Sony XPER-800 Service manual

XP-ER800/ER800N/ER800R

SERVICE MANUAL

Ver 1.3 2003. 12

Photo : XP-ER800

Model Name Using Similar Mechanism D-EJ985

CD Mechanism Type CDM-3325ER

Optical Pick-up Name DAX-25E

SPECIFICATIONS

System

Compact disc digital audio system

Laser diode properties

Material: GaAlAs

Wavelength: λ = 780 nm

Emission duration: Continuous

Laser output: Less than 44.6 µW (This output is the value

measured at a distance of 200 mm from the objective lens

surface on the optical pick-up block with 7 mm aperture.)

Frequency range

10 kHz step:

US, CND Models

TV: 2 - 13 ch

WB (weather band): 1 - 7 ch

FM: 87.5 - 108.0 MHz

AM: 530 - 1 710 kHz

E13, AUS, HK, TW Models

FM: 87.5 - 108.0 MHz

AM: 530 - 1 710 kHz

9 kHz step:

US, CND Models

TV: 2 - 13 ch

WB (weather band): 1 - 7 ch

FM: 87.5 - 108.0 MHz

AM: 531 - 1 602 kHz

AEP Model

FM: 87.5 - 108.0 MHz

AM: 531 - 1 602 kHz

E13, AUS, HK, TW Models

FM: 87.5 - 108.0 MHz

AM: 531 - 1 602 kHz

Power requirements

• Two LR6 (size AA) batteries (not supplied): 3 V DC

• AC power adaptor (DC IN 4.5 V jack):

• Two Ni-MH rechargeable batteries (size AA): 1.2V × 2 DC

Dimensions (w/h/d) (without projecting

parts and controls)

Approx. 136.0 × 20.4 × 139.0 mm (5 3⁄

Mass (excluding accessories)

Approx. 200 g (7 oz)

Operating temperature

5°C – 35°C (41°F – 95°F)

Design and specifications are subject to change without

notice.

US, CND, TW Models

120 V, 60 Hz

AEP Model

220 - 230 V, 50 Hz

E13 Model

220 - 230 V, 50/60 Hz

AUS Model

240 V, 50/60 Hz

HK Model

230 V, 50 Hz

US Model

XP-ER800/ER800N

Canadian Model

XP-ER800

AEP Model

XP-ER800/ER800R

UK Model

XP-ER800R

E Model

XP-ER800/ER800R

Australian Model

XP-ER800

• Abbreviation

AUS : Australian model

CND: Canadian model

E13 : 220 – 230 V AC area in E model

HK : Hong Kong model

TW : Taiwan model

× 13⁄16 × 5 1⁄2 in.)

8

9-877-194-04

2003L16-1

© 2003.12

PORTABLE CD PLAYER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

XP-ER800/ER800N/ER800R

d

e

Ver 1.1 2003.06

TABLE OF CONTENTS

1. SERVICING NOTE ·························································· 3

2. GENERAL ·········································································· 4

3. DISASSEMBLY

3-1. Cabinet (REAR) Section ··············································· 6

3-2. Cabinet (Front) Sub Section ·········································· 7

3-3. Upper Lid ······································································8

3-4. CD Mechanism Deck (CDM-3325ER) ························· 9

3-5. MAIN Board ······························································· 10

3-6. Motor (turn table) Assy (M902),

Optical Pick-Up Assy ·················································· 11

4. ELECTRICAL ADJUSTMENT ·································· 12

5. DIAGRAMS······································································ 17

5-1. Block Diagram – Main Section – ······························· 18

5-2. Block Diagram – TUNER (4Band) Section – ············ 19

5-3. Block Diagram – TUNER (2Band) Section – ············· 20

5-4. Printed Wiring Board

– MAIN Board (4Band)(Side A) –······························ 21

5-5. Printed Wiring Board

– MAIN Board (4Band)(Side B) – ······························ 22

5-6. Printed Wiring Board

– MAIN Board (2Band)(Side A) –······························ 23

5-7. Printed Wiring Board

– MAIN Board (2Band)(Side B) – ······························ 24

5-8. Schematic Diagram – MAIN Board (1/6) – ················ 25

5-9. Schematic Diagram – MAIN Board (2/6) – ················ 26

5-10.Schematic Diagram – MAIN Board (3/6) – ················ 27

5-11.Schematic Diagram – MAIN Board (4/6) – ················ 28

5-12.Schematic Diagram – MAIN Board (5/6) – ················ 29

5-13.Schematic Diagram – MAIN Board (6A/6) – ············· 30

5-14.Schematic Diagram – MAIN Board (6B/6) – ·············31

5-15.IC Block Diagram ·······················································32

5-16.IC Pin Function Description········································ 35

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

On AC power adaptor

•

Use only the commercially-available AC power a

output is 4.5 V DC, 500 mA. Do not use any oth

It may cause a malfunction.

Polarity of the plug

6. EXPLODED VIEWS ······················································ 37

7. ELECTRICAL PARTS LIST······································· 40

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

2

SECTION 1

SERVICING NOTE

XP-ER800/ER800N/ER800R

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

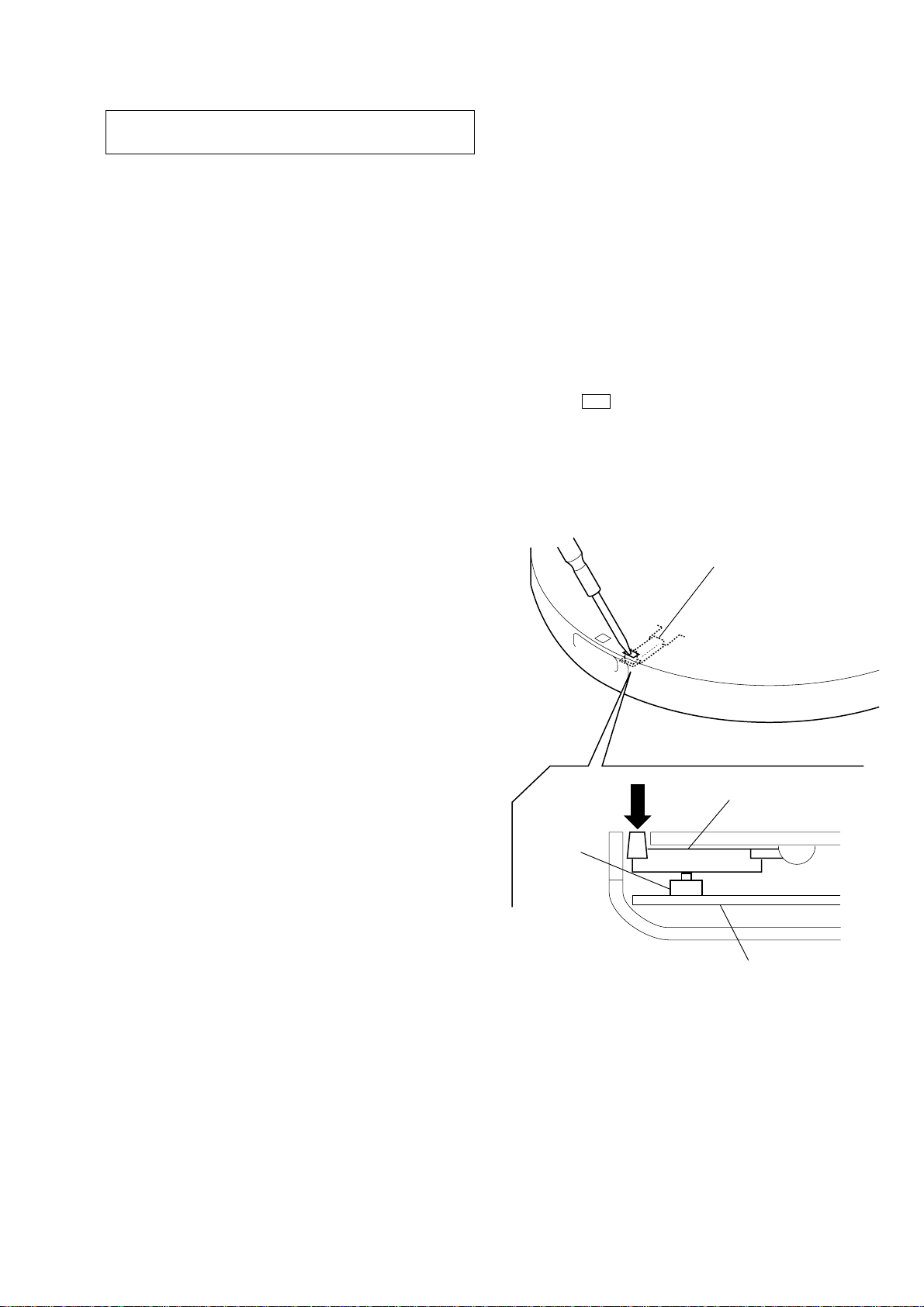

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

BEFORE REPLACING THE OPTICAL PICK-UP BLOCK

Please be sure to check thoroughly the parameters as par the “Optical

Pick-Up Block Checking Procedures” (Part No.: 9-960-027-11)

issued separately before replacing the optical pick-up block.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

