Sony XR-1100 Service manual

XR-1100

SERVICE MANUAL

Ver 1.2 2004.09

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS (US model only)

POWER OUTPUT AND TOTAL HARMONIC DISTORTION

17 watts per channel minimum continuous average power into

4 ohms, 4 channels driven from 20 Hz to 20 kHz with no more than

1% total harmonic distortion.

Cassette player section

Tape track 4-track 2-channel stereo

Wow and flutter 0.13 % (WRMS)

Frequency response 30 – 15,000 Hz

Signal-to- noise ratio 55 dB

Tuner section

FM

Tuning range

US and Canadian models :

E and UK models:

Antenna terminal

Intermediate frequency

Usable sensitivity

Selectivity

Signal-to-noise ratio

Harmonic distortion at 1 kHz

Separation

Frequency response 30 – 15,000 Hz

87.5 – 107.9 MHz

FM tuning interval :

50kHz/ 200kHz

switchable

87.5 -108.0MHz

(at 50 kHz step)

87.5 -107.9 MHz

(at 200 kHz step)

External antenna connector

10.7 MHz

9 dBf

75 dB at 400 kHz

65 dB (stereo),

68 dB (mono)

0.7% (stereo),

0.4% (mono)

35 dB at 1 kHz

US Model

Canadian Model

UK Model

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type MG-36SZ10-32

AM

Tuning range

US and Canadian models :

E and UK models:

Antenna terminal

Intermediate frequency 10.71 MHz/450 kHz

Sensitivity 30 µV

Power amplifier section

Outputs Speaker outputs

Speaker impedance 4 – 8 ohms

Maximum power output 45 W × 4 (at 4 ohms)

530 – 1,710 kHz

AM tuning interval:

9 kHz/10 kHz switchable

531 – 1,602 kHz

(at 9 kHz step)

530 – 1,710 kHz

(at 10 kHz step)

External antenna connector

(sure seal connectors)

– Continued on next page –

E Model

9-870-060-13 Sony Corporation

2004I05-1 e Vehicle Company

© 2004.09 Published by Sony Engineering Corporation

FM/AM CASSETTE CAR STEREO

XR-1100

General

Outputlead Power antenna relay

Tone controls Bass ±8 dB at 100

Power requirements 12 V DC car battery

Dimensions Approx. 188 × 58 ×177 mm

Mounting dimension Approx. 182 × 53 × 163 mm

Mass Approx. 1.2 kg (2 lb. 10 oz.)

Supplied accessories Parts for installation and

Design and specifications are subject to change

without notice.

control lead

Treble ±8 dB at 10 kHz

(negative ground)

123

(7 / × 2 / × 7 in.)

(w/h/d) not incl.

projecting parts and

controls

(7 / × 2 / × 6 / in.)

(w/h/d) not incl.

projecting parts and

controls

connections (1 set)

8

14181

2

TABLE OF CONTENTS

1. GENERAL

Location of Controls ....................................................... 3

Setting the Clock ............................................................. 3

Installation....................................................................... 4

Connections ..................................................................... 6

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 8

2-2. Front Panel Assy ............................................................. 9

2-3. Mechanism Deck (MG-36SZ10-32)............................... 9

2-4. MAIN board .................................................................... 10

2-5. Heat Sink......................................................................... 10

2-6. Bracket (MD) .................................................................. 11

2-7. Motor (Capstan/Reel) (M901) ........................................ 11

2-8. Head (Play Back) (HP901) ............................................. 12

2-9. Main Belt, Sub Belt (C) .................................................. 13

3. MECHANICAL ADJUSTMENTS ....................... 14

4. ELECTRICAL ADJUSTMENTS

Tape Deck Section .......................................................... 14

Tuner Section .................................................................. 15

5. DIAGRAMS

5-1. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 18

5-2. Printed Wiring Board – MAIN Board – ........................ 19

5-3. Schematic Diagram – MAIN Board (1/2) – .................. 20

5-4. Schematic Diagram – MAIN Board (2/2) – .................. 21

5-5. Printed Wiring Board – CONTROL Board – ................ 22

5-6. Schematic Diagram – CONTROL Board – ................... 23

5-7. IC Pin Function Description ........................................... 25

6. EXPLODED VIEWS

6-1. General Section ............................................................... 27

6-2. Front Panel Section ......................................................... 28

6-3. Mechanism Deck Section (MG-36SZ10-32) ................. 29

7. ELECTRICAL PARTS LIST ............................... 30

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

2

SECTION 1

GENERAL

XR-1100

Ver 1.1 2001.06

This section is extracted from

instruction manual.

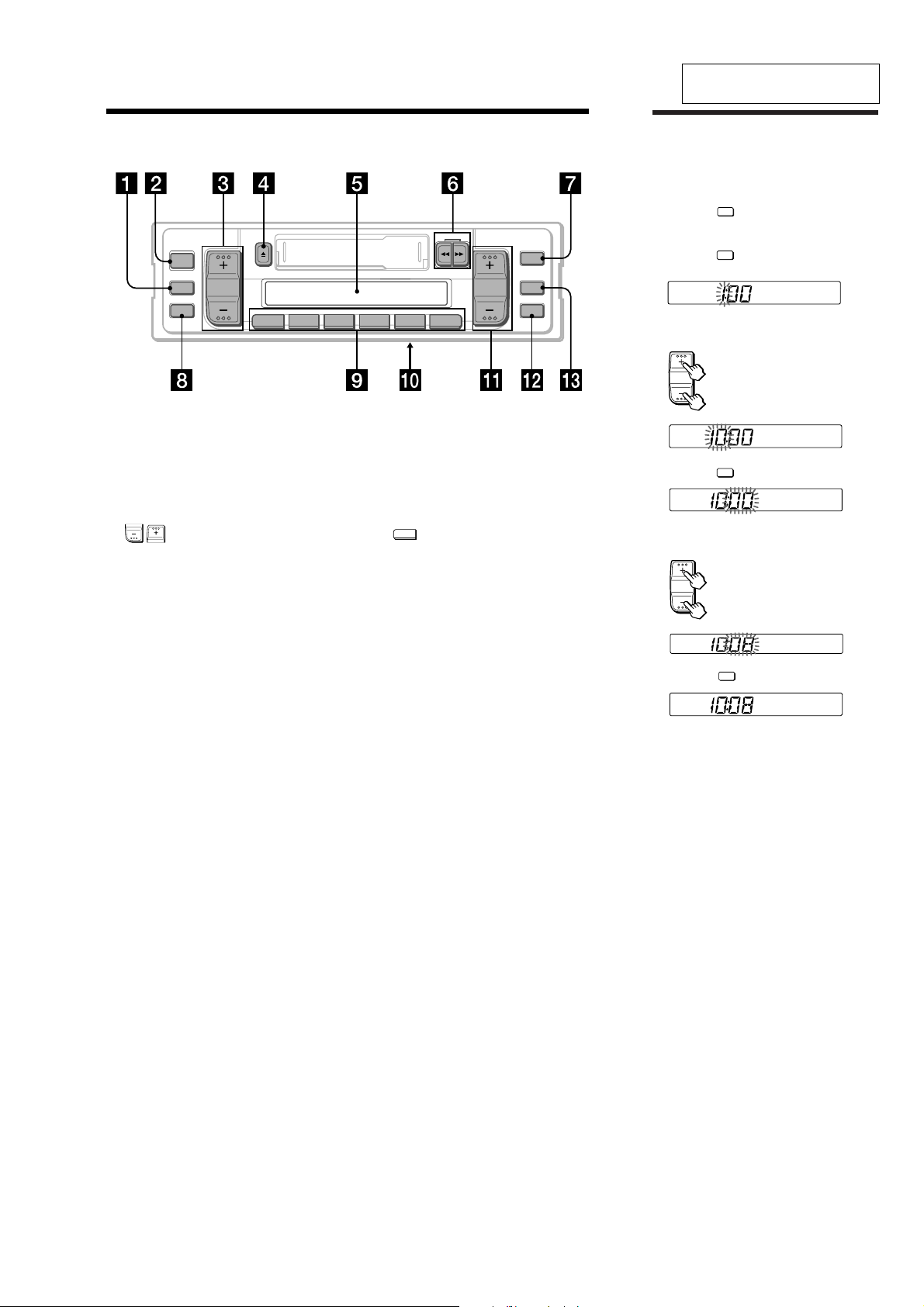

Location of controls

A MEM

TUNER

SOUND

OFF

Refer to the pages for further details.

