Sony XDRS-1 Service manual

XDR-S1

SERVICE MANUAL

Ver 1.0 2004. 09

SPECIFICATIONS

Time display

UK 12-hour system

Other countries/regions 24-hour system

Frequency range

Band Frequency Channel step

DAB (L-Band) 1452.960

– 1490.624 MHz

DAB (Band-III) 174.928

– 239.200 MHz

FM 87.5 – 108 MHz 0.05 MHz

MW 531 – 1,602 kHz 9 kHz

LW 153 – 279 kHz 3 kHz

AEP Model

UK Model

9-879-193-01

2004I04-1

© 2004. 09

Speaker: 8 cm (3

Power output: 2.3 W+2.3 W (at 10% harmonic distortion)

Output: Headphone jack (stereo mini jack)

Power requirements: 230 V AC, 50 Hz

Power consumption: 13 W

Dimensions: Approx. 320 × 142 × 154 mm (w/h/d)

Mass: Approx. 2.5 kg (5 lb 8 oz)

Supplied accessories: AC power cord (1),

Design and specifications are subject to change

without notice.

1/4 inches) dia., 3.2 Ω

(Approx. 12 3/4 × 5 5/8 × 6 1/8 inches) incl.

projecting parts and controls

Remote control (RMT-CS1AD) (1)

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

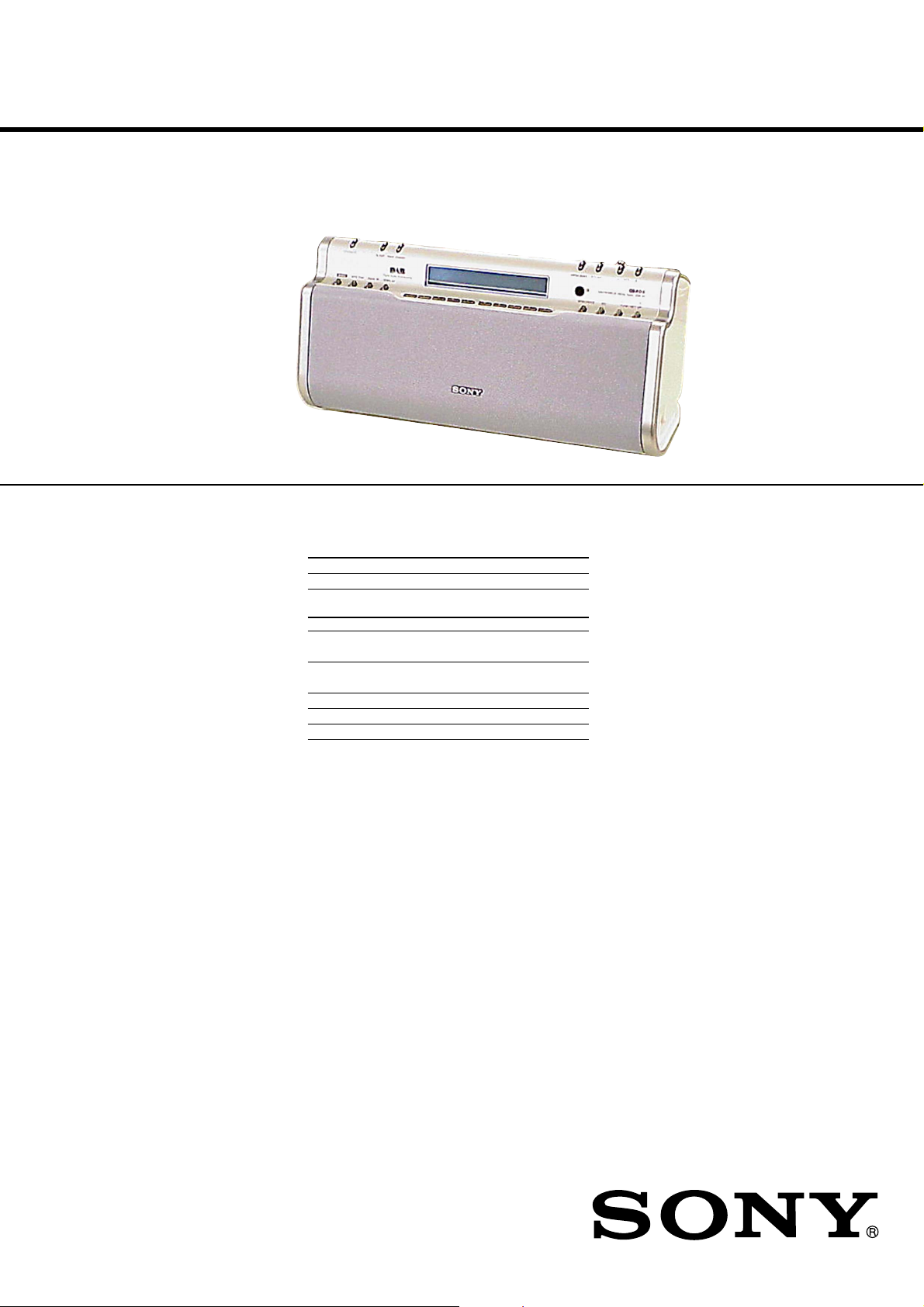

DAB/FM/MW/LW DIGITAL RADIO

1

XDR-S1

Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on Chip Component Replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

UNLEADED SOLDER

•

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to

be applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set

to about 350°C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder

may also be added to ordinary solder.

