Sony XR C 5600 Service Manual

XR-C5300X/C5305/C5600X

SERVICE MANUAL

Photo: XR-C5300X

SPECIFICATIONS

US Model

Canadian Model

XR-C5300X/C5305

E Model

XR-C5600X

Model Name Using Similar Mechanism XR-C5100

T ape Transport Mechanism Type MG-25F-136

MICROFILM

FM/AM CASSETTE CAR STEREO

XR-C5300X/C5305

FM/MW/SW CASSETTE CAR STEREO

XR-C5600X

TABLE OF CONTENTS

1. SERVICE NOTE

............................................................. 2

2. GENERAL ........................................................................ 3

3. DISASSEMBLY .............................................................. 13

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

4. ASSEMBLY OF MECHANISM DECK................ 14

5. MECHANICAL ADJUSTMENTS ............................ 17

6. ELECTRICAL ADJUSTMENTS

6-1. Test Mode........................................................................ 17

• Tape Deck Section ........................................................ 17

• Tuner Section................................................................ 17

7. DIAGRAMS

7-1. Block Diagrams

• TUNER/TAPE/MAIN Section ..................................... 18

• DISPLAY/KEY CONTROL/BUS CONTROL/

POWER SUPPLY Section ........................................... 19

7-2. Printed Wiring Board – MAIN Board – ......................... 21

7-3. Schematic Diagram – MAIN Board (1/2) – ................... 22

7-4. Schematic Diagram – MAIN Board (2/2) – ................... 23

7-5. Printed Wiring Boards – KEY/SUB Boards – .............. 24

7-6. Schematic Diagrams – KEY/SUB Boards – .................. 25

7-7. IC Block Diagrams ......................................................... 26

7-8. IC Pin Function ............................................................... 27

8. EXPLODED VIEWS................................................ 32

9. ELECTRICAL PARTS LIST ............................... 35

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

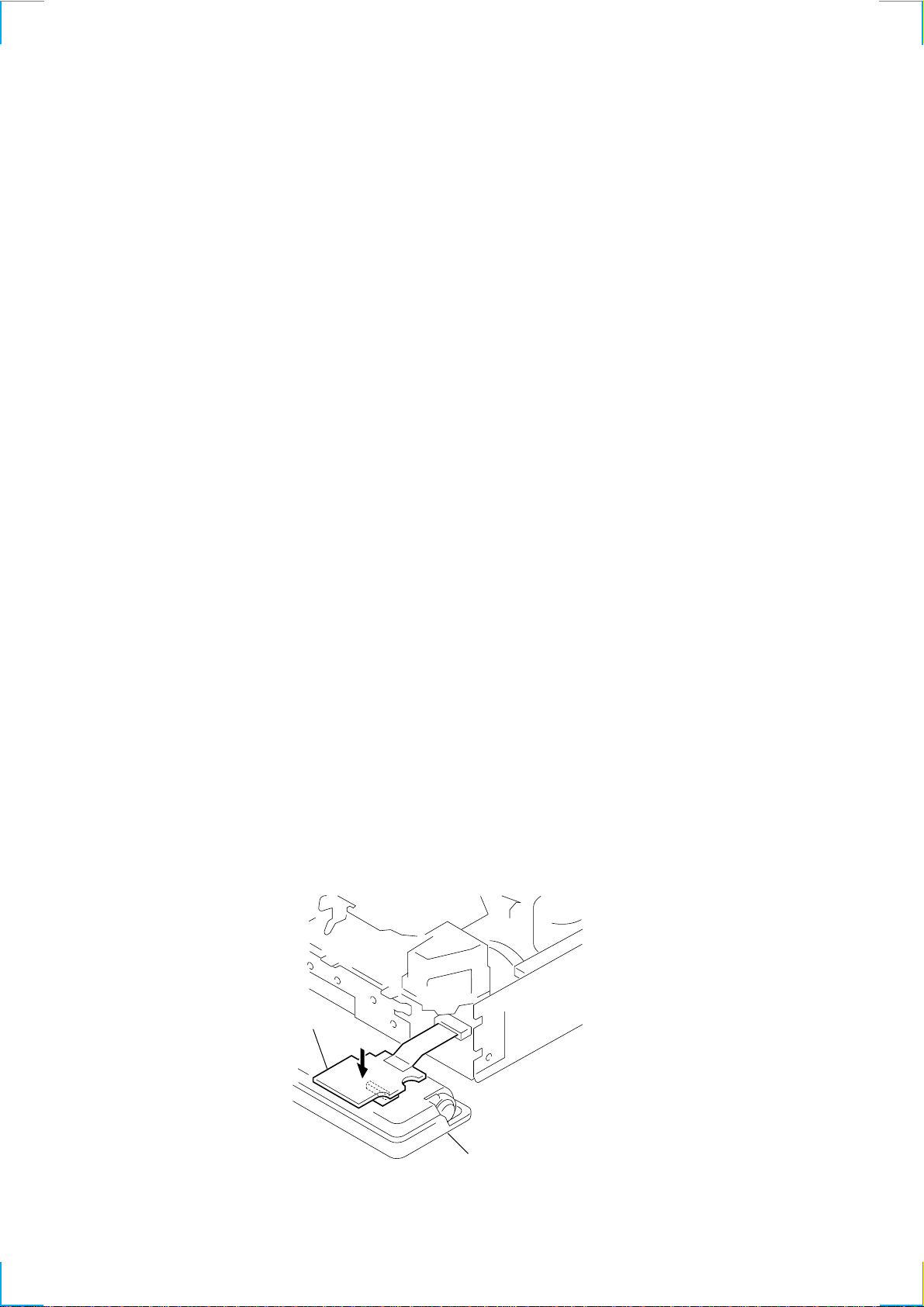

SERVICE NOTE

Please press on the sub board from above when checking it.