1 SOUND (control mode select) button

6, 9, 10

2 TUNER/A MEM (radio on • band select/

automatic memory) button 8, 9

3

(volume/bass/treble/balance/

fader control) buttons 6, 9

4 Z (eject) button 7

5 Display window

6 m/M (fast winding)/DIR (tape

transport direction change) buttons 7

ATA

234561

DIR

XR-1100

SEEK

MANU

D-BASS

DSPL

LOCAL

7 D-BASS button 9

8 OFF button

9 During radio reception:

Preset number buttons 9

During tape playback:

ATA

1

(Automatic Tuner Activation)

button 7

q; Frequency select switch (located on the

bottom of the unit) (E and UK models only)

See ”Frequency select switch” in the

Installation/Connections manual.

qa SEEK/MANU button 8

qs LOCAL (local seek) button 8

qd DSPL (display mode change/time set)

button 6

Setting the clock

The clock has a 12-hour digital indication.

For example, setting it to 10:08

1

GB

Display the time.

(Press the

operation.)

2

Press the

seconds.

The hour digit blinks.

Set the hour digits.

3

Press the

The minute digits blink.

Set the minute digits.

4

Press the

DSPL

button during unit

DSPL

button for more than two

to go forward

to go back

SOUND

button momentarily.

to go forward

to go back

DSPL

button momentarily.

The clock activates.

Note

The clock cannot be set unless the power is turned

on. Set the clock after you turn on the radio, or

during tape playback.

5

3

XR-1100

(US and Canadian models)

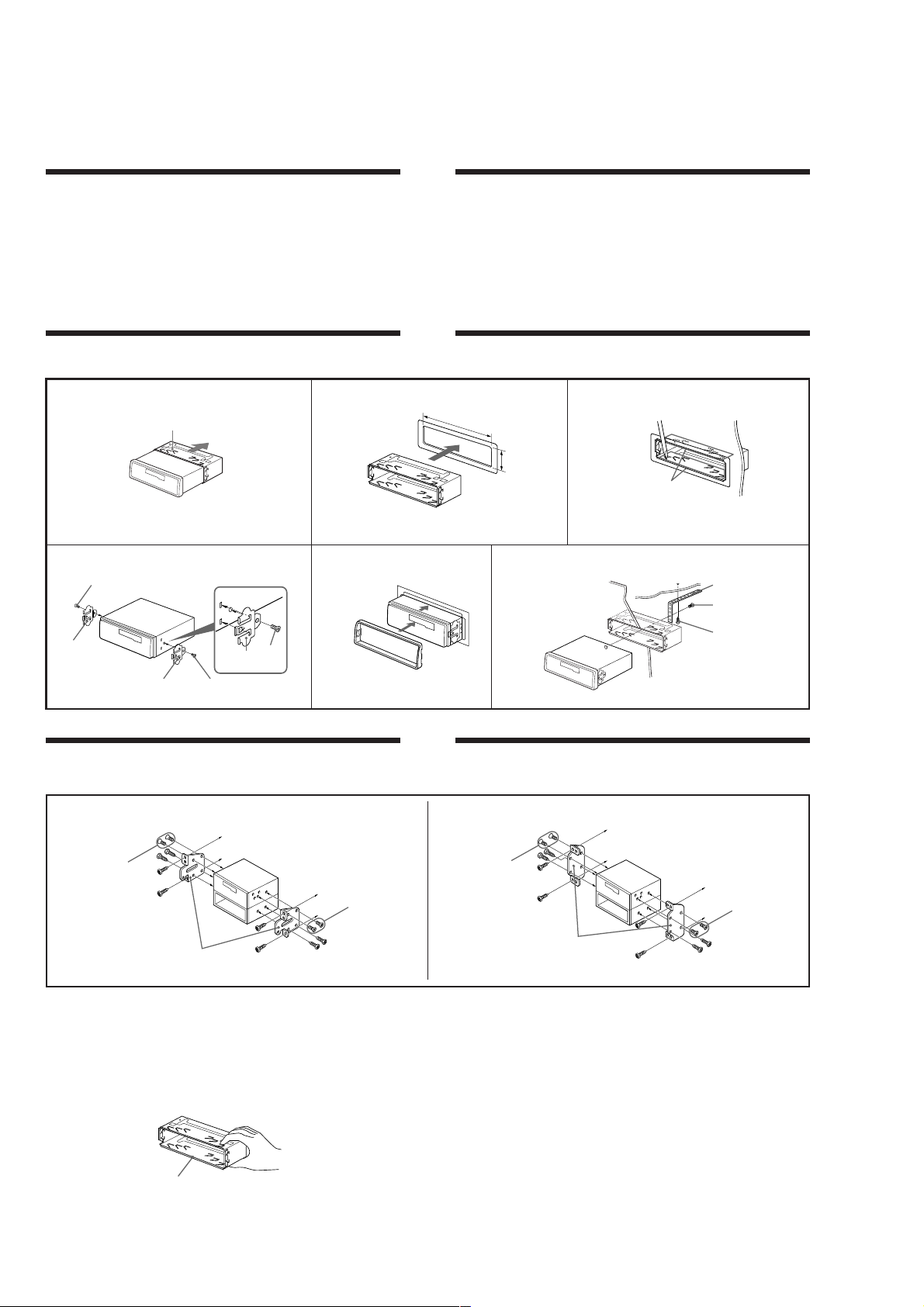

Installation

Precautions

•Choose the installing location carefully so that

the unit will not interfere with driving.

•Avoid installing the unit where it would be

subject to high temperatures, such as direct

sunlight or hot air from the heater, or where it

would be subject to dust, dirt, or excessive

vibration.

•Use only the supplied mounting hardware for

safe and secure installation.

Mounting example

Installing in the dashboard

1

1

4

7

Mounting angle adjustment

Adjust the mounting angle to less than 20°.

Remove the bracket.

Enlevez le support.

2

5

Installation

Précautions

•Choisir soigneusement l’emplacement de

l’installation, pour que l’appareil ne gêne pas

la conduite.

•Eviter d’installer l’appareil dans un endroit

exposé à des températures élevées, comme en

plein soleil ou à proximité d’une bouche d’air

chaud, ou dans un endroit exposé à de la

poussière, de la saleté ou des vibrations

violentes.

•Pour garantir un montage sûr, n’utiliser que le

matériel fourni.

Réglage de l’angle de montage

Ajuster l’inclinaison à un angle inférieur à 20°.

Exemple de montage

Installation dans le tableau de bord

3

182 mm

53 mm

Bend these claws, if necessary.

Courbez les griffes en cas de

1

To support the unit

Pour soutenir l’appareil

Dashboard

Tableau de bord

besoin.

Fire wall

Paroi ignifuge

2

3

7

6

7

7

6

5

Mounting the unit in a Japanese car

This unit may not be installed in some makes of cars. In this case, consult your nearest Sony dealer.

TOYOTA

to dashboard/center console

au tableau de bord/console centrale

7 max. size ø5 × 8 mm

Dimension max.

ø5 × 8 mm

Bracket

Support

Note

To prevent malfunction, install only with the supplied screws 7.

Caution

Cautionary notice for handling the bracket 1.

Handle the bracket carefully to avoid injuring

your fingers.

Attention

Remarque importante pour la manipulation du

support 1.

Manipulez précautionneusement le support

pour éviter de vous blesser aux doigts.

7 max. size ø5 × 8 mm

Dimension max.

ø5 × 8 mm

4

1

Installation de l’appareil dans une voiture japonaise

Cet appareil ne peut pas être installé dans certaines voitures. Consultez, dans ce cas, votre revendeur

Sony.

NISSAN

7 max. size ø5 × 8 mm

Dimension max.

ø5 × 8 mm

Bracket

Support

Remarque

Pour éviter tout mauvais fonctionnement, utilisez uniquement les vis fournies 7 pour le montage.

to dashboard/center console

au tableau de bord/console centrale

max. size ø5 × 8 mm

7

Dimension max.

ø5 × 8 mm

1

4

(E and UK models)

Installation

XR-1100

Ver 1.1 2001.06

Instalación

Precautions

•Choose the installing location carefully so that the unit will not

interfere with the normal driving functions of the driver.