During normal operation of the equipment, emission of the laser

diode is prohibited unless the upper lid is closed while turning ON

the S302. (push switch type)

The following checking method for the laser diode is operable.

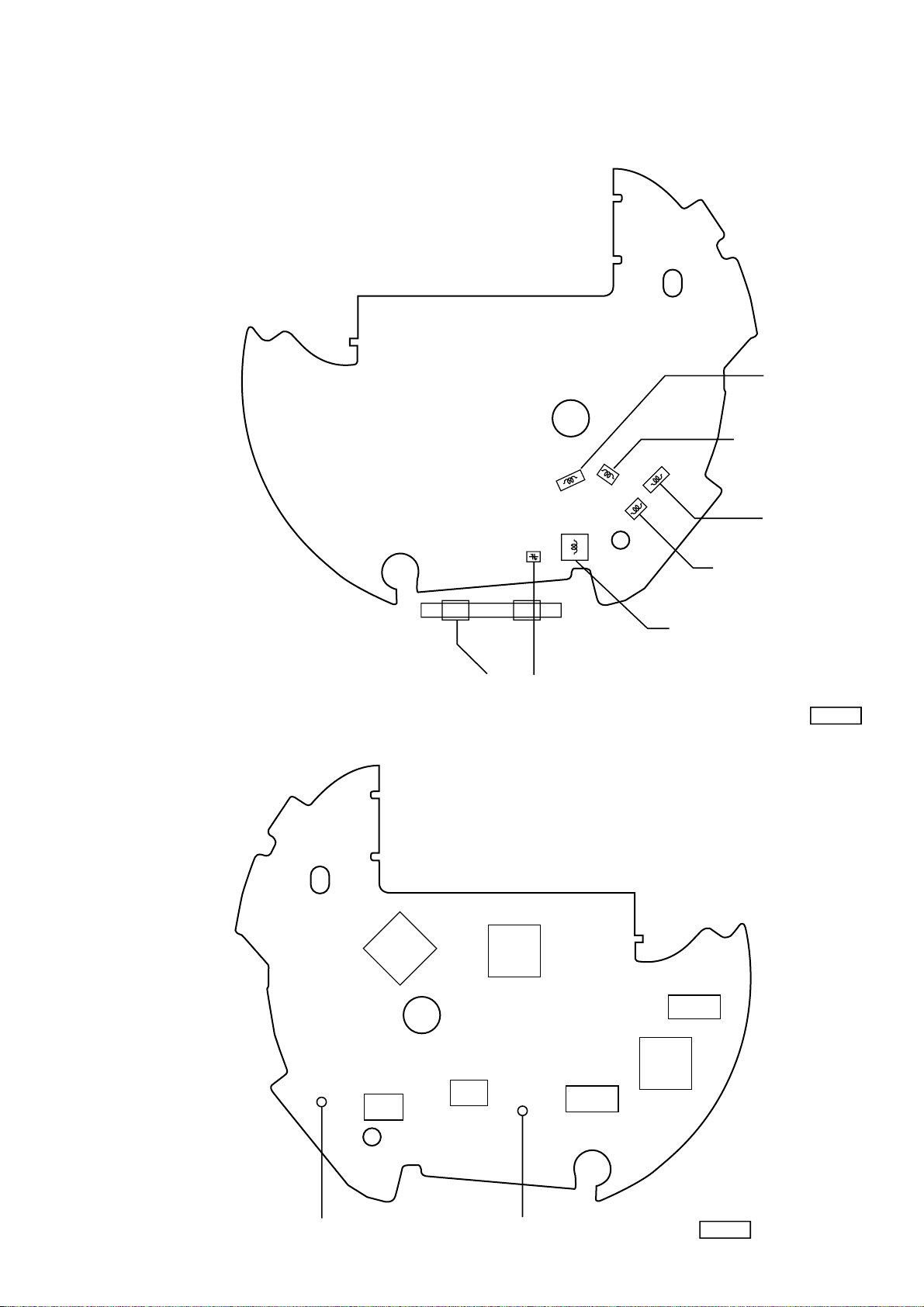

• Method:

Emission of the laser diode is visually checked.

1. Open the upper lid.

2. With a disc not set, turn on the S302 with a screwdr iver ha ving a

thin tip as shown in Fig.1.

3. Press the u button.

4. Observing the objective lens, check that the laser diode emits

light.

When the laser diode does not emit light, automatic power control

circuit or optical pickup is faulty.

In this operation, the objective lens will move up and down 4

times along with inward motion for the focus search.

