Sony XCL-S600, XCL-S900, XCL-S600C, XCL-S900C Technical Manual

Digital Video

Camera Module

A-EHZ-100-11 (1)

Technical Manual

XCL-S600/S600C/S900/S900C

© 2013 Sony Corporation

Table of Contents

Overview

Features .................................................................. 3

Typical CCD Phenomena ...................................... 4

System Components .............................................. 5

Connection ............................................................. 5

Location and Function of Parts and

Operation ............................................................... 6

Front/Top/Bottom ............................................... 6

Using a tripod ..................................................... 6

Rear .................................................................... 7

Connecting the cables ........................................ 8

Connections

Communication Setting ........................................ 9

Camera Link Tap .................................................. 9

Data Order ........................................................... 10

1tap ................................................................... 10

2tap (when sensor tap is 1 or 2) ....................... 10

2tap (when sensor tap is 4) ............................... 11

Port assignment ................................................ 12

Color pixel array .............................................. 12

Trigger Signal Input ............................................ 13

Trigger signal polarity ...................................... 13

GPIO Connector .................................................. 14

Functions

Partial Scan .......................................................... 16

Binning ................................................................. 16

Sensor Tap ............................................................ 16

Switching sensor tap ........................................ 16

Level correction between sensor taps ............... 17

Adjusting level correction between sensor

taps ................................................................. 17

Output Bit Depth ................................................. 17

Gain ...................................................................... 17

Analog gain ...................................................... 17

Digital gain ....................................................... 17

Auto gain (AGC) .............................................. 17

Shutter (Exposure) .............................................. 18

Configuring the setting ..................................... 18

Auto exposure (AE) ......................................... 18

Combination of Continuous AGC and Continuous

AE ......................................................................... 18

Trigger Control .................................................... 19

Free run/Trigger mode ..................................... 19

Special trigger .................................................. 20

Trigger source .................................................. 21

Trigger inhibition ............................................. 21

Trigger shift ...................................................... 22

Trigger delay .................................................... 23

Trigger counter ................................................. 23

Frame counter .................................................. 23

Trigger range limit ............................................23

Trigger control ..................................................24

Frame Rate ...........................................................24

Auto frame rate .................................................24

Specifying frame rate ........................................25

Displaying frame rate .......................................25

Fastest frame rate for partial scanning ..............26

Timing Chart ........................................................28

Horizontal timing ..............................................28

Vertical timing ..................................................28

Trigger latency ..................................................29

Sensor Readout (Sensor Output) ........................30

White Balance ......................................................31

LUT .......................................................................31

Binarization ......................................................31

5-point interpolation .........................................31

Arbitrary setting ................................................32

Save LUT ..........................................................32

Color Matrix Conversion ....................................32

3 × 3 filter ..............................................................32

3 × 3 filter .........................................................32

Test Chart Output ................................................32

GPIO .....................................................................33

GPI ....................................................................33

GPO ..................................................................33

Pulse Train Generator .........................................35

Status LED ............................................................35

Temperature Readout Function .........................35

Defect Correction .................................................35

Shading Correction ..............................................36

Sensitivity Control ...............................................38

User Set .................................................................38

User set name ....................................................38

User set memory ...............................................38

Free Memory ........................................................38

User ID ..................................................................38

Saving and Startup ..............................................39

Initializing .............................................................39

Camera Information ............................................39

Help Command ....................................................39

Echo off .................................................................39

Restart ...................................................................39

Camera Control Commands

Command Form ...................................................40

Command Input and Response ..........................40

Command List ......................................................41

Parameter List ......................................................48

Specifications

Specifications ........................................................49

Spectral Sensitivity Characteristics (Typical

Values) ...................................................................52

Dimensions ............................................................53

2

Table of Contents

Overview

• Defect correction

• Shading correction

This unit is a digital video camera module that outputs

digital images utilizing LVDS via the DIGITAL IF

connector.

Features

DIGITAL IF connector

Equipped with a Camera Link standard mini connector.

The unit can output a detailed and high speed digital

image.

High definition and high speed image

capture

The unit includes a 9,000,000-pixel or 6,000,000-pixel

high-resolution CCD, with high speed read out

depending on each model.

You can select 1ch, 2ch or 4ch sensor output. The frame

rate depends on the channel selected.

