page 17.

– 15 –

Page 16

MW Auto Scan/Stop Level Adjustment

µ

TP402 (PLT)

MAIN board

level meter

+

–

Setting:

[SOURCE] and [MODE] button: MW

30

Ω

15 pF

65 pF

FM Polar Pilot Adjustment

Setting:

[SOURCE] button: FM2

FM RF signal

generator

antenna terminal

AM RF signal

generator

AM dummy antenna

(50 Ω)

Carrier frequency : 999 kHz

30% amplitude

modulation by

1 kHz signal

Output level : 33 dB (44.7

MAIN board

TP (SD)

V)

digital

voltmeter

+

–

set

antenna terminal

Procedure:

1. Tune the set to 999 kHz

2. Connect the digital voltmeter to TP (SD) on MAIN board.

3. Adjust RV1 on TU1 so that the reading on the digital voltmeter changes point from low to high.

Adjustment Location: See page 17.

FM Polar VCO Adjustment

Setting:

[SOURCE] button: FM2

set

Carrier frequency : 69.5 MHz

Output level : 66 dB (1.995 mV)

Procedure:

1. Connect the level meter to the TP402 (PLT) on MAIN board.

2. Set the modulation frequency of the FM RF signal generator

to 1 kHz, 40 kHz deviation (80 %)

3. Then output level is supposing that (A) dB.

4. Set the modulation frequency of the FM RF signal generator

to 31.25 kHz, 10 kHz deviation (20%)

5. Adjust L401 so that the reading on the level meter becomes to

maximum.

6. Adjust RV401 so that the reading on the level meter becomes

to (A) + 13.0 dB ± 0.5 dB.

Adjustment Location: See page 17.

FM RF signal

generator

Carrier frequency : 69.5 MHz

Output level : 66 dB (1.995 mV)

MAIN board

TP401 (VCO)

antenna terminal

set

frequency counter

+

–

Procedure:

1. Tune the set to 69.5 MHz, and set the internal modulation lev el

of the FM RF signal generator to 10 kHz deviation (20%).

2. Connect the frequency counter to the TP401 (VCO) on MAIN

board.

3. Adjust RV402 so that the reading on the frequency counter

becomes to 31.25 ± 0.1 kHz.

Adjustment Location: See page 17.

– 16 –

Page 17

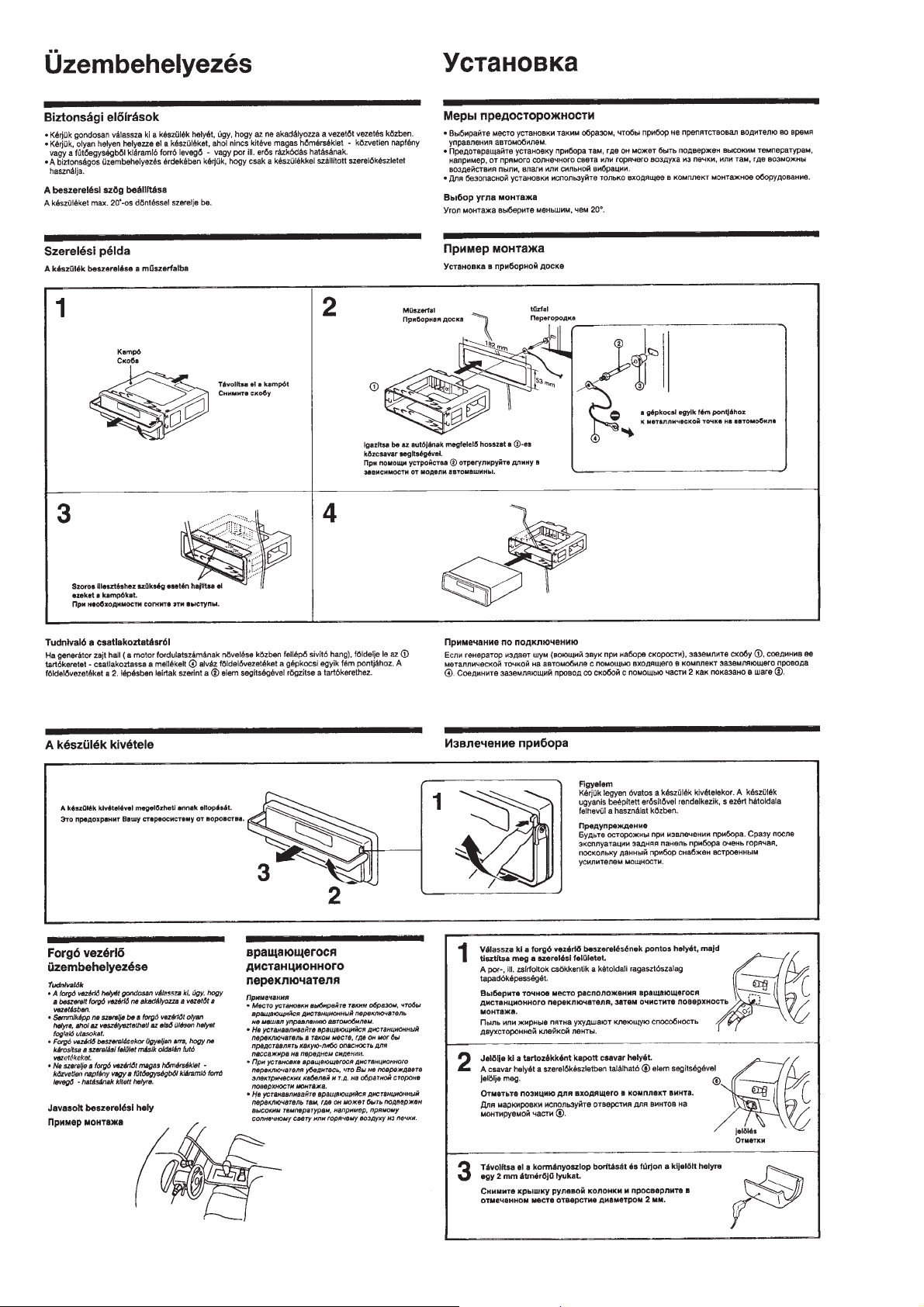

Adjustment Location:

Tape Speed Adjustment

– SET UPPER VIEW –

TU1

[MAIN BOARD] (CONDUCTOR SIDE)

RV221 (R-CH)

RV121 (L-CH)

RV1 MW Auto Scan/Stop Level Adjustmetnt

RV2 FM Auto Scan/Stop Level Adjustmetnt

RV4 FM Stereo Separation Adjustmetnt

L401

RV401

RV402

FM Polar VCO Adjustmetnt

FM Polar Pilot Adjustment

DOLBY Level Adjustment

TU1

1

13 TP (SD)

24

TP402

(PLT)

TP201

(DOLBY-R)

TP101

(DOLBY-L)

IC401

TP401

(VCO)

– 17 –

Page 18

SECTION 6

DIAGRAMS

6-1. IC PIN FUNCTION DESCRIPTION

• MAIN BOARD IC701 µPD78058GC-F54-3B9 (SYSTEM CONTROLLER)