detection lever

detection lever

S302

Fig. 1 Method to push the S302

MAIN board

3

XP-ER800/ER800N/ER800R

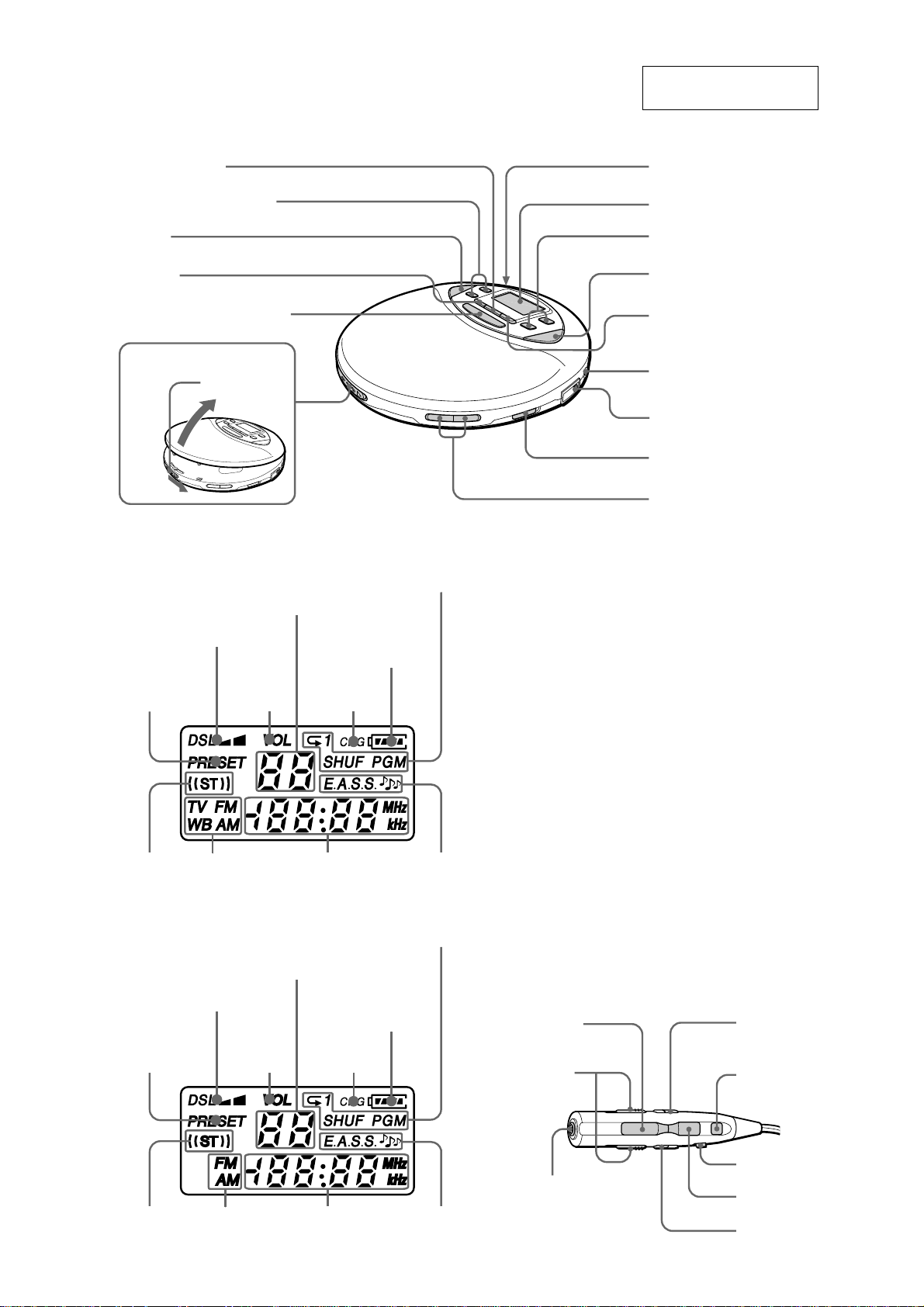

CD player (front)

SECTION 2

GENERAL

This section is extracted

from instruction manual.

1ENTER/DISPLAY

2PRESET CALL UP/DOWN

3BAND

4SOUND

567 s(stop)/OFF/CHARGE

A

*The button has a tactile dot.

Display on CD player

(4 Band)

OPEN

Track number/PRESET number

Strap holes

Display

8r/t

SKIP/SEARCH

9ca*

0MODE

DC IN 4.5 V

(external power

input) jack

\ (headphones)

jack

!HOLD

@VOL +*/–

Play mode

(2 Band)

PRESET

PRESET

Sound mode

VOL CHG

BandST

Track number/PRESET number

Sound mode

Playing time/

Frequency

VOL CHG

Remaining

battery power

Remaining

battery power

E•A•S•S

Play mode

Remote control (XP-ER800R only)Display on CD player

9ca 8tF SKIP

@VOL

3BAND

!HOLD

Earphones jack

BandST

Playing time/

Frequency

E•A•S•S

56s

8rB SKIP

4

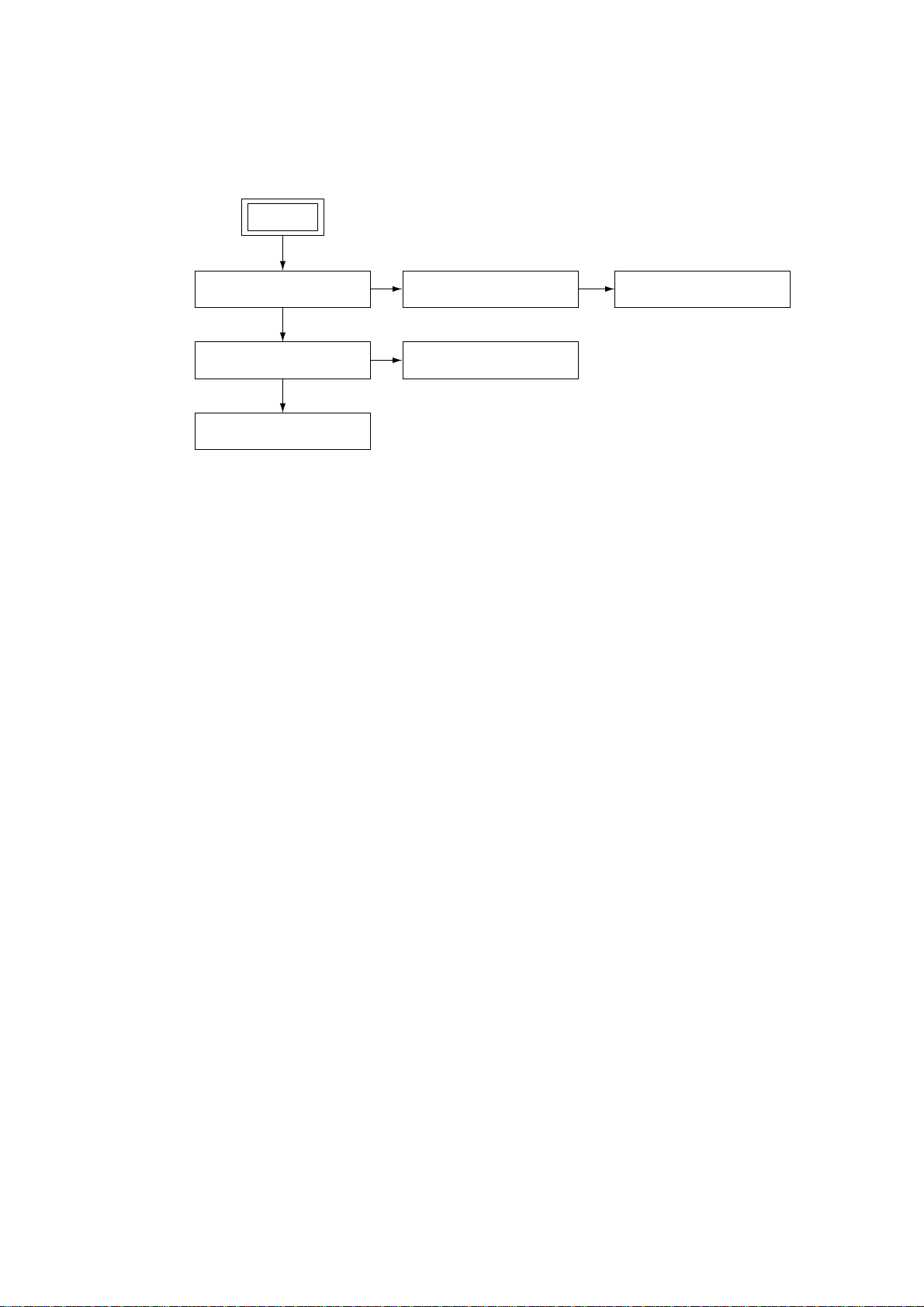

DISASSEMBLY

Note : Disassemble the unit in the order as shown below.

SET

XP-ER800/ER800N/ER800R

SECTION 3

CABINET (REAR) SECTION

CD mechanism deck

(CDM-3325ER)

Motor (turn table) assy (M902),

optical pick-up assy

CABINET (FRONT)