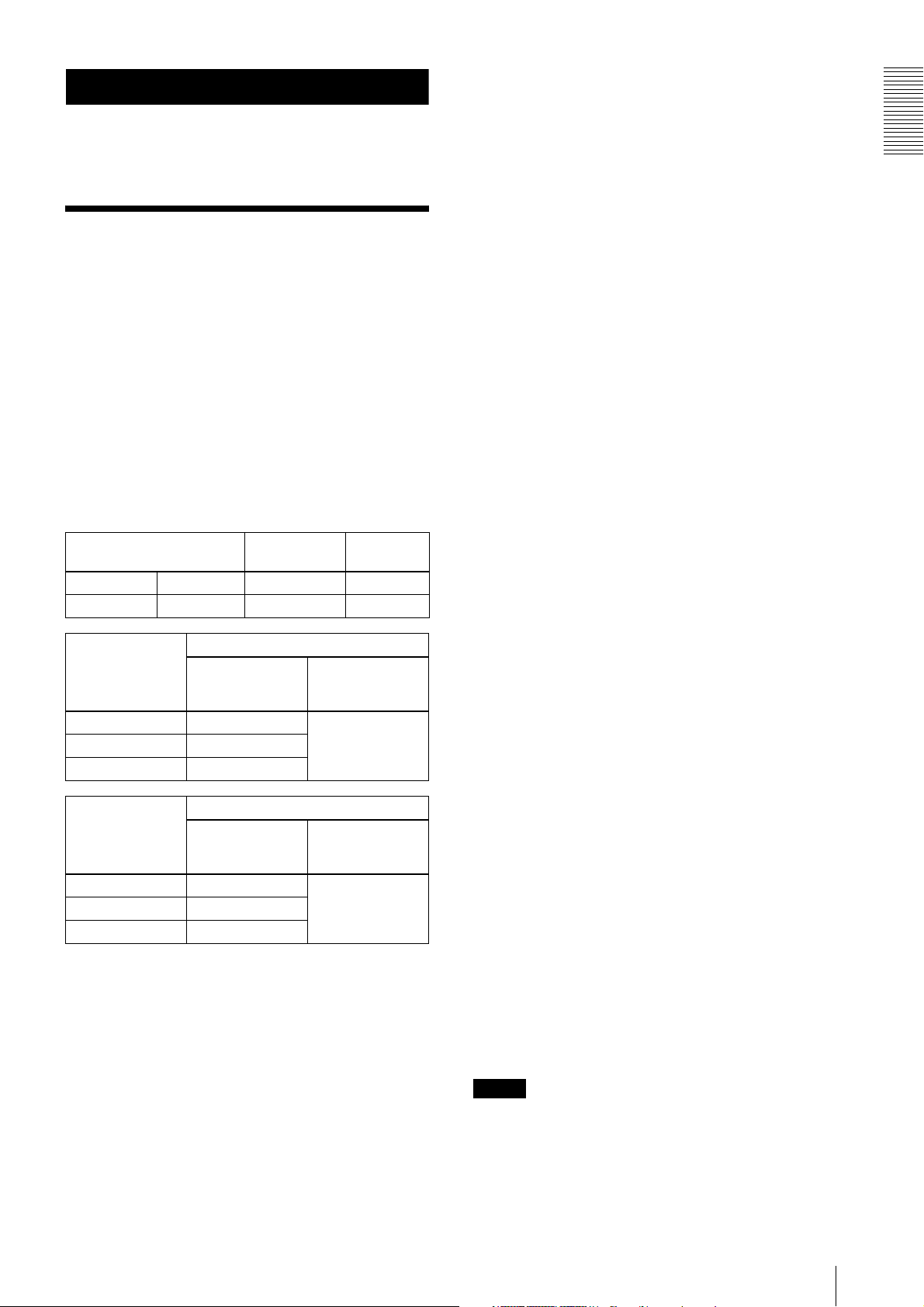

CCD size and resolution

1/1 type CCD 9 Mega XCL-S900 XCL-S900C

1/1 type CCD 6 Mega XCL-S600 XCL-S600C

Sensor tap

4ch 27 fps

1ch 7.5 fps

Sensor tap

4ch 18 fps

1ch 5 fps

Monochrome

XCL-S600/S600C

Frame rate

XCL-S900/S900C

Frame rate

model

output of pixels

output of pixels

The XCL-S900 and XCL-S600 monochrome models

use an EXview HAD CCD II

TM high sensitivity sensor,

usable even in the near-infrared region.