TABLE OF CONTENTS

1. GENERAL

2. DISASSEMBLY

2-1. Cabinet (Rear) Assy ............................................................ 4

2-2. Wires ...................................................................................5

2-3. Cabinet Upper Assy ............................................................ 5

2-4. Key Board ........................................................................... 6

2-5. Tuner Board......................................................................... 6

2-6. Micon Board ....................................................................... 7

2-7. Power Board, Jack Board ....................................................7

3. ELECTRICAL ADJUSTMENTS................................... 8

4. DIAGRAMS

4-1. Printed Wiring Board –Tuner Section– .............................10

4-2. Printed Wiring Boards –Micon Section– .......................... 11

4-3. Schematic Diagram –Tuner, Micon Section– ................... 12

4-4. Printed Wiring Boards –Audio, Power Supply Section– .. 13

4-5. Schematic Diagram –Audio, Power Supply Section–....... 14

5. EXPLODED VIEWS

5-1. Cabinet (Rear) Section ...................................................... 17

5-2. Cabinet Front Section........................................................ 18

5-3. Chassis Section ................................................................. 19

6. ELECTRICAL PARTS LIST ........................................ 20

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY P ARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

• LOCATION OF CONTROLS

SECTION 1

GENERAL

XDR-S1

This section is extracted

from instruction manual.

3

XDR-S1

)