SUB SECTION

MAIN BOARD

UPPER LID

5

XP-ER800/ER800N/ER800R

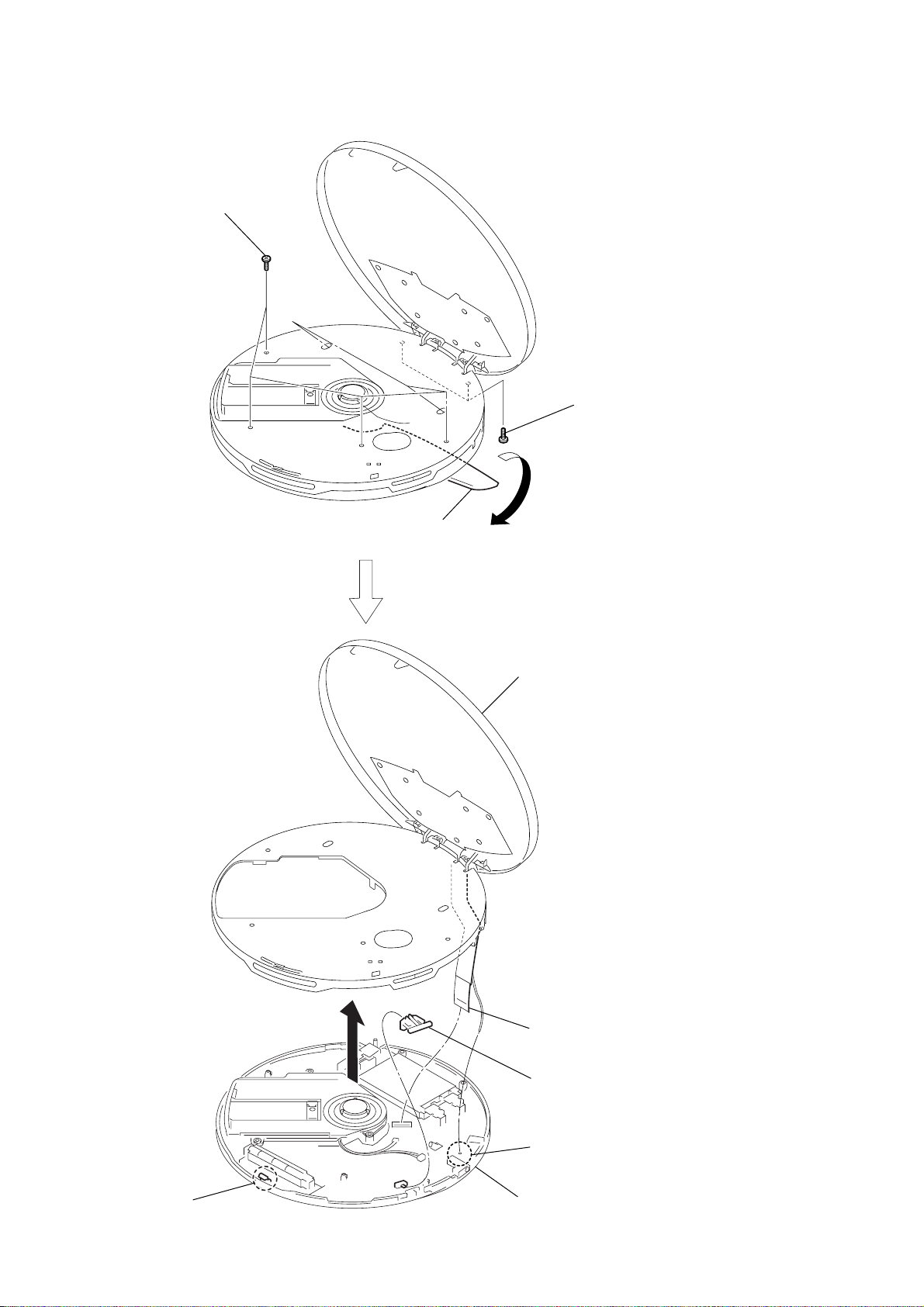

Note : Follow the disassembly procedure in the numerical order given.

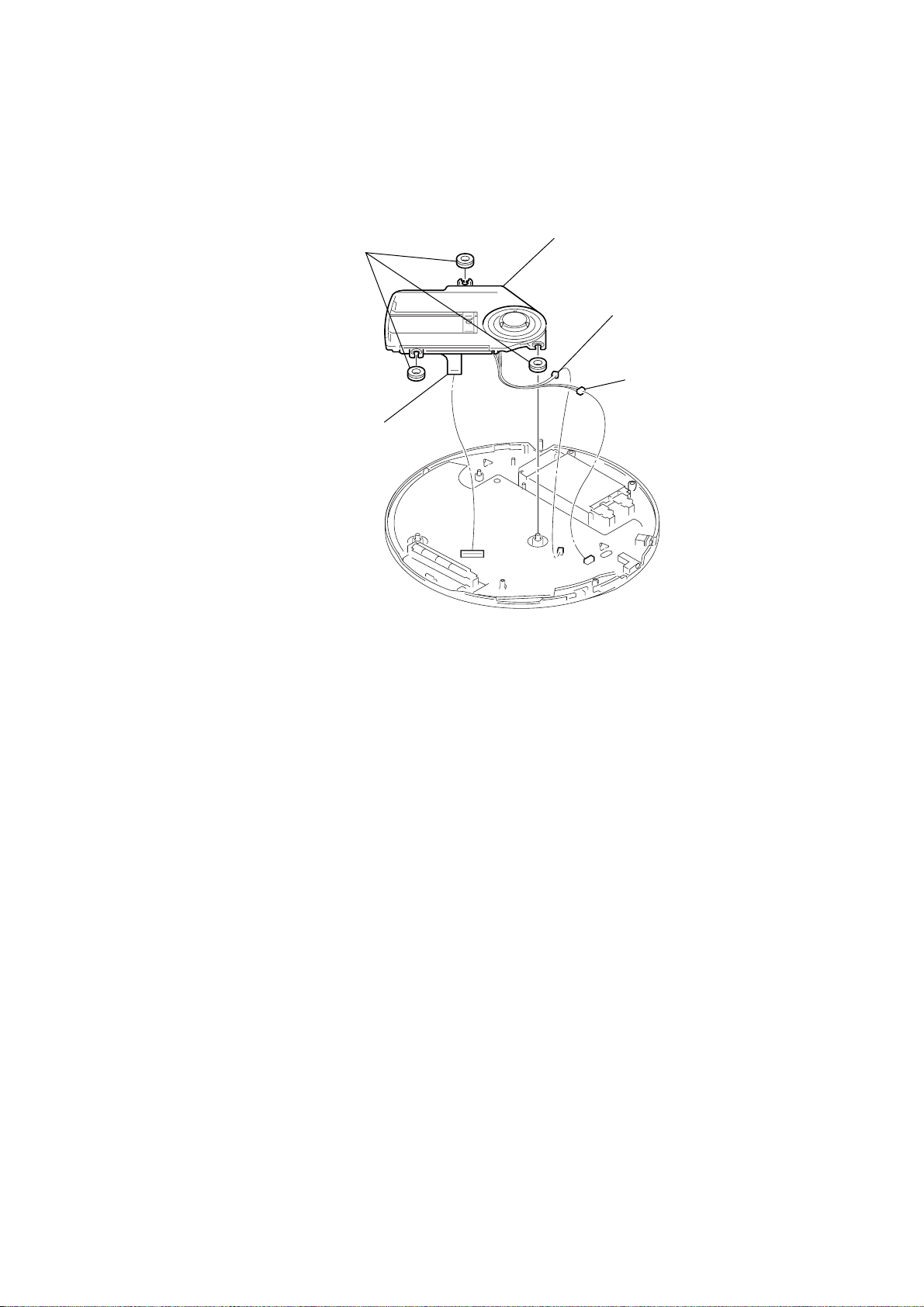

3-1. Cabinet (Rear) Section

3

six screws (B2)

2

two screws (B2)

1

Open the battery lid.

5

Remove the cabinet (front) assy,

upper lid assy in the direction of

the arrow.

7

switch unit assy (28P)

(CN301)

