Sony XR-1800RD Service Manual

XR-1800RD

m

m

SERVICE MANUAL

SPECIFICATIONS

Cassette player section

Tape track 4-track 2-channel stereo

Wow and flutter 0.13 % (WRMS)

Frequency response 30 – 15,000 Hz

Signal-to- noise ratio 55 dB

UK Model

Model Name Using Similar Mechanism XR-1800R

T ape Transport Mechanism Type MG-36SZ9-32

Power amplifier section

Outputs Speaker outputs

Speaker impedance 4 – 8 ohms8

Maximum power output 35 W × 4 (at 4 ohms)

(sure seal connectors)

Tuner section

FM

Tuning range 87.5 – 108.0 MHz

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz

Usable sensitivity 9 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 65 dB (stereo),

Harmonic distortion at 1 kHz

Separation 35 dB at 1 kHz

Frequency response 30 – 15,000 Hz

MW/LW

Tuning range MW:531 – 1,602 kHz

Aerial terminal External aerial connector

Intermediate frequency 450 kHz

Sensitivity MW:30 µV

68 dB (mono)

0.7% (stereo),

0.4% (mono)

LW:153 – 281 kHz –

LW:50 µV

General

Output lead Power aerial relay control

Tone controls Bass ±8 dB at 100 Hz

Power requirements 12 V DC car battery

Dimensions Approx. 186 × 57 × 176 m

Mounting dimension Approx. 182 × 53 × 163 m

Mass Approx. 1.2 kg

Supplied accessories Parts for installation and

Design and specifications are subject to change

without notice.

lead

Treble ±8 dB at 10 kHz

(negative ground)

(w/h/d) not incl.

projecting parts and

controls

(w/h/d) not incl.

projecting parts and

controls

connections (1 set)

FM/MW/LW CASSETTE CAR STEREO

TABLE OF CONTENTS

1. GENERAL

Button Locations ............................................................. 3

Setting the Clock ............................................................. 3

2. DISASSEMBLY ......................................................... 4

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

3. MECHANICAL ADJUSTMENTS....................... 8

4. ELECTRICAL ADJUSTMENTS

Tape Deck Section .......................................................... 8

Tuner Section .................................................................. 9

5. DIAGRAMS

5-1. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 13

5-2. Printed Wiring Board – MAIN Board – ........................ 15

5-3. Schematic Diagram – MAIN Board (1/2) – .................. 16

5-4. Schematic Diagram – MAIN Board (2/2) – .................. 17

5-5. Printed Wiring Board – KEY Board –........................... 18

5-6. Schematic Diagram – KEY Board – ............................. 19

5-7. IC Pin Function Description ........................................... 21

6. EXPLODED VIEWS................................................ 23

7. ELECTRICAL PARTS LIST ............................... 29

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

2

SECTION 1

GENERAL

This section is extracted from

instruction manual.