Various settings

Sending a command from the host device allows various

settings, including the following.

•Gain

•Shutter

• Partial scan

• Trigger control

• LUT (Look Up Table)

• Output: 8/10/12-bit or RGB 24-bit

Color

model

Maximum

(H) × (V)

2,758 × 2,2082ch 13 fps

Maximum

(H) × (V)

3,388 × 2,7122ch 9 fps

Electronic shutter function

Set anywhere from 1/100,000 sec to 2 sec in 1 µs

increments.

External trigger shutter function

By synchronizing with an external trigger signal, any

shutter timing can be used.

Partial scan

The camera module can limit the number of video

output lines to achieve high frame rates, enabling highspeed image processing.

Body fixing

The screw holes to install the camera module are located

under the front panel (the CCD reference plane).

Installing the camera module on the front panel

minimizes deviation of the optical axis.

LUT (Look Up Table)

You can switch to OFF or ON. When set to OFF, you can

select from five preset values, such as inversion,

binarization, any of five-point approximation, etc.

Switching an Output Bit Length

You can select 8-bit output, 10-bit output, or 12-bit

output.

For color models, you can also select an RGB 24-bit

output.

Binning (Monochrome camera only)

Sensitivity can be doubled by combining two pixels

aligned vertically, you can achieve a standard output

frame rate between 1.8x and 2x. Sensitivity can be

doubled by combining two pixels align horizontally.

You can set horizontal and vertical binning at the same

time.

Defect correction

The unit includes a function to reduce sensor defects,

and can be set to ON or OFF.

Shading correction

The unit includes a function to correct shading, resulting

from a light source or a particular lens, and can be set to

ON or OFF.

Note

The CCD is driven at high speed during a Partial scan or

Binning operation. In this situation, if intense light is

input to the camera, the peripheral areas of the video

image may be affected. In such a situation, adjust the

amount of light using the iris.

Overview

Features

3

Overview

Typical CCD Phenomena

The following effects on the monitor screen are

characteristic of CCD cameras. They do not indicate any

fault with the camera module.

Smear

This occurs when shooting a very bright object such as

electric lighting, the sun, or a strong reflection.

This phenomenon is caused by an electric charge

induced by infrared radiation deep in the photosensor. It

appears as a vertical smear, since the CCD imaging

element uses an interline transfer system.

Vertical aliasing

When you shoot vertical stripes or lines, they may

appear jagged.

Blemishes

A CCD image sensor consists of an array of individual

sensor elements (pixels). A malfunctioning sensor

element will cause a single pixel blemish in the picture

(This is generally not a problem.).

White speckles

While CCD image pickup device is made by an accurate

technique, imperceptible speckless may rarely come up

on the screen due to cosmic rays and so on. This is

connected to the principle of CCD image pickup device,

not a malfunction. And the white speckless are easy to

come up in the following conditions.

• Using the camera in high temperature

• When turning up the gain

Note

If strong light enters a wide area of the screen, the screen

may become dark. This is not a malfunction.

If this occurs, avoid strong light or adjust the lens iris to

reduce the light amount.

Note on laser beams

Laser beams may damage a CCD. You are cautioned

that the surface of a CCD should not be exposed to

laser beam radiation in an environment where a laser

beam device is used.