This assures that the connector does not lose contact.

SUB board

SECTION 1

Front panel assembly

2

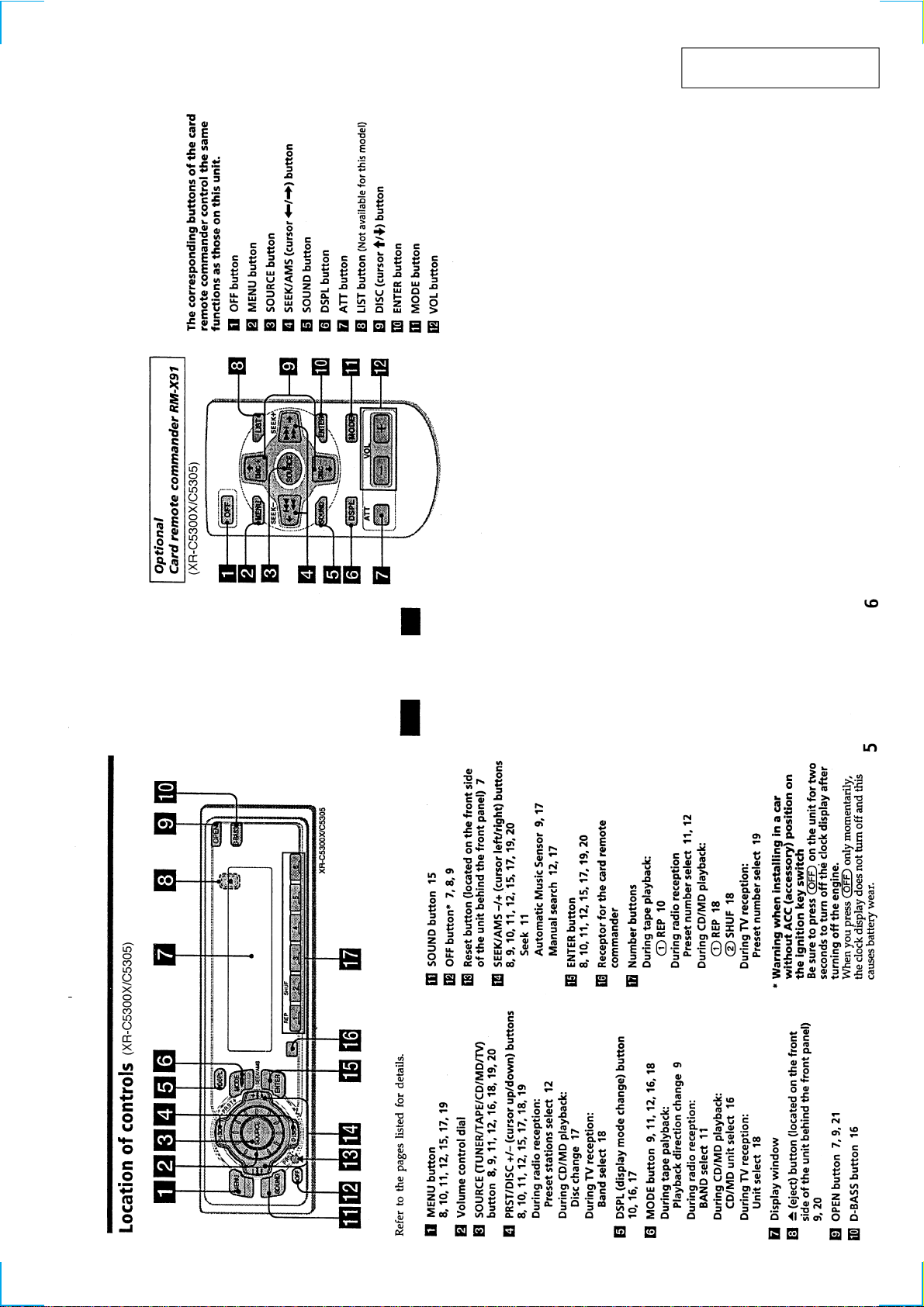

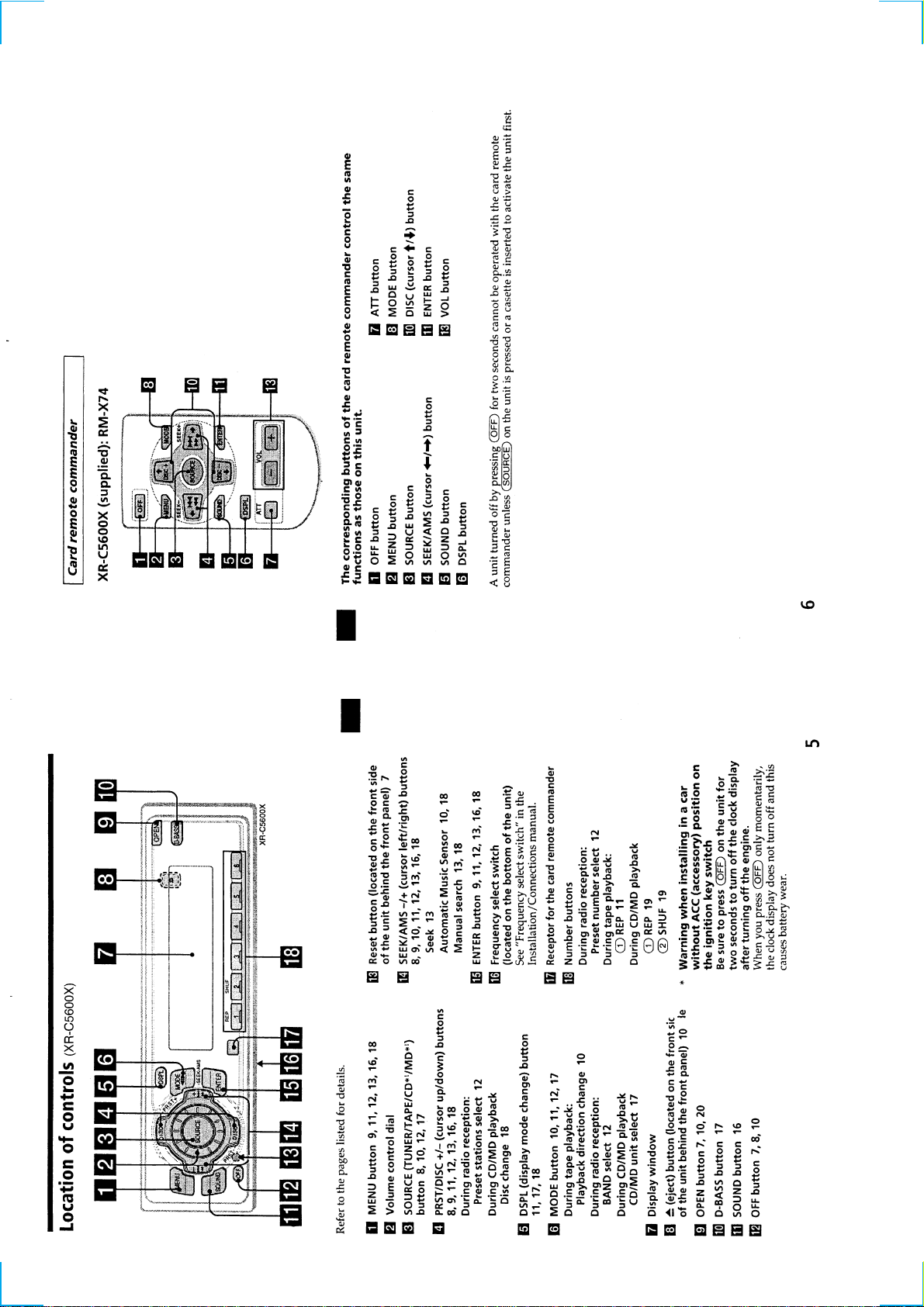

SECTION 2