Pin No. Pin Name I/O Function

1 DSEL I Destination setting terminal (fixed at center voltage)

2 RCIN0 I Rotary remote commander shift key A/D input terminal

3 SD IN I

4 AVSS — Ground terminal (for A/D converter)

5 ST I/O

6 PLLCE O PLL serial chip enable output to the FM/AM PLL (IC31)

7 AVREF1 I Reference voltage (+5V) input terminal (for D/A converter)

8 PLLSI I PLL serial data input from the FM/AM PLL (IC31)

9 PLLSO O PLL serial data output to the FM/AM PLL (IC31)

10 PLLCKO O PLL serial data transfer clock signal output to the FM/AM PLL (IC31)

11 P-STIN I Polar stereo signal input from the polar multiplexer (IC401)

12 LCDSO O Serial data output to the liquid crystal display driver (IC901)

13 LCDCKO O Serial data transfer clock signal output to the liquid crystal display driver (IC901)

14 LCDCE O Chip enable output to the liquid crystal display driver (IC901)

15 LCDINH O

16 UNISI I Serial data input from the bus interface (IC571) (for SONY bus)

17 UNISO O Serial data output to the bus interface (IC571) (for SONY bus)

18 UNICKI I Serial data reading clock signal input terminal (for SONY bus)

19 UNICKO O Serial data transfer clock signal output to the bus interface (IC571) (for SONY bus)

20 BUSON O Bus on/off control signal output to the bus interface (IC571) (for SONY bus) “L”: bus on

21 SYSRST O Reset signal output to the bus interface (IC571) (for SONY bus) “L”: reset

22 AMPON O Standby control signal output to the power amplifier (IC471) “L”: standby

23 AMPMUTE O Muting control signal output to the power amplifier (IC471) “L”: muting on

24 TUNON O Tuner system power supply on/off control signal output to the BA3918 (IC601) “H”: tuner on

25 FM ON O FM system power supply on/off control signal output to the BA3918 (IC601) “H”: FM on

26 PW ON O Main system power supply on/off control signal output to the BA3918 (IC601) “H”: power on

27 COLOR I

28 AMS ON O

29 REL I Reel table rotation detect signal input from the take-up and supply reel sensor

30 MTLIN I

31 POS3 I

32 POS2 I

33 GND — Ground terminal

34 POS0 I

35 POS1 I

36 LM LOD O

37 LM EJ O

Station detector detect input from the FM/AM tuner unit (TU1)

Stop level for SEEK, BTM, etc. is determined SD is present at input of “H”

Input of FM stereo detection signal from FM/AM tuner unit (TU1), and output of forced

monaural control signal to FM/AM tuner unit (TU1) (Commonly used for stereo display input

and forced monaural output)

FM stereo detection at input of “L”, forced monaural at output of “L”

Blank indicate control signal output to the liquid crystal display driver (IC901)

“L”: no display

Input terminal to set whether the illumination color change function is present or not

“L”: illumination color change function is present (fixed at “L”)

Tape auto music sensor control signal output to the CXA2510Q (IC101)

“L” is output to lower the gain for audio level at FF/REW

Input terminal to set whether the auto metal function is present or not

“L”: auto metal function is present (fixed at “L”)

Tape position detect input from the tape operation switch on the mechanism block

Tape position detect input from the tape operation switch on the mechanism block

Loading/tape operation motor control signal output to the LB1638M (IC651)

(For the loading direction and forward side operation) *1

Loading/tape operation motor control signal output to the LB1638M (IC651)

(For the eject direction and reverse side operation) *1

– 18 –

Page 19

Pin No. Pin Name I/O Function

38 N/R OUT O

39 NC O Not used (open)

40 CMON O Capstan/reel motor (M901) drive signal output terminal “H”: motor on

41 TAPEON O Tape system power supply on/off control signal output terminal “H”: tape on

42 COLSEL I Setting terminal for the illumination color “L”: amber, “H”: green (fixed at “L”)

43 RCIN1 I Rotary remote commander shift key A/D input terminal

44 TEST I Setting terminal for the test mode “L”: test mode (normally fixed at “H”)

45 ILLON O

46 BEEP O Beep sound output terminal

47 MUTE O Line muting control signal output terminal “H”: line muting on

48 VOLCE O Chip enable signal output to the electrical volume (IC301)

49 SUBCE O Chip enable signal output for the sub volume Not used in this set (open)

50 VOLCKO O Serial data transfer clock signal output to the electrical volume (IC301)

51 SUBCKO O Serial data transfer clock signal output for the sub volume Not used in this set (open)

52 VOLSO O Serial data output to the electrical volume (IC301)

53 TAPMUT O Tape muting on/off control signal output to the CXA2510Q (IC101) “H”: tape muting on

54 DOLON I/O

Forward/reverse direction control signal output to the CXA2510Q (IC101)

“L: forward direction, “H”: reverse direction

Power supply on/off control signal output terminal at the illumination and liquid crystal display

driver (IC901) “H”: power on

At power select on mode (refer to pin ^£): “H” output at the accessory on

At power select off mode (refer to pin ^£): “H” output at the power on

Dolby control in/out terminal

At initial mode: valid/invalid selection input of dolby function (“L” input: valid)

At normal mode: dolby on/off control signal output to the CXA2510Q (IC101)

“H”: dolby on

Dolby B/C selection control in/out terminal

55 DOLBC I/O

56 AMSIN I

57 MTLSEL I/O

58 AD ON O Power supply on/off control signal output for the A/D converter “L”: power on

59 RAMBU I

60 RESET I

61 SIRCS I Sircs signal input terminal Not used in this set (fixed at “L”)

62 BUIN I Battery detect signal input terminal “H”: battery on

63 PW SEL I

64 ACCIN I Accessory detect signal input terminal “L”: accessory on

65 UNISI I Serial data input (for release of the stop mode)

66 TELMUTE I Telephone muting signal input terminal At input of “L”, the signal is attenuated by –20 dB

At initial mode: dolby B only/dolby B and C type selection input (“L” input: dolby B and C)

At normal mode: dolby type selection signal output “L”: dolby B, “H”: dolby C

Not used this function (fixed at “H”)

Whether a music is present or not from CXA2510Q (IC101) is detected at auto music sensor

“L”: music is present, “H”: music is not present

METAL control in/out terminal

At initial mode: auto/manual mode selection input of METAL function “L”: manual mode

At manual mode: METAL on/off control signal output to the CXA2510Q (IC101)

“H”: METAL on

At auto mode: input at MTLIN (pin #º)

Internal RAM reset detection signal input terminal

Input terminal to check that RAM data are not destroyed due to low voltage

This checking is made within 100 msec after reset

System reset signal input from the reset switch (S901)

“L” is input for several 100 msec after power on, then it changes to “H”

Position signal input from the mechanism block (for release of the stop mode)

“L”: power select off mode (halt mode), “H”: power select on mode (operation mode)

– 19 –

Page 20

Pin No. Pin Name I/O Function

67 KEYACK I

68 VDD — Power supply terminal (+5V)

69 X OUT O Main system clock output terminal (5 MHz)

70 X IN I Main system clock input terminal (5 MHz)

71 GND — Ground terminal

72 XT OUT O Sub system clock output terminal (32.768 kHz) Not used in this set (open)

73 XT IN I Sub system clock input terminal (32.768 kHz) Not used in this set (fixed at “L”)

74 AVDD — Power supply terminal (+5V) (for A/D converter)

75 AVREF0 I Reference voltage input terminal (+5V) (for A/D converter)

76 KEYIN0 I

77 KEYIN1 I

78 D-BASS I D-BASS switch (SW970) input (A/D input)

79 VSM I FM and AM (MW/LW) signal meter voltage detection input from the FM/AM tuner unit (TU1)

80 KEYSEL I Setting terminal for the key (fixed at center voltage)

Input of acknowledge signal for the key entry Acknowledge signal is input to accept function

and eject keys in the power off status On at input of “H”

Key input terminal (A/D input)

OFF, SOURCE, MODE *, + ) + SEEK AMS, – = 0 SEEK AMS, VOLUME –,

SEL, VOLUME +, DSPL, ATT keys input (LSW901 to LSW910)

Key input terminal (A/D input)

6, INTRO 1, REPEAT 2, SHUF/a 3, BL SKIP 6, ATA 5, BANK/MTL 4, BTM SENS,

FILE, PRESET DISC +/– keys input

(LSW921 to LSW928, LSW931, LSW930 and LSW932)

*1 loading/tape operation motor control

MODE

TERMINAL

LM LOD (pin #§) “L” “H” “L” “H”

LM EJ (pin #¶) “L” “L” “H” “H”

STOP

LOADING/

FORWARD

EJECT/

REVERSE

BRAKE

– 20 –

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

• IC Block Diagrams

IC31 BU2624F-E2 (MAIN BOARD)