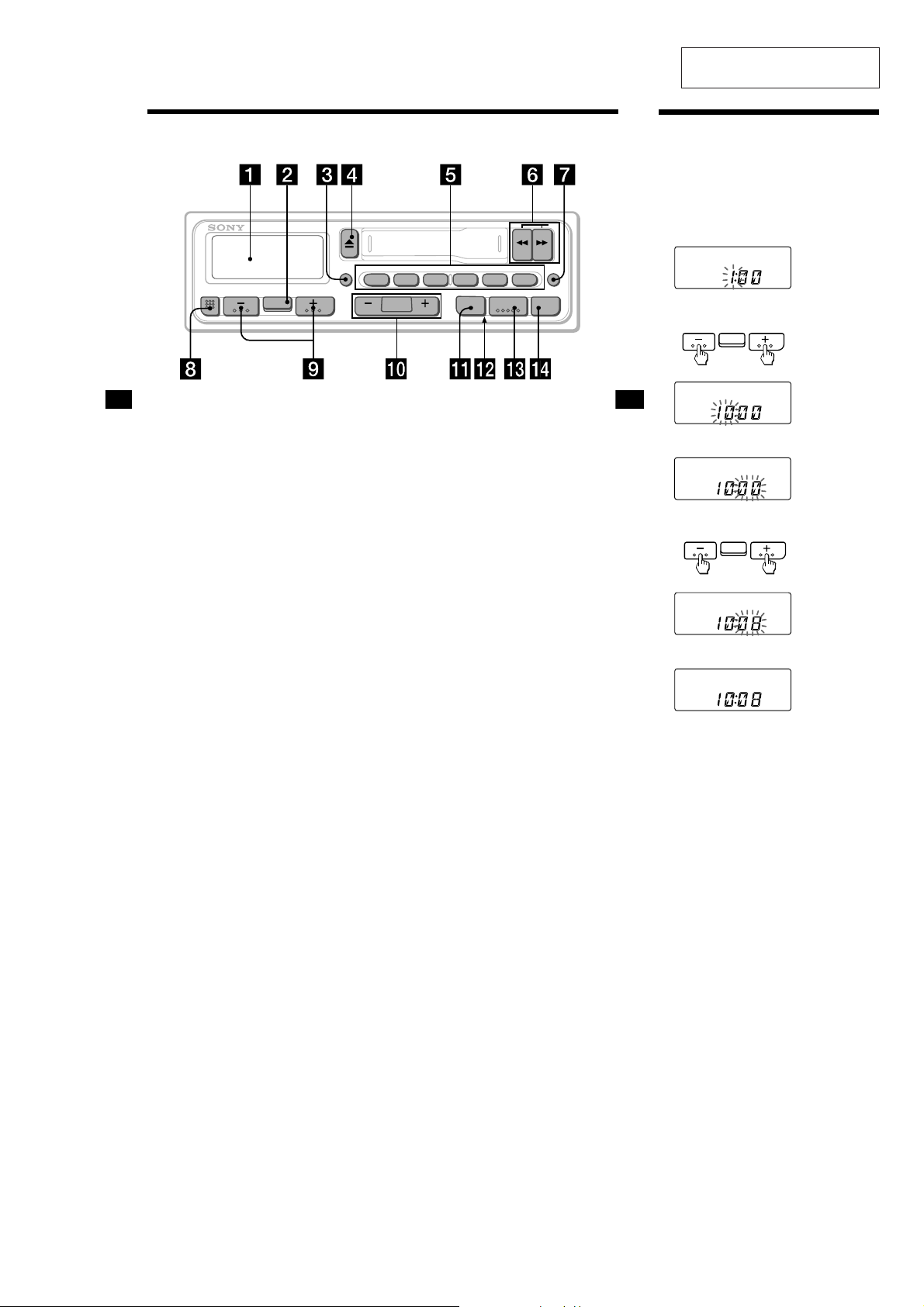

Button locations

RELEASE

EN

Refer to the pages for further details.

1 Display window

2 SEL (control mode select) button 6, 11,

13, 14

3 DSPL (display mode change/time set)

button 6, 10

4 Z (eject) button 6

5 During radio reception:

Preset number buttons 8, 9, 11, 12

During tape playback:

(1) ATA (Automatic Tuner Activation)

button 7

6 m/M (fast winding)/DIR (tape

transport direction change) buttons 6, 7

7 AF/TA (alternative frequency/traffic

announcement) button 10, 11, 12

SEL PTY

DSPL ATA

DIR

213 64 5

SEEK

MANU

8 RELEASE (front panel release) button

5, 15

9 (--)(+) (volume/bass/treble/balance/

fader control) buttons 6, 14

0 SEEK/MANU button 7, 8, 10, 13

qa PTY/LOUD (Programme type/loudness)

button 13, 14

qs Reset button (located on the front side

of the unit hidden by the front panel) 5

Press this button when you use this unit

for the first time, when you have changed

the car battery, or when the buttons of this

unit do not function properly.

qd TUNER/BTM (radio on • band select/Best

tuning memory function) button 7, 8, 9,

12

qf OFF button 5

LOUD

TUNER OFF

AF/TA

BTM

XR-1800R

Setting the clock

The clock has a 24-hour digital indication.

For example, setting it to 10:08

1

Display the time.

(Press (DSPL) during unit operation.)

2

Press (DSPL) for more than two seconds.

The hour digit blinks.

Set the hour digits.

(to go back) (to go forward)

EN

3

Press the (SEL) button momentarily.

The minute digits blink.

Set the minute digits.

(to go back)

4

Press (DSPL) momentarily.

(to go forward)

The clock starts.

Note

The clock cannot be set unless the power is turned

on. Set the clock after you turn on the radio, or

during tape playback.