6

hold knob

8

remove the

soldering

4

claw

9

cabinet (rear) assy

6

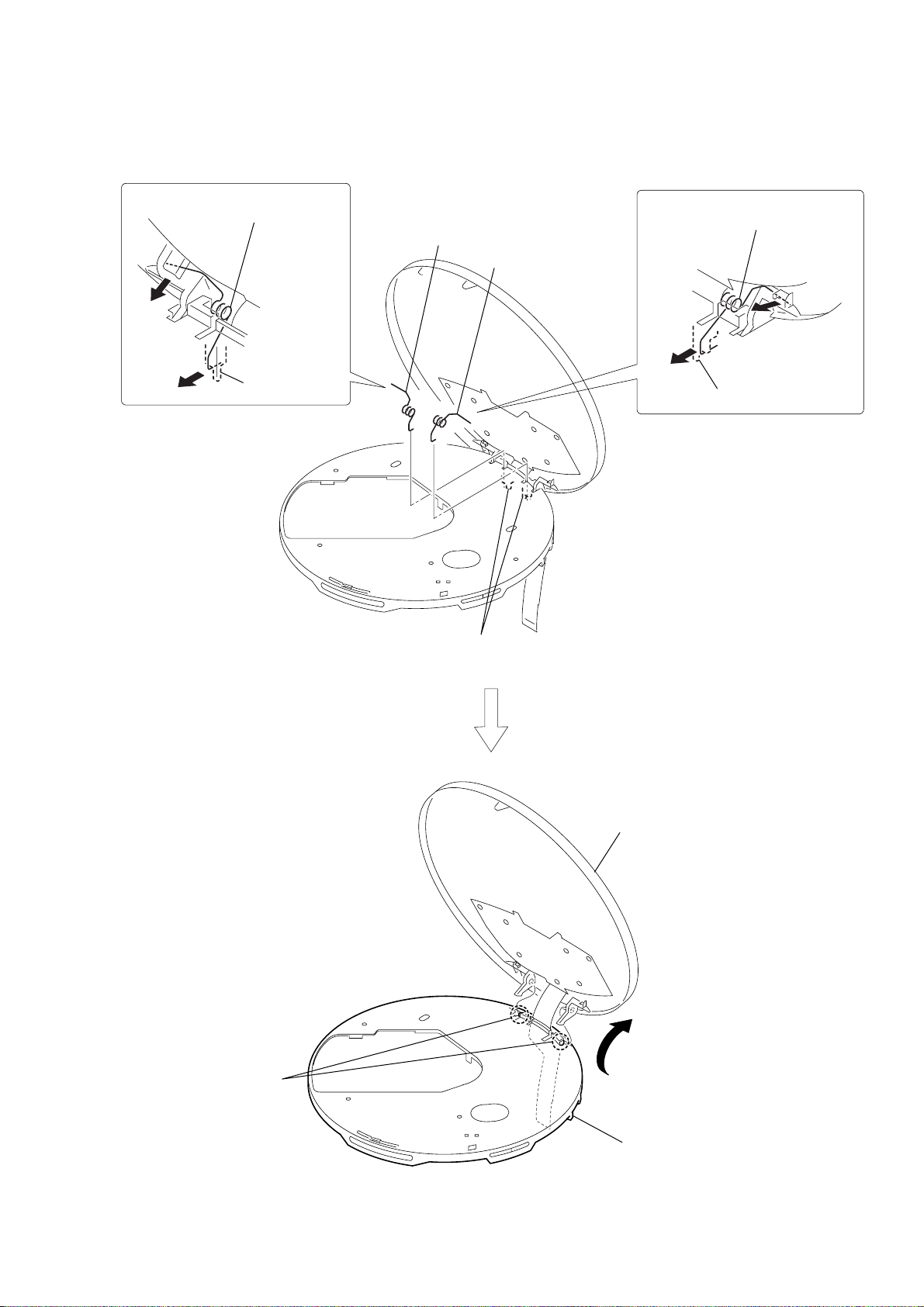

3-2. Cabinet (Front) Sub Section

1

Remove the full open left spring in

the direction of the arrow.

2

full open left spring

4

full open right spring

XP-ER800/ER800N/ER800R

3

Remove the full open right spring in

the direction of the arrow.

upper cabinet

upper cabinet

upper cabinet

6

Remove the upper lid assy in

the direction of the arrow.