1

XOUT

I/O

CONTROL

REFERENCE

DIVIDER

SHIFT

REGISTER

LATCH

MAIN

COUNT

IF COUNT

CONTROL

XIN

2

3

CE

4

CK

5

DA

6

CD

7

P0

8

P1

9

P3

PHASE

DETECT

PRESCALLER

IC301 LC75373ED (MAIN BOARD)

20

VSS

19

PD1

18

VDD

LSELO

L4

L3

VDD

RSELO

L2

L1

R1

R2

R3

R4

17

FMIN

16

AMIN

15

P2

14

IF1

LVRIN

34

35

36

37

38

39

40

41

42

43

44

LCOM

+

–

–

+

+

–

+

–

–

+

–

+

LT1

LT2

LT3

–

+

+

–

+

–

+

–

LS1

LSIN

LTOUT

–

+

–

+

DECODER LATCH

+

–

+

–

LS2

LS3

SHIFT

REGISTER

2324252627282930313233

LSOUT

CONTROL

22

LFIN

+

–

+

–

–

+

–

+

LFOUT

21

LROUT

20

19

VREF

18

CE

17

DI

16

CL

15

VSS

14

RROUT

RFOUT

13

12

RFIN

10

P4

20BIT COUNT

IC101 CXA2510AQ-T4 (MAIN BOARD)

AUXIN1

TAPEIN1

PBOUT1

GND

120µ/

70µ

+

–

+

120µ/

70µ

345 6 7 8 9 10

2

VCC

PBOUT2

X1

+

X1

TAPEIN2

T1

AUXIN2

T2

NR BIAS

TAPE/AUX

TAPE EQ

FWD/RVS

VCC

LPF

+

–

F3

–

+

MSLPF

LINEOUT2

PBFB1

PBRIN1

PBREF1

PBFIN1

VCT

PBGND

PBFIN2

PBREF2

PBRIN2

PBFB2

PBEQ1

–

31

32

33

34

35

36

37

38

39

40

F2

VCT

F1

1

PBEQ2

DIREF

OFF/B

NR

2425

+

TCH2

LINEOUT1

NR

–

OFF/B

NC

PLAY

TCH1

NC

MSSW

2122232627282930

MS

MODE

NR

MODE

DETECT

13

12

11

IF2

SD

PD2

MS ON/

OFF

20

19

18

17

16

15

14

13

12

11

MSMODE

DRSW

TAPESW

INSW

NRSW

NC

MSOUT

DGND

MSTC

FF

1

RVRIN

2 345 6 7 8 9 10

RT1

RT2

RCOM

RT3

RSIN

RTOUT

RS1

IC401 IR3R42 (MAIN BOARD)

SUBIN

SUBOUT

AMP

1

VCC

MON

1/2

PHASE

AMP

2 3

IN

WAVEFORM

SEP.

GATE

POUT

20 19 18 17 16 15 14 13 12 11

REGULATOR

VCO

OSC

1/2

SAMPLE

& HOLD

BUFFER

4

RHC

LPF1A

LPF1B

DETIN

LPF2A

AMP

PHASE

COMPARATOR

PHASE

COMPARATOR 2

MUTE

5 6 7 8 9 10

ROUT

LOUT

ST

VCO STOP

LHC

IC471 TDA7384 (POWER BOARD)

DRIVER

5

3 4

1

2

TAB

GND

OUT2–

OUT2+

STNBY

DRIVER

11

10

12

9

7 8

6

VCC

GND

OUT1–

OUT1+

SVR

IN1

IN2

13

S-GND

DRIVER

14

16

17

15

IN4

IN3

OUT3+

AC-GND

GND

1918

OUT3–

20

VCC

RS2

LPF2B

TRIGGER

DRIVER

21

OUT4+

RS3

2322

MUTE

GND

LAMP

24

OUT4–

25

GND

N.C.

11

RSOUT

IC402, 403 M5201FP (MAIN BOARD)

SWC

1

CONTROL

CIRCUIT

IN+A

2

IN–A

3

+

–

4

–VCC

8

+VCC

IN+B

7

IN–B

6

+

–

OUT

5

– 41 – – 42 –

Page 28

IC571 BA8270F-E2 (MAIN BOARD)

BUS ON

1

2

RST

BATT

3

4

CLK

5

VREF

6

DATA

GND

7 8

BUS ON

SWITCH

RESET

SWITCH

BATTERY

SWITCH

14

13

12

11

10

9

VCC

RST

BUS ON

CLK IN

BU IN

DATA IN

DATA OUT

IC601 BA3918-V2 (MAIN BOARD)

REGULATOR

OVER VOLTAGE

PROTECT

–

+

2 3

4

1

NC

STB

MODE2

MODE1

5 6 7 8 9 10 1211

VCC

AMP

ANT

VDD

IC651 LB1638M (MAIN BOARD)

GND

IN1

VCC

IN2

1

2

3

4

CONTROL LOGIC

10

9

8

7

COM

N.C.

OUT1

VS

OUT2

–

+

AM

–

+

FM

–

+

GND

5 6

GND

N.C.

– 43 –

Page 29

SECTION 7

EXPLODED VIEWS

NOTE:

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

↑↑

Parts Color Cabinet's Color

(1) CHASSIS SECTION

not supplied

MG-25E-136

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

• The mechanical parts with no reference number in the exploded views are not supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of the

electrical parts list.

#1

#1

#2

#4

8

7

9

#5

10

#2

8

#2

11

6

20

5

BT501

21

4

3

2

#1

19

#1

#1

18

14

Front panel ass'y

#1

1

Ref. No. Part No. Description Remark

1 3-012-567-01 COLLAR (A)

2 X-3372-126-1 HANDLE ASSY

* 3 3-012-574-01 INSULATOR

* 4 A-3313-521-A MAIN BOARD, COMPLETE

5 3-915-923-01 SCREW, GROUND POINT

15

17

5

#1

F901

12

13

Ref. No. Part No. Description Remark

13 3-012-593-01 BRACKET

* 14 X-3373-590-1 CHASSIS ASSY

15 3-012-587-01 PLATE (C), GROUND

16 1-782-345-11 CORD (WITH CONNECTOR) (POWER)

17 3-338-263-01 CUSHION (U)

16

* 6 3-012-565-01 COVER

* 7 3-012-568-01 BRACKET (CONNECTOR)

* 8 3-022-201-01 HEAT SINK

* 9 3-022-214-01 BRACKET (IC)

* 10 A-3313-523-A POWER BOARD, COMPLETE

11 3-012-575-01 PANEL (REAR)

12 3-340-614-11 SCREW (JACK), STEP

* 18 3-014-628-01 CHASSIS (FRONT)

19 3-012-577-01 BUTTON (RELEASE)

20 3-022-253-01 SHEET, INSULATING (A)

21 3-022-254-01 SHEET, INSULATING (B)

BT501 1-528-225-31 BATTERY, LITHIUM

F901 1-532-677-00 FUSE, GLASS TUBE (10 A)

– 44 –

Page 30

53

51

68

60

61

59

58

54

55 56

57

63

62

67

64

65

66

LCD901

not supplied

#3

#3

(2) FRONT PANEL SECTION

Ref. No. Part No. Description Remark

51 3-018-799-01 BUTTON (D-BASS)

53 3-016-932-01 BUTTON (L) (2) (+. –)

54 3-904-194-01 EMBLEM (NO. 2.5), SONY

55 3-012-576-01 BUTTON (RESET)

56 3-009-300-01 BUTTON (SOURCE)

57 3-018-658-01 BUTTON (L) (r. OFF. +. + ). SEEK AMS.

