Sony XRC-543-SP Service manual

XR-C543SP

SERVICE MANUAL

Refer to RM-X2S/X3S SERVICE MANU AL (9-960-039-∏)

issued previously for information of remote commander

(RM-X2S) supplied with this set.

East European Model

Dolby noise reduction manufactured under license

from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks

of Dolby Laboratories Licensing Corporation.

Cassette player section

Tape track 4-track 2-channel stereo

Wow and flutter 0.08% (WRMS)

Frequency response 30 – 20,000 Hz

Signal-to-noise ratio

Cassette type Dolby B NR Dolby NR off

TYPE II, IV 67 dB 61 dB

TYPE I 64 dB 58 dB

Tuner section

FM

*

Turning range 65.0 – 74.0 MHz

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz

Usable sensitivity 8 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 65 dB (stereo),

Harmonic distortion at 1 kHz

Separation 35 dB at 1 kHz

Frequency response 30 – 15,000 Hz

Capture ratio 2 dB

* There are the numerical values mesured at 87.5 – 108.0 MHz.

(at 30 kHz step)

87.5 – 108.0 MHz

(at 50 kHz step)

68 dB (mono)

0.5% (stereo),

0.3% (mono)

SPECIFICATIONS

Power amplifier section

Outputs Speaker outputs

Speaker impedance 4 – 8 ohms

Maximum power output 35 W × 4 (at 4 ohms)

General

Outputs Power amplifier control

Tone controls Bass ± 8 dB at 100 Hz

Power requirements 12 V DC car battery

Dimensions Approx. 188 × 58 × 183 mm (w/h/d)

Mounting dimensions Approx. 182 × 53 × 164 mm (w/h/d)

Mass Approx. 1.6 kg

Supplied accessories Parts for installation and connections (1 set)

Design and specifications are subject to change without notice.

Model Name Using Similar Mechanism XR-C553SP

T ape Transport Mechanism T ype

(sure seal connectors)

lead/Power aerial control

lead/Telephone mute

control lead

Line out (2)

Treble ± 8 dB at 10 kHz

(negative ground)