•Avoid installing the unit where it would be subject to high

temperatures, such as from direct sunlight or hot air from the

heater, or where it would be subject to dust, dirt or excessive

vibration.

•Use only the supplied mounting hardware for a safe and secure

installation.

Mounting angle adjustment

Adjust the mounting angle to less than 20°.

Mounting example

Installing in the dashboard

1

1

Remove the bracket.

Retire el soporte.

4

6

Precauciones

•Elija cuidadosamente el lugar de instalación de forma que la

unidad no impida la conducción.

•Evite instalar la unidad donde pueda quedar sometida a altas

temperaturas, como a la luz solar directa o al aire caliente de

calefacción, o a polvo, suciedad, o vibraciones excesivas.

•Para realizar una instalación segura y firme, emplee solamente la

ferretería de montaje suministrada.

Ajuste del ángulo de montaje

Ajuste el ángulo de montaje a menos de 20°.

Ejemplo de montaje

Instalación en el salpicadero

2

1

8

2

m

m

5

3

m

m

1

To support the unit

5

Sujeción de la unidad

3

Bend these claws, if necessary.

Si es necesario, doble estas pestañas.

Dashboard

Salpicadero

Fire wall

Panel cortafuegos

2

5

65

6

5

Mounting the unit in a Japanese car

You may not be able to install this unit in some makes of Japanese

cars. In such a case, consult your Sony dealer.

to dashboard/center console

al salpicadero/consola central

6

max. size

ø 5 × 8 mm

Tamaño máx.

ø 5 × 8 mm

Bracket

Soporte

Note

To prevent malfunction, install only with the supplied screws 6.

4

Montaje de la unidad en un automóvil

japonés

Usted no podrá instalar esta unidad en algunos automóviles

japoneses. En tal caso, consulte a su proveedor Sony.

NISSANTOYOTA

6

max. size

ø 5 × 8 mm

6

max. size

ø 5 × 8 mm

Tamaño máx.

ø 5 × 8 mm

Nota

Para evitar que se produzcan fallos, realice la instalación solamente con

los tornillos suministrados 6.

Tamaño máx.

ø 5 × 8 mm

Bracket

Soporte

1

to dashboard/center console

al salpicadero/consola central

6

max. size

ø 5 × 8 mm

Tamaño máx.