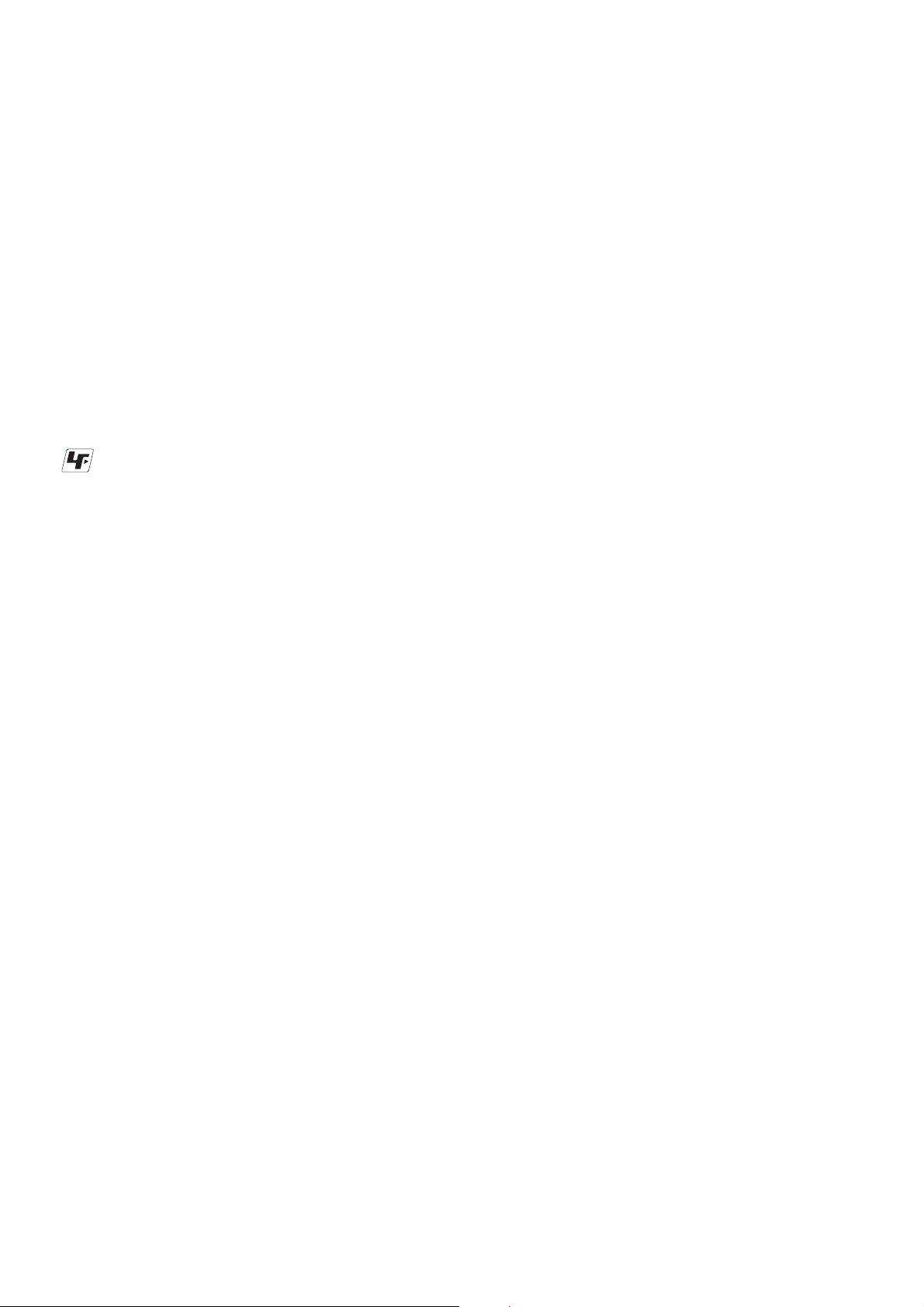

SECTION 2

DISASSEMBLY

• The equipment can be removed using the following procedure.

SET

2-1. CABINET (REAR) ASSY

(Page 4)

2-2. WIRES

(Page 5)

2-3. CABINET UPPER ASSY

(Page 5)

2-4. KEY BOARD

(Page 6)

2-5. TUNER BOARD

(Page 6)

2-6. MICON BOARD

(Page 7)

2-7. POWER BOARD,

JACK BOARD

(Page 7)

Note : Follow the disassembly procedure in the numerical order given.