5

two claws

7

cabinet (front) sub assy

7

XP-ER800/ER800N/ER800R

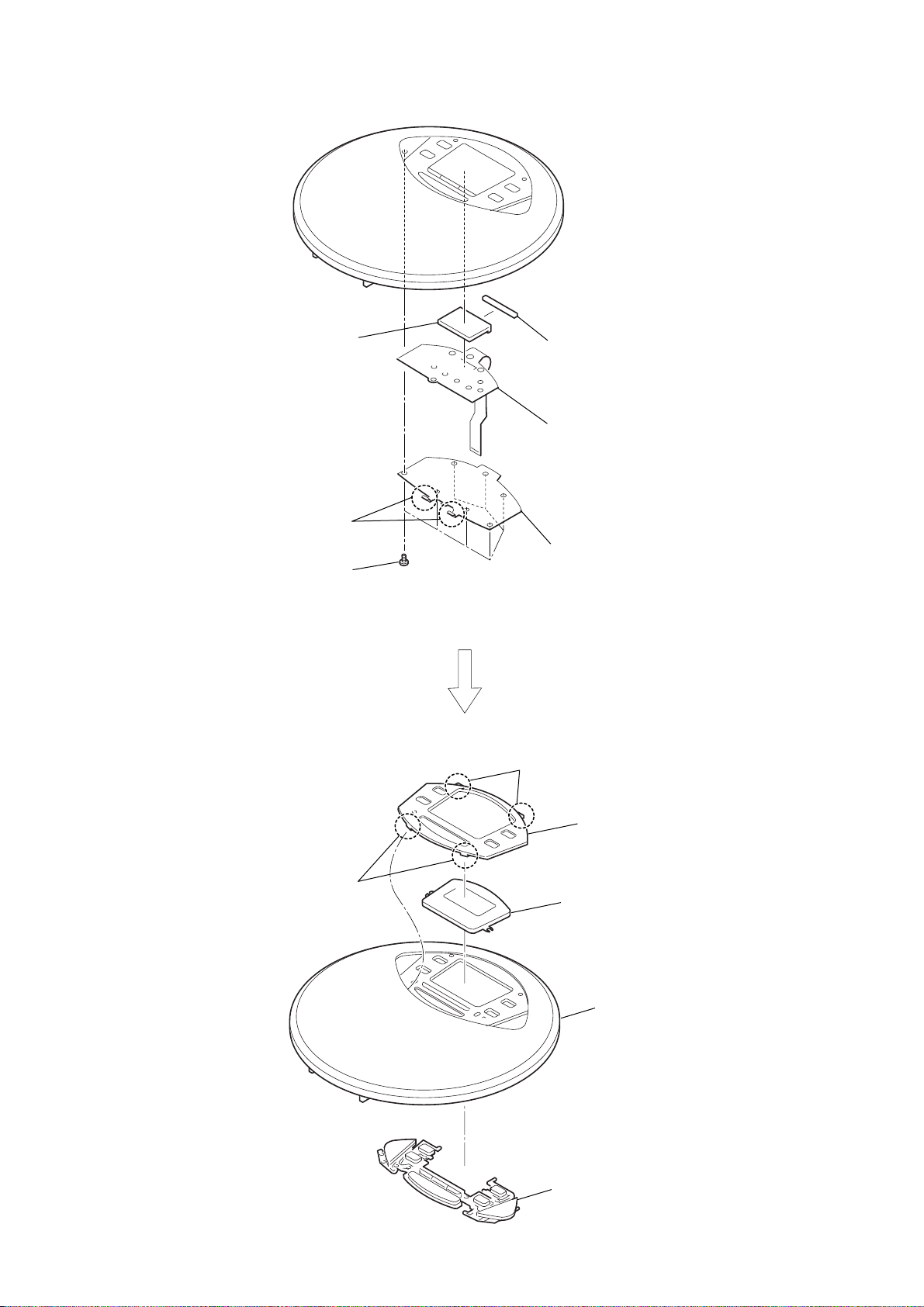

l

3-3. Upper Lid

5

liquid crystal display panel

6

LCD rubber

4

switch unit assy

2

two claws

1

seven screws

8

two claws

3

lid cover

9

two claws

0

display pane

qa

display window

qs

upper lid

7

control button

8

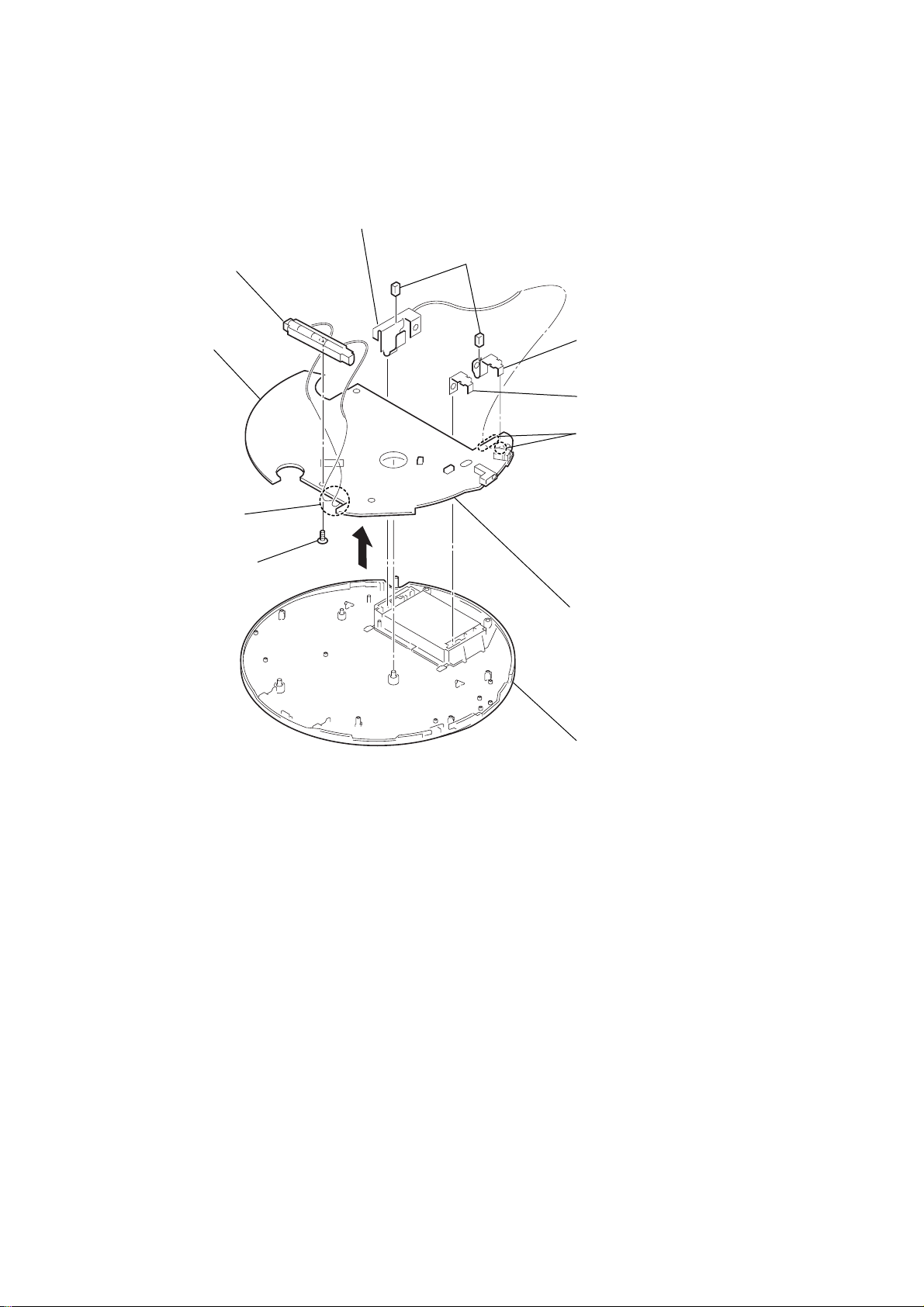

3-4. CD Mechanism Deck (CDM-3325ER)

P)

4

three insulators

3

flexible board

(15P) (CN501)

XP-ER800/ER800N/ER800R

5

CD mechanism deck

(CDM-3325ER )

1

connector (2P)

(CN202)

2

connector (4

(CN201)

9

XP-ER800/ER800N/ER800R

3-5. MAIN Board

9

bar-ant holder

qa

MAIN board

6

battery terminal board (relay)

1

two comtact cushions

4

battery terminal

−

board (

5

battery terminal

board (

3

Remove soldering from

the three points.

)

+

)

7

Remove soldering

from the two points.

8

tapping screw

(B1.7 )

2

Remove the MAIN board

in the direction of the arrow.

0

lower cabinet

10

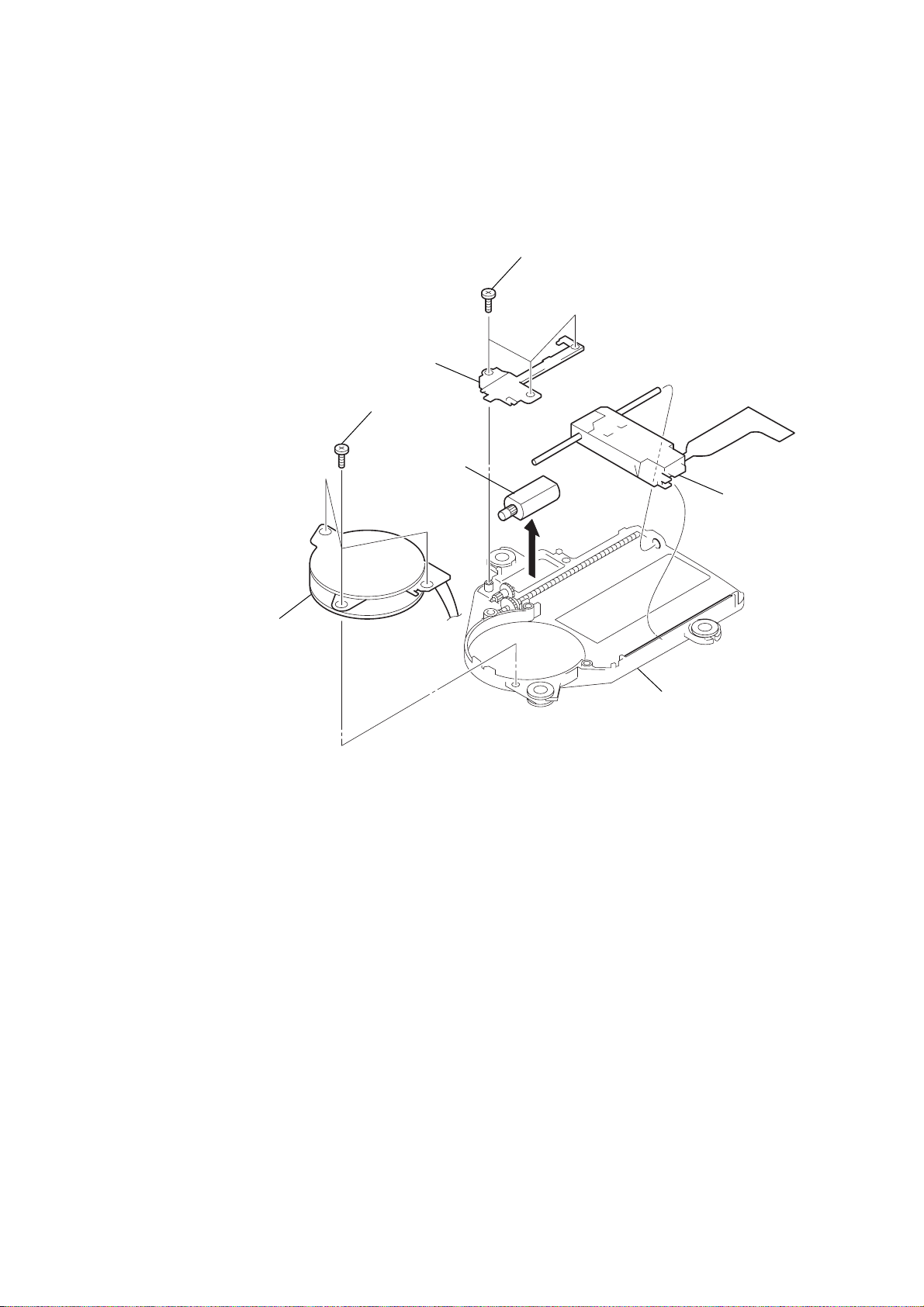

3-6. Motor (Turn Table) Assy (M902), Optical Pick-Up Assy

1

(B1.7x4)

2

gear cover

5

three screws

(B1.7x4)

3

motor assy

(sled) (M901)

three screws

XP-ER800/ER800N/ER800R

4

optical pick-up

(DAX-25E)

6

motor (Turn table )

assy (M902)

chassis

11

XP-ER800/ER800N/ER800R

)