4

6

3

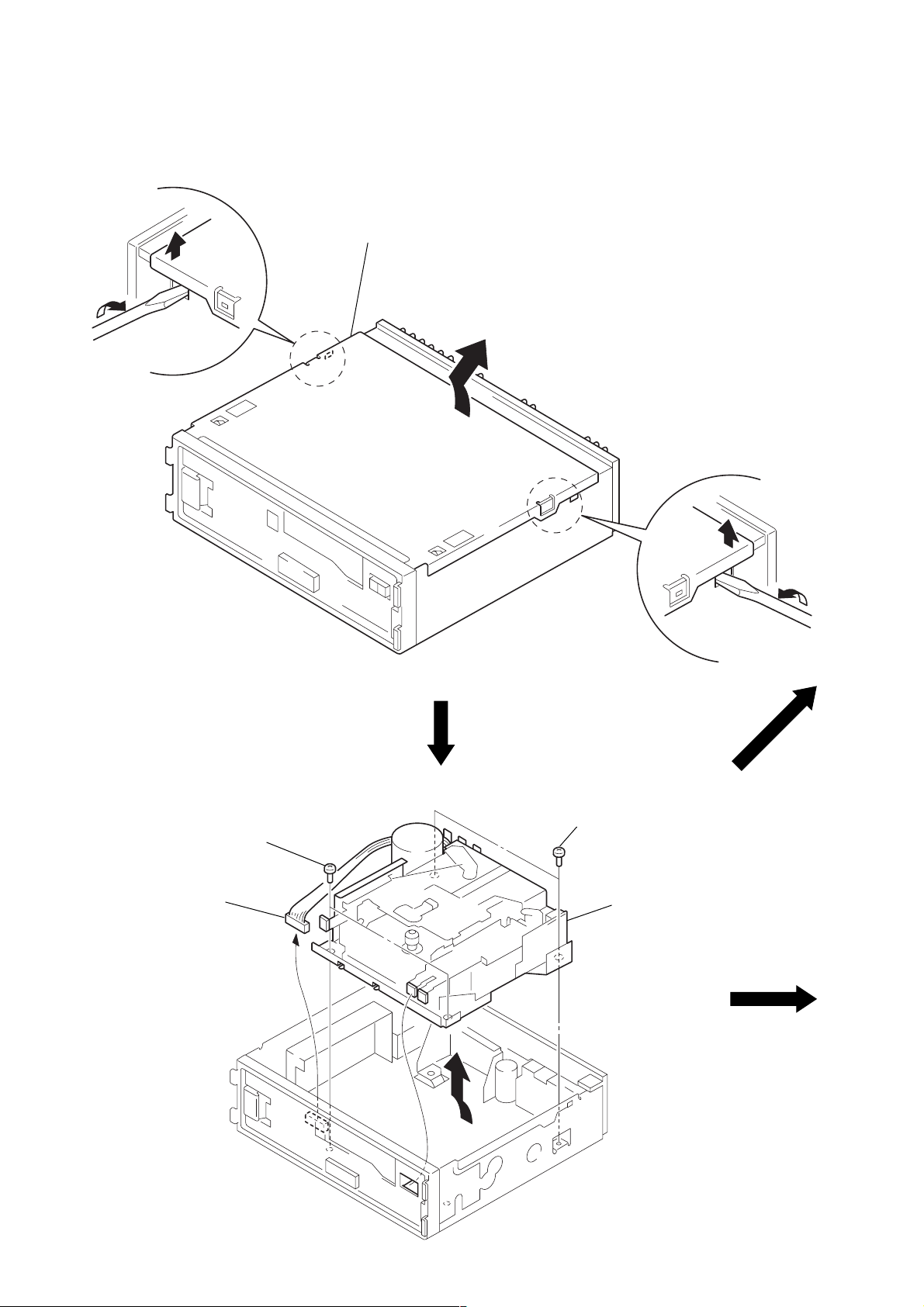

SECTION 2

k

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

COVER ASSY

3

2

1

cover assy

MECHANISM DECK BLOCK

1

two screws

(PTT2.6 × 6)

2

connector

(CN901)

1

two screws

(PTT2.6

2

×

6)

3

mechanism deck bloc

1

4

MAIN BOARD, HEAT SINK

)

k

2

two screws

(ground point)

3

main board

4

five screws

(PTT2.6

×

1

two screws

(PTT2.6

5

8)

×

heat sink

6

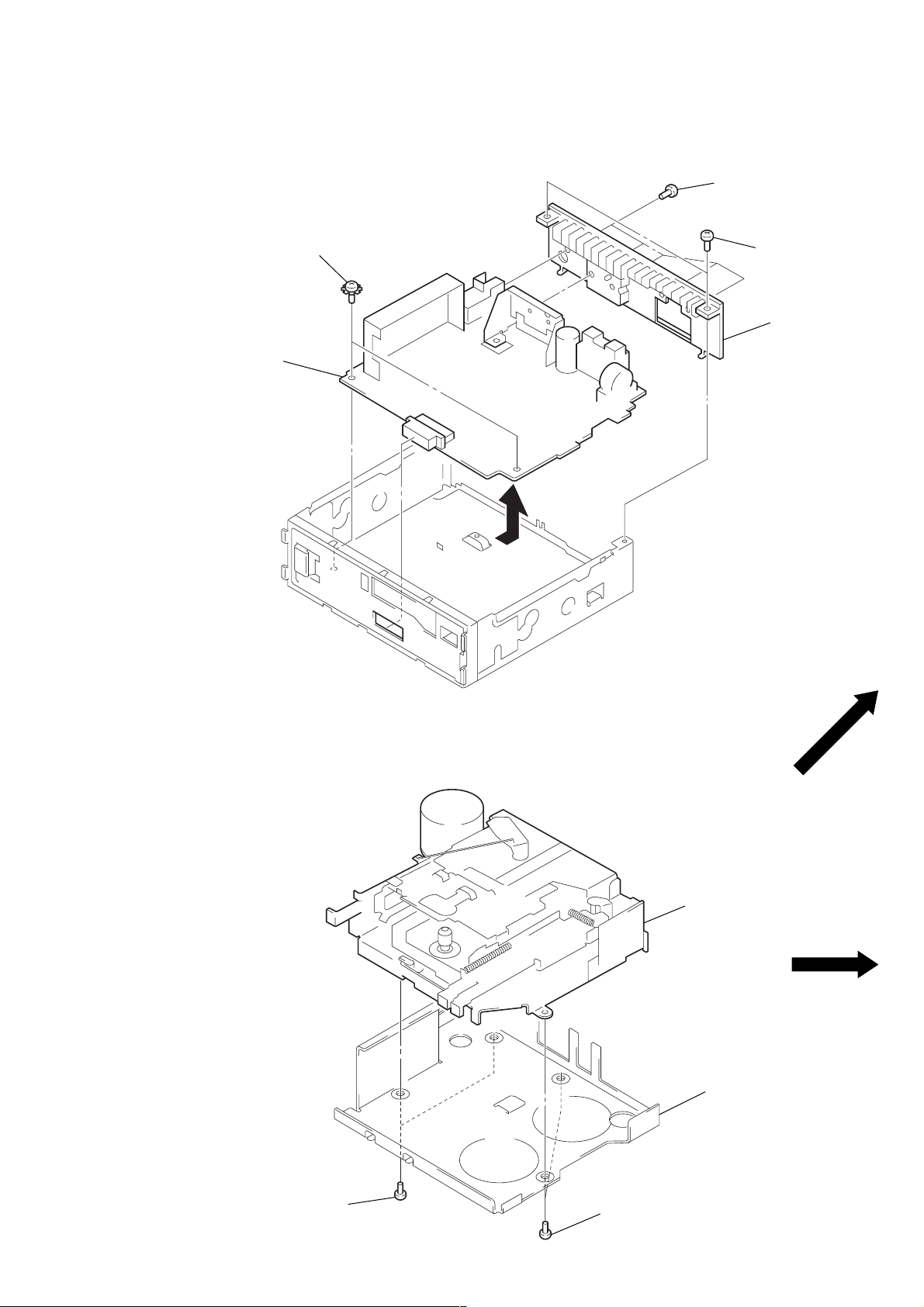

MECHANISM DECK

(MG-36SZ9-32)