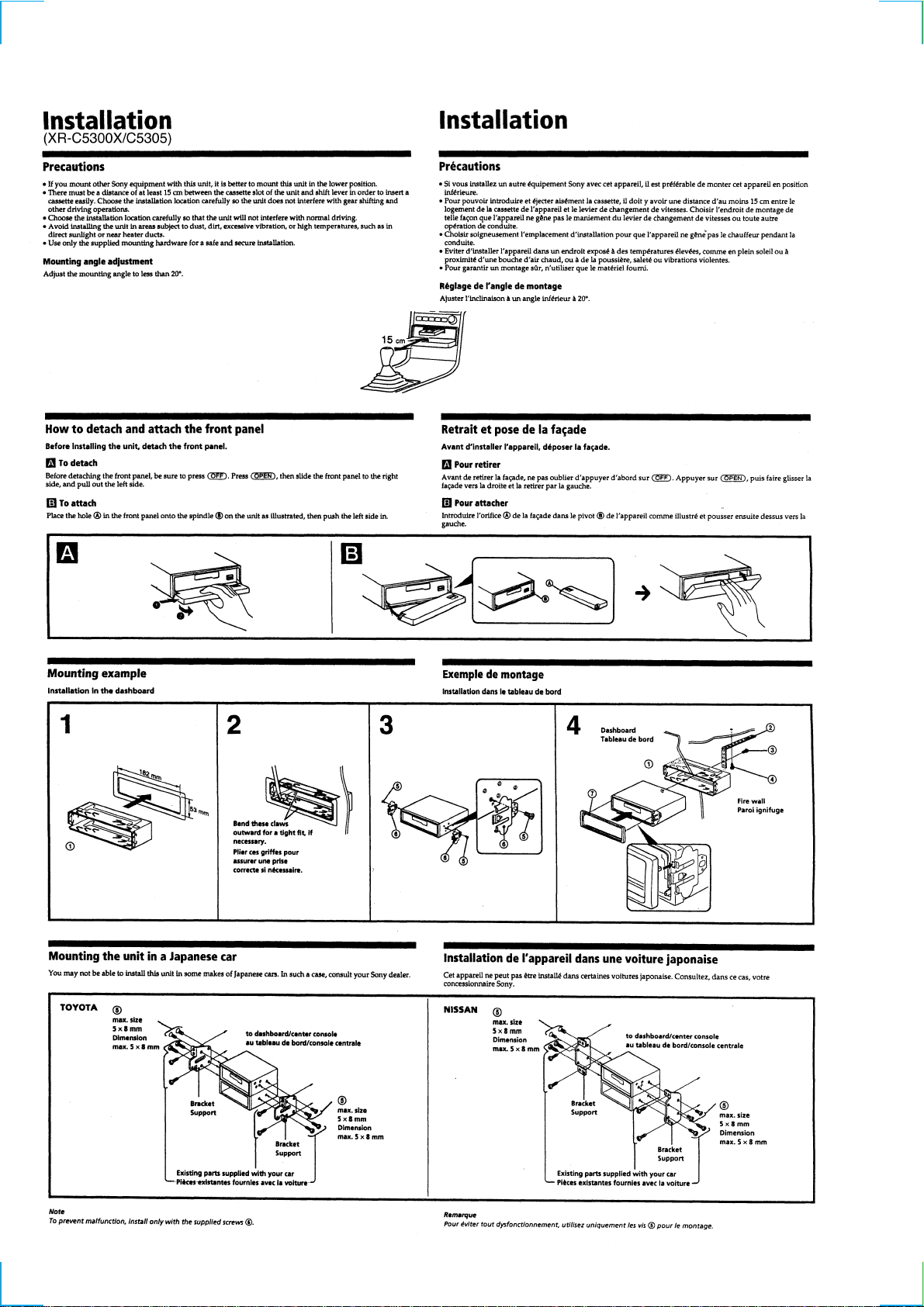

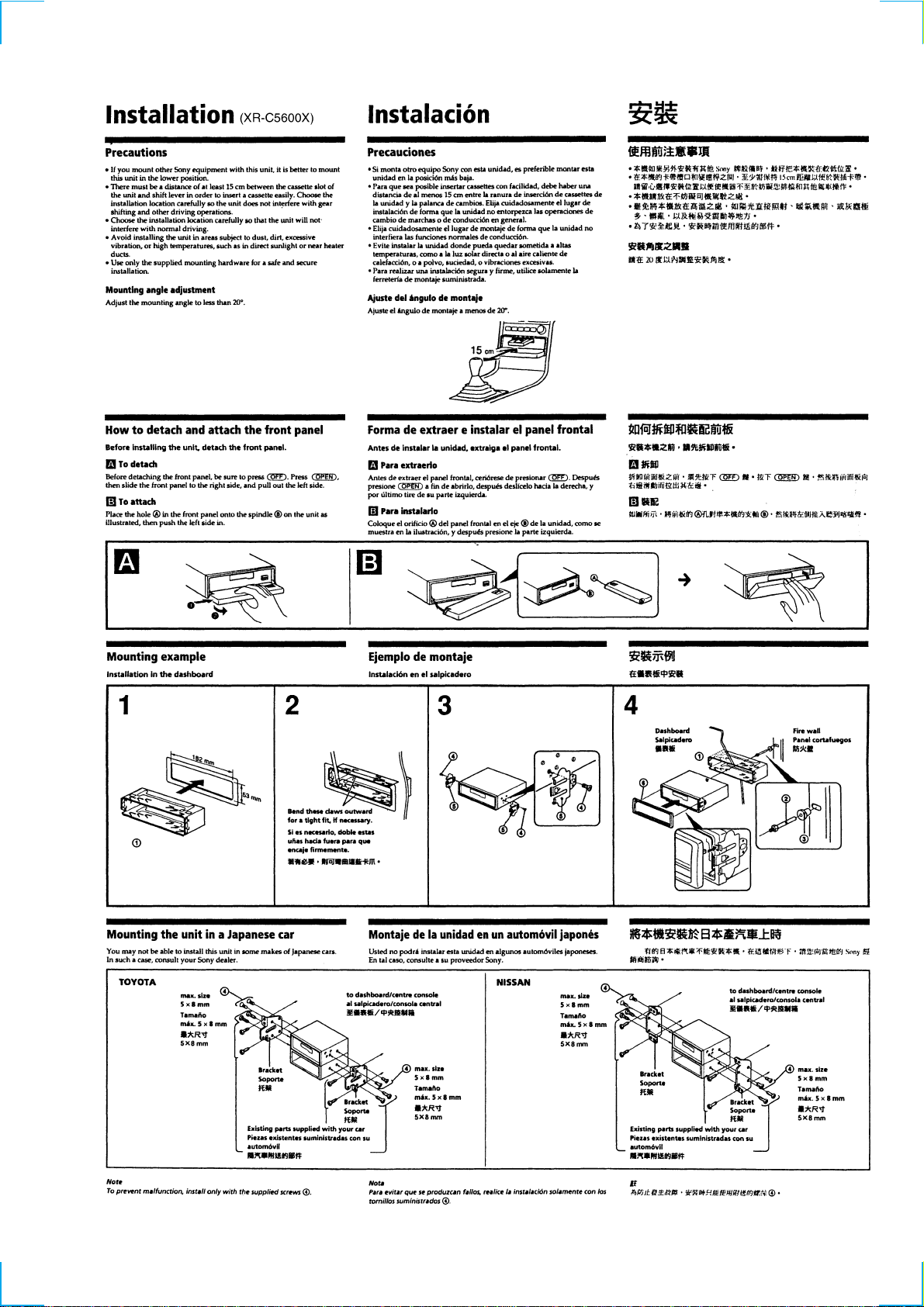

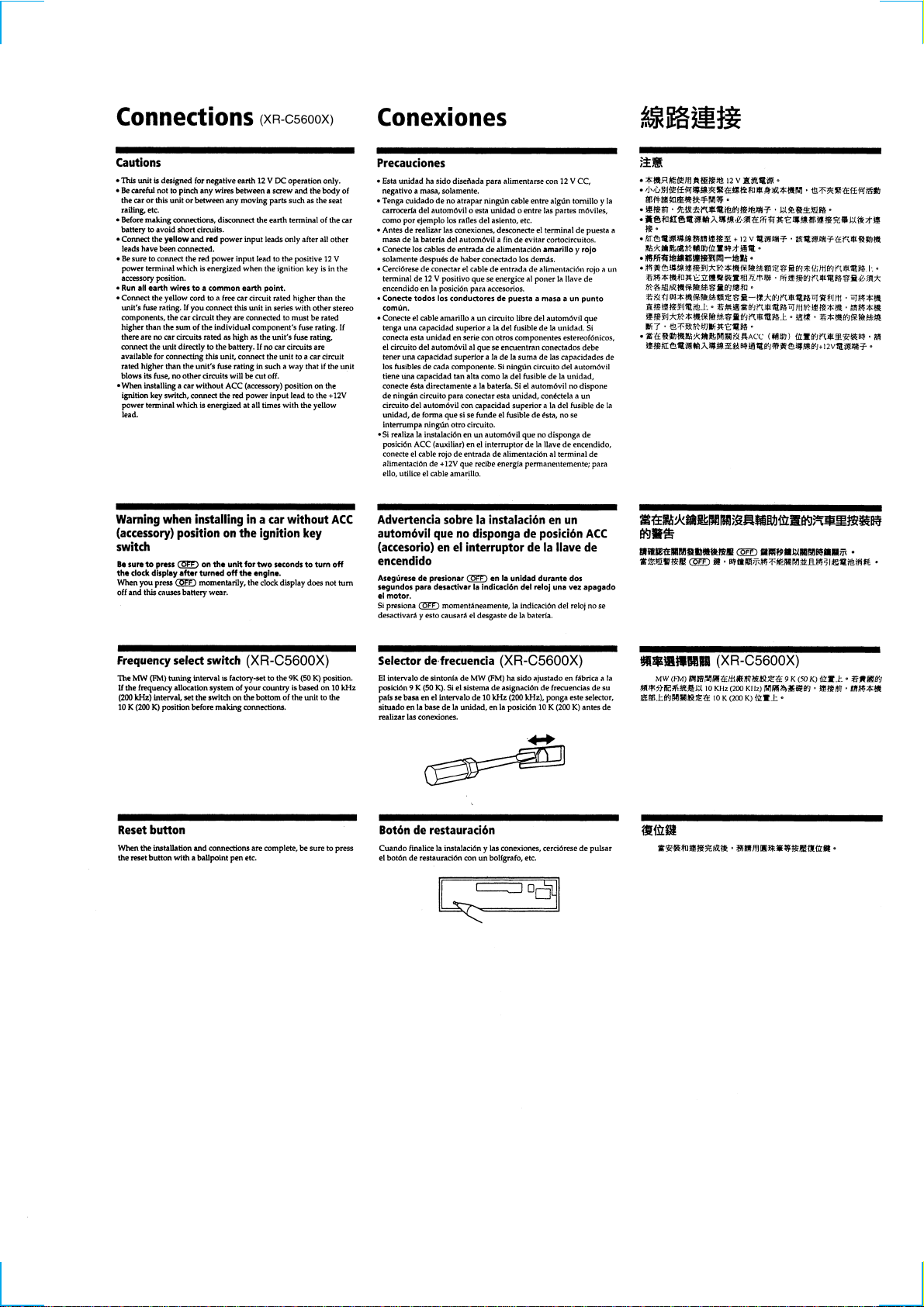