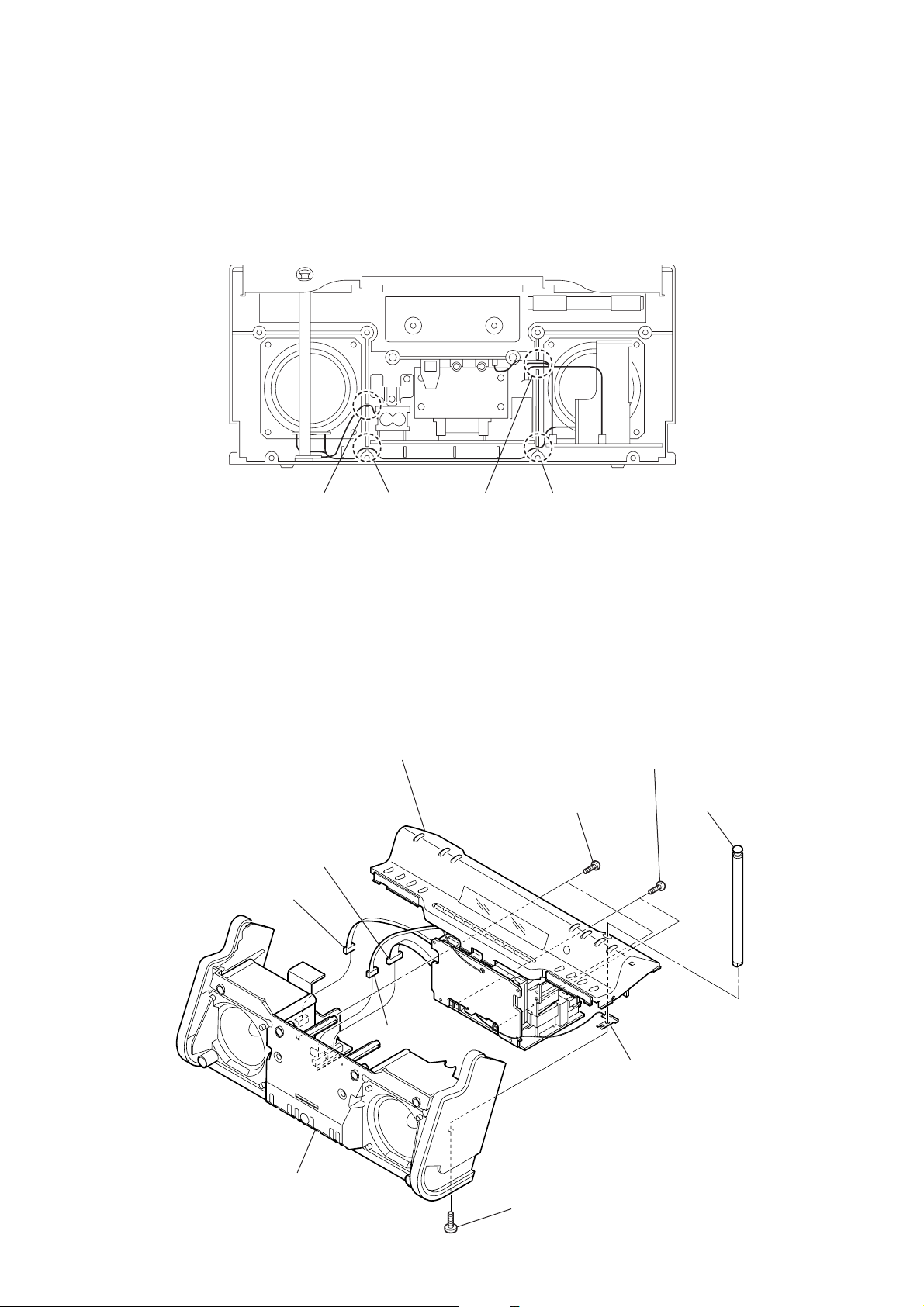

2-1. CABINET (REAR) ASSY

6

cabinet (rear) assy

four claws

2

four

screws

BV tapping (B3)

(+

)

5

two

screws

BV tapping (B3)

(+

)

4

two

screws

BV tapping (B3)

(+

3

four

screws

1

net assy

BV tapping (B3)

(+

)

4

2-2. WIRES

a

Put flat cable and wires between the cabinets and push them in the

grooves located at A to D in the figure to prevent disconnection

before assembling the set.

XDR-S1

front side

2-3. CABINET UPPER ASSY

2

CN304 (9P)

1

CN302 (4P)

AB CD

8

cabinet upper assy

7

two

screws

(+

BV tapping (B3)

6

two

screws

(+

BV tapping (B3)

)

5

telescopic antenn

)

cabinet front assy

3

CN301 (6P)

4

screw

(M3x6 lock ace)

terminal (antenna)