58 3-016-933-01 BUTTON (1-3) (6. 1. 2. 3)

59 3-016-931-01 BUTTON (4-6) (4. 5. 6)

60 3-016-937-01 BUTTON (R) (S) (SENS. FILE. – DISC +)

= 0 –. SEL. ATT)

Ref. No. Part No. Description Remark

61 3-932-205-11 DOOR, CASSETTE

62 3-935-003-01 SPRING, TORSION

* 63 3-019-151-01 PLATE (LCD), GROUND

* 64 3-022-497-01 SHEET (REFLECTOR)

* 65 3-018-612-01 PLATE, LIGHT GUIDE

* 66 3-018-611-01 HOLDER (LCD)

* 67 A-3294-375-A CONTROL BOARD, COMPLETE

68 X-3375-266-1 PANEL SUB ASSY

LCD901 1-801-968-31 DISPLAY PANEL, LIQUID CRYSTAL

– 45 –

Page 31

(3) MECHANISM DECK SECTION

(MG-25E-136)

154

153

#6

155

158

152

157

156

159

A

160

163

A

HP901

161

162

M901

164

165

168

151

Ref. No. Part No. Description Remark

151 A-3291-667-A CLUTCH (FR) ASSY

* 152 3-019-130-01 LEVER (LDG-A)

* 153 3-019-131-01 LEVER (LDG-B)

154 3-020-539-01 SPRING (LD-1), TENSION

155 3-020-540-01 SPRING (LD-2), TENSION

156 3-020-542-01 GEAR (LOADING FT)

157 3-341-753-11 WASHER, POLYETHYLENE

158 3-020-533-01 HOUSING

* 159 3-020-532-01 ARM (SUCTION)

160 3-020-534-01 HANGER

#7

168

166

167

Ref. No. Part No. Description Remark

161 3-933-346-01 CATCHER

162 3-933-344-01 GUIDE (C)

163 3-014-798-01 SCREW (HEAD), SPECIAL

164 3-364-151-01 WASHER

165 X-3375-625-1 CHASSIS (SV) ASSY (D)

166 3-017-302-01 BELT (25)

167 3-936-853-01 FLYWHEEL (F)

168 3-701-437-21 WASHER

HP901 1-500-157-21 HEAD, MAGNETIC (PLAYBACK)

M901 A-3291-665-A MOTOR ASSY, MAIN (CAPSTAN/REEL)

– 46 –

Page 32

SECTION 8

ELECTRICAL PARTS LIST

CONTROL

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used

on the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms.

METAL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F: nonflammable

Ref. No. Part No. Description Remark

* A-3294-375-A CONTROL BOARD, COMPLETE

************************

* 3-018-611-01 HOLDER (LCD)

* 3-018-612-01 PLATE, LIGHT GUIDE

* 3-019-151-01 PLATE (LCD), GROUND

* 3-022-497-01 SHEET (REFLECTOR)

< CAPACITOR >

C901 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C902 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C903 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C904 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. .

uPD. . : µPD. .

• CAPACITORS

uF: µF

• COILS

uH: µH

When indicating parts by reference

number, please include the board.

Ref. No. Part No. Description Remark

LSW923 1-762-620-11 SWITCH, KEY BOARD (WITH LED) (2/REPEAT)

LSW924 1-762-620-11 SWITCH, KEY BOARD (WITH LED) (3/SHUF/a)

LSW925 1-762-620-11 SWITCH, KEY BOARD (WITH LED) (6/BL SKIP)

LSW926 1-762-620-11 SWITCH, KEY BOARD (WITH LED) (5/ATA)

LSW927 1-762-620-11 SWITCH, KEY BOARD (WITH LED)

(4/BANK/MTL)

LSW928 1-762-620-11 SWITCH, KEY BOARD (WITH LED) (SENS/BTM)

LSW930 1-762-620-11 SWITCH, KEY BOARD (WITH LED)

(+, DISC/PRESET)

LSW931 1-762-620-11 SWITCH, KEY BOARD (WITH LED) (FILE)

LSW932 1-762-620-11 SWITCH, KEY BOARD (WITH LED)

(–, DISC/PRESET)

< CONNECTOR >

CN901 1-778-960-21 SOCKET, CONNECTOR 12P

< DIODE >

D901 8-719-420-90 DIODE MA8051-M

< IC >

IC901 8-759-365-90 IC LC75824W

< LIQUID CRYSTAL DISPLAY >

LCD901 1-801-968-31 DISPLAY PANEL, LIQUID CRYSTAL

< SWITCH >

LSW901 1-762-620-11 SWITCH, KEY BOARD (WITH LED) (OFF)

LSW902 1-762-620-11 SWITCH, KEY BOARD (WITH LED) (SOURCE)

LSW903 1-762-620-11 SWITCH, KEY BOARD (WITH LED)

(MODE *)

LSW904 1-762-620-11 SWITCH, KEY BOARD (WITH LED)

(+ + ), SEEK/AMS)

LSW905 1-762-620-11 SWITCH, KEY BOARD (WITH LED)

(– = 0, SEEK/AMS)

LSW906 1-762-620-11 SWITCH, KEY BOARD (WITH LED) (–)

LSW907 1-762-620-11 SWITCH, KEY BOARD (WITH LED) (SEL)

LSW908 1-762-620-11 SWITCH, KEY BOARD (WITH LED) (+)

LSW909 1-762-620-11 SWITCH, KEY BOARD (WITH LED) (DSPL)

LSW910 1-762-620-11 SWITCH, KEY BOARD (WITH LED) (ATT)

LSW921 1-762-620-11 SWITCH, KEY BOARD (WITH LED) (6)

LSW922 1-762-620-11 SWITCH, KEY BOARD (WITH LED) (1/INTRO)

< PILOT LAMP >

PL901 1-517-633-21 LAMP, PILOT (LCD BACK LIGHT)

PL902 1-517-633-21 LAMP, PILOT (LCD BACK LIGHT)

< TRANSISTOR >

Q901 8-729-901-97 TRANSISTOR 2SA1036K-Q

Q902 8-729-901-97 TRANSISTOR 2SA1036K-Q

Q903 8-729-900-53 TRANSISTOR DTC114EK

Q904 8-729-900-53 TRANSISTOR DTC114EK

< RESISTOR >

R901 1-216-045-00 METAL CHIP 680 5% 1/10W

R902 1-216-045-00 METAL CHIP 680 5% 1/10W

R903 1-216-045-00 METAL CHIP 680 5% 1/10W

R904 1-216-049-11 RES, CHIP 1K 5% 1/10W

R905 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R906 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R907 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R908 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R909 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R921 1-216-045-00 METAL CHIP 680 5% 1/10W

R922 1-216-045-00 METAL CHIP 680 5% 1/10W

R923 1-216-045-00 METAL CHIP 680 5% 1/10W

R924 1-216-049-11 RES, CHIP 1K 5% 1/10W

R925 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R926 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R927 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R928 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R929 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

– 47 –

Page 33

CONTROL MAIN

Ref. No. Part No. Description Remark

R930 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R931 1-216-073-00 METAL CHIP 10K 5% 1/10W

R951 1-216-041-00 METAL CHIP 470 5% 1/10W

R952 1-216-109-00 METAL CHIP 330K 5% 1/10W

R953 1-216-049-11 RES, CHIP 1K 5% 1/10W

R954 1-216-049-11 RES, CHIP 1K 5% 1/10W

R955 1-216-049-11 RES, CHIP 1K 5% 1/10W

R956 1-216-198-00 RES, CHIP 1K 5% 1/8W

R961 1-216-037-00 METAL CHIP 330 5% 1/10W

R962 1-216-033-00 METAL CHIP 220 5% 1/10W

R963 1-216-029-00 METAL CHIP 150 5% 1/10W

R964 1-216-025-00 RES, CHIP 100 5% 1/10W

R965 1-216-037-00 METAL CHIP 330 5% 1/10W

R966 1-216-033-00 METAL CHIP 220 5% 1/10W

R967 1-216-029-00 METAL CHIP 150 5% 1/10W

R968 1-216-025-00 RES, CHIP 100 5% 1/10W

R969 1-216-037-00 METAL CHIP 330 5% 1/10W

R970 1-216-033-00 METAL CHIP 220 5% 1/10W

R971 1-216-029-00 METAL CHIP 150 5% 1/10W

R972 1-216-025-00 RES, CHIP 100 5% 1/10W

R980 1-216-073-00 METAL CHIP 10K 5% 1/10W

R981 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R982 1-216-073-00 METAL CHIP 10K 5% 1/10W