Rotary commander

RM-X2S

MG-52A-135

MW/LW

Tuning range MW: 531 – 1,602 kHz

LW: 153 – 281 kHz

Aerial terminal External aerial connector

Intermediate frequency 10.71 MHz/450 kHz

Sensitivity MW: 30 µV

LW: 50 µV

MICROFILM

FM/MW/LW CASSETTE CAR STEREO

TABLE OF CONTENTS

SERVICING NOTES

1. GENERAL

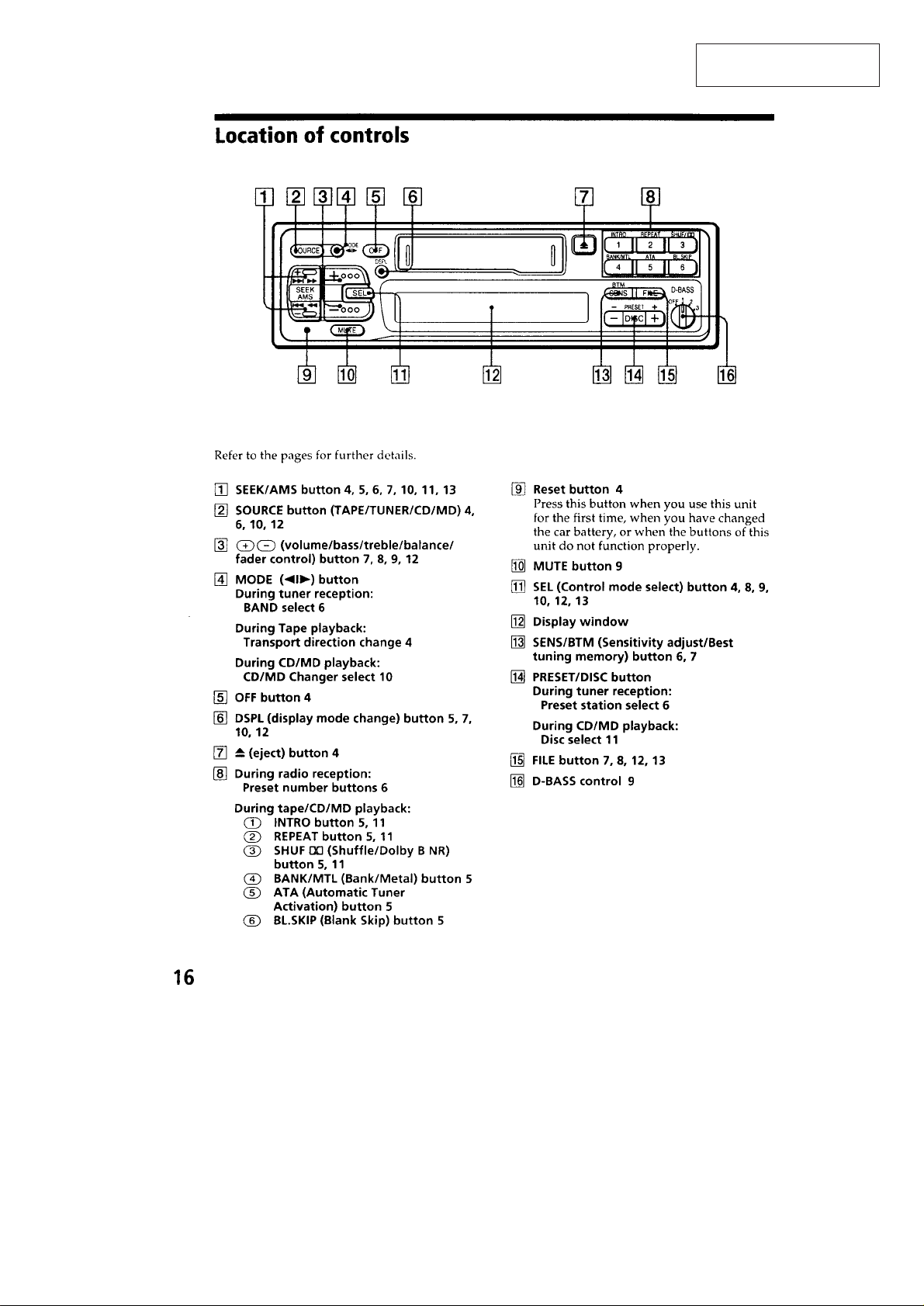

Location of Controls ........................................................ 3

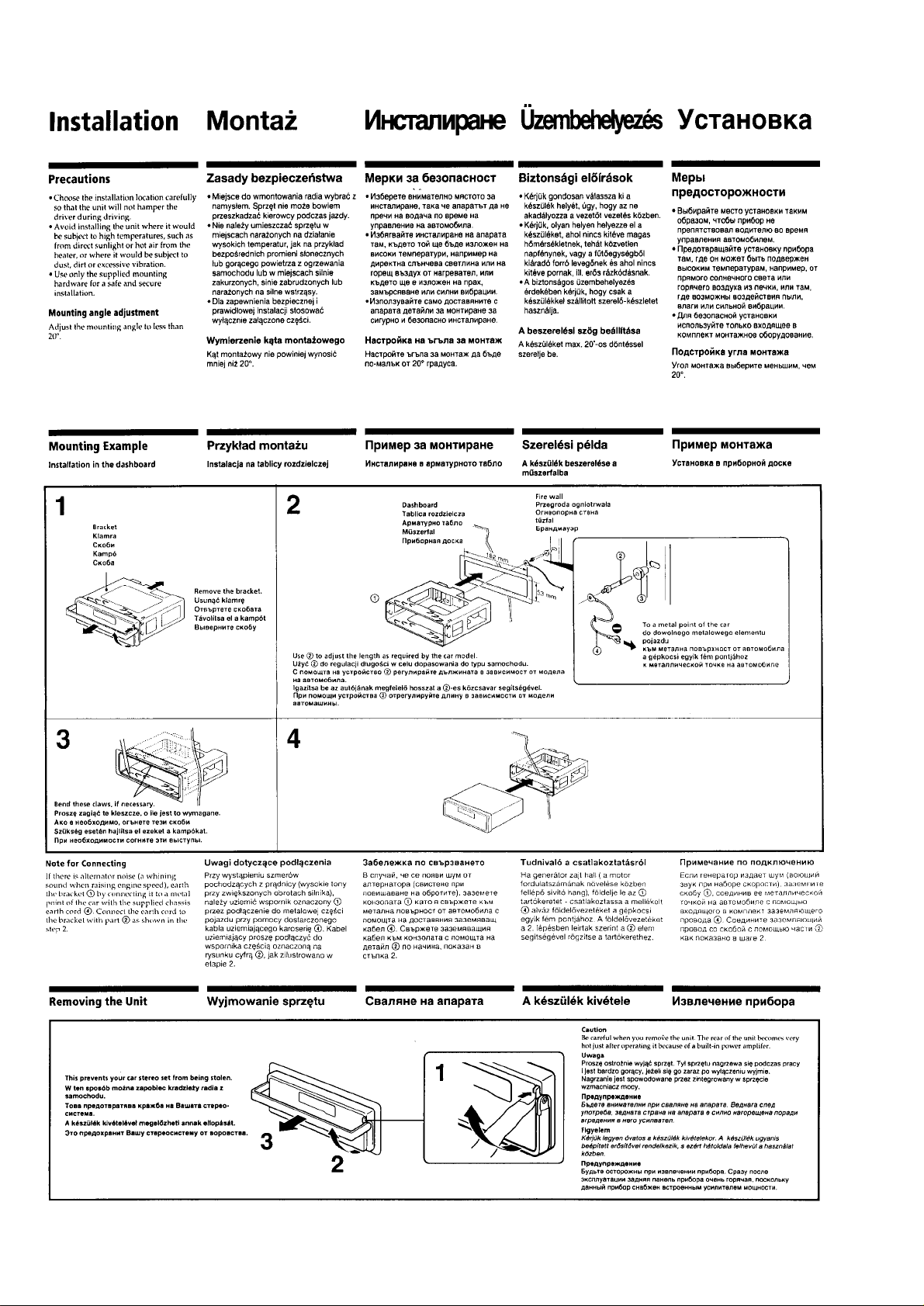

Installation ....................................................................... 4