5

XDR-S1

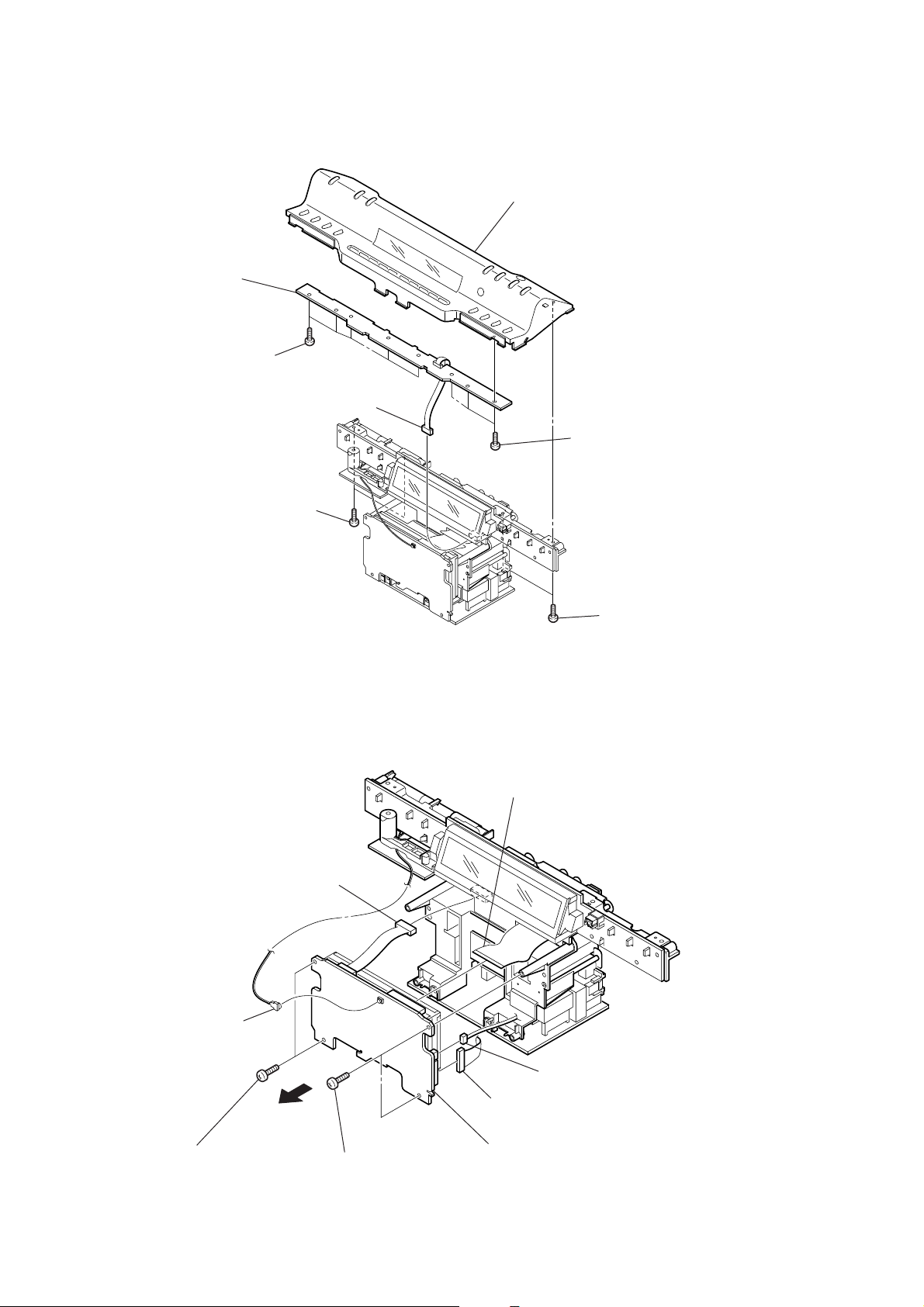

2-4. KEY BOARD

6

7

KEY board

five

screws

(+

P tapping (B2.6)

)

1

CN702 (4P)

4

cabinet upper assy (SVX)

5

three

screws

(+

P tapping (B2.6)

)

2-5. TUNER BOARD

3

two

screws

(+

P tapping (B2.6)

7

CN704 (6P)

)

2

two

screws

(+

8

CN502 (22P)

P tapping (B2.6)

)

1

CN501

2

CN504 (3P)

6

CN503 (9P)

9

TUNER board

3

two

screws

(+

P tapping (B2.6)

5

4

two

)

screws

P tapping (B2.6)

(+

)