R983 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R984 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R985 1-216-081-00 METAL CHIP 22K 5% 1/10W

R986 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R987 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

< SWITCH >

S901 1-692-431-21 SWITCH, TACTILE (RESET)

SW970 1-762-937-11 SWITCH, ROTARY (D-BASS)

************************************************************

* A-3313-521-A MAIN BOARD, COMPLETE

*********************

Ref. No. Part No. Description Remark

C20 1-163-986-00 CERAMIC CHIP 0.027uF 10% 25V

C21 1-163-024-00 CERAMIC CHIP 0.018uF 10% 50V

C22 1-163-024-00 CERAMIC CHIP 0.018uF 10% 50V

C23 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C24 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C26 1-124-234-00 ELECT 22uF 20% 16V

C27 1-164-222-11 CERAMIC CHIP 0.22uF 25V

C31 1-126-157-11 ELECT 10uF 20% 16V

C33 1-164-222-11 CERAMIC CHIP 0.22uF 25V

C34 1-126-157-11 ELECT 10uF 20% 16V

C35 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C36 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C37 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C38 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C39 1-163-237-11 CERAMIC CHIP 27PF 5% 50V

C40 1-163-104-00 CERAMIC CHIP 30PF 5% 50V

C51 1-126-157-11 ELECT 10uF 20% 16V

C52 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C53 1-136-165-00 FILM 0.1uF 5% 50V

C54 1-136-169-00 FILM 0.22uF 5% 50V

C121 1-130-469-00 MYLAR 680PF 5% 50V

C122 1-130-469-00 MYLAR 680PF 5% 50V

C124 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C125 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C126 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C127 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C128 1-126-163-11 ELECT 4.7uF 20% 50V

C129 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C151 1-126-163-11 ELECT 4.7uF 20% 50V

C152 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C153 1-126-160-11 ELECT 1uF 20% 50V

C154 1-126-160-11 ELECT 1uF 20% 50V

C155 1-164-182-11 CERAMIC CHIP 0.0033uF 10% 50V

C156 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C157 1-126-157-11 ELECT 10uF 20% 16V

C158 1-164-492-11 CERAMIC CHIP 0.15uF 10% 16V

3-022-253-01 SHEET, INSULATING (A)

3-022-254-01 SHEET, INSULATING (B)

< BATTERY >

BT501 1-528-225-31 BATTERY, LITHIUM

< CAPACITOR >

C1 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C2 1-124-234-00 ELECT 22uF 20% 16V

C3 1-124-234-00 ELECT 22uF 20% 16V

C4 1-124-234-00 ELECT 22uF 20% 16V

C5 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C7 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C8 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C9 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C10 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C11 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C12 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C13 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C14 1-126-160-11 ELECT 1uF 20% 50V

C15 1-126-160-11 ELECT 1uF 20% 50V

C159 1-164-492-11 CERAMIC CHIP 0.15uF 10% 16V

C160 1-126-157-11 ELECT 10uF 20% 16V

C171 1-126-163-11 ELECT 4.7uF 20% 50V

C172 1-124-464-11 ELECT 0.22uF 20% 50V

C181 1-126-163-11 ELECT 4.7uF 20% 50V

C182 1-124-464-11 ELECT 0.22uF 20% 50V

C221 1-130-469-00 MYLAR 680PF 5% 50V

C222 1-130-469-00 MYLAR 680PF 5% 50V

C224 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C225 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C226 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C227 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C228 1-126-163-11 ELECT 4.7uF 20% 50V

C229 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C251 1-126-163-11 ELECT 4.7uF 20% 50V

C252 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C253 1-126-160-11 ELECT 1uF 20% 50V

C254 1-126-160-11 ELECT 1uF 20% 50V

C255 1-164-182-11 CERAMIC CHIP 0.0033uF 10% 50V

C256 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C257 1-126-157-11 ELECT 10uF 20% 16V

– 48 –

Page 34

MAIN

Ref. No. Part No. Description Remark

C258 1-164-492-11 CERAMIC CHIP 0.15uF 10% 16V

C259 1-164-492-11 CERAMIC CHIP 0.15uF 10% 16V

C260 1-126-157-11 ELECT 10uF 20% 16V

C271 1-126-163-11 ELECT 4.7uF 20% 50V

C272 1-124-464-11 ELECT 0.22uF 20% 50V

C281 1-126-163-11 ELECT 4.7uF 20% 50V

C282 1-124-464-11 ELECT 0.22uF 20% 50V

C320 1-124-234-00 ELECT 22uF 20% 16V

C322 1-124-584-00 ELECT 100uF 20% 10V

C323 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C324 1-126-159-11 ELECT 0.47uF 20% 50V

C325 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C326 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C327 1-126-157-11 ELECT 10uF 20% 16V

C329 1-126-157-11 ELECT 10uF 20% 16V

C331 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C332 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C333 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C334 1-126-157-11 ELECT 10uF 20% 16V

C335 1-115-175-11 ELECT 100uF 20% 16V

C336 1-124-234-00 ELECT 22uF 20% 16V

C337 1-115-175-11 ELECT 100uF 20% 16V

C351 1-124-584-00 ELECT 100uF 20% 10V

C352 1-124-234-00 ELECT 22uF 20% 16V

C353 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C358 1-163-205-00 CERAMIC CHIP 0.001uF 5% 50V

C359 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C371 1-126-160-11 ELECT 1uF 20% 50V

C372 1-124-589-11 ELECT 47uF 20% 16V

C374 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C375 1-124-589-11 ELECT 47uF 20% 16V

C401 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C402 1-126-157-11 ELECT 10uF 20% 16V

C403 1-126-160-11 ELECT 1uF 20% 50V

C404 1-137-522-11 FILM 0.01uF 5% 50V

C405 1-137-150-11 FILM 0.01uF 5% 100V

C406 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C407 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C408 1-163-003-11 CERAMIC CHIP 330PF 10% 50V

C409 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C410 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C411 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C412 1-126-159-11 ELECT 0.47uF 20% 50V

C413 1-126-159-11 ELECT 0.47uF 20% 50V

C414 1-126-160-11 ELECT 1uF 20% 50V

C415 1-126-160-11 ELECT 1uF 20% 50V

C416 1-126-160-11 ELECT 1uF 20% 50V

C417 1-126-160-11 ELECT 1uF 20% 50V

C418 1-126-160-11 ELECT 1uF 20% 50V

C420 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C421 1-163-011-11 CERAMIC CHIP 0.0015uF 10% 50V

C422 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C423 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C424 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C425 1-126-159-11 ELECT 0.47uF 20% 50V

C428 1-163-141-00 CERAMIC CHIP 0.001uF 5% 50V

C429 1-163-141-00 CERAMIC CHIP 0.001uF 5% 50V

C430 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

Ref. No. Part No. Description Remark

C431 1-163-019-00 CERAMIC CHIP 0.0068uF 10% 50V

C434 1-163-019-00 CERAMIC CHIP 0.0068uF 10% 50V

C435 1-124-589-11 ELECT 47uF 20% 16V

C436 1-124-234-00 ELECT 22uF 20% 16V

C551 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C553 1-126-925-11 ELECT 470uF 20% 10V

C554 1-163-077-00 CERAMIC CHIP 0.1uF 10% 25V

C556 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C571 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C601 1-126-163-11 ELECT 4.7uF 20% 50V