)

SECTION 4

ELECTRICAL ADJUSTMENT

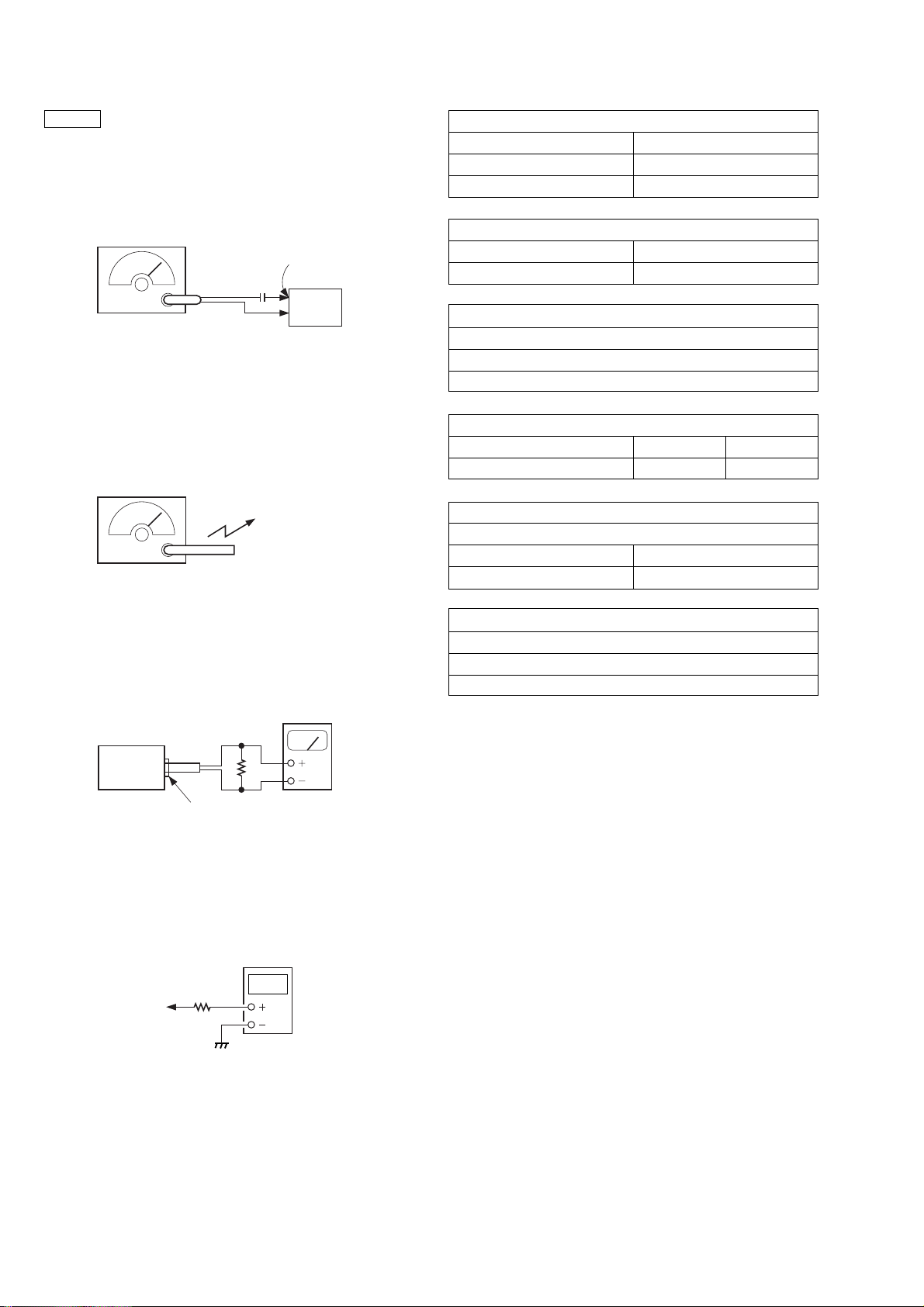

TUNER SECTION 0 dB = 1 µV

4 band

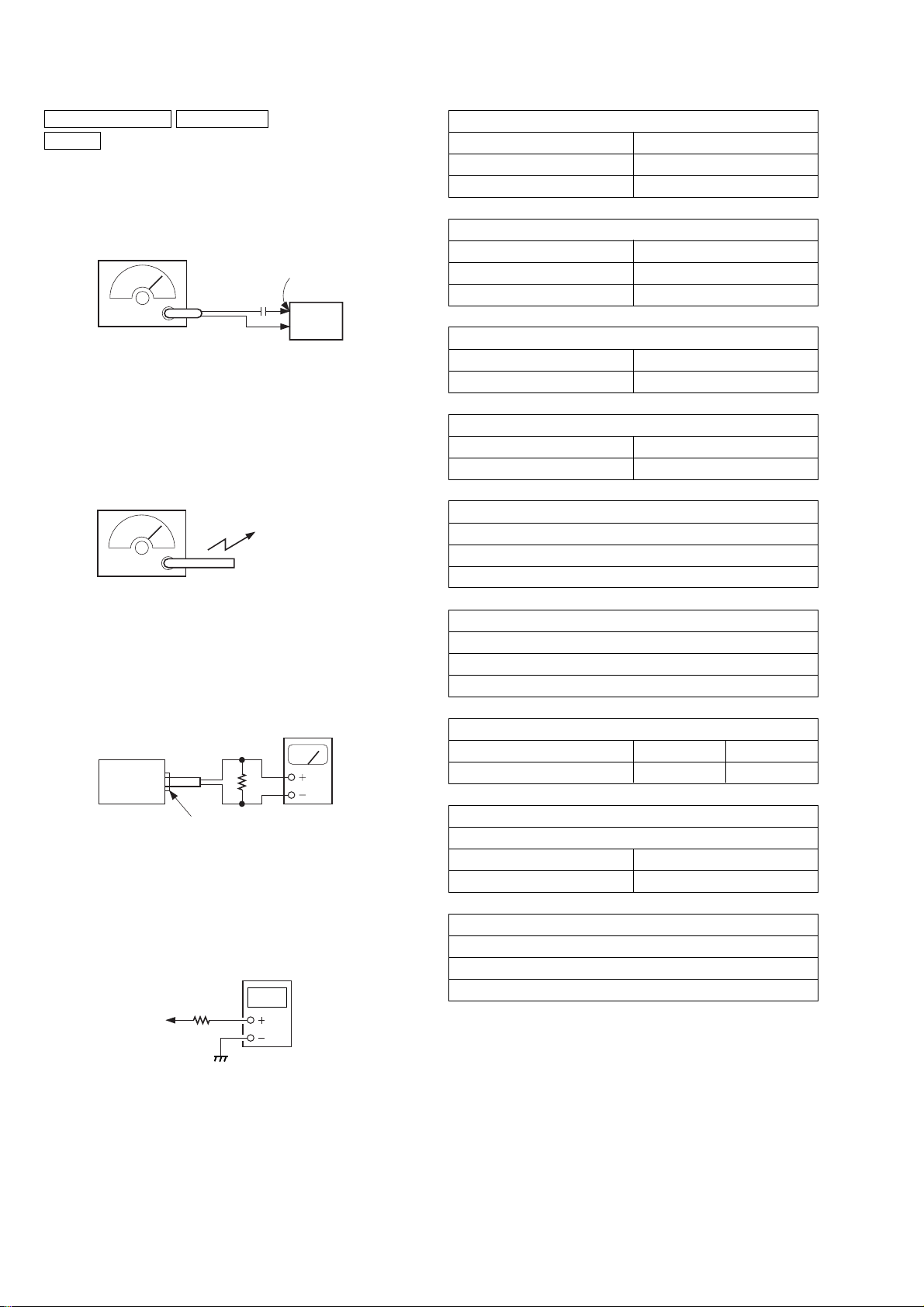

• FM Section (TRACKING ADJUSTMENT)

Setting :

BAND : FM, WB

FM RF signal

generator

TP901 (RF-IN

0.01

µ

F

set

75kHz frequency

deviation by 1kHz signal

output level : as low as possible

• AM Section (TRACKING/IF ADJUSTMENT)

Setting :

BAND : AM

AM RF signal

generator

30% amplitude

modulation by

1kHz signal

Put the lead-wire

antenna close to

the set.