6

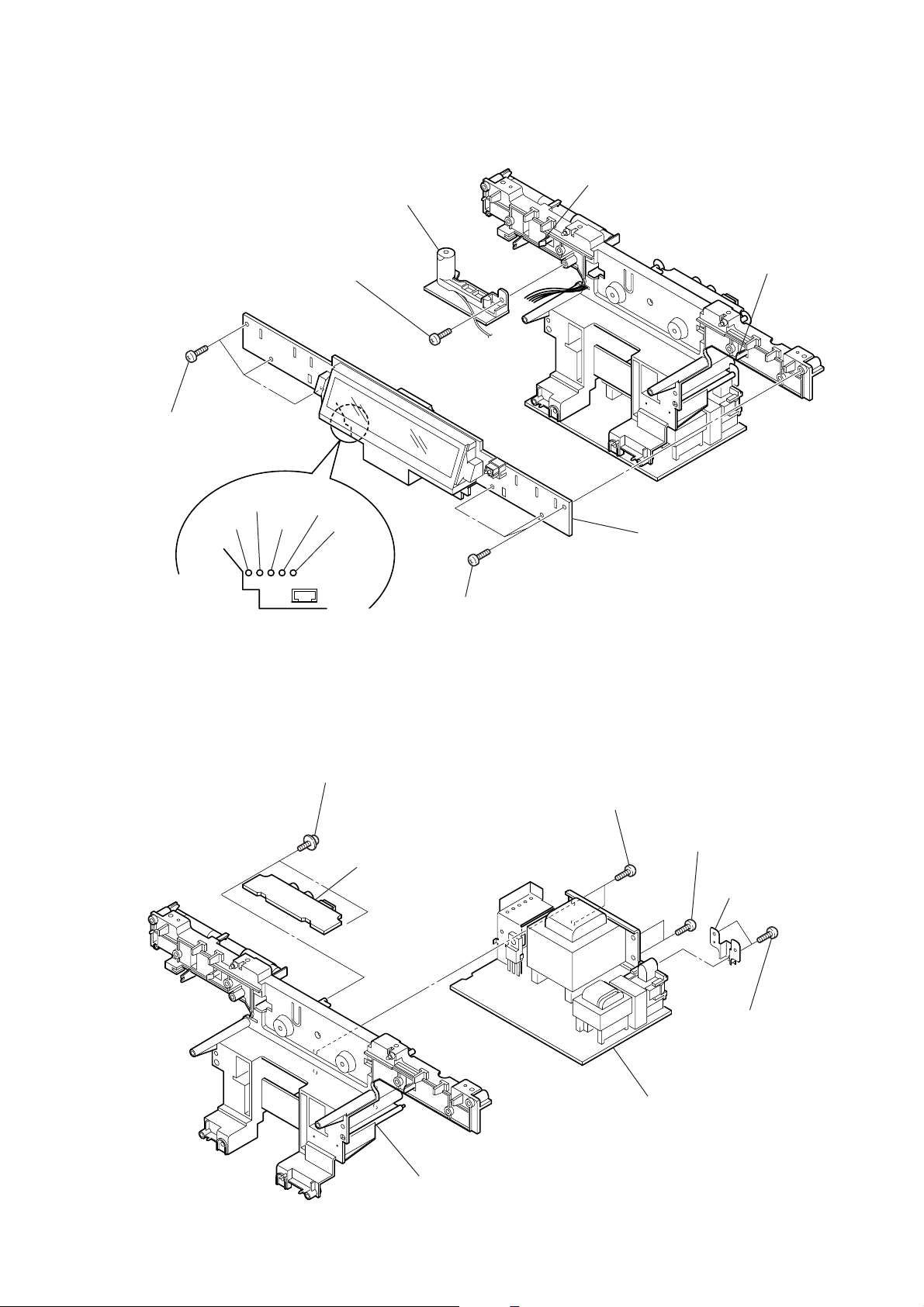

2-6. MICON BOARD

4

three

screws

(+

P tapping (B2.6)

1

screw

(+

P tapping (B2.6)

)

2

helical antenna

)

XDR-S1

claw

claw

green

red

3

Remove the five solderings.

black

yellow

natural

2-7. POWER BOARD, JACK BOARD

1

two

(+

PWH tapping (B2.6)

2

screws

JACK board

5

three

screws

(+

P tapping (B2.6)

)

6

MICON board

)

6

two

screws

(+

BV tapping (B3)

)

5

two

screws

(+

BV tapping (B3)

4

)

bracket (AC inlet)

chassis

7

POWER board

3

two

screws

(+

BV tapping (B3)

)

7

XDR-S1

SECTION 3

ELECTRICAL ADJUSTMENTS

TRACKING ADJUSTMENT

This set has the calibration function for tracking adjustment. It is

calibrated on each of LW and MW bands using frequencies at 7

points or 9 points.

Setting:

BAND: MW or LW

AM RF signal

generator

Put the lead-wire

antenna close to

the set.

30% amplitude

modulation by

400 Hz signal

• LW

1. With the power of f, press the 4 ke ys: [TIMER STANDBY], [SC],

0 and [DISPLAY] simultaneousl y for 3 seconds. The LCD

display shows “Calibration Mode” on the top and “LW MW

EXIT” on the bottom.

Calibration Mode

LW MW EXIT

2. Select “LW” using the TUNE/SET UP [+]/[--] key, and press

the [MENU/ENTER] key.

3. The LCD display shows “Calibration” on the top and the

frequency at 1st point “153 kHz” on the bottom.

• MW

1. Select “MW” using the TUNE/SET UP [+]/[--] key, and press

the [MENU/ENTER] key .

2. The LCD display shows “Calibration” on the top and the

frequency at 1st point “531 kHz” on the bottom.

3. Set the output frequency of the signal generator to 531 kHz.

4. When adjustment at 1st point is completed (it takes for about 3

seconds), press the [MENU/ENTER] key.

5. Repeat steps 2 to 4 until adjustment at 2nd point to 9th point is

completed.

Frequency at each point:

1st point: 531 kHz

2nd point: 603 kHz

3rd point: 702 kHz

4th point: 801 kHz

5th point: 900 kHz

6th point: 999 kHz

7th point: 1305 kHz

8th point: 1503 kHz

9th point: 1602 kHz

6. Once adjustment at all the points is completed, the LCD display

shows “Complete Cancel” on the top. Select either of the

following options using the TUNE/SET UP [+]/[--] key and press

the [MENU/ENTER] key .

Complete: Writes the data and returns to the menu.

Cancel: Aborts the data and returns to the menu.

• Termination of Adjustment

1. Select “EXIT” using the TUNE/SET UP [+]/[--] key, and press

the [MENU/ENTER] key .

2. The LCD display shows “Please Reset”. Press the [RESET] ke y

to terminate the Calibration Mode.

Calibration

153kHz

4. Set the output frequency of the signal generator to 153 kHz.

5. When adjustment at 1st point is completed (it takes for about 3

seconds), press the [MENU/ENTER] key.

6. Repeat steps 3 to 5 until adjustment at 2nd point to 7th point is

completed.

Frequency at each point:

1st point: 153 kHz

2nd point: 162 kHz

3rd point: 174 kHz

4th point: 186 kHz

5th point: 195 kHz

6th point: 243 kHz

7th point: 279 kHz

7. Once adjustment at all the points is completed, the LCD display

shows “Complete Cancel” on the top. Select either of the

following options using the TUNE/SET UP [+]/[--] key and press

the [MENU/ENTER] key.

Complete: Writes the data and returns to the menu.

Cancel: Aborts the data and returns to the menu.