C604 1-126-157-11 ELECT 10uF 20% 16V

C605 1-126-157-11 ELECT 10uF 20% 16V

C606 1-126-157-11 ELECT 10uF 20% 16V

C607 1-126-157-11 ELECT 10uF 20% 16V

C608 1-126-157-11 ELECT 10uF 20% 16V

C609 1-126-157-11 ELECT 10uF 20% 16V

C621 1-124-257-00 ELECT 2.2uF 20% 50V

C622 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C623 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C668 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C703 1-126-157-11 ELECT 10uF 20% 16V

C704 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C705 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C706 1-164-232-11 CERAMIC CHIP 0.01uF 50V

< CONNECTOR >

CNJ400 1-770-382-11 CONNECTOR, BOARD TO BOARD 12P

CNJ401 1-770-386-11 CONNECTOR, BOARD TO BOARD 20P

CNJ661 1-770-407-11 CONNECTOR, BOARD TO BOARD 12P

CNP301 1-766-260-11 CONNECTOR, FFC/FPC (ZIF) 7P

* CNP331 1-506-995-11 PIN, CONNECTOR (PC BOARD) 13P

< COMPOSITION CIRCUIT BLOCK >

CP1 1-519-504-11 GAP, DISCHARGE

< DIODE >

D1 8-719-991-65 DIODE SB02W03C

D31 8-719-109-89 DIODE RD5.6ESB2

D51 8-719-110-17 DIODE RD10ESB2

D321 8-719-991-33 DIODE 1SS133T-77

D331 8-719-110-14 DIODE RD9.1ES-B3

D332 8-719-970-02 DIODE 1SR139-400

D371 8-719-109-72 DIODE RD3.9ES-B2

D372 8-719-991-33 DIODE 1SS133T-77

D375 8-719-991-33 DIODE 1SS133T-77

D421 8-719-988-62 DIODE 1SS355

D422 8-719-988-62 DIODE 1SS355

D423 8-719-988-62 DIODE 1SS355

D551 8-719-400-20 DIODE MA152WA

D552 8-719-041-79 DIODE MA721WA-TX

D553 8-719-991-33 DIODE 1SS133T-77

D554 8-719-049-26 DIODE RB721Q

D571 8-719-109-93 DIODE RD6.2ESB2

D572 8-719-109-97 DIODE RD6.8ES-B2

D600 8-719-970-02 DIODE 1SR139-400

D601 8-719-970-02 DIODE 1SR139-400

D602 8-719-970-02 DIODE 1SR139-400

– 49 –

Page 35

MAIN

Ref. No. Part No. Description Remark

D603 8-719-110-49 DIODE RD18ES-B2

D604 8-719-110-06 DIODE RD8.2ESB1

D605 8-719-991-33 DIODE 1SS133T-77

D621 8-719-923-74 DIODE MTZJ-T-77-11A

D743 8-719-988-62 DIODE 1SS355

D744 8-719-988-62 DIODE 1SS355

< IC >

IC31 8-759-448-84 IC BU2624F-E2

IC101 8-752-079-79 IC CXA2510AQ-T4

IC301 8-759-443-67 IC LC75373ED

IC401 8-759-063-04 IC IR3R42

IC402 8-759-603-27 IC M5201FP

IC403 8-759-603-27 IC M5201FP

IC571 8-759-449-89 IC BA8270F-E2

IC601 8-759-347-49 IC BA3918-V2

IC651 8-759-823-87 IC LB1638M

IC701 8-759-522-60 IC uPD78058GC-F54-3B9

< SHORT >

JR2 1-216-295-11 SHORT 0

JR4 1-216-295-11 SHORT 0

JR5 1-216-295-11 SHORT 0

JR6 1-216-295-11 SHORT 0

JR9 1-216-296-11 SHORT 0

< COIL >

L1 1-410-180-51 INDUCTOR CHIP 0.1uH

L31 1-410-509-11 INDUCTOR 10uH

L401 1-411-999-11 COIL (VCO)

L421 1-410-336-11 INDUCTOR 220uH

L701 1-410-509-11 INDUCTOR 10uH

< TRANSISTOR >

Q1 8-729-209-41 TRANSISTOR 2SC2532-TE85L

Q32 8-729-106-68 TRANSISTOR 2SD1615A-GP

Q51 8-729-106-68 TRANSISTOR 2SD1615A-GP

Q52 8-729-021-94 TRANSISTOR 2SK1657-T1B

Q171 8-729-920-21 TRANSISTOR DTC314TKH04

Q181 8-729-920-21 TRANSISTOR DTC314TKH04

Q271 8-729-920-21 TRANSISTOR DTC314TKH04

Q281 8-729-920-21 TRANSISTOR DTC314TKH04

Q331 8-729-015-11 TRANSISTOR 2SD1802FAST-TL

Q332 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q333 8-729-900-53 TRANSISTOR DTC114EK

Q334 8-729-106-60 TRANSISTOR 2SB1115A

Q335 8-729-900-53 TRANSISTOR DTC114EK

Q371 8-729-620-06 TRANSISTOR 2SC3052-EF

Q372 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q374 8-729-216-22 TRANSISTOR 2SA1162-G

Q401 8-729-900-53 TRANSISTOR DTC114EK

Q420 8-729-620-06 TRANSISTOR 2SC3052-EF

Q421 8-729-620-06 TRANSISTOR 2SC3052-EF

Q422 8-729-900-53 TRANSISTOR DTC114EK

Q423 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q551 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q552 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q601 8-729-620-06 TRANSISTOR 2SC3052-EF

Ref. No. Part No. Description Remark

Q602 8-729-900-53 TRANSISTOR DTC114EK

Q623 8-729-900-53 TRANSISTOR DTC114EK

Q624 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q625 8-729-026-68 TRANSISTOR 2SD2525(TP)

Q626 8-729-026-68 TRANSISTOR 2SD2525(TP)

< RESISTOR >

R1 1-216-049-11 RES, CHIP 1K 5% 1/10W

R2 1-216-029-00 METAL CHIP 150 5% 1/10W

R3 1-216-097-00 RES, CHIP 100K 5% 1/10W

R4 1-216-105-00 RES, CHIP 220K 5% 1/10W

R5 1-216-041-00 METAL CHIP 470 5% 1/10W

R6 1-216-081-00 METAL CHIP 22K 5% 1/10W

R7 1-216-073-00 METAL CHIP 10K 5% 1/10W

R9 1-216-073-00 METAL CHIP 10K 5% 1/10W

R20 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R21 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R22 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R31 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R32 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R33 1-216-073-00 METAL CHIP 10K 5% 1/10W

R34 1-216-206-00 RES, CHIP 2.2K 5% 1/8W

R35 1-216-073-00 METAL CHIP 10K 5% 1/10W

R36 1-216-073-00 METAL CHIP 10K 5% 1/10W

R37 1-216-073-00 METAL CHIP 10K 5% 1/10W

R38 1-216-214-00 RES, CHIP 4.7K 5% 1/8W

R51 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R52 1-216-049-11 RES, CHIP 1K 5% 1/10W

R54 1-216-073-00 METAL CHIP 10K 5% 1/10W

R121 1-216-089-00 RES, CHIP 47K 5% 1/10W

R122 1-216-089-00 RES, CHIP 47K 5% 1/10W

R123 1-216-109-00 METAL CHIP 330K 5% 1/10W

R124 1-216-077-00 METAL CHIP 15K 5% 1/10W

R125 1-216-079-00 METAL CHIP 18K 5% 1/10W

R126 1-216-079-00 METAL CHIP 18K 5% 1/10W

R127 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R128 1-216-073-00 METAL CHIP 10K 5% 1/10W

R151 1-216-063-00 RES, CHIP 3.9K 5% 1/10W

R171 1-216-033-00 METAL CHIP 220 5% 1/10W

R172 1-216-089-00 RES, CHIP 47K 5% 1/10W

R173 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R174 1-216-089-00 RES, CHIP 47K 5% 1/10W