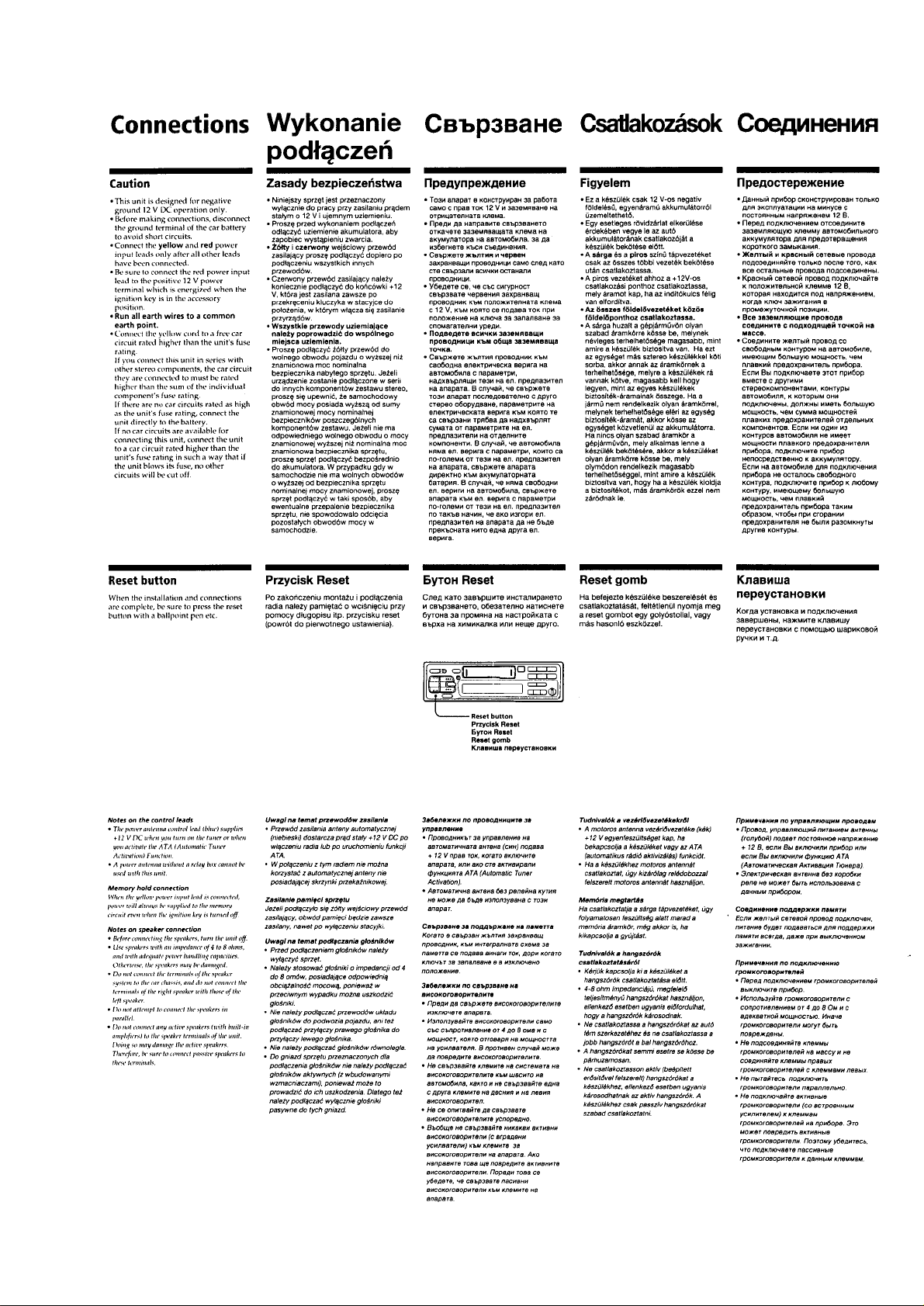

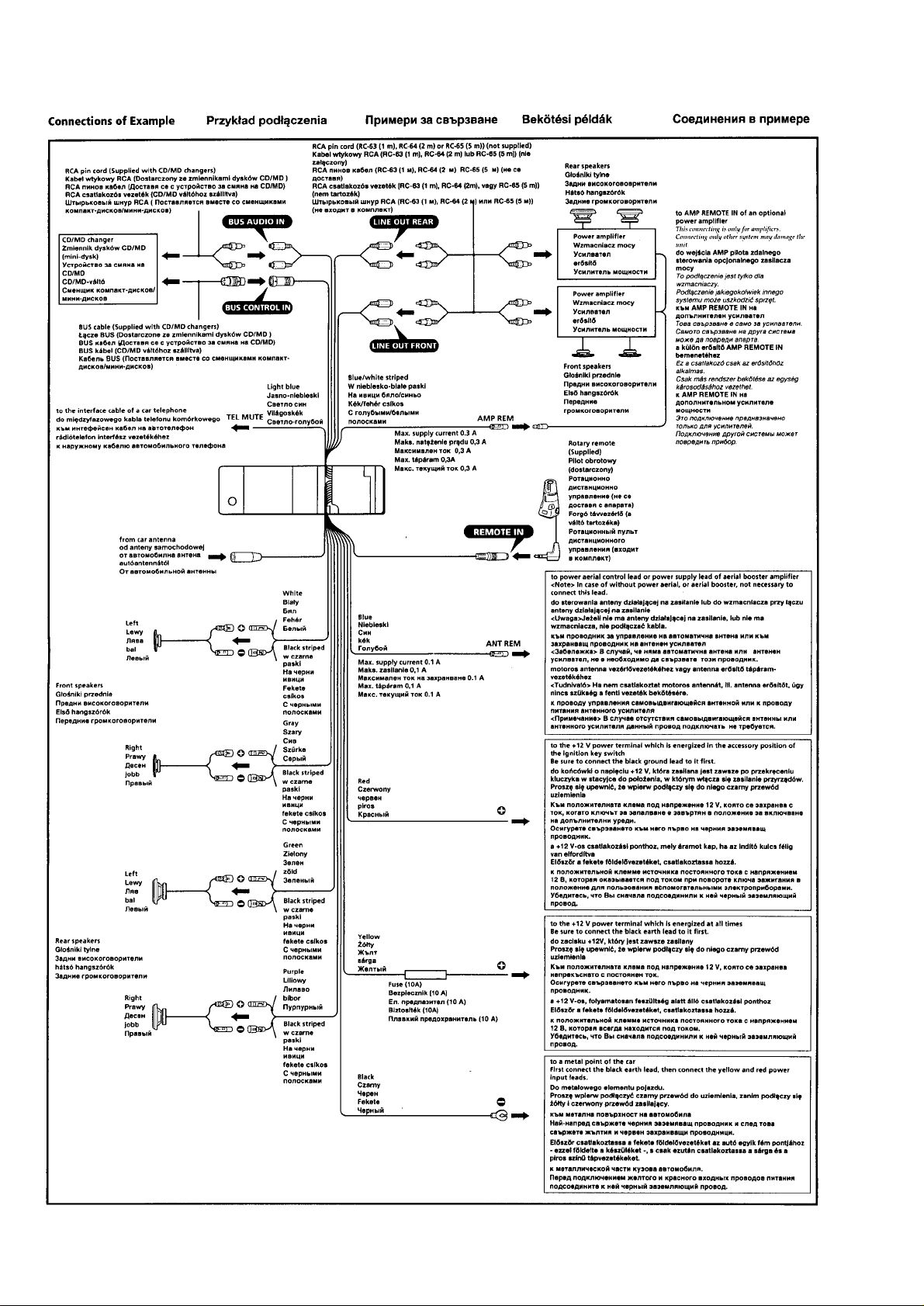

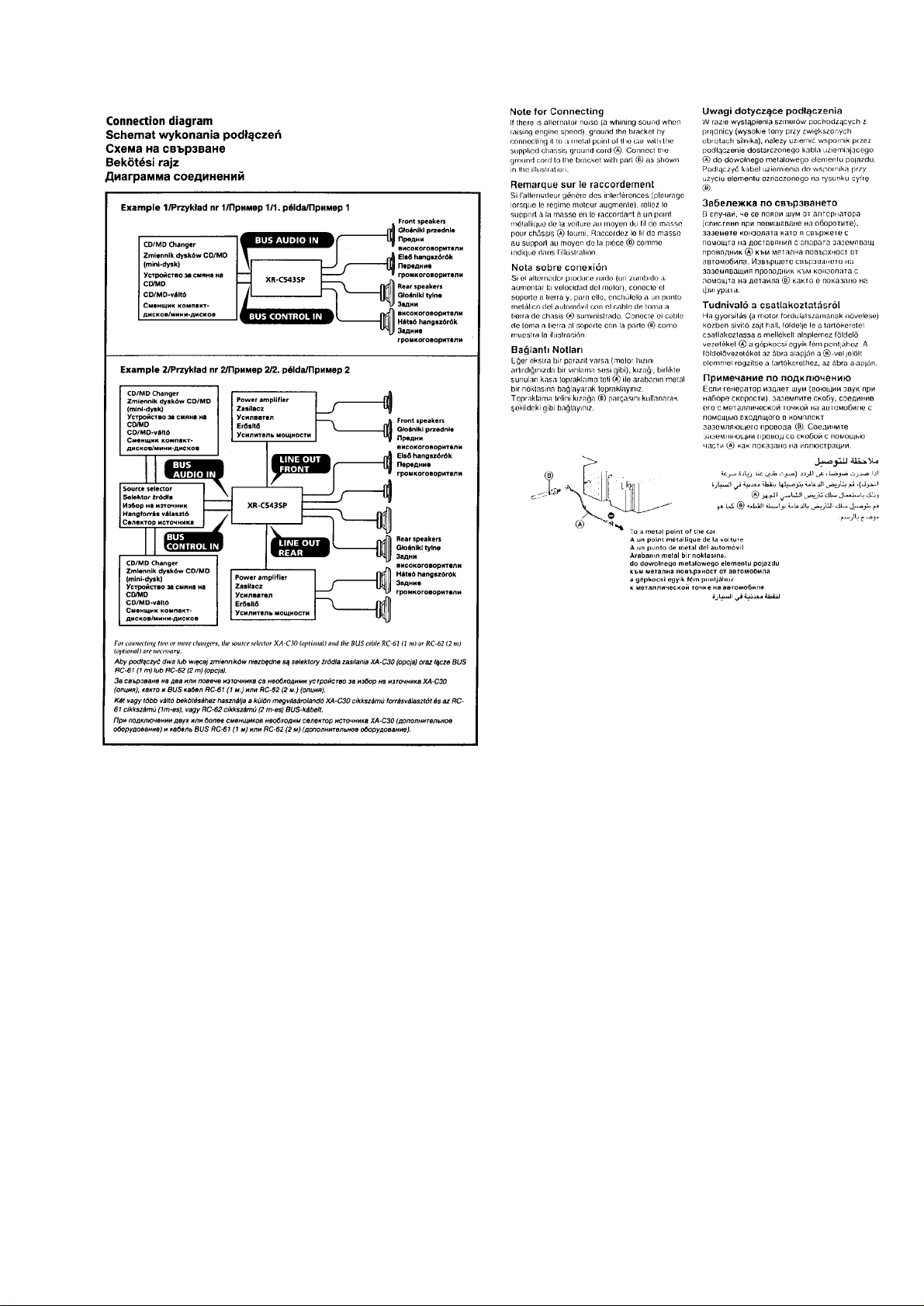

Connections ..................................................................... 5

2. DISASSEMBLY.......................................................... 8

3. ASSEMBLY OF MECHANISM DECK ........... 11

4. MECHANICAL ADJUSTMENTS ....................... 17

5. ELECTRICAL ADJUSTMENTS

Test Mode ........................................................................ 17

Tape Deck Section ........................................................... 18

Tuner Section................................................................... 18

6. DIAGRAMS

6-1. IC Pin Function Description ............................................ 22

6-2. Printed Wiring Boards – MAIN Section – ..................... 25

6-3. Schematic Diagram – MAIN Section – ........................... 29

6-4. Printed Wiring Board – POWER Section –.................... 34

6-5. Schematic Diagram – POWER Section –........................ 37

6-6. Printed Wiring Board – CONTROL Section –............... 41

6-7. Schematic Diagram – CONTROL Section –................... 43

7. EXPLODED VIEWS ................................................ 47

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the manufacturer.

Discard used batteries according to the manufacturer’ s instructions.

ADV ARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

8. ELECTRICAL PARTS LIST................................ 51

ADVARSEL

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type

anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens

instruksjoner.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ som

rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande föreskrifter.

VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

V aihda paristo ainoastaan laitev almistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

– 2 –

SECTION 1

GENERAL

This section is extracted

from instruction manual.