1

two screws

(P2.6

3

mechanism dec

(MG-36SZ9-32)

2

bracket (MD)

1

×

4)

two screws

(P2.6 × 4)

5

MOTOR ASSY (CAPSTAN/REEL) (M901)

)

2

belt

3

belt

1

two screws

×

3)

(P2

4

motor assy (CAPSTAN/REEL

(M901)

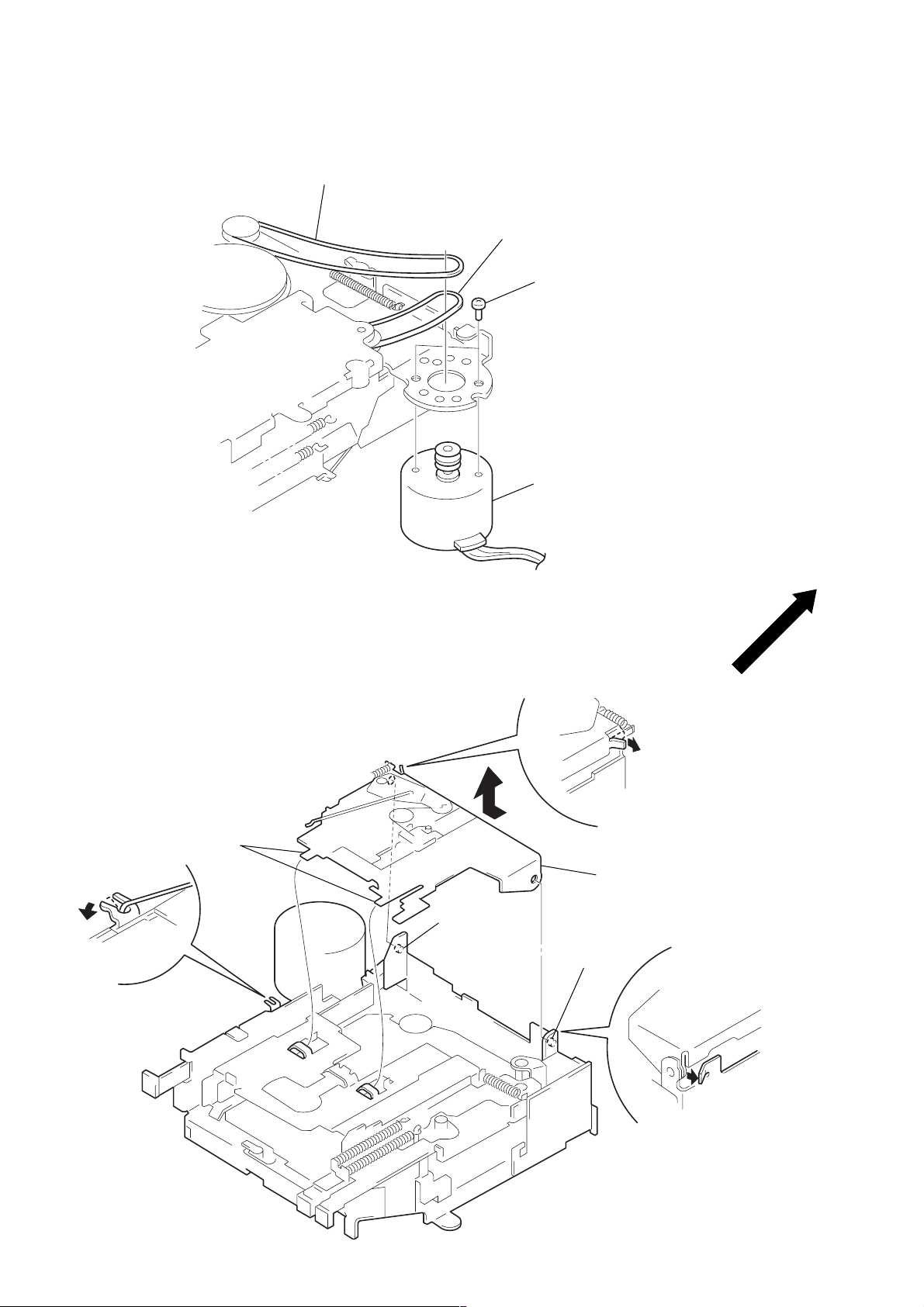

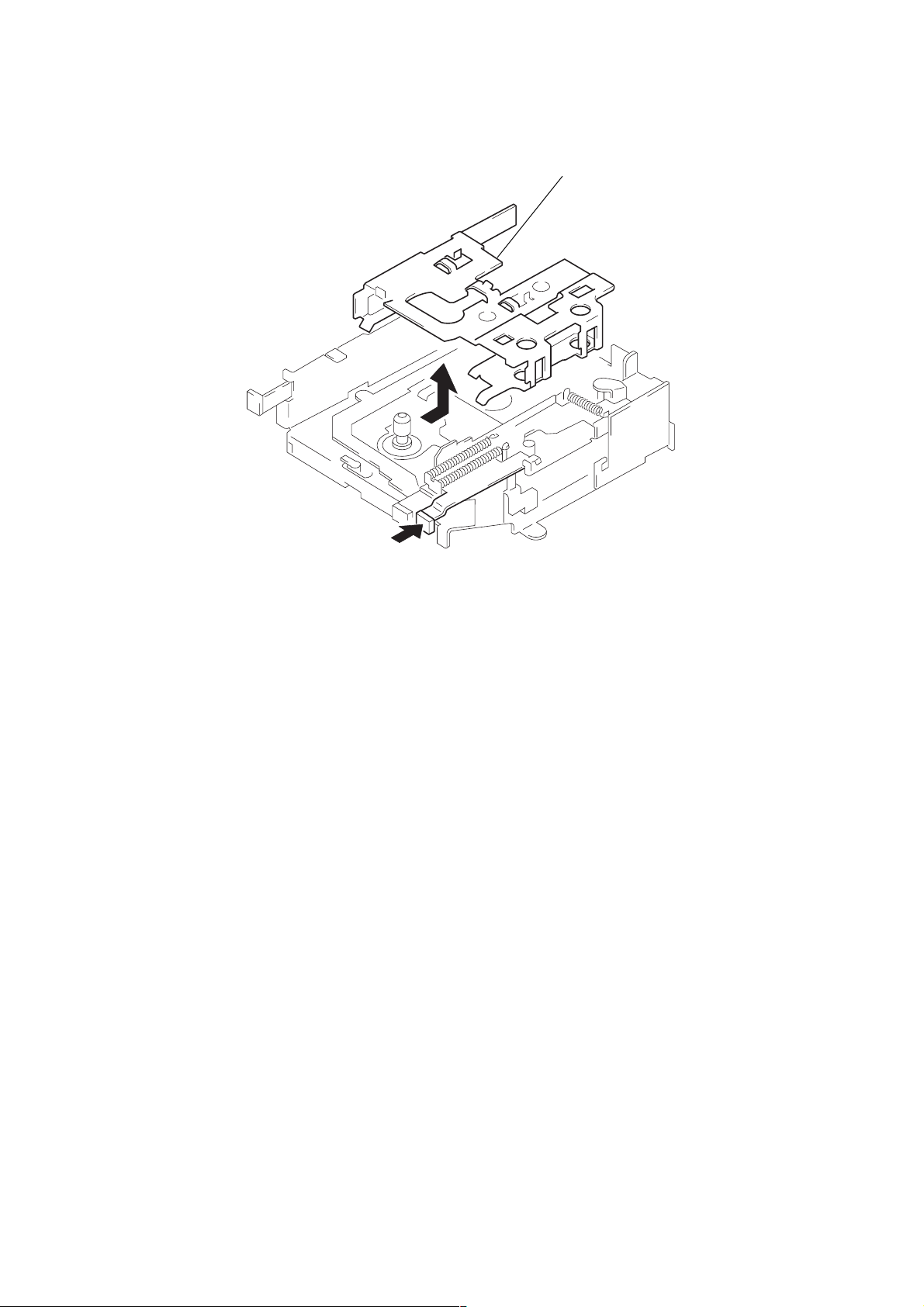

CASSETTE HANGER (X)

4

2

Remove the return link

in the direction of the arrow.

two claws

3

boss

3

1

Remove the claw

in the direction of the arrow.

5

cassette hanger (x)

boss

1

Remove the claw

in the direction of the arrow.

6

CASSETTE HOLDER (X)

)

A

1

Push the arrow A part.

2

Remove the cassette holder (x

in the direction of the arrow.

7

SECTION 3

l

e

MECHANICAL ADJUSTMENTS

SECTION 4

ELECTRICAL ADJUSTMENTS

1. Clean the follo wing parts with a denatured-alcohol-moistened

swab:

playback head pinch roller

rubber belt capstan

idler

2. Demagnetize the playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the power supply

voltage (14.4 V) unless otherwise noted.

• Tor que Measurement

Mode Torque Meter Meter Reading

Forward CQ-102C (25 – 55 g•cm)

Forward

Back Tension

Reverse CQ-102RC (25 – 55 g•cm)

Reverse

Back Tension

FF, REW CQ-201B (50 – 150 g•cm)

CQ-102C (1.5 – 4 g•cm)

CQ-102RC (1.5 – 4 g•cm)

2.46 – 5.39 mN•m

(0.35 – 0.76 oz•inch)

0.15 – 0.39 mN•m

(0.02 – 0.06 oz•inch)