8

SECTION 4

d

VIN1

VIN2

SEL2

SEL1

A1

A2

B1

B2

C1

C2

FILTER

GND

CAP

TNF1

TNF2

BNF2

BOUT2

BNF1

BOUT1

OUT1

OUT2

SI

SC

VCC

BASS1

f

0

=80Hz

BASS2

f0=80Hz

21 20 19 18 17 16 15 14 13

TREBLE2

f

0

=8kHz

22

TREBLE1

f

0

=8kHz

23

SURROUND

24

1 2 3 4

LOGIC

VCC/2

VCC/2

VCC/2 VCC/2

VCC/2

5 6 7 8 9 10 11 12

DIAGRAMS

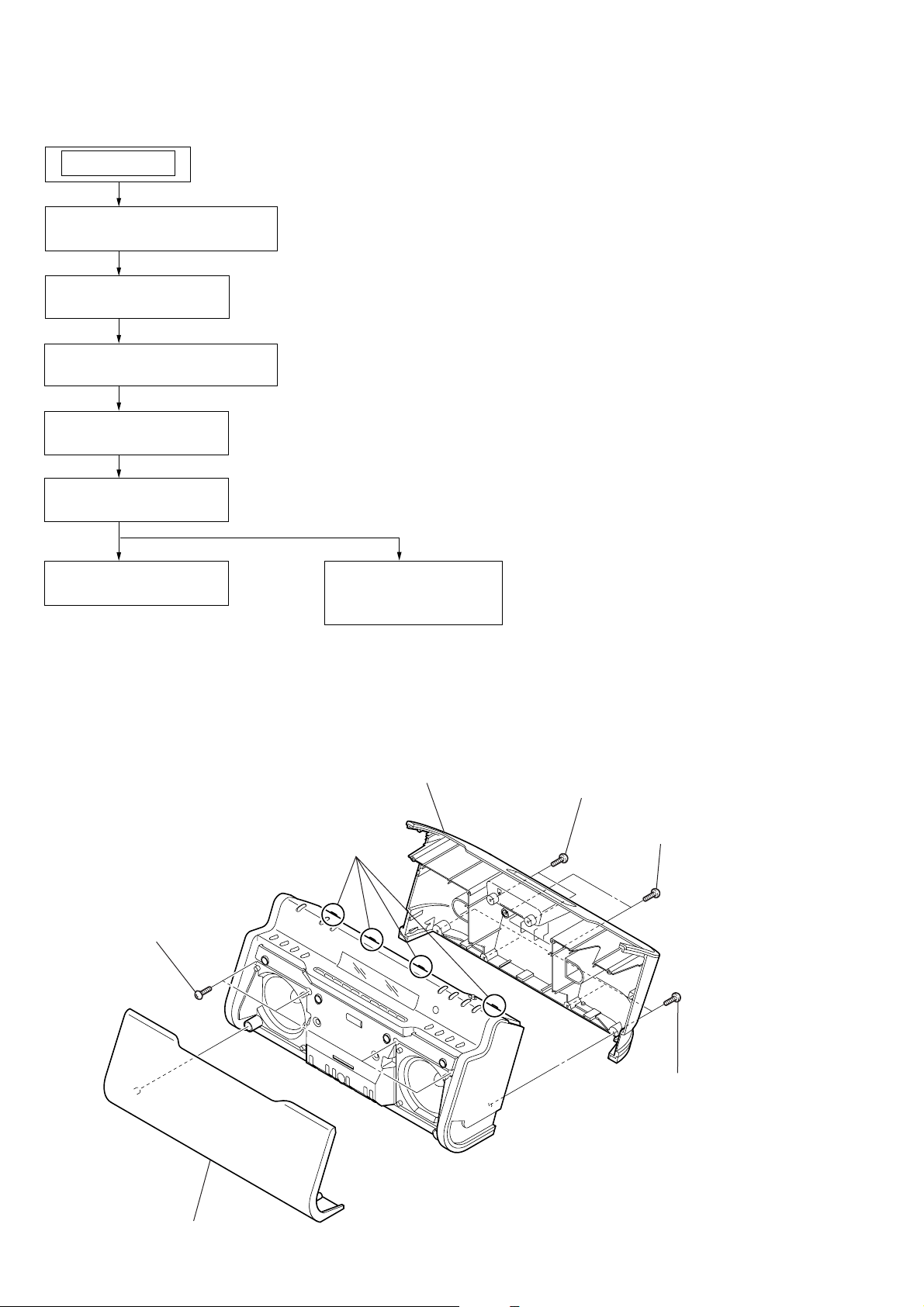

• CIRCUIT BOARDS LOCATION • NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is

MICON board

JACK board

KEY board

AUDIO board

TUNER boar

POWER board

printed in each block.)

for schematic diagram:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

4

W or less unless otherwise

• C : panel designation.

Note: The components identified by mark 0 or dotted line

with mark 0 are critical for safety.

Replace only with part number specified.

• A : B+ Line.