– 3 –

– 4 –

– 5 –

– 6 –

– 7 –

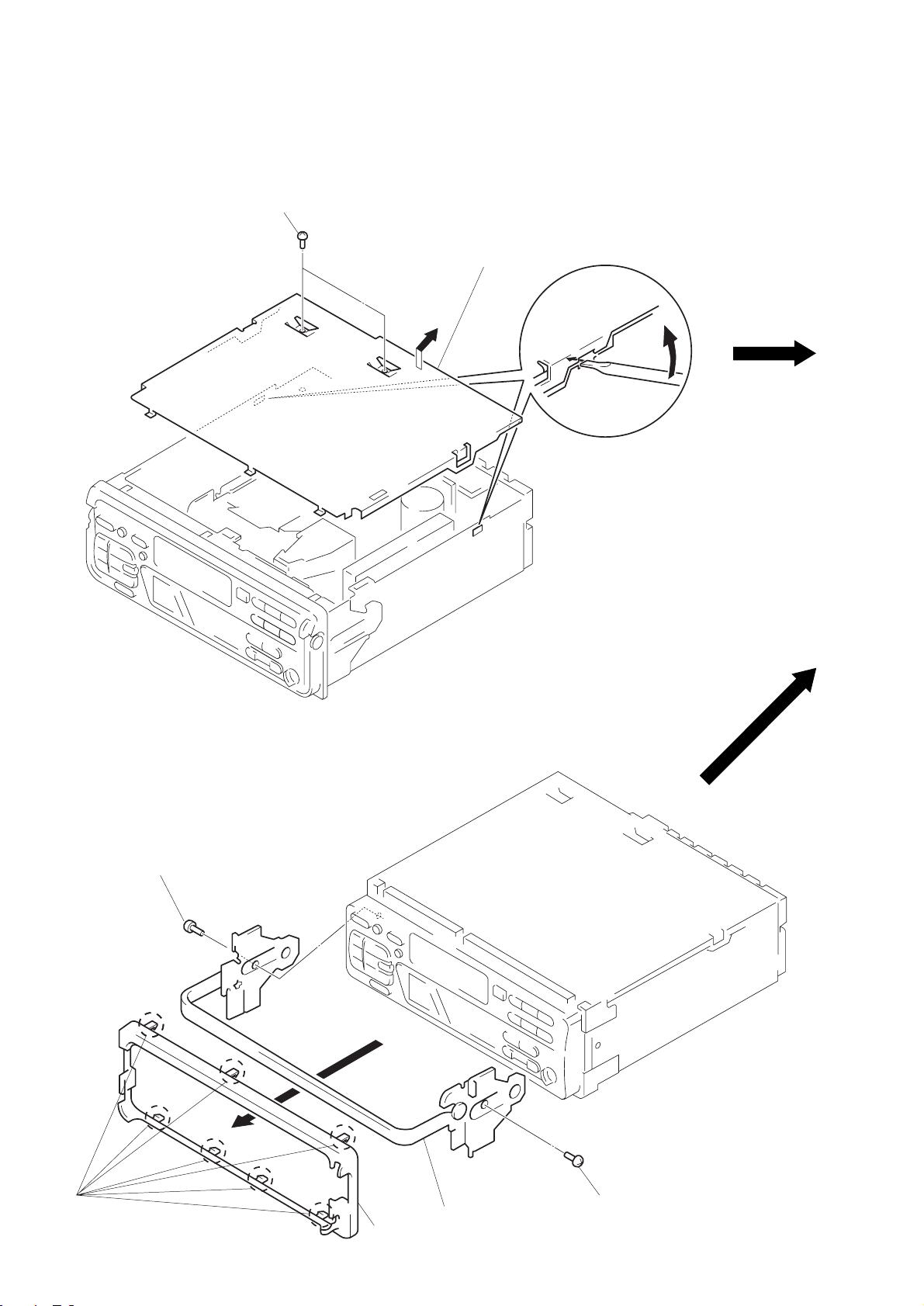

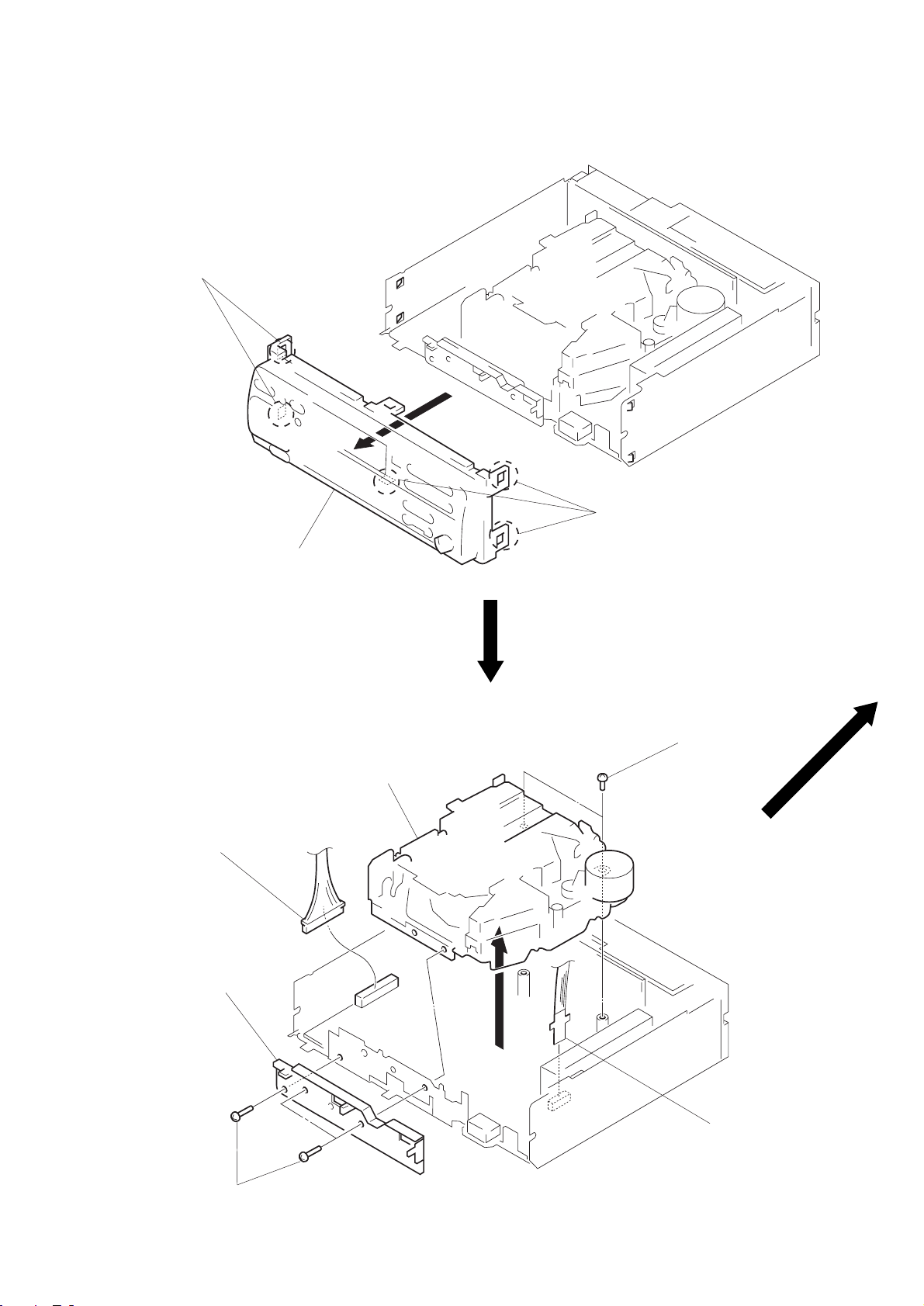

SECTION 2

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

COVER

1

two screws

(PTT2.6 × 6)

A

3

Remove the cover

toward direction A.