2.46 – 5.39 mN•m

(0.35 – 0.76 oz•inch)

0.15 – 0.39 mN•m

(0.02 – 0.06 oz•inch)

4.91 – 14.70 mN•m

(0.69 – 2.08 oz•inch)

TAPE DECK SECTION 0 dB= 0.775 V

1. The adjustments should be performed in the order given in

this service manual.

2. The adjustments should be performed for both L-CH and

R-CH.

Test T ape

Type Signal Used for

P-4-A063 6.3 kHz, –10 dB head azimuth adjustment

WS-48A 3 kHz, 0 dB tape speed adjustment

PB Head Azimuth Adjustment

Procedure:

1. Put the set into the FWD PB mode.

test tape

P-4-A063

(6.3 kHz, –10 dB)

set

4 Ω

speaker out termina

2. Turn the screw and check the output peak value. Adjust the

screw so that the peak value in channels L and R coincides

within 2 dB.

level

meter

+

–

• Tape T ension Measurement

Mode Tension Meter Meter Reading

Forward CQ-403A more than 60 g

Reverse CQ-403R (more than 2.12 oz)

output

level

within

2 dB

L-CH

peak

R-CH

peak

L-CH

peak

screw

position

R-CH

peak

3. Check the phase in the FWD PB mode.

test tape

P-4-A063

(6.3 kHz, –10 dB)

L-CH

set

R-CH

4 Ω

4 Ω

speaker out terminal

Screen pattern

oscilloscope

within

2 dB

angl

V

H

+

+

–

–

in phase

8

45 °

good wrong

90 °

135 ° 180 °

4. Repeat the above adjustment for the REV PB mode.

r

)

)

5. Check that output level difference between FWD PB mode

and REV PB mode is within 4 dB.