ø 5 × 8 mm

3

5

XR-1100

Ver 1.1 2001.06

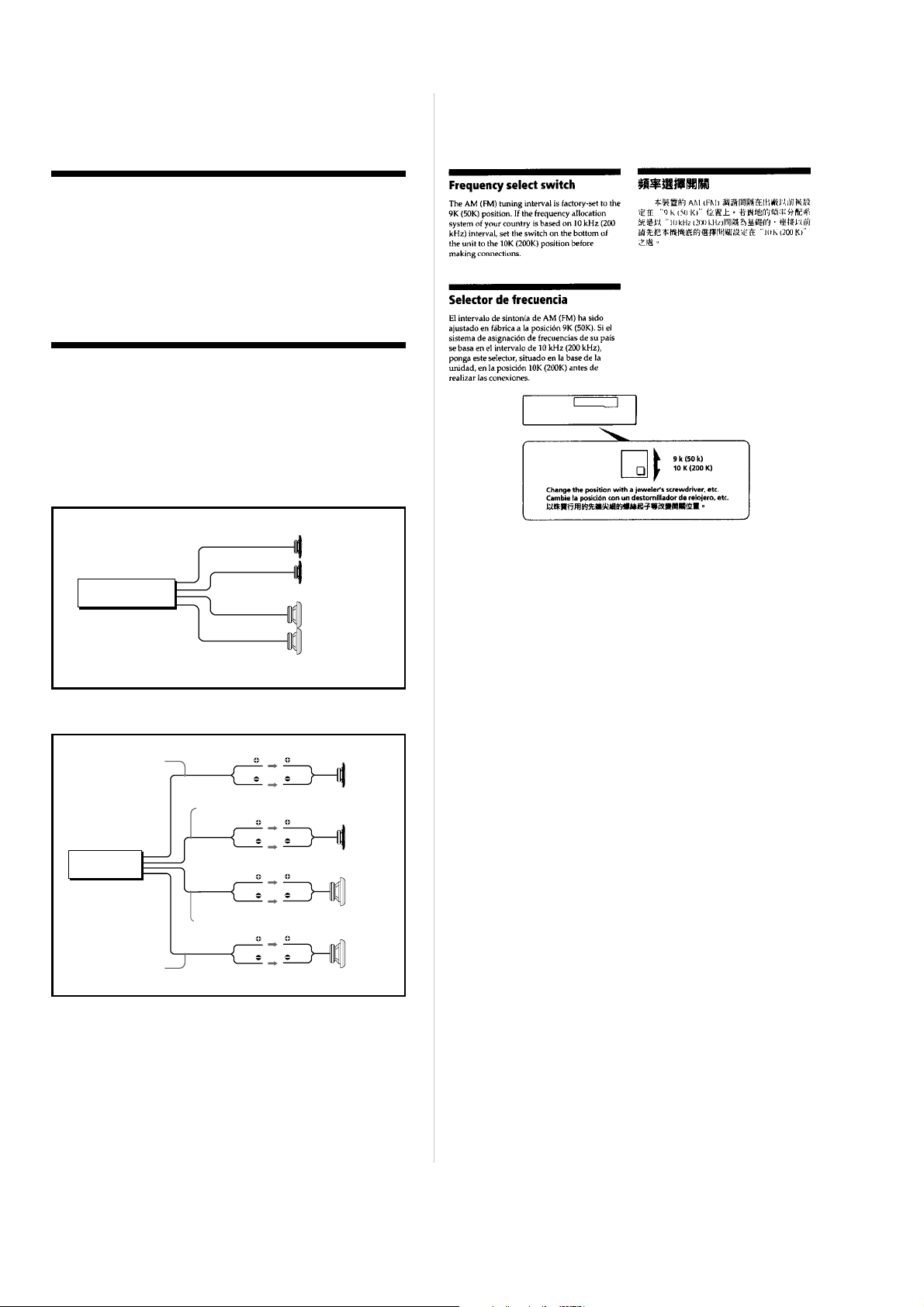

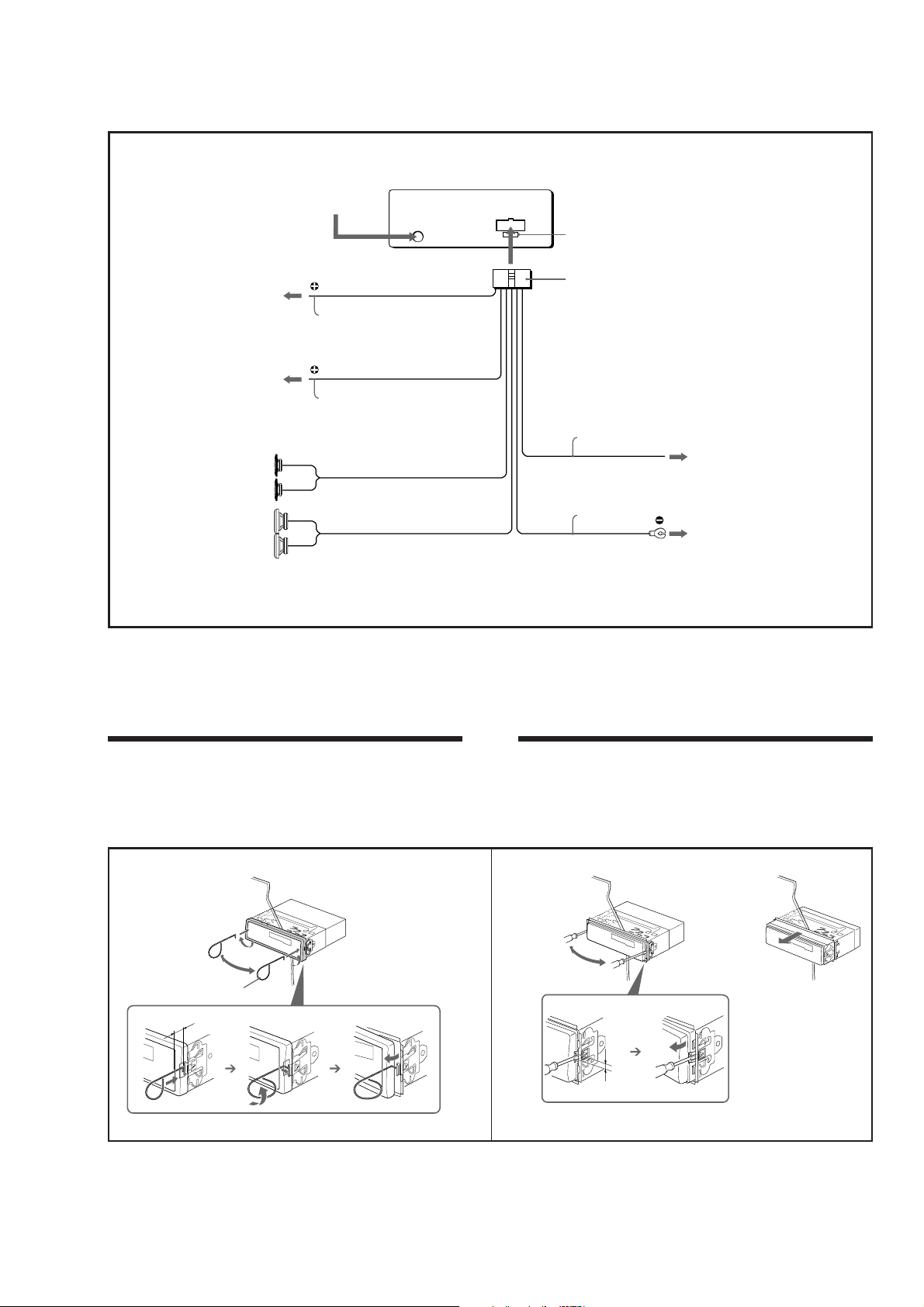

Connections

Caution

•This unit is designed for negative ground 12 V DC operation only.

•Before making connections, disconnect the ground terminal of the car battery to avoid short circuits.

•Connect the yellow and red power input leads only after all other leads have been connected.

•Be sure to connect the red power input lead to the positive 12 V power terminal which is energized

when the ignition key is in the accessory position.

•Run all ground wires to a common ground point.

•Be sure to insulate any loose unconnected wires with electrical tape for safety.

Connexions

Prcautions

•Cet appareil est conçu pour fonctionner uniquement sur courant continu de 12 V avec masse négative.

•Avant d’effectuer les connexions, débrancher la borne de terre de la batterie du véhicule pour éviter

tout court-circuit.

•Brancher les fils d’entrée d’alimentation jaune et rouge seulement après avoir terminé tous les

autres branchements.

•Veiller à ne pas raccorder le fil rouge d’entrée d’alimentation à la borne positive de 12 V qui est

alimentée quand la clé de contact est sur la position accessoires.

•Rassembler tous les fils de terre en un point de masse commun.

•Afin de garantir une sécurité optimale, assurez-vous d’isoler correctement tout câble ou fil

déconnecté ou lâche avec un ruban d’isolation électrique adéquat.

(E and UK models only)

Connection diagram/Schmas de connexion

Front speakers

Haut-parleurs avant

XR-1100

Rear speakers

Haut-parleurs arrière

Speaker connections/Raccordements des haut-parleurs

White

Blanc

Front speakers

Haut-parleurs avant

Rear speakers

Haut-parleurs arriére

XR-1100

E: Striped cord

E: Cordon rayé

Purple

Mauve

Gray

Gris

Green

Vert

Left

Gauche

Right

Droit

Left

Gauche

Right

Droit

Notes on speaker connection

• Use speakers with an impedance of 4 to 8 ohms,

and with adequate power handling capacities.

Otherwise, the speakers may be damaged.

• Do not connect the terminals of the speaker

system to the car chassis, and do not connect the

terminals of the right speaker with those of the

left speaker.

• Do not connect the speakers in parallel.

• Do not connect any active speakers (with built-in

amplifiers) to the speaker terminals of the unit.

Doing so may damage the active speakers.

Therefore, be sure to connect passive speakers to

these terminals.

6

Remarques sur le raccordement des haut-parleurs

• Utilisez des haut-parleurs d’une impédance de 4 à

8 ohms et d’une charge nominale efficace

appropriée. Vous risquez sinon d’endommager les

haut-parleurs.

• Ne raccordez pas les bornes du système de hautparleur au châssis de la voiture et ne raccordez pas

les bornes du haut-parleur droit à celles du hautparleur gauche.

• Ne raccordez pas les haut-parleurs en parallèle.

• Ne raccordez pas de haut-parleurs actifs (dotés

d’un amplificateur intégré) aux bornes de hautparleurs de cet appareil. Vous risquez sinon

d’endommager les haut-parleurs actifs. Veillez par

conséquent à brancher des haut-parleurs passifs

sur ces bornes.

Connection example/Exemple de connexion

Notes on the control leads

•The power antenna control lead (blue) supplies 12V DC when you turn on the unit.

•When your car has a built-in FM/AM antenna in the rear/side glass, it is necessary to connect the power

antenna control lead (blue) or the accessory power input lead (red) to the power terminal of the existing

antenna booster. For details, consult your dealer.

•A power antenna without relay box cannot be used with this unit.

to the power antenna control lead or power

supply lead of antenna booster amplifier

Notes

•It is not necessary to connect this lead if there

is no power antenna or antenna booster, or

with a manually-operated telescopic antenna.

•When your car has a built-in FM/AM antenna

in the rear/side glass, see “Notes on the

control leads.”

vers le fil de commande d’antenne électrique

ou le fil d’entrée d’alimentation de

l’amplificateur d’antenne

Remarques

•Il n’est pas nécessaire de raccorder ce fil s’il n’y

a pas d’antenne électrique ou d’amplificateur

d’antenne ni dans le cas d’une antenne

télescopique à commande manuelle.

•Si votre voiture est équipée d’une antenne

FM/AM intégrée dans la vitre arrière/latérale,

voir “Remarques sur les fils de commande”.

to the +12 V power terminal which is

energized in the accessory position of the

ignition key switch.

Be sure to connect the black earth lead to

it first.

à la borne +12 V qui est alimentée quand

la clé de contact est sur la position

accessoires.

Raccordez d‘abord le fil de masse noir.

to the +12 V power terminal which is

energized at all times.

Be sure to connect the black earth lead

first.

à la borne +12 V qui est alimentée en

permanence.

Raccordez d‘abord le fil de masse noir.

to a metal point of the car.

First connect the black earth lead, then connect

the yellow and red power input leads.

à un point métallique de la voiture.

Branchez d‘abord le fil de masse noir et,

ensuite, les fils d‘entrée d‘alimentation jaune et

rouge.

Remarques sur les fils de commande

•Le fil de commande de l’antenne électrique (bleu) fournit une alimentation de + 12 V CC lorsque vous mettez

l’appareil sous tension.

•Si votre voiture est équipée d’une antenne FM/AM intégrée dans la vitre arrière/latérale, vous devez

raccorder le fil de commande d’antenne électrique (bleu) ou le fil d’entrée d’alimentation d’accessoire

(rouge) à la borne d’alimentation de l’amplificateur d’antenne existant. Pour plus de détails, consultez votre

revendeur.

•Une antenne électrique sans boîtier de relais ne peut être utilisée avec cet appareil.

8

ANT REM

Max. supply current 0.1 A

Alimentation: 0,1 A max.

from a car antenna

de l‘antenne de la voiture

Fuse (10 A)

Fusible (10 A)

Blue

Bleu

Red

Rouge

Yellow

Jaune

Black

Noir

Rear speakers

Haut-parleurs arrière

Front speakers

Haut-parleurs avant

XR-1100

Removing the unit

1

Insert the supplied tool 9 between the unit and the frame, and rotate 90° to release the

hidden mounting spring. Repeat on the opposite side and remove the frame.

2

Insert a flathead screwdriver between the bracket and mounting spring. Gently pry the

spring toward the unit while pulling the unit out a little. Repeat on the opposite side and

remove the unit.

Retrait de l’appareil

1

Insérez l’outil 9 fourni entre l’appareil et le cadre et faites-le pivoter de 90º de manière à

dégager le ressort de montage dissimulé. Répétez l’opération de l’autre côté et retirez le

cadre.