• Connecting Level Meter (FM and AM)

TV VT ADJUSTMENT

Frequency display

Reading on digital voltmeter

Adjustment part

FM VT ADJUSTMENT

Frequency display

Reading on digital voltmeter

Adjustment part

WB VT CHECK

Frequency display

Reading on digital voltmeter

TV VT CHECK

Frequency display

Reading on digital voltmeter

WB TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter

L904

WB 1ch

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter

L902

87.5 MHz

TV 13ch (215.75MHz)

9.0 ± 0.3V

L903

108MHz

10.0 ± 0.3V

L901

WB 2ch (162.400MHz)

5.4 ± 0.5V

TV 2ch (59.75MHz)

0.7 ± 0.5V

level meter

(range: 0.5–5 V ac

16

Ω

set

i

jack (J702)

• Connecting Digital Voltmeter

(FM/TV/WB/AM VT ADJUSTMENT or CHECK)

digital

voltmeter

Ω

100 k

TP903 (VT)

Repeat the procedures in each adjustment several times.

Adjustment and Check Location : MAIN Board (see page 13)

AM VT CHECK

Frequency display

Reading on digital voltmeter

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter

L801

600kHz

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter

1.0 ± 0.5V

T901

1,000kHz

530kHz

1710kHz

7.0 ± 1V

CT801

1,400kHz

12

Adjustment and Check Location :

— MAIN Board (Side A) —

L901

CT801

T901

XP-ER800/ER800N/ER800R

L901

FM VT

adjustment

L903

TV VT

L902

L903

L904

adjustment

L902

FM TRACKING

adjustment

L904

WB TRACKING

adjustment

@

@

@

— MAIN Board (Side B) —

IC201

L801

L801,CT801

AM TRACKING

adjustment

IC304

L901

AM IF

adjustment

4band

IC451

IC401

IC902

IC901

IC501

TP903 (VT)TP901 (RF-IN)

4band

13

XP-ER800/ER800N/ER800R

)

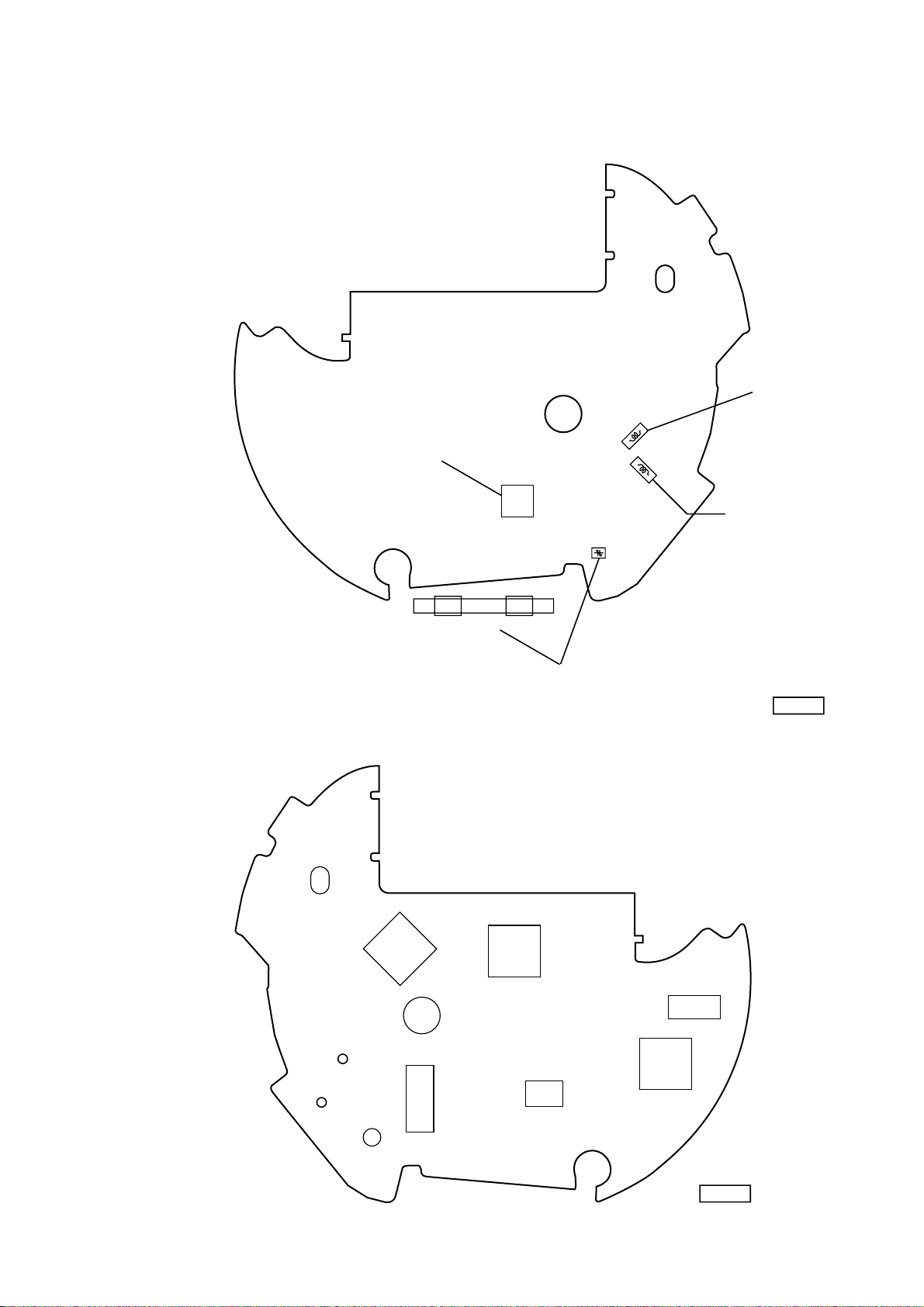

2 band

• FM Section (TRACKING ADJUSTMENT)

Setting :

BAND : FM

FM RF signal

generator

TP851 (RF-IN

µ

F

0.01

set

75kHz frequency

deviation by 1kHz signal

output level : as low as possible

• AM Section (TRACKING/IF ADJUSTMENT)

Setting :

BAND : AM

AM RF signal

generator

30% amplitude

modulation by

1kHz signal

Put the lead-wire

antenna close to

the set.

• Connecting Level Meter (FM and AM)

level meter

(range: 0.5–5 V ac)

Ω

16

FM VT ADJUSTMENT

Frequency display

Reading on digital voltmeter

Adjustment part

FM VT CHECK

Frequency display

Reading on digital voltmeter

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter

L852

108MHz

AM VT CHECK

Frequency display

Reading on digital voltmeter

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter

L801

603kHz

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter

1.0 ± 0.5V

T851

999kHz

531kHz

108MHz

8.0 ± 0.3V

L853

87.5MHz

1.5 ± 1.0V

1602kHz

6.5 ± 1V

CT801

1,404kHz

set

i

jack (J702)(EXCEPT AEP,HK)

(J701)(AEP,HK)

• Connecting Digital Voltmeter

(FM/TV/WB/AM VT ADJUSTMENT or CHECK)

digital

voltmeter

Ω

100 k

TP854 (VT)

Repeat the procedures in each adjustment several times.

Adjustment and Check Location : MAIN Board (see page 15)

14

@

Adjustment and Check Location :

— MAIN Board (Side A) —

XP-ER800/ER800N/ER800R

L853

FM VT

adjustment

— MAIN Board (Side B) —

T851

AM IF

adjustment

@

L801

T851

L801,CT801

AM TRACKING

adjustment

L853

CT801

L852

L852

FM TRACKING

adjustment

@

2band

TP854

(VT)

TP851

(RF-IN)

IC201

IC851

IC304

IC501

IC451

IC401

2band

15

Loading...

Loading...