2

COLLAR (A), HANDLE ASS’Y

3

screw

(PTT2.6 × 6)

1

Seven claws

2

coller (A)

– 8 –

4

handle ass’y

3

screw

(PTT2.6 × 6)

FRONT PANEL ASS’Y

1

two claws

2

front panel ass’y

1

three claws

MECHANISM DECK

1

connector

(CNP331)

4

front chassis

5

mechanism deck

3

two screws

(PTT2.6 × 6)

2

flexible board

(CNP301)

3

three screws

(PTT2.6 × 6)

– 9 –

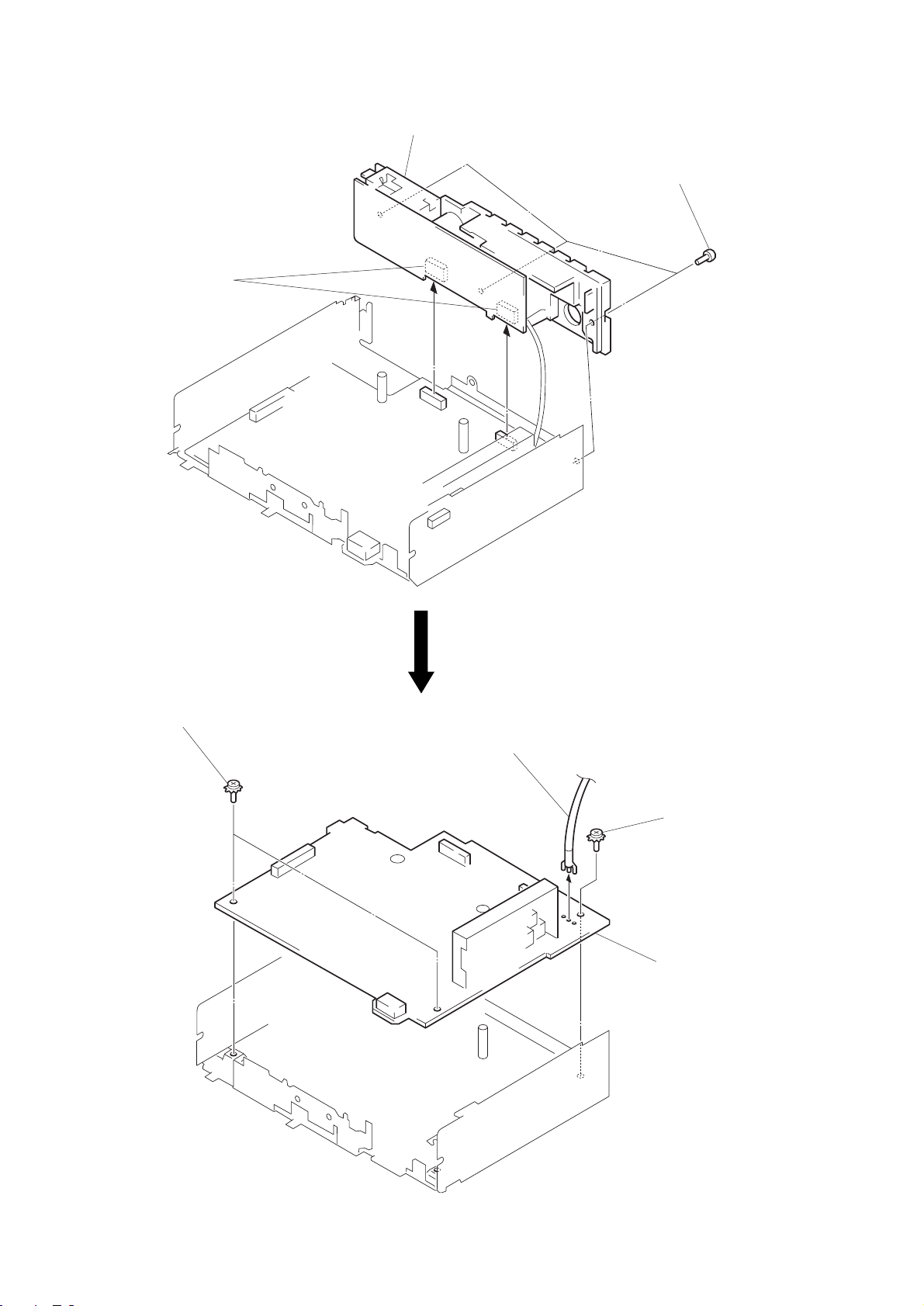

POWER BOARD

2

two connectors

(CNJ400,401)

3

power board

1

three screws

(PTT2.6 × 8)