2

Insérez un tournevis à lame plate entre le support et le ressort de montage. Exercez un léger

mouvement de levier en direction de l’appareil tout en tirant un peu sur l’appareil. Répétez

l’opération de l’autre côté et retirez l’appareil.

1

10 mm ( / in./po.)

13

32

90º

2

9

4 mm ( / in./po.)

3

16

XR-1100

7

XR-1100

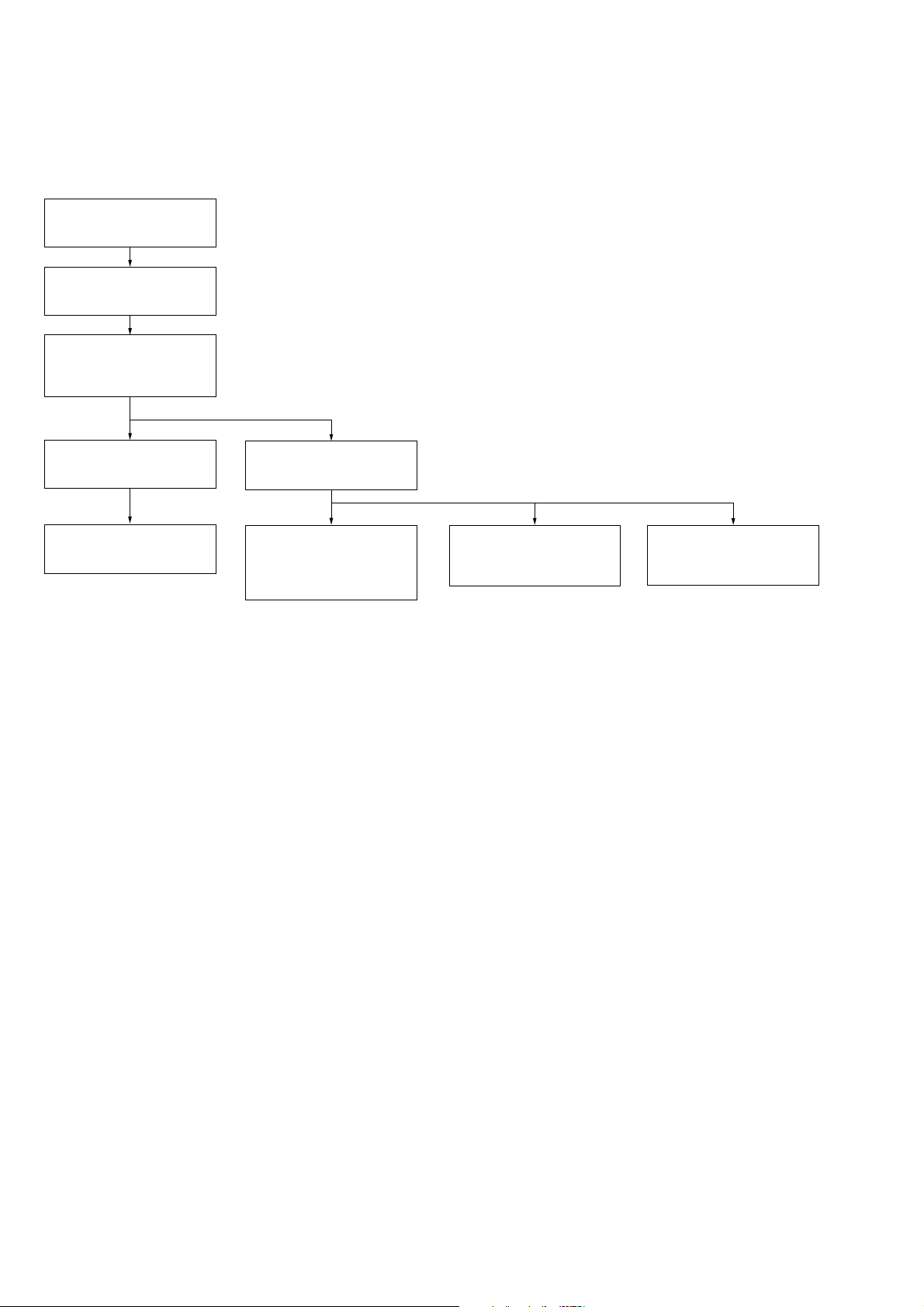

• This set can be disassembled in the order shown below.

2-1. DISASSEMBLY FLOW

SET

2-2. FRONT PANEL ASSY

(Page 9)

2-3. MECHANISM DECK

(MG-36SZ10-32)

(Page 9)

SECTION 2

DISASSEMBLY

2-4. MAIN BOARD

(Page 10)

2-5. HEAT SINK

(Page 10)

2-6. BRACKET (MD)

(Page 11)

2-7. MOTOR

(CAPSTAN/REEL)

(M901)

(Page 11)

2-8. HEAD (PLAY BACK)

(HP901)

(Page 12)

2-9. MAIN BELT,

SUB BELT (C)

(Page 13)

8

Note: Follow the disassembly procedure in the numerical order given.

k

)