R175 1-216-278-11 RES, CHIP 2.2M 5% 1/8W

R181 1-216-033-00 METAL CHIP 220 5% 1/10W

R182 1-216-089-00 RES, CHIP 47K 5% 1/10W

R183 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R184 1-216-089-00 RES, CHIP 47K 5% 1/10W

R185 1-216-278-11 RES, CHIP 2.2M 5% 1/8W

R221 1-216-089-00 RES, CHIP 47K 5% 1/10W

R222 1-216-089-00 RES, CHIP 47K 5% 1/10W

R223 1-216-109-00 METAL CHIP 330K 5% 1/10W

R224 1-216-077-00 METAL CHIP 15K 5% 1/10W

R225 1-216-079-00 METAL CHIP 18K 5% 1/10W

R227 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R228 1-216-073-00 METAL CHIP 10K 5% 1/10W

R251 1-216-063-00 RES, CHIP 3.9K 5% 1/10W

R271 1-216-033-00 METAL CHIP 220 5% 1/10W

– 50 –

Page 36

MAIN

Ref. No. Part No. Description Remark

R272 1-216-089-00 RES, CHIP 47K 5% 1/10W

R273 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R274 1-216-089-00 RES, CHIP 47K 5% 1/10W

R275 1-216-278-11 RES, CHIP 2.2M 5% 1/8W

R281 1-216-033-00 METAL CHIP 220 5% 1/10W

R282 1-216-089-00 RES, CHIP 47K 5% 1/10W

R283 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R284 1-216-089-00 RES, CHIP 47K 5% 1/10W

R285 1-216-278-11 RES, CHIP 2.2M 5% 1/8W

R321 1-216-063-00 RES, CHIP 3.9K 5% 1/10W

R322 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R323 1-216-113-00 METAL CHIP 470K 5% 1/10W

R324 1-216-001-00 METAL CHIP 10 5% 1/10W

R325 1-216-049-11 RES, CHIP 1K 5% 1/10W

R326 1-216-049-11 RES, CHIP 1K 5% 1/10W

R327 1-216-049-11 RES, CHIP 1K 5% 1/10W

R328 1-216-049-11 RES, CHIP 1K 5% 1/10W

R330 1-216-049-11 RES, CHIP 1K 5% 1/10W

R331 1-216-049-11 RES, CHIP 1K 5% 1/10W

R332 1-249-385-11 CARBON 2.2 5% 1/6W

R333 1-249-385-11 CARBON 2.2 5% 1/6W

R335 1-216-073-00 METAL CHIP 10K 5% 1/10W

R336 1-216-210-00 RES, CHIP 3.3K 5% 1/8W

R371 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R373 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R376 1-216-081-00 METAL CHIP 22K 5% 1/10W

R377 1-216-105-00 RES, CHIP 220K 5% 1/10W

R378 1-216-073-00 METAL CHIP 10K 5% 1/10W

R401 1-216-172-00 METAL CHIP 82 5% 1/8W

R402 1-216-238-00 RES, CHIP 47K 5% 1/8W

R403 1-216-085-00 METAL CHIP 33K 5% 1/10W

R404 1-216-099-00 METAL CHIP 120K 5% 1/10W

R405 1-216-098-00 METAL CHIP 110K 5% 1/10W

R406 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R407 1-216-073-00 METAL CHIP 10K 5% 1/10W

R408 1-216-073-00 METAL CHIP 10K 5% 1/10W

R409 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R410 1-216-076-00 METAL CHIP 13K 5% 1/10W

R411 1-216-049-11 RES, CHIP 1K 5% 1/10W

R412 1-216-073-00 METAL CHIP 10K 5% 1/10W

R413 1-216-073-00 METAL CHIP 10K 5% 1/10W

R414 1-216-073-00 METAL CHIP 10K 5% 1/10W

R421 1-216-073-00 METAL CHIP 10K 5% 1/10W

R422 1-216-093-00 METAL CHIP 68K 5% 1/10W

R423 1-216-041-00 METAL CHIP 470 5% 1/10W

R424 1-216-117-00 METAL CHIP 680K 5% 1/10W

R425 1-216-041-00 METAL CHIP 470 5% 1/10W

R426 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R427 1-216-097-00 RES, CHIP 100K 5% 1/10W

R428 1-216-097-00 RES, CHIP 100K 5% 1/10W

R429 1-216-073-00 METAL CHIP 10K 5% 1/10W

R430 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R432 1-216-075-00 METAL CHIP 12K 5% 1/10W

R433 1-216-077-00 METAL CHIP 15K 5% 1/10W

R434 1-216-097-00 RES, CHIP 100K 5% 1/10W

R435 1-216-097-00 RES, CHIP 100K 5% 1/10W

R436 1-216-073-00 METAL CHIP 10K 5% 1/10W

R437 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

Ref. No. Part No. Description Remark

R438 1-216-073-00 METAL CHIP 10K 5% 1/10W

R439 1-216-075-00 METAL CHIP 12K 5% 1/10W

R440 1-216-077-00 METAL CHIP 15K 5% 1/10W

R441 1-216-049-11 RES, CHIP 1K 5% 1/10W

R442 1-216-075-00 METAL CHIP 12K 5% 1/10W

R451 1-216-073-00 METAL CHIP 10K 5% 1/10W

R452 1-216-073-00 METAL CHIP 10K 5% 1/10W

R453 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R454 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R551 1-208-806-11 RES, CHIP 10K 0.5% 1/10W

R552 1-208-806-11 RES, CHIP 10K 0.5% 1/10W

R553 1-216-097-00 RES, CHIP 100K 5% 1/10W

R554 1-216-113-00 METAL CHIP 470K 5% 1/10W

R555 1-216-174-00 RES, CHIP 100 5% 1/8W

R556 1-216-049-11 RES, CHIP 1K 5% 1/10W

R571 1-249-401-11 CARBON 47 5% 1/4W

R572 1-216-073-00 METAL CHIP 10K 5% 1/10W

R601 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R602 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R603 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R604 1-216-689-11 METAL CHIP 39K 0.5% 1/10W

R605 1-216-089-00 RES, CHIP 47K 5% 1/10W

R606 1-216-073-00 METAL CHIP 10K 5% 1/10W

R607 1-216-025-00 RES, CHIP 100 5% 1/10W

R608 1-216-025-00 RES, CHIP 100 5% 1/10W

R609 1-208-806-11 RES, CHIP 10K 0.5% 1/10W

R623 1-216-298-00 METAL CHIP 2.2 5% 1/10W

R624 1-216-298-00 METAL CHIP 2.2 5% 1/10W

R625 1-216-041-00 METAL CHIP 470 5% 1/10W

R626 1-216-041-00 METAL CHIP 470 5% 1/10W

R665 1-216-025-00 RES, CHIP 100 5% 1/10W

R666 1-216-025-00 RES, CHIP 100 5% 1/10W

R675 1-216-025-00 RES, CHIP 100 5% 1/10W

R701 1-216-097-00 RES, CHIP 100K 5% 1/10W

R702 1-216-097-00 RES, CHIP 100K 5% 1/10W

R703 1-216-097-00 RES, CHIP 100K 5% 1/10W

R704 1-216-097-00 RES, CHIP 100K 5% 1/10W

R705 1-216-097-00 RES, CHIP 100K 5% 1/10W

R706 1-216-081-00 METAL CHIP 22K 5% 1/10W

R707 1-216-081-00 METAL CHIP 22K 5% 1/10W

R708 1-216-081-00 METAL CHIP 22K 5% 1/10W

R710 1-216-097-00 RES, CHIP 100K 5% 1/10W

R711 1-216-097-00 RES, CHIP 100K 5% 1/10W

R712 1-216-097-00 RES, CHIP 100K 5% 1/10W

R713 1-216-097-00 RES, CHIP 100K 5% 1/10W

R715 1-216-097-00 RES, CHIP 100K 5% 1/10W

R717 1-216-097-00 RES, CHIP 100K 5% 1/10W

R718 1-216-097-00 RES, CHIP 100K 5% 1/10W

R719 1-216-097-00 RES, CHIP 100K 5% 1/10W

R720 1-216-041-00 METAL CHIP 470 5% 1/10W

R721 1-216-093-00 METAL CHIP 68K 5% 1/10W

R722 1-216-222-00 RES, CHIP 10K 5% 1/8W

R723 1-216-049-11 RES, CHIP 1K 5% 1/10W

R724 1-216-041-00 METAL CHIP 470 5% 1/10W

R725 1-216-041-00 METAL CHIP 470 5% 1/10W

R726 1-216-041-00 METAL CHIP 470 5% 1/10W

R727 1-216-049-11 RES, CHIP 1K 5% 1/10W

– 51 –

Page 37

MAIN PO WER

Ref. No. Part No. Description Remark

R728 1-216-049-11 RES, CHIP 1K 5% 1/10W

R729 1-216-049-11 RES, CHIP 1K 5% 1/10W

R730 1-216-049-11 RES, CHIP 1K 5% 1/10W

R732 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R733 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R734 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R735 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R736 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R737 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R738 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R739 1-216-049-11 RES, CHIP 1K 5% 1/10W

