Sony XRC-4103 Service manual

XR-C4103

SERVICE MANUAL

SPECIFICA TIONS

East European Model

Model Name Using Similar Mechanism NEW

Tape T ransport Mechanism T ype MG-25F-136

MICROFILM

– Continued on next page –

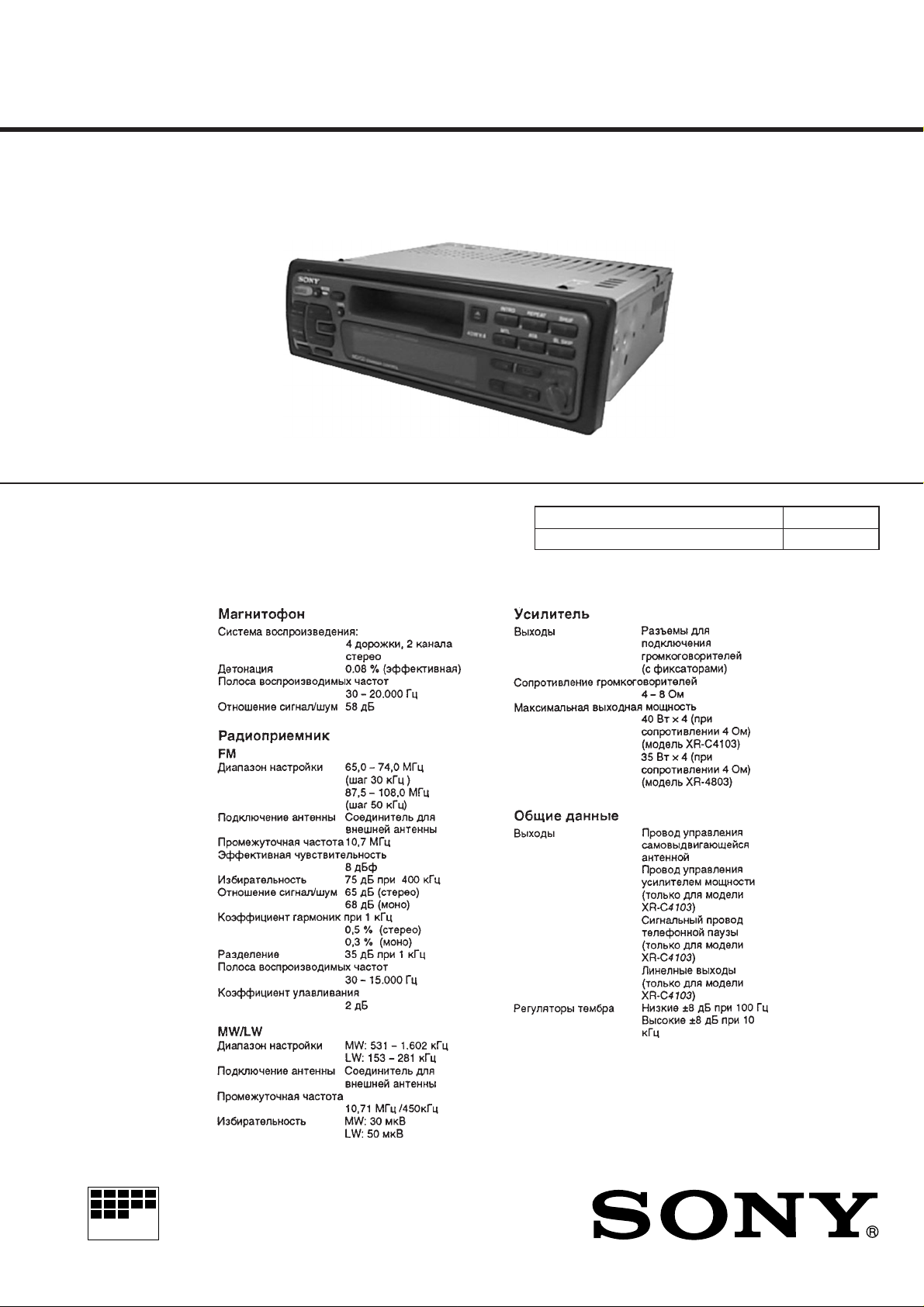

FM/MW/LW CASSET TE CAR STEREO

TABLE OF CONTENTS

1. GENERAL .................................................................. 3

2. DISASSEMBLY ......................................................... 9

3. ASSEMBLY OF MECHANISM DECK........... 11

4. MECHANICAL ADJUSTMENTS ....................... 14

5. ELECTRICAL ADJUSTMENTS

Test Mode........................................................................ 14

Tape Deck Section .......................................................... 14

Tuner Section .................................................................. 15

6. DIAGRAMS

6-1. IC Pin Function Description ........................................... 17

6-2. Printed Wiring Board – MAIN Section – ...................... 21

6-3. Schematic Diagram – MAIN Section – .......................... 23

6-4. Printed Wiring Board – PANEL Section – .................... 27

6-5. Sc hematic Dia gram – PANEL Section –....................... 29

7. EXPLODED VIEWS ................................................ 33

8. ELECTRICAL PARTS LIST ............................... 36

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

– 2 –

SECTION 1

GENERAL

This section is extracted from

instruction manual.