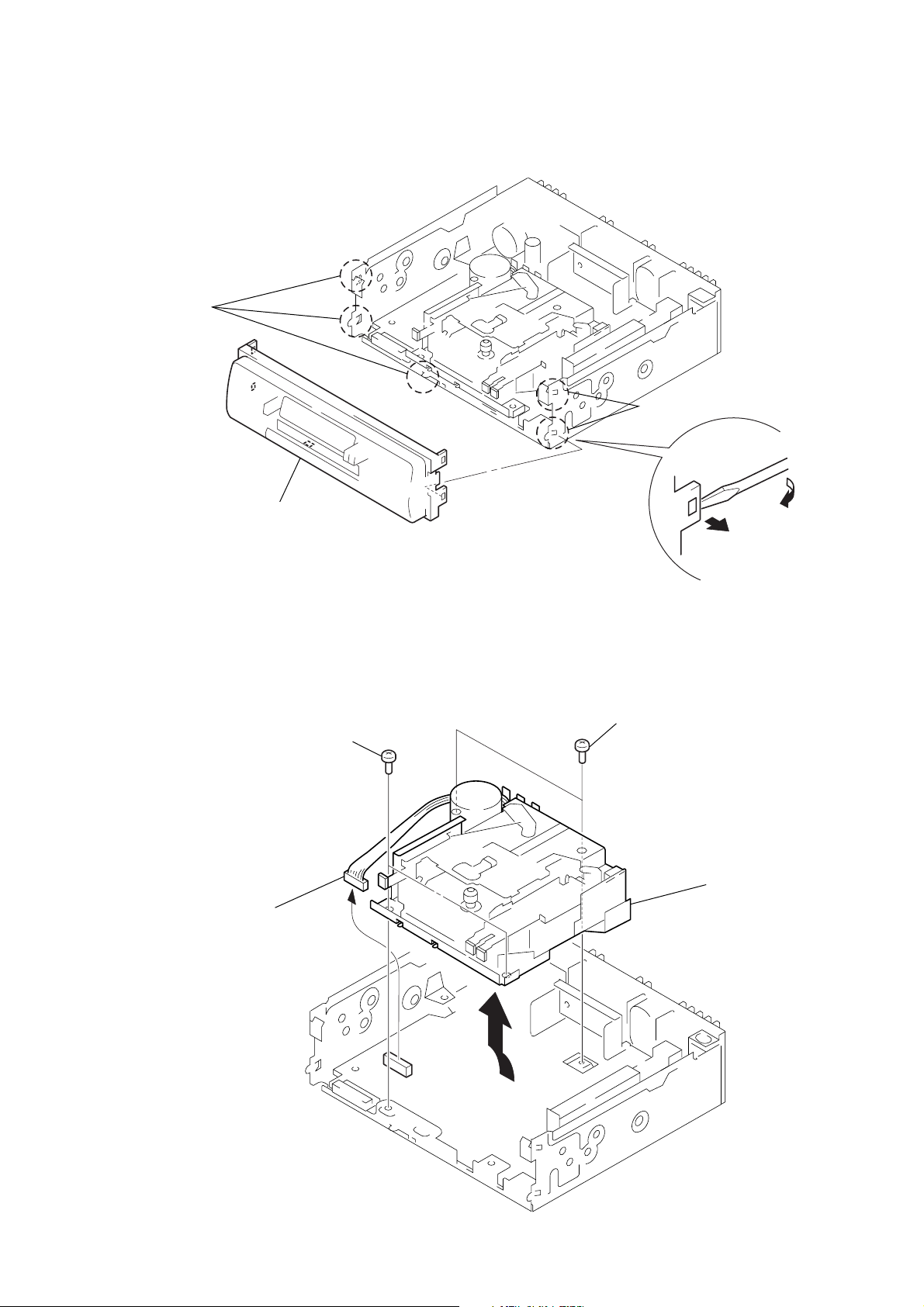

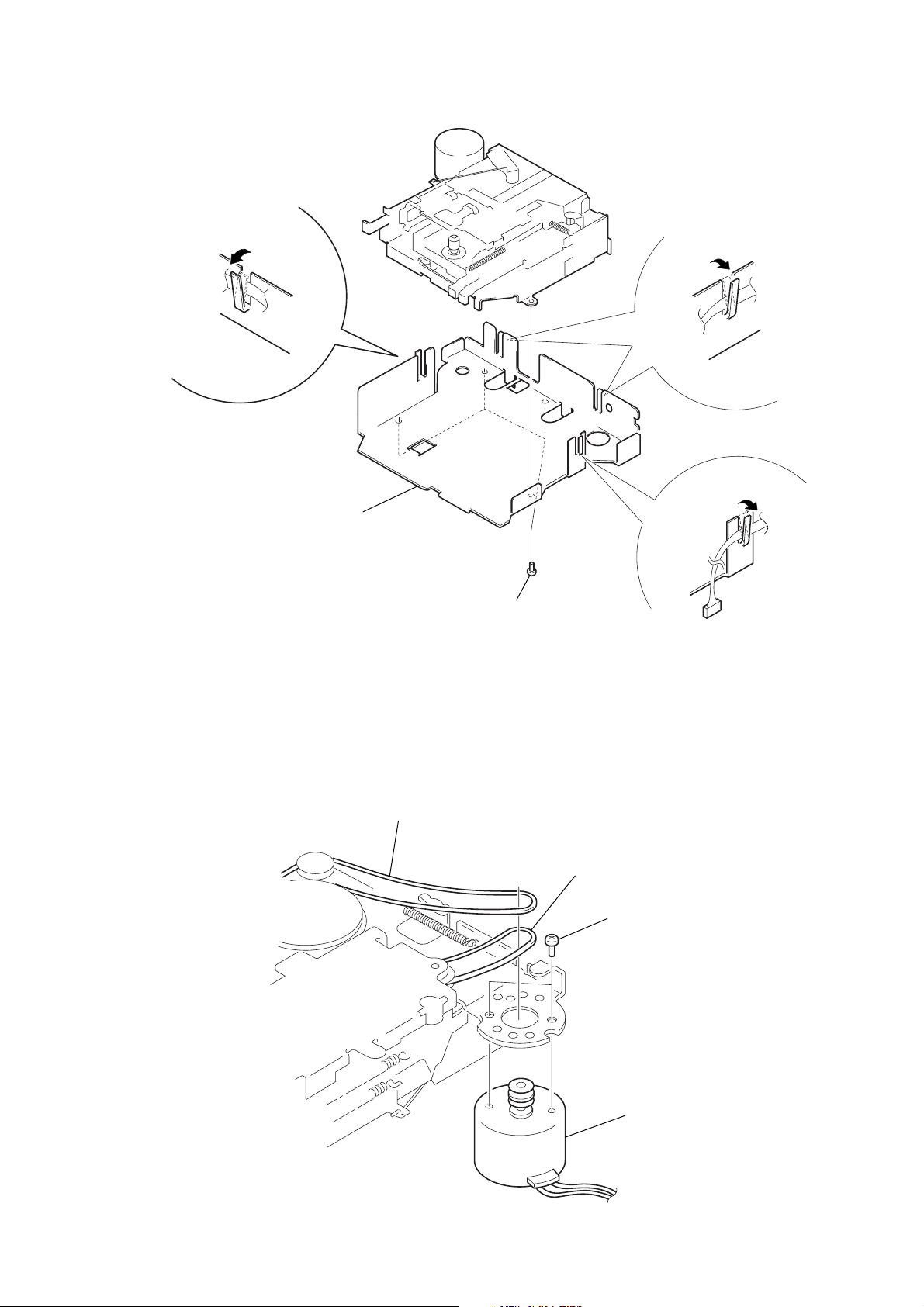

2-2. FRONT PANEL ASSY

1

three claws

1

two claws

XR-1100

2

front panel assy

2-3. MECHANISM DECK (MG-36SZ10-32)

2 two screws

(PTT2.6 × 6)

1 connector

(CN901)

2 two screws

(PTT2.6 × 6)

3 mechanism dec

(MG-36SZ10-32

9

XR-1100

)