R740 1-216-049-11 RES, CHIP 1K 5% 1/10W

R741 1-216-049-11 RES, CHIP 1K 5% 1/10W

R742 1-216-049-11 RES, CHIP 1K 5% 1/10W

R745 1-216-049-11 RES, CHIP 1K 5% 1/10W

R746 1-216-049-11 RES, CHIP 1K 5% 1/10W

R747 1-216-049-11 RES, CHIP 1K 5% 1/10W

R748 1-216-113-00 METAL CHIP 470K 5% 1/10W

R749 1-216-049-11 RES, CHIP 1K 5% 1/10W

R750 1-216-073-00 METAL CHIP 10K 5% 1/10W

R752 1-216-097-00 RES, CHIP 100K 5% 1/10W

R753 1-216-097-00 RES, CHIP 100K 5% 1/10W

R754 1-216-049-11 RES, CHIP 1K 5% 1/10W

R755 1-216-097-00 RES, CHIP 100K 5% 1/10W

R756 1-216-049-11 RES, CHIP 1K 5% 1/10W

R757 1-216-049-11 RES, CHIP 1K 5% 1/10W

R758 1-216-049-11 RES, CHIP 1K 5% 1/10W

< VARIABLE RESISTOR >

Ref. No. Part No. Description Remark

C456 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C465 1-126-301-11 ELECT 1uF 20% 50V

C466 1-124-589-11 ELECT 47uF 20% 16V

C471 1-113-501-11 ELECT 4700uF 20% 16V

C473 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C475 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C476 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C478 1-126-157-11 ELECT 10uF 20% 16V

C479 1-126-301-11 ELECT 1uF 20% 50V

C572 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C602 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C603 1-164-232-11 CERAMIC CHIP 0.01uF 50V

< CONNECTOR >

CN3 1-779-534-11 PIN, CONNECTOR (PC BOARD)

CNP400 1-770-407-11 CONNECTOR, BOARD TO BOARD 12P

CNP401 1-770-411-11 CONNECTOR, BOARD TO BOARD 20P

< DIODE >

D176 8-719-200-82 DIODE 11ES2

D177 8-719-200-82 DIODE 11ES2

D186 8-719-200-82 DIODE 11ES2

D187 8-719-200-82 DIODE 11ES2

D276 8-719-200-82 DIODE 11ES2

D277 8-719-200-82 DIODE 11ES2

D286 8-719-200-82 DIODE 11ES2

D287 8-719-200-82 DIODE 11ES2

D471 8-719-049-38 DIODE 1N5404TU

D472 8-719-109-93 DIODE RD6.2ESB2

RV121 1-223-829-11 RES, ADJ, CARBON 1.0K

RV221 1-223-829-11 RES, ADJ, CARBON 1.0K

RV401 1-238-601-11 RES, ADJ, CARBON 22.0K

RV402 1-223-831-11 RES, ADJ, CARBON 4.7K

< TUNER UNIT >

TU1 A-3282-031-A FM/AM TUNER UNIT TUX-006/2 (EE)

< VIBRATOR >

X11 1-577-126-51 VIBRATOR, CRYSTAL (7.2MHz)

X701 1-579-233-11 VIBRATOR, CERAMIC (5MHz)

************************************************************

* A-3313-523-A POWER BOARD, COMPLETE

***********************

* 3-012-568-01 BRACKET (CONNECTOR)

3-012-593-01 BRACKET

* 3-022-201-01 HEAT SINK

* 3-022-214-01 BRACKET (IC)

7-682-548-04 SCREW +P 3X8

7-685-792-09 SCREW +PTT 2.6X6 (S)

7-685-794-09 SCREW +PTT 2.6X10 (S)

< CAPACITOR >

D473 8-719-923-92 DIODE MTZJ-T-77-16B

D573 8-719-109-93 DIODE RD6.2ESB2

D574 8-719-109-93 DIODE RD6.2ESB2

D608 8-719-109-93 DIODE RD6.2ESB2

D609 8-719-109-93 DIODE RD6.2ESB2

< IC >

IC471 8-759-490-74 IC TDA7384

< COIL >

L471 1-411-670-23 COIL, CHOKE 400uH

< RESISTOR >

R471 1-216-073-00 METAL CHIP 10K 5% 1/10W

R472 1-216-222-00 RES, CHIP 10K 5% 1/8W

R475 1-216-073-00 METAL CHIP 10K 5% 1/10W

R478 1-216-073-00 METAL CHIP 10K 5% 1/10W

R479 1-216-049-11 RES, CHIP 1K 5% 1/10W

R573 1-216-025-00 RES, CHIP 100 5% 1/10W

R574 1-216-025-00 RES, CHIP 100 5% 1/10W

************************************************************

MISCELLANEOUS

**************

C451 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C452 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C453 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C454 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C455 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

16 1-782-345-11 CORD (WITH CONNECTOR) (POWER)

F901 1-532-677-00 FUSE, GLASS TUBE (10 A)

HP901 1-500-157-21 HEAD, MAGNETIC (PLAYBACK)

M901 A-3291-665-A MOTOR ASSY, MAIN (CAPSTAN/REEL)

************************************************************

– 52 –

Page 38

Ref. No. Part No. Description Remark

**************

HARDWARE LIST

**************

#1 7-685-792-09 SCREW +PTT 2.6X6 (S)

#2 7-685-793-09 SCREW +PTT 2.6X8 (S)

#3 7-685-105-19 TPG +P 2X8, TYPE 2, NON-SLIT

#4 7-682-548-04 SCREW +P 3X8

#5 7-685-794-09 SCREW +PTT 2.6X10 (S)

#6 7-624-104-04 STOP RING 2.0, TYPE -E

#7 7-627-553-17 PRECISION SCREW +P 2X2 TYPE 3

************************************************************

ACCESSORIES & PACKING MATERIALS

*******************************

1-473-067-71 REMOTE COMMANDER (RM-X4S)

3-861-993-11 MANUAL, INSTRUCTION

3-861-994-11 MANUAL, INSTRUCTION, INSTALL

3-921-278-01 LABEL (DSPL) (for RM-X4S)

************************************************************

PARTS FOR INSTALLATION AND CONNECTIONS

**************************************

(HUNGARIAN, RUSSIAN)

(HUNGARIAN, RUSSIAN)

501 3-012-593-01 BRACKET

502 X-3366-405-1 SCREW ASSY (EXP), FITTING

503 1-775-543-11 CORD, GROUND

504 X-3373-432-1 BRACKET ASSY (for RM-X4S)

501

502

504

503

– 53 –

Page 39

XR-C6093SP

Sony Corporation

Personal & Mobile Communication Company9-925-679-11

– 54 –

Published by Quality Assurance Dept.

Printed in Japan © 1998. 1

98A05076-1

Loading...

Loading...