Adjustment Location: PB head

TUNER SECTION

0 dB=1 µV

Cautions during repair

When the tuner unit is defective, replace it by a new one because its internal block is difficult to repair.

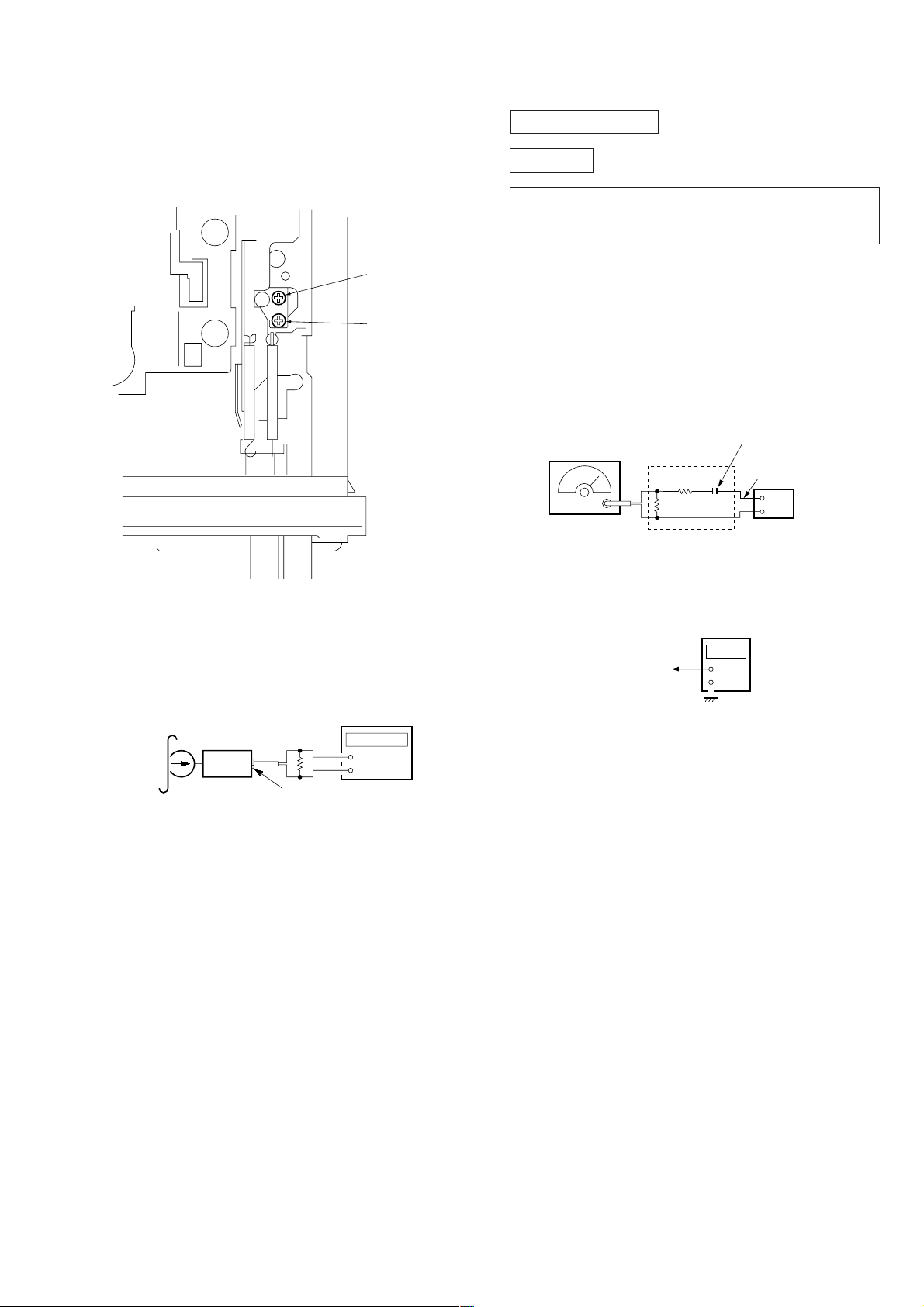

Tape Speed Adjustment

Setting:

test tape

WS-48A

(3 kHz, 0 dB)

set

FWD

REV

frequency counte

4

Ω

+

–

speaker out terminal

adjustment

screws

Note: Adjust the tuner section in the sequence shown below.

1. FM Auto Scan/Stop Level Adjustment

2. FM Noise Focus Adjustment

3. FM Stereo Separation Adjustment

4. FM Signal Meter Adjustment

5. MW Auto Scan/Stop Level Adjustment

FM Auto Scan/Stop Level Adjustment

Setting:

[TUNER] button: FM 1

FM RF signal

generator

Carrier frequency : 98.0 MHz

Output level : 28 dB (25.1 µV)

Mode : mono

Modulation : 1 kHz, 22.5 kHz deviation (30%

MAIN board

TP101 (SD)

dummy

antenna

50 Ω

50 Ω

Procedure:

1. Tune the set to 98.0 MHz.

2. Connect the digital voltmeter to TP101 (SD) on MAIN board.

3. Adjust RV2 on TU100 so that the reading on the digital voltmeter changes point from low to high.

0.1pF

digital

voltmeter

+

–

antenna

jack (CN900

set

Procedure:

1. Put the set into the FWD PB mode.

2. Adjust adjustment resistor for inside capstan motor so that the

reading on the frequency counter becomes in 3,015 Hz.