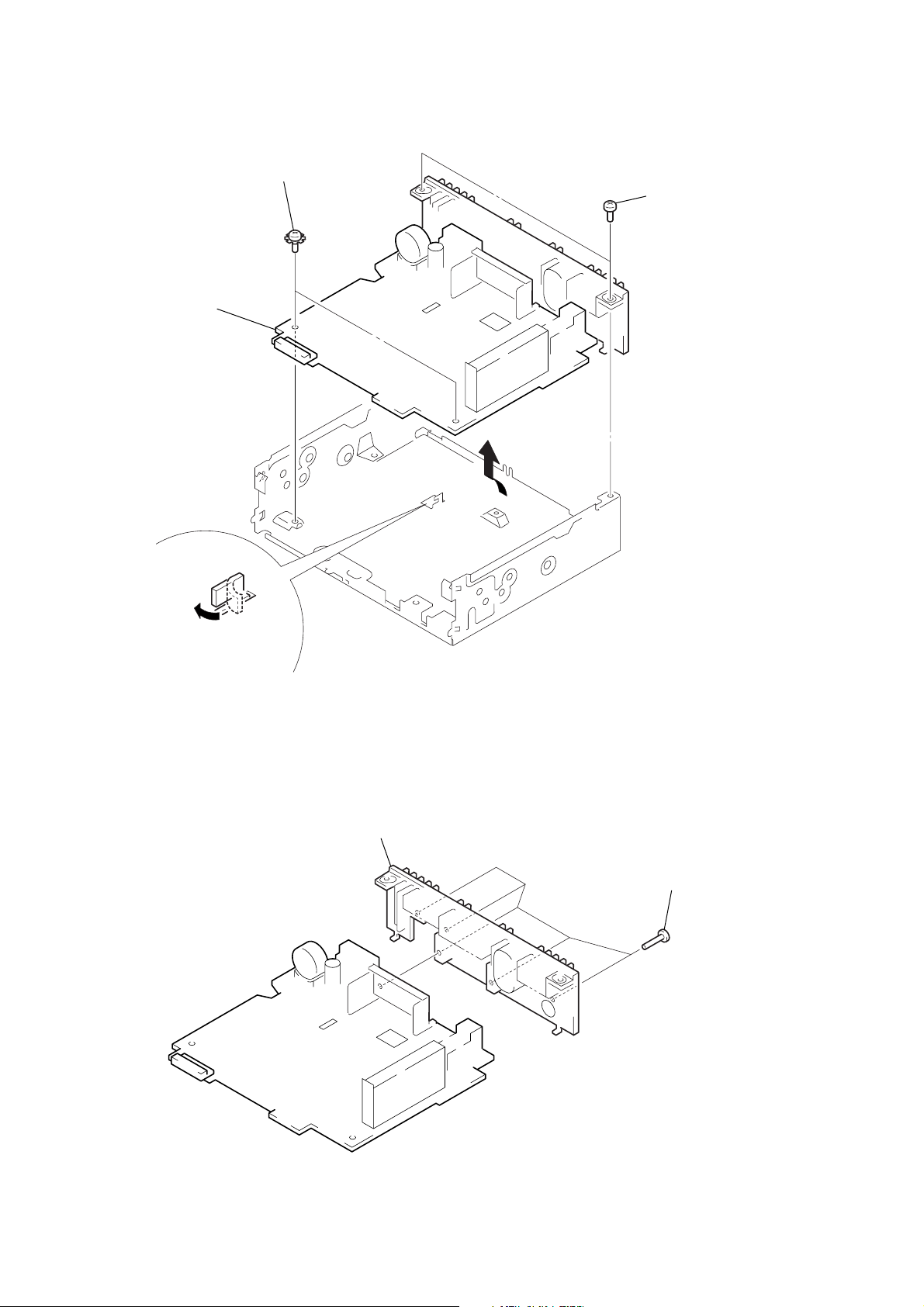

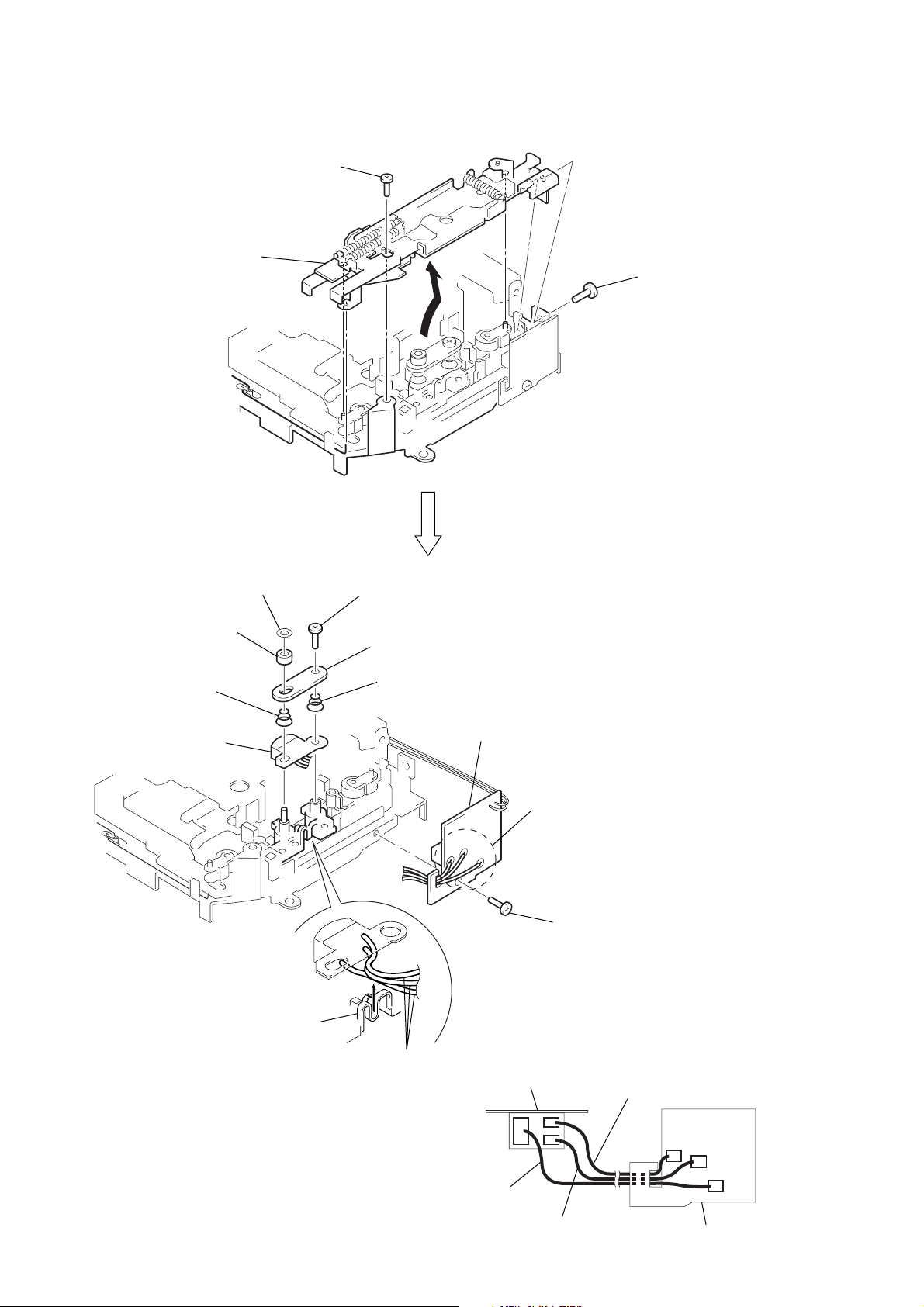

2-4. MAIN BOARD

4

main board

3

two screws

(ground point)

2

two screws

(PTT2.6 × 6

2-5. HEAT SINK

1

claw

2

heat sink

1

five screws

(PTT2.6

×

10)

10

2-6. BRACKET (MD)

XR-1100

1 claw

1 claw

3 bracket (MD)

1 claw

2 four screws

(B2.6 × 4)

2-7. MOTOR (CAPSTAN/REEL) (M901)

2

main belt

3

sub belt (C)

1

two screws

(P2

×

2.5)

4

motor (capstan/reel)

(M901)

Note :When installing motor,

adjust the screw and

screw hole of motor.

11

XR-1100

2-8. HEAD (PLAY BACK) (HP901)

2

screw

(PTT2

3

FF/REV lever section

×

4)

1

screw

(P2 × 3)

8

HP roller (A)

qs

adjuster arm SPG (B)

qf

head (play back) (HP901)

qd

Remove three head lead

wires from the

adjuster arm blue.

7

PSW (reel) B

adjuster arm blue

9

screw

×

4)

(P2

0

SPG support plate

qa

adjuster arm SPG (A)

head lead wire

6

slide SW board

4

Remove the three solders

of head lead wires.

5

screw

×

3)

(PTP2

• HEAD LEAD WIRE COLOR INDICATION

ON HEAD (HP901) AND SLIDE SW BOARD.

head (HP901)