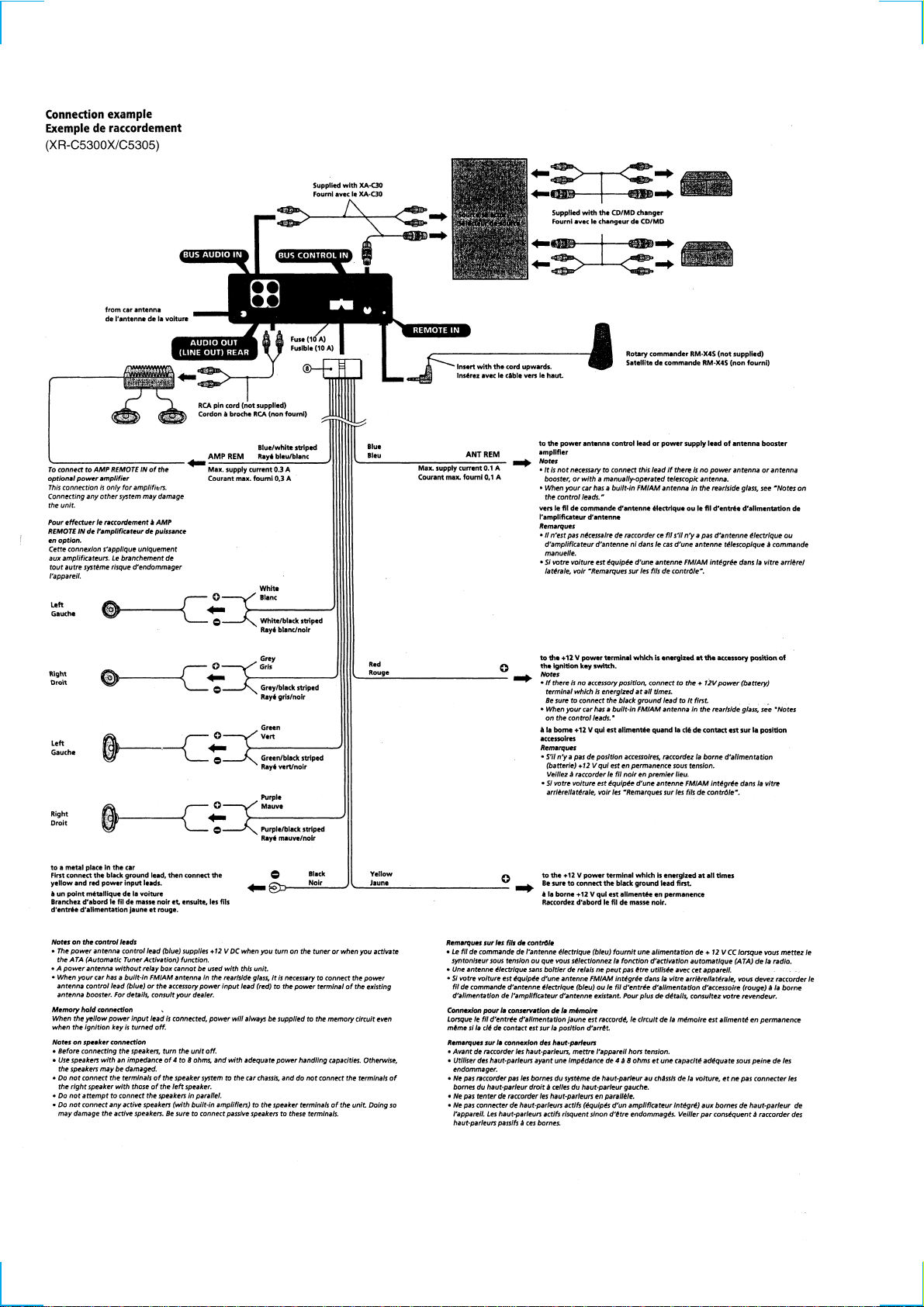

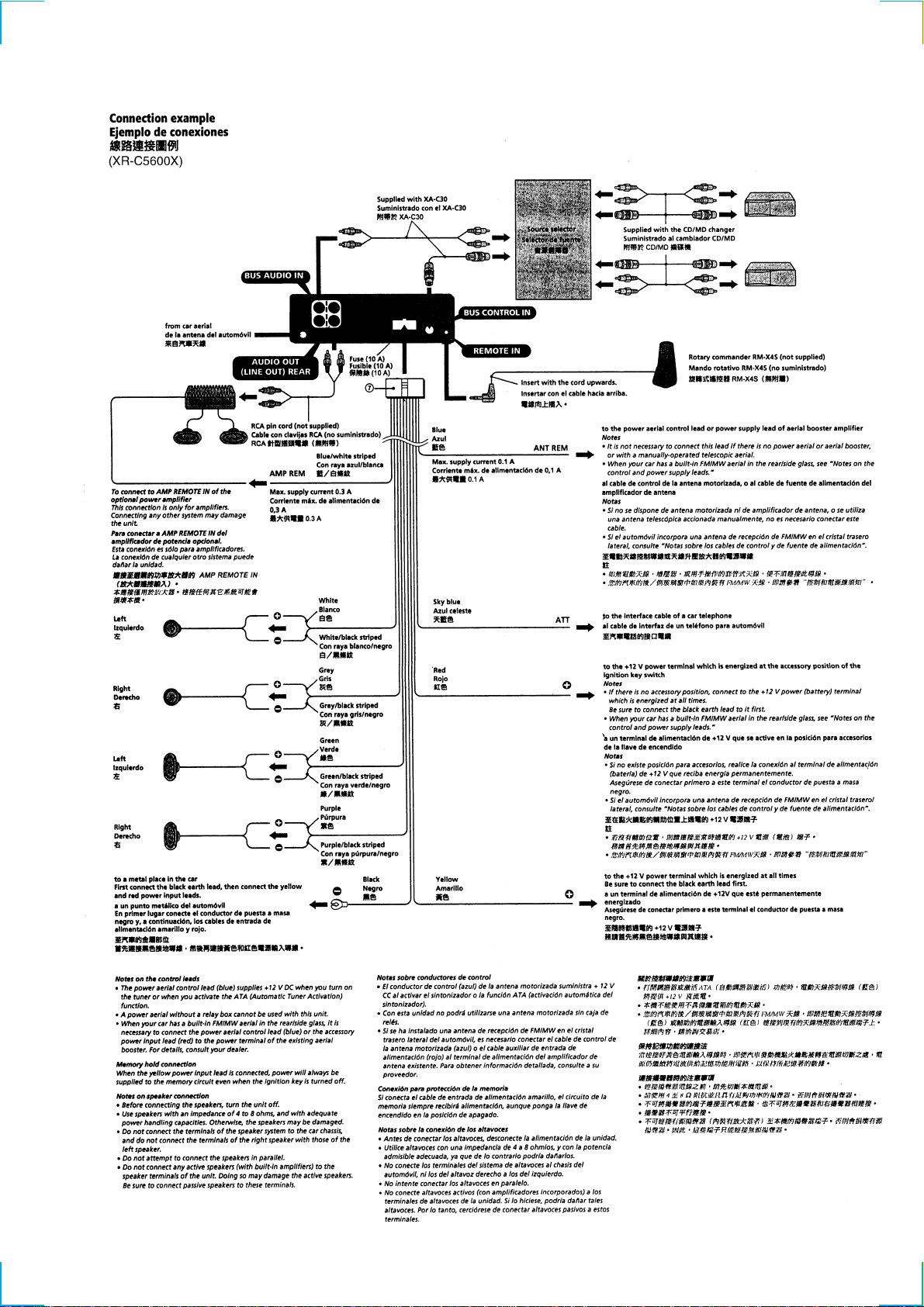