MAIN BOARD

1

two ground point

screws

4

antenna cable

2

ground point

screw

3

main board

– 10 –

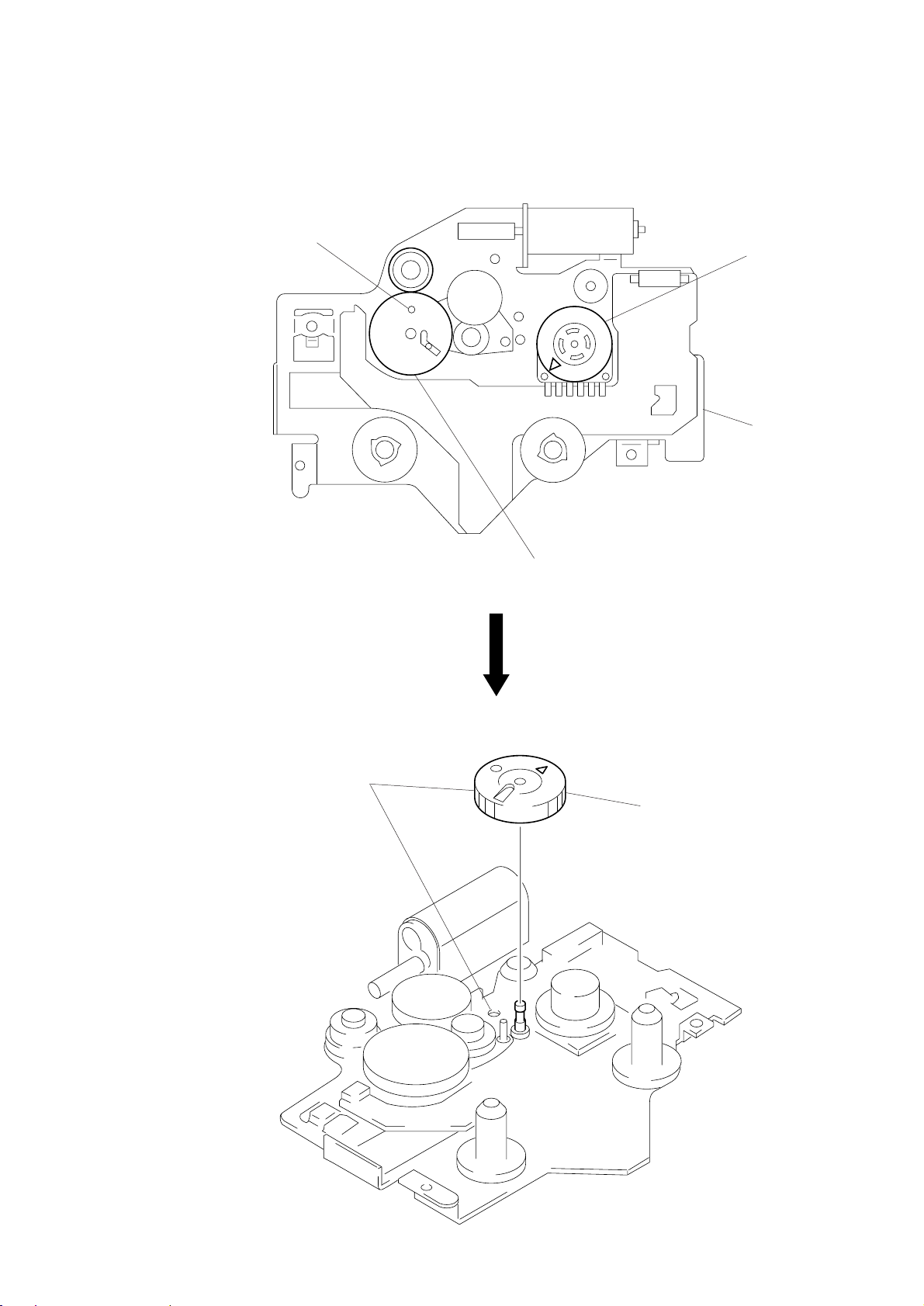

SECTION 3

ASSEMBLY OF MECHANISM DECK

Note: Follow the assembly procedure in the numerical order given.

ALIGNMENT OF FRONT SWITCH

hole

1

Align ¢ mark on the rotary switch

the position shown in the figure.

chassis (S) ass’y

GEAR (LDGE)

1

Align hole as shown in the figure.

2

Align hole in the gear (LDG-D) with the

position shown in the figure.

2

Install the gear (LDG-E).