Specified V alue: 2,940 to 3,090 Hz

Adjustment Location: See page 12.

Adjustment Location: See page 12.

9

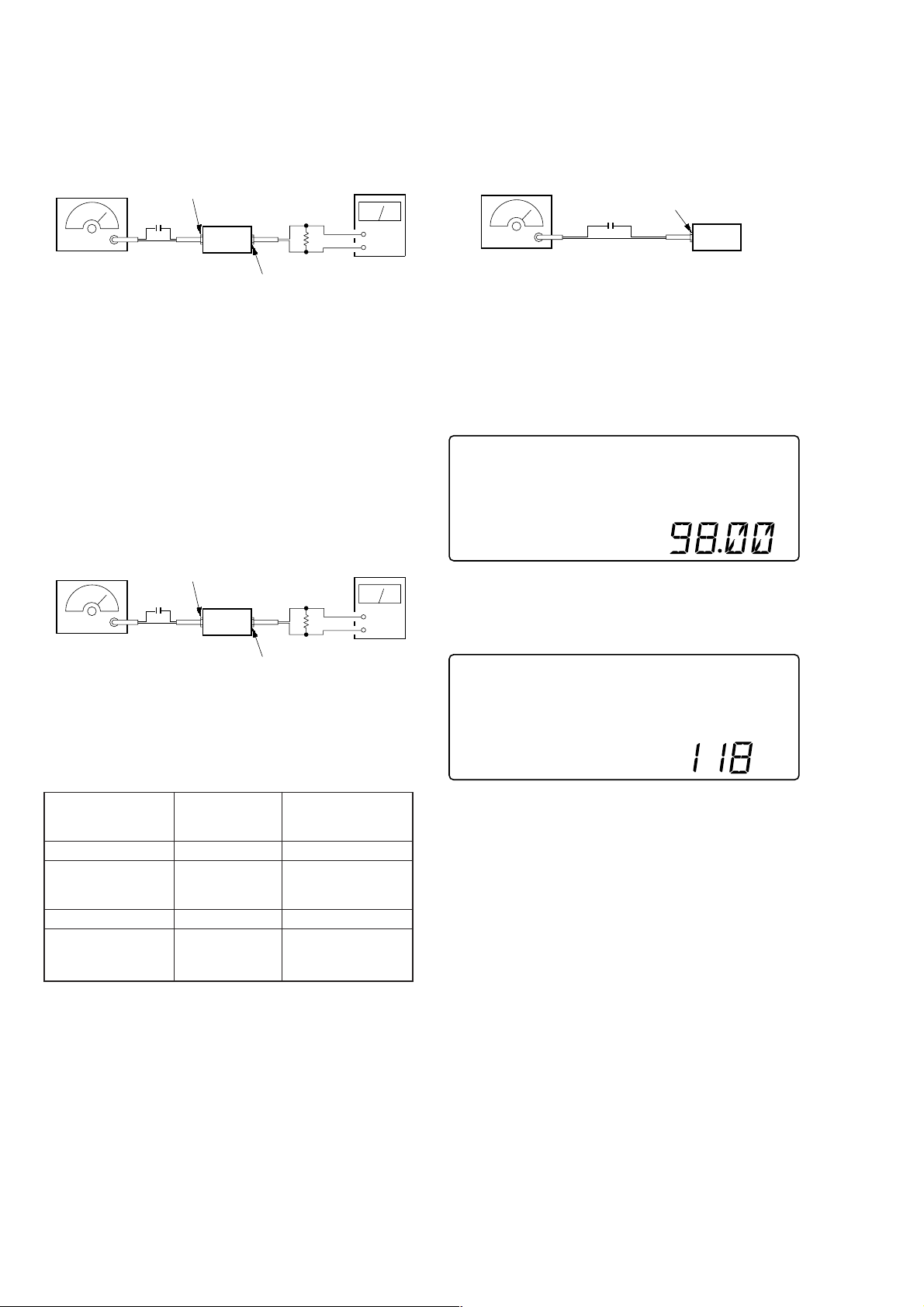

FM Noise Focus Adjustment

Setting:

[TUNER] button: FM1

FM RF signal

generator

Carrier frequency : 98.0 MHz

Output level : 60 dB (1 mV)

Mode : mono

Modulation : 1 kHz, 75 kHz deviation (100%)

antenna jack (CN900)

0.01 µF

set

speaker out terminal

4 Ω

Procedure:

1. Tune the 98.0 MHz.

2. The then output level is supposing that (A) dB.

3. Adjust with the v olume R V3 on TU100 so that the output level

is (A) –31 dB then signal generator input set to –20 dB.

level meter

+

–

FM Signal Meter Adjustment

Setting:

[TUNER] button: FM1

FM RF signal

generator

antenna jack (CN900)

0.01 µF

set

Carrier frequency : 98.00 MHz

Output level : 35 dB (56.2 µV)

Mode : mono

Modulation : no modulation

Procedure:

1. Press [OFF] button to turn the set OFF.

2. Press [4] button and [5] button.

3. Press and hold [1] button for 3 to 4 seconds.

4. Press [TUNER] button for 2 to 3 times.

Display

Adjustment Location: See page 12.