4

Typical CCD Phenomena

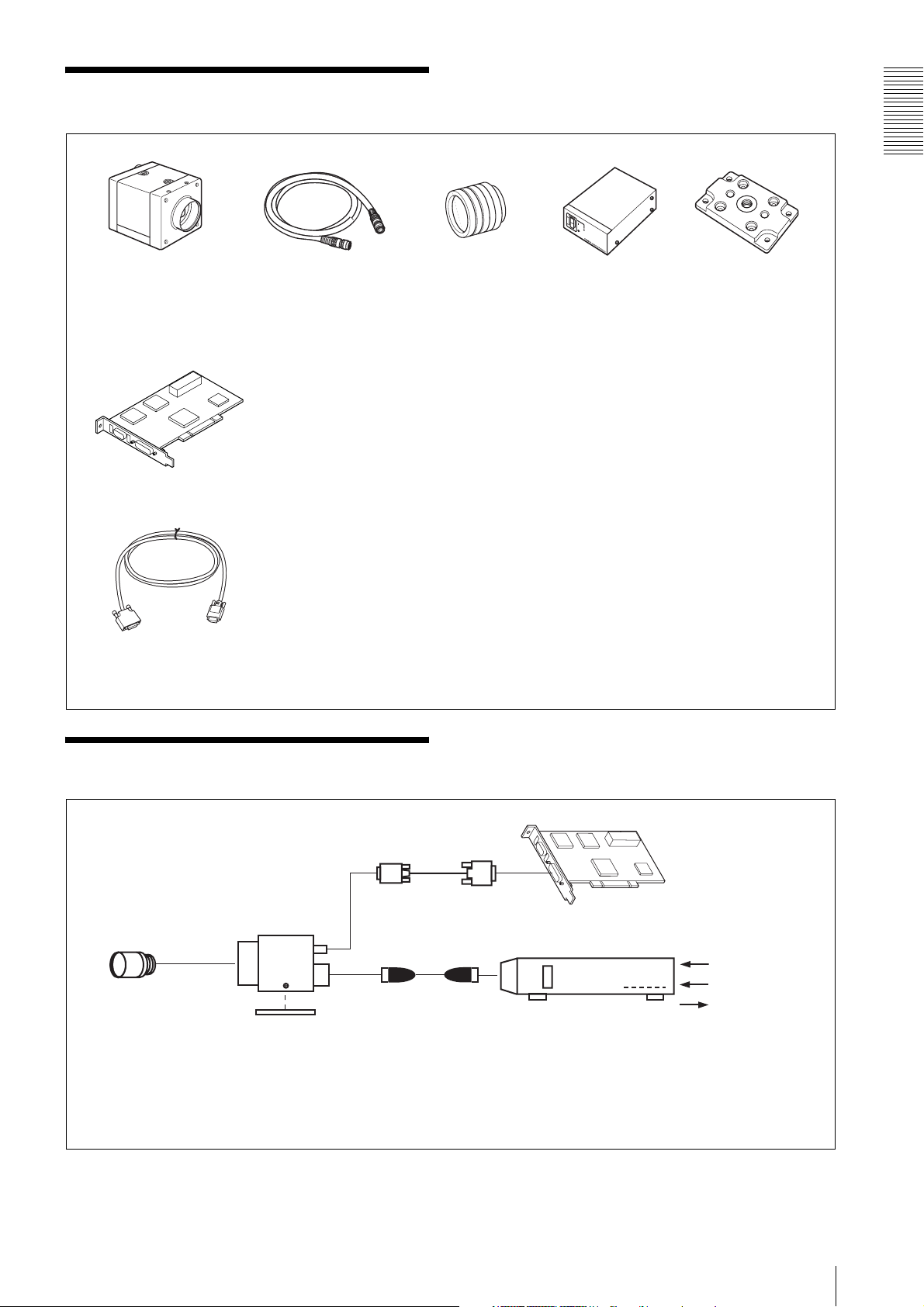

System Components

Overview

Video Camera Module Camera cable

Camera module interface

board

Camera Link cable

(Sony Camera-compatible)

CCXC-12P02N (2 m, 6.6 ft)

CCXC-12P05N (5 m, 16.4 ft)

CCXC-12P10N (10 m, 32.8 ft)

CCXC-12P25N (25 m, 82 ft)

Install the board in a PCI bus slot in devices such as a computer. Select a commercially

available interface board compatible with the Camera Link feature. You can use either a board

that supports PoCL, or one that does not.

Due to the performance of the board, the frame rate may become low according to lack of

processing capacity. To have this product output frames at the highest speed, use a board

corresponding to PCI-Express.

Performance may also be dependent on the host device (e.g., Computer), so consult the

dealer if images are not displayed properly.

This cable connects to the DIGITAL IF connector on the rear panel of the camera module.

Image/control signals are transmitted via this cable.

Select a proper cable as the maximum usable length of a cable differs due to the attribute of

each cable.

Spotted noise may appear in a specific brightness in the window according to the attribute of

the cable. If this noise is an obstacle, shorten the cable.