yellow lead wire

12

black lead wire

red lead wire

slide SW board

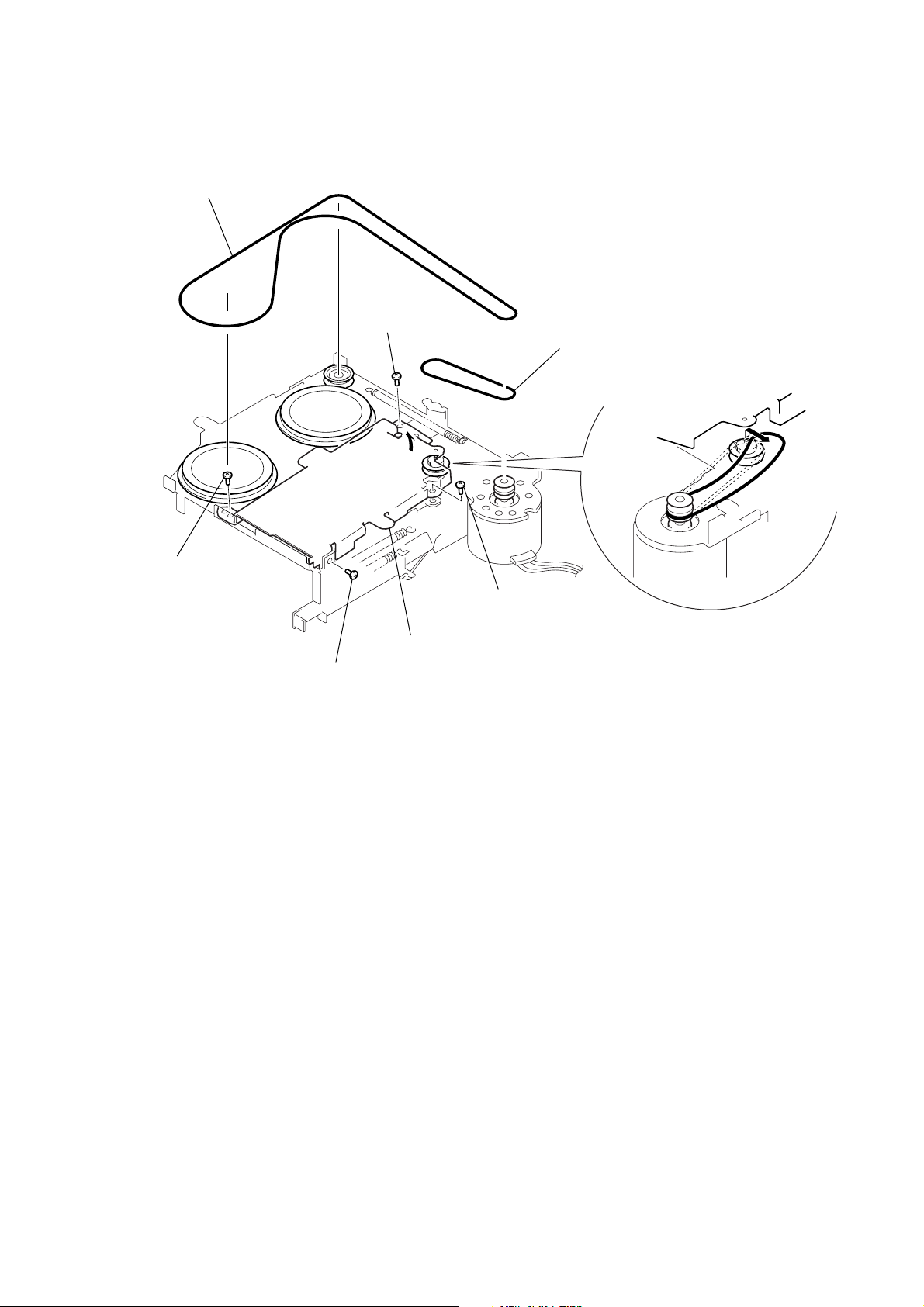

2-9. MAIN BELT, SUB BELT (C)

1

main belt

2

screw

(PTP2

A

XR-1100

×

3)

4

sub belt (c)

2

screw

(PTP2

×

3)

2

screw

(PTP2

×

3)

3

2

screw

(PTP2

Lift up the bottom BKT (TS)

in the direction of arrow

×

3)

(as far as the belt can be removed).

A

13

XR-1100

e

SECTION 3

MECHANICAL ADJUSTMENTS

SECTION 4

ELECTRICAL ADJUSTMENTS

1. Clean the follo wing parts with a denatured-alcohol-moistened

swab:

playback head pinch roller

rubber belt capstan

idler

2. Demagnetize the playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the power supply

voltage (14.4 V) unless otherwise noted.

Note: With this set, it is not necessary to apply suitable locking

compound to the parts after the azimuth adjustment.

• Tor que Measurement

Mode Torque Meter Meter Reading

Forward CQ-102C (25 – 55 g•cm)

Forward

Back Tension

Reverse CQ-102RC (25 – 55 g•cm)

Reverse

Back Tension

FF, REW CQ-201B (50 – 150 g•cm)

CQ-102C (1.5 – 4 g•cm)

CQ-102RC (1.5 – 4 g•cm)

2.46 – 5.39 mN•m

(0.35 – 0.76 oz•inch)

0.15 – 0.39 mN•m

(0.02 – 0.06 oz•inch)

2.46 – 5.39 mN•m

(0.35 – 0.76 oz•inch)

0.15– 0.39 mN•m

(0.02 – 0.06 oz•inch)

4.91 – 14.70 mN•m

(0.69 – 2.08 oz•inch)

• Tape T ension Measurement

Mode Tension Meter Meter Reading

Forward CQ-403A

Reverse CQ-403R

more than 60 g

(more than 2.12 oz)

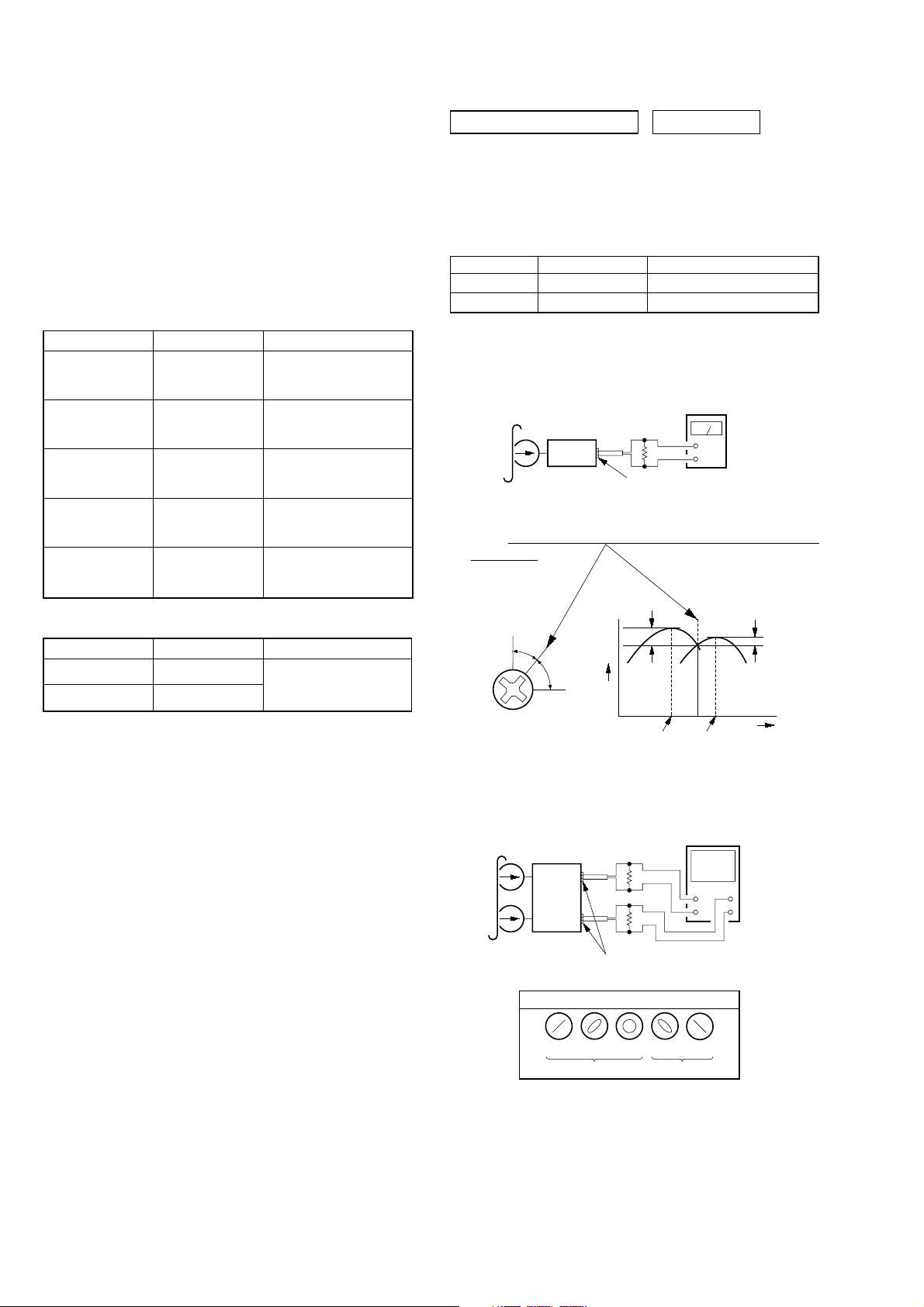

TAPE DECK SECTION 0 dB= 0.775 V

1. The adjustments should be performed in the order given in

this service manual.

2. The adjustments should be performed for both L-CH and

R-CH.

Test T ape

Type Signal Used for

P-4-A063 6.3 kHz, –10 dB head azimuth adjustment

WS-48A 3 kHz, 0 dB tape speed adjustment

PB Head Azimuth Adjustment

Procedure:

1. Put the set into the FWD PB mode.

test tape

P-4-A063

(6.3 kHz, –10 dB)

set

4 Ω

speaker out terminal

2. Turn the screw and check the output peak value. Adjust the

screw so tha t the peak value in channels L and R coincides

within 3 dB.

output

level

within

3 dB

L-CH

peak

L-CH

peak

screw

position

R-CH

peak

level

meter

+

–

R-CH

peak

within

3 dB

angl

3. Check the phase in the FWD PB mode.

test tape

P-4-A063

(6.3 kHz, –10 dB)

L-CH

set

R-CH

in phase

4 Ω

4 Ω

speaker out terminal

Screen pattern

45 °

90 °

good wrong

oscilloscope

V

135 ° 180 °

H

+

+

–

–

4. Repeat the above adjustment for the REV PB mode.

5. Check that output level difference between FWD PB mode

and REV PB mode is within 4 dB.

14

Loading...

Loading...