FM Stereo Separation Adjustment

Setting:

[TUNER] button: FM1

FM RF signal

generator

Carrier frequency : 98.0 MHz

Output level : 76 dB (6.3 mV)

Mode : stereo

Modulation : main: 1 kHz, 33.75 kHz deviation (45%)

antenna jack (CN900)

0.01 µF

set

sub: 1 kHz, 33.75 kHz deviation (45%)

19 kHz pilot: 7.5 kHz deviation (10%)

4 Ω

speaker out terminal

Procedure:

FM Stereo

signal generator

output channel

L-CH L-CH A

R-CH L-CH Adjust RV4 on TU100

R-CH R-CH C

L-CH R-CH Adjust RV4 on TU100

Level meter Level meter

connection reading (dB)

for minimum reading.

for minimum reading.

level meter

B

D

FM

AMSREG

5. Press [6] button, the test mode is set.

6. Adjust RV100 so that the display indication is “118”.

+

–

Display

FM

AMSREG

Specified Value: Display indication: 116 to 120

Adjustment Location: See page 12.

L-CH Stereo separation: A-B

R-CH Stereo separation: C-D

The separations of both channels should be equal.

Specified Value: Separation more than 26 dB

Adjustment Location: See page 12.

10

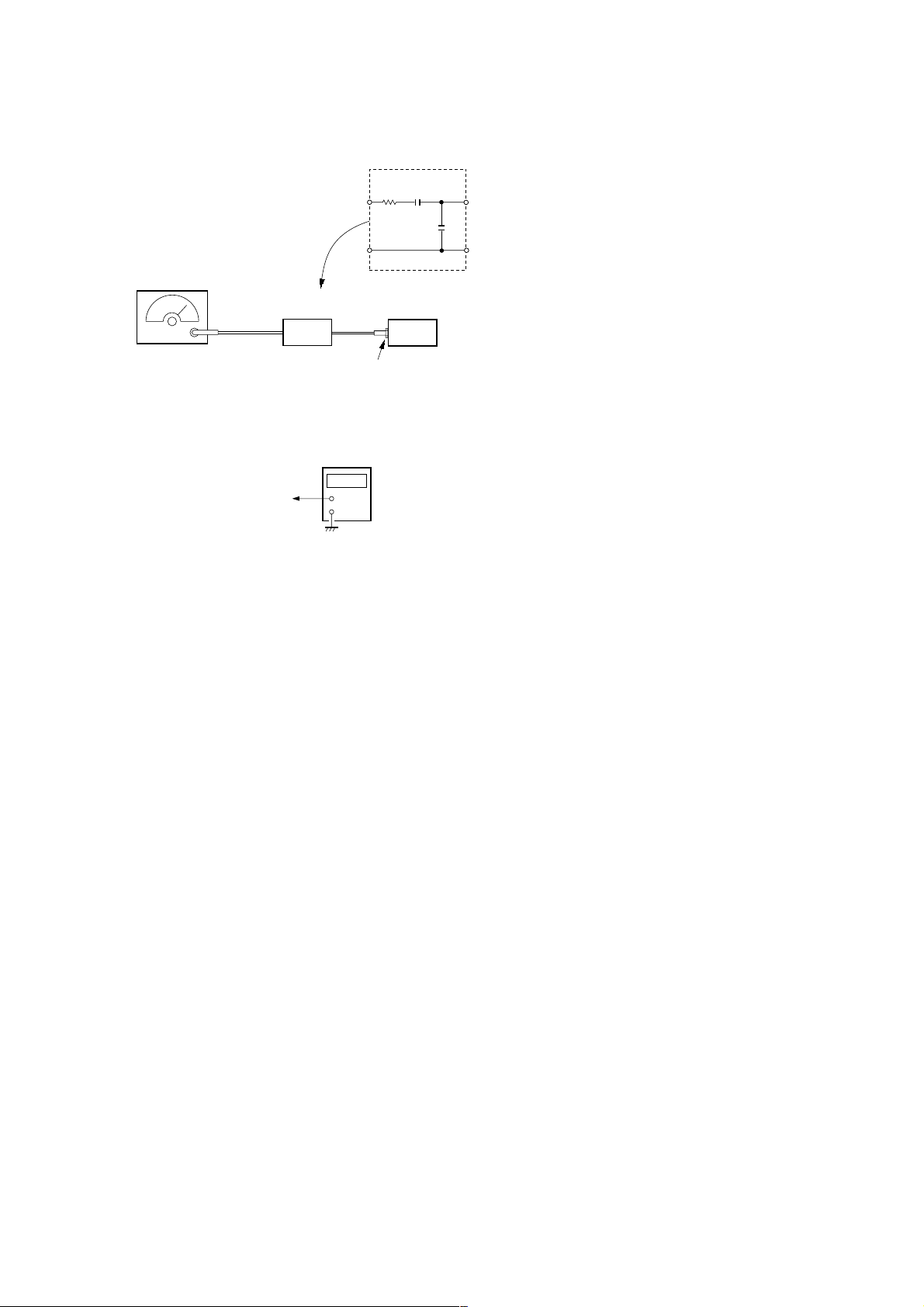

MW Auto Scan/Stop Level Adjustment

Setting:

[TUNER] button: MW

AM RF signal

generator

(50 Ω)

AM dummy

antenna

30 Ω

15 pF

65 pF

set

Carrier frequency : 999 kHz

30% amplitude

modulation by

1 kHz signal

Output level : 33 dB (44.7 µV)

MAIN board

TP101 (SD)

antenna jack (CN900)

digital

voltmeter

+

–

Procedure:

1. Tune the set to 999 kHz

2. Connect the digital v oltmeter to TP101 (SD) on MAIN board .

3. Adjust RV1 on TU100 so that the reading on the digital voltmeter changes point from low to high.

Adjustment Location: See page 12.

11

Loading...

Loading...