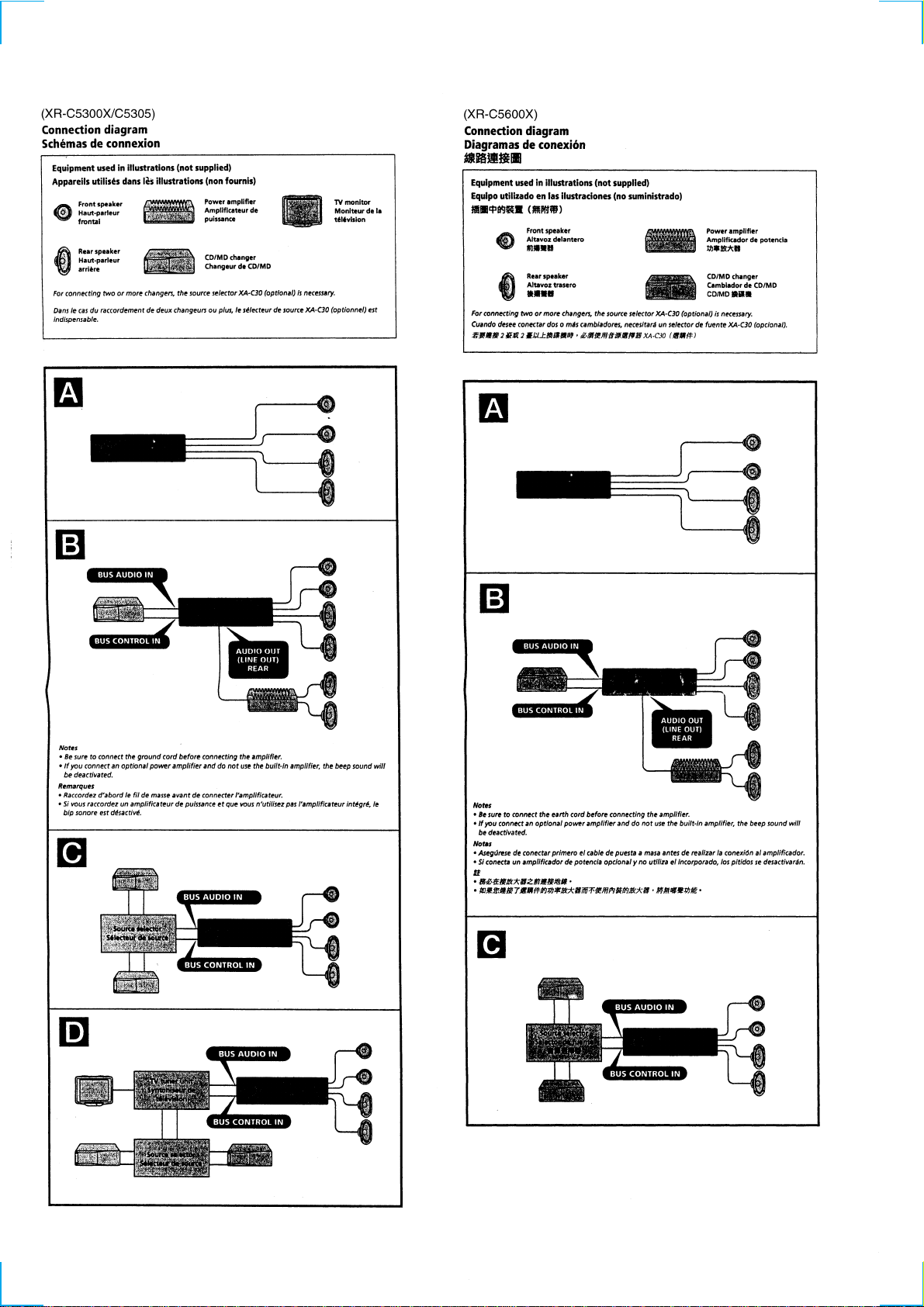

GENERAL

This section is extracted from

instruction manual.