– 11 –

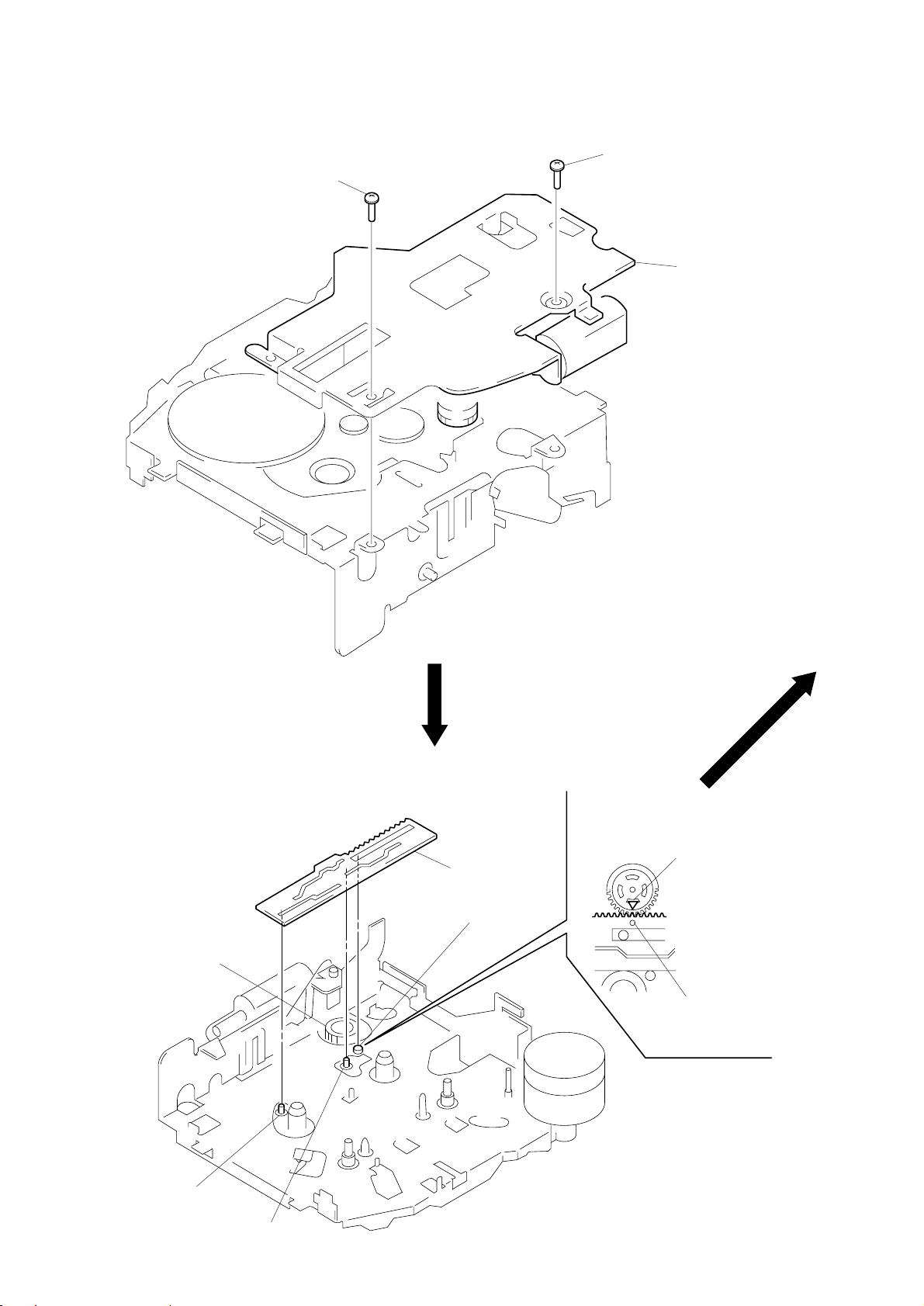

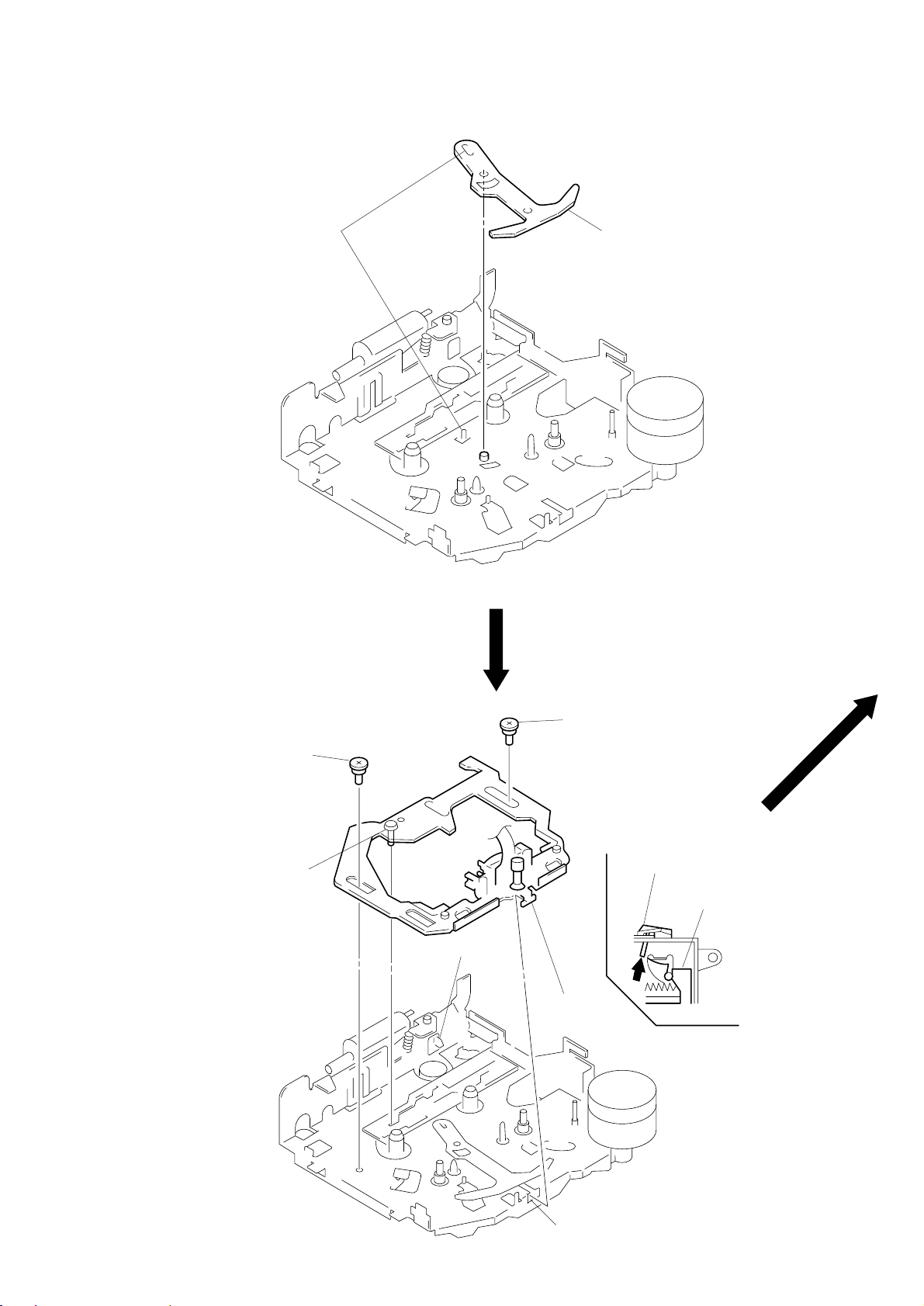

CHASSIS (S) ASS’Y

2

screw (PS2 × 4)

2

screw (PS2 × 4)

1

chassis (S) ass’y

LEVER (MODE)

1. Align ¢ mark on the rotary switch with

hole in the lever (mode).

2. Fit on positions A, B and C and install

the lever (mode).

rotary switch

lever (mode)

C

¢

mark on rotary switch

hole in lever (mode)

A

B

– 12 –

LEVER (PINCH SELECTION)

1

Align.

2

lever (pich selection)

HEAD PLATE ASS’Y

5

step screw (HP)

2

Fit shaft in groove.

ATS lever

5

1

Fit in groove.

step screw (HP)

3

Press the ATS lever.

4

Position the head plate sub

ass’y as shown in the figure.

– 13 –

groove

Loading...

Loading...