– 3 –

– 4 –

– 5 –

– 6 –

– 7 –

– 8 –

SECTION 2

1

3

cover ass’y

2

2

2

1

1

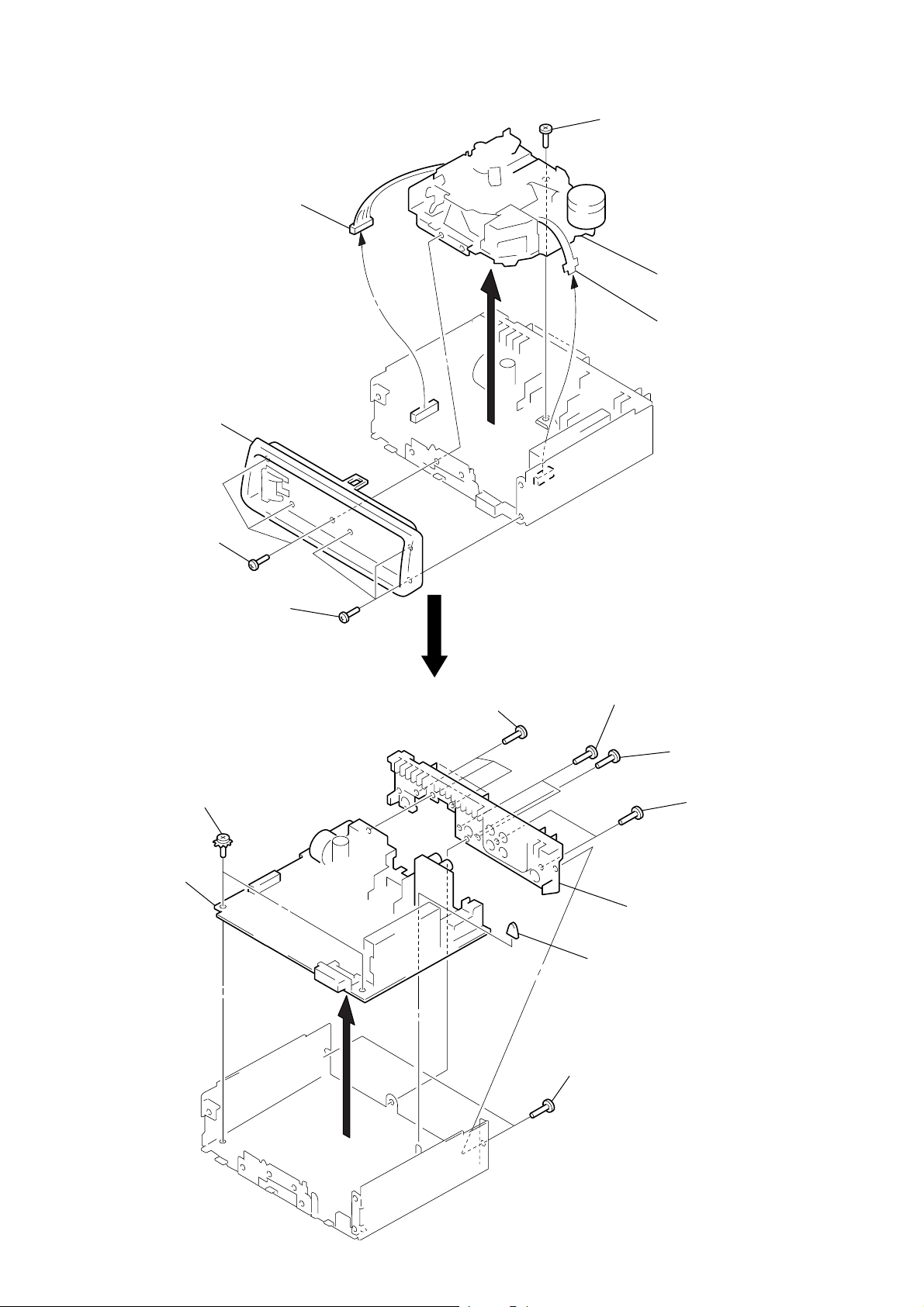

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

FRONT PANEL ASS’Y

Push the button

1

(release).

COVER ASS’Y

2

Remove the front panel ass’y

to the direction of the arrow

A

A

.

– 9 –

SUB PANEL, MECHANISM DECK (MG-25F-136)

k

3

connector

(CN351)

2

sub panel

1

three screws

(PTT2.6

×

8)

5

screw

(PTT2.6

×

6)

6

mechanism dec

(MG-25F-136)

4

flexible flat cable

(CN301)

1

three screws

(PTT2.6

MAIN BOARD, HEAT SINK

3

two ground point

screws

4

main board

×

8)

5

three screws

(PTT2.6

×

8)

5

two screws

(PTT2.6

6

heat sink

2

rubber cap (25)

1

×

10)

5

screw

(PTT2.6

two screws

(PTT2.6

×

8)

×

8)

– 10 –

1

two screws

(PTT2.6

×

8)

SECTION 3

w

ASSEMBLY OF MECHANISM DECK

Note: Follow the assembly procedure in the numerical order given.

HOUSING

4

Fit claw on B part.

3

Put the housing

under A part.

housing

2

Install the hanger onto

two claws of the housing.

5

Fit projection on C part.

C

part

7

Holder the hanger by bending the claw.

1

Install the catch to the hanger.

hanger

6

Fit projection on D part.

8

Hold the hanger by

bending the claw.

ARM (SUCTION)

A

projection

part

B

part

D

part

2

Move the arm (suction) in the arro

direction and fit on projection.

1

Fit the arm (suction) on the shaft.

– 11 –

Loading...

Loading...