3

4

567891011

12

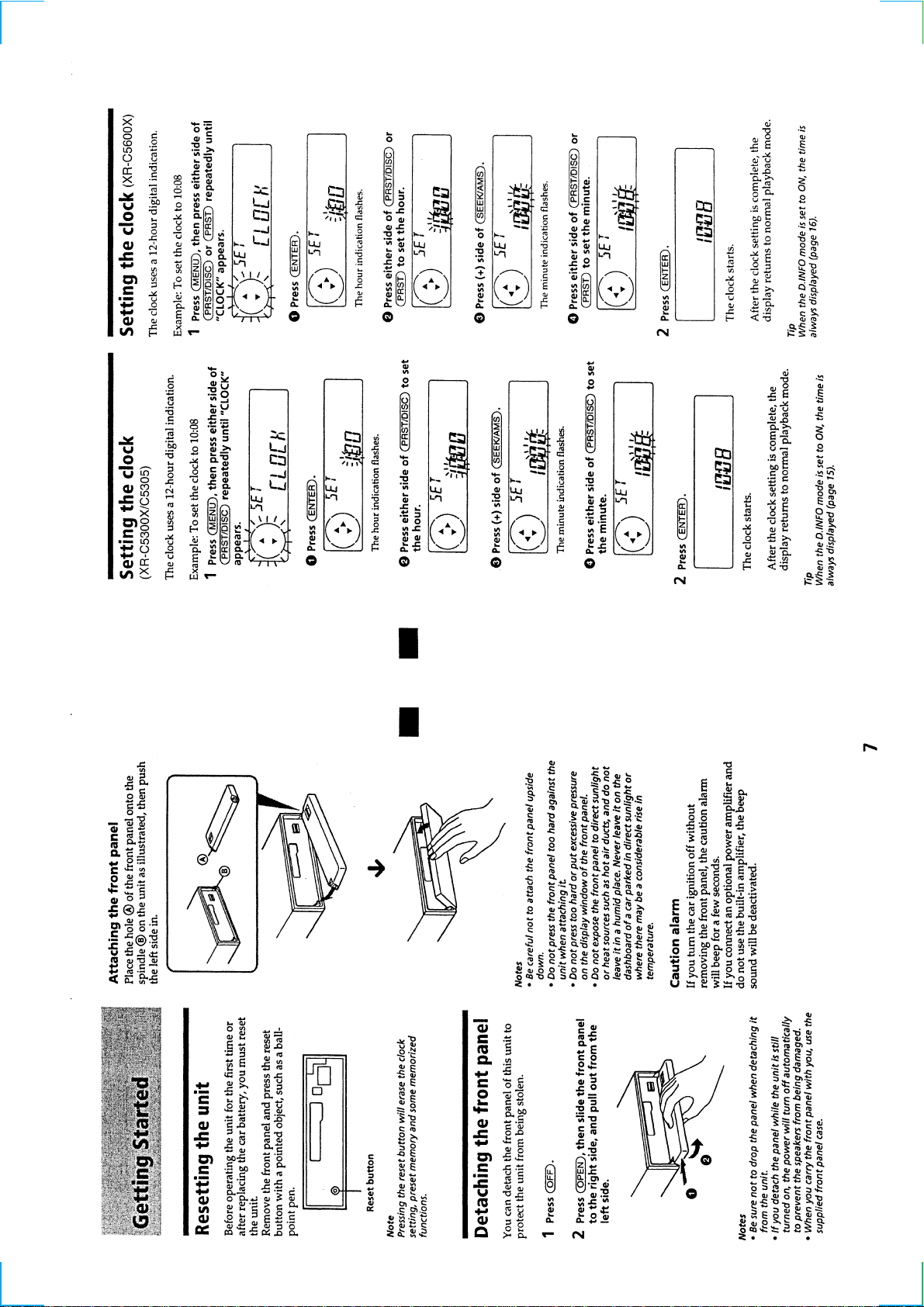

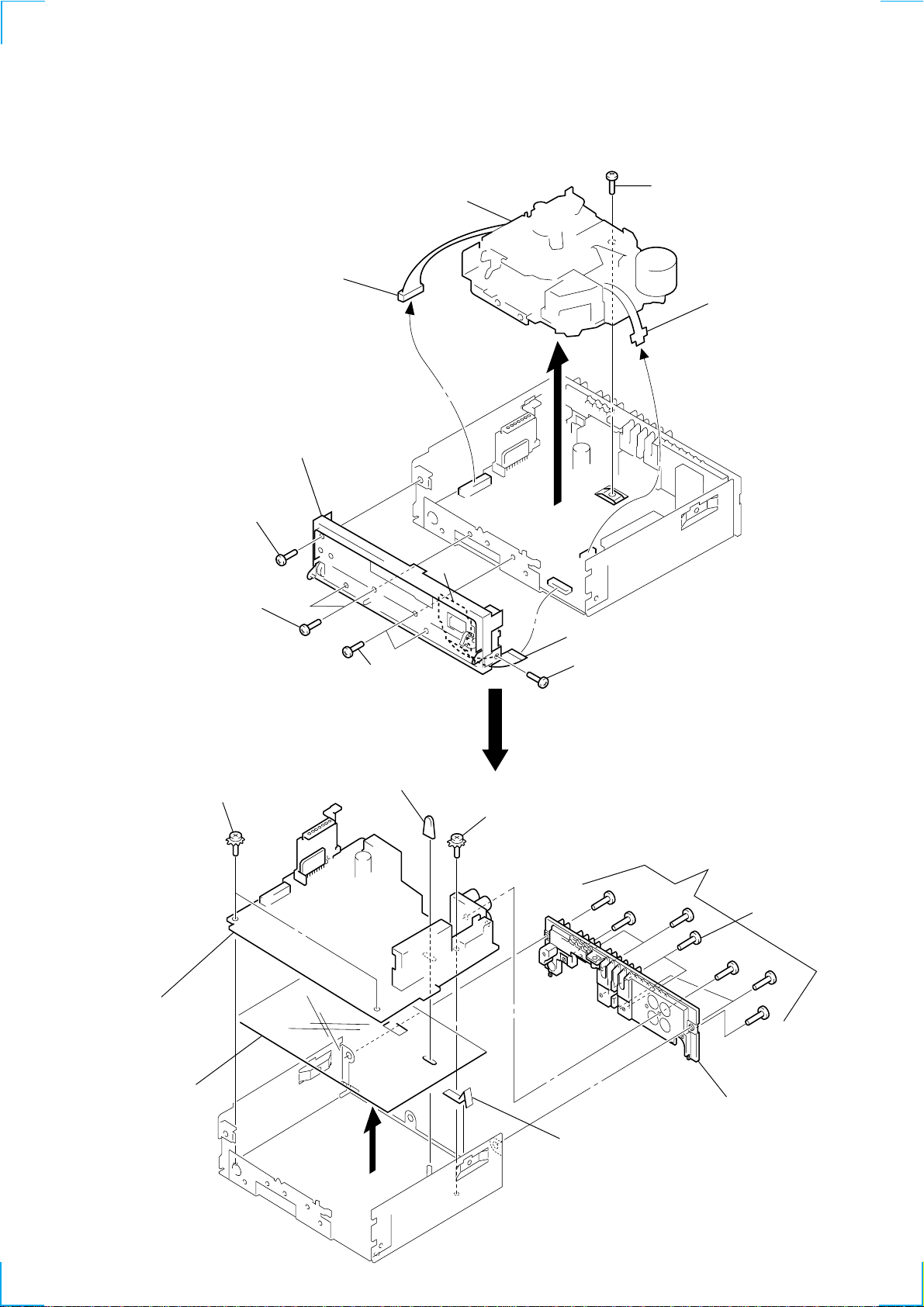

SECTION 3

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

SUB PANEL, MECHANISM DECK (MG-25F-136)

0 Mechanism deck

(MG-25F-136)

8 Connector(CN351)

5 Sub panel ass'y

3 Screw

(PTT2.6 × 6)

9 Screw

(PTT2.6 × 6)

7 Flexible flat cable

(CNP301)

2 T wo screws

(PTT2.6 × 6)

MAIN BOARD, HEAT SINK

7 Two ground screws

8 Main board

Sub board

1 T wo screws

(PTT2.6 × 6)

5 Rubber cap(25)

6 Flat cable (WR801)

4 Screw (PTT2.6 × 6)

6 Ground screw

1 Eight screws

(PTT2.6 × 8)

2 T wo screws

(PTT2.6 × 12)

9 Insulated

plate

3 Heat sink

4 Ground plate(TU)

13

Loading...

Loading...