•Voltage and waveforms are dc with respect to ground

under no-signal conditions.

no mark : FM

(): MW

<>: LW

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : FM

f : MW

E : DAB

j : LW

for printed wiring boards:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• : Pattern from the side which enables seeing.

(The other layer’s patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

✩ When IC701 is damaged, replace the MICON board.

XDR-S1

• WAVEFORMS — MICON BOARD —

IC701 uk (XOA)

1

1.8Vp-p

32.768kHz

500 mV/DIV 0.1 msec/DIV

i;

IC701

2

(XO)

1.3Vp-p

✩ When IC701 is damaged, replace the MICON board.

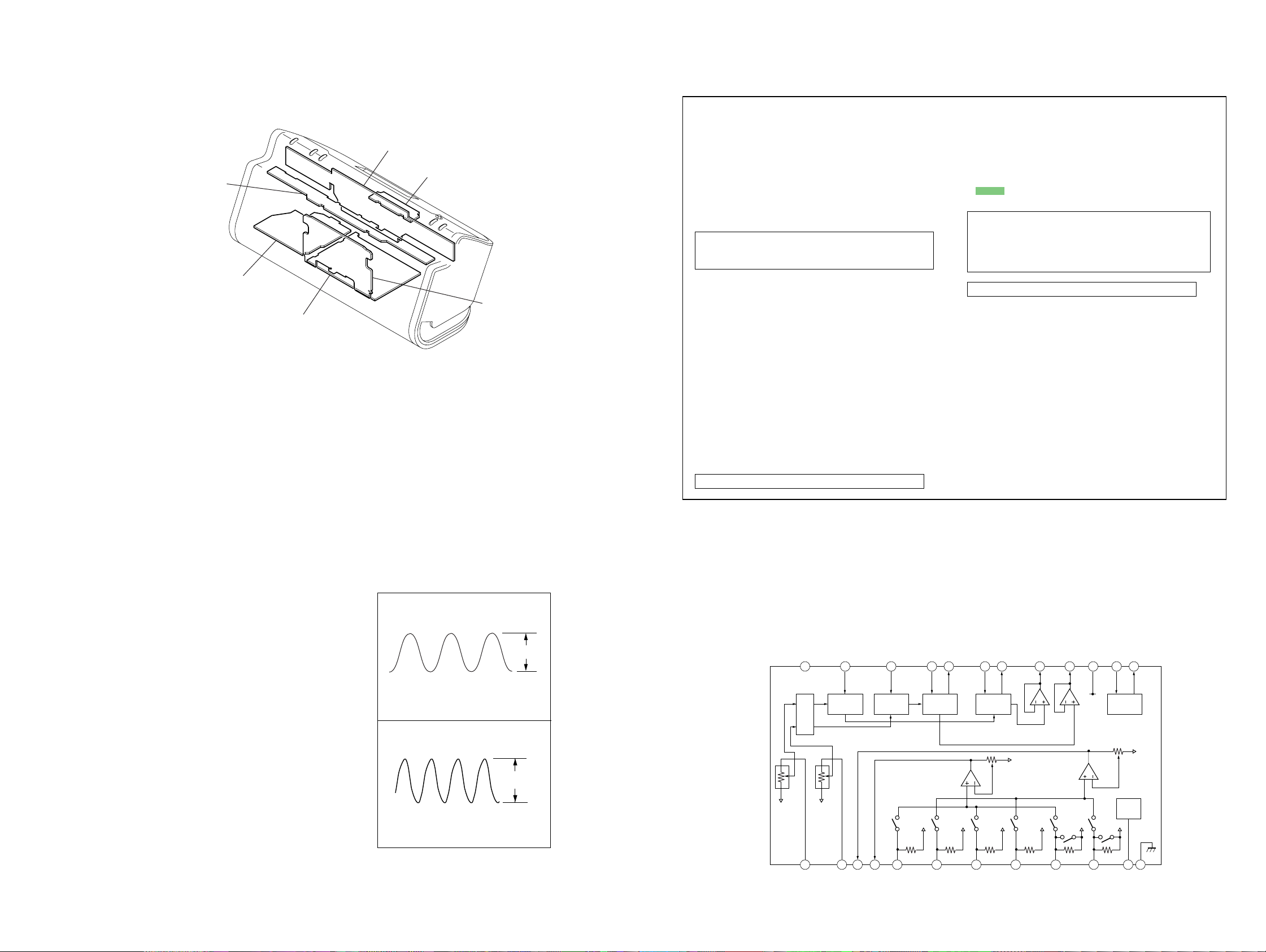

• IC BLOCK DIAGRAM

IC303 BD3870FS-E2 (AUDIO Board)

XDR-S1

4.19MHz

500 m V/DIV 0.5

µ

sec/DIV

99

Loading...

Loading...