C-mount lens

Use a lens appropriate

for the pixel count of

the camera.

Camera adaptor

DC-700/700CE

Tripod adaptor

VCT-ST70I (Insulated

type)

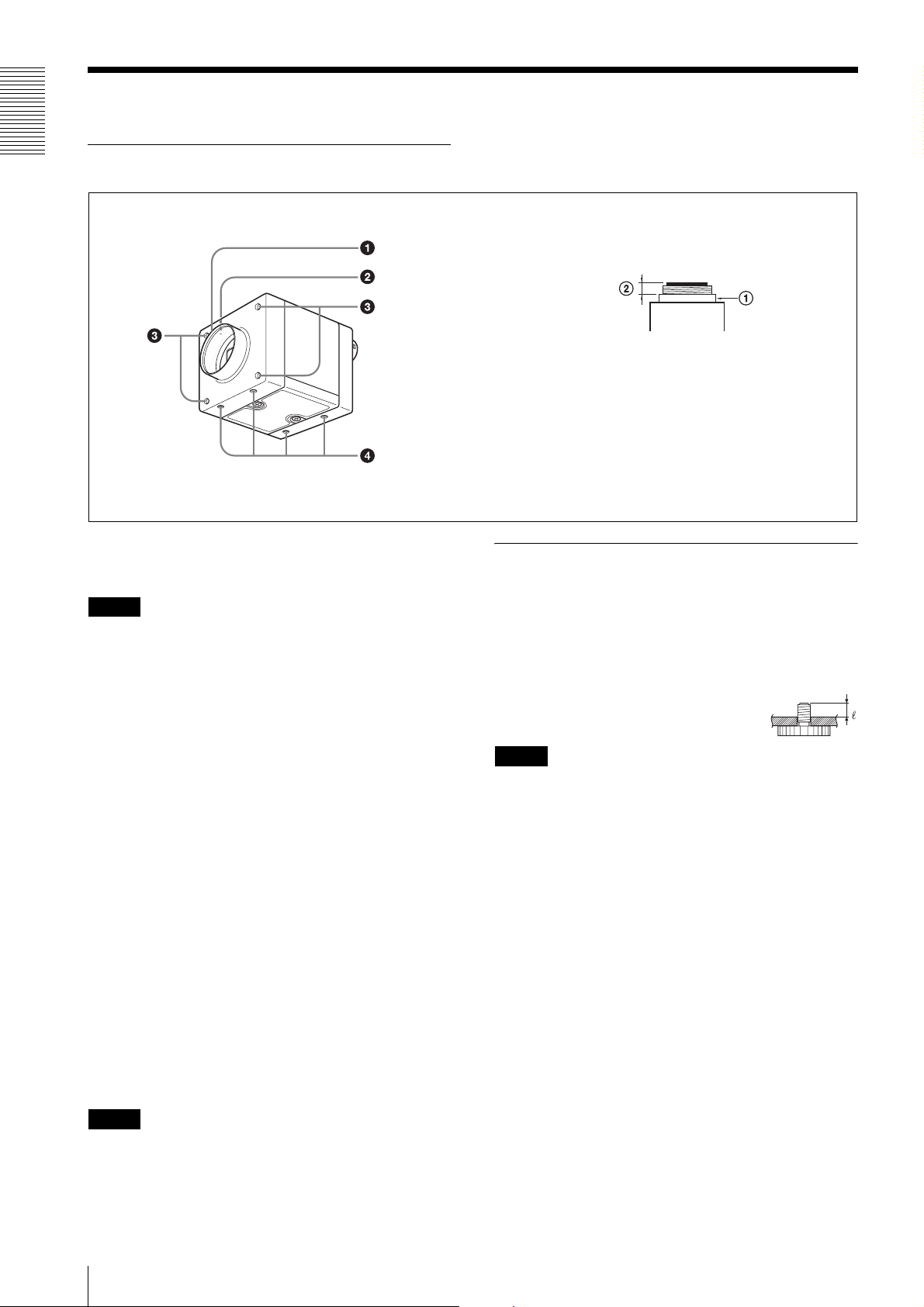

Connection

Camera Link cable

Camera module

C-mount lens

Camera cable

CCXC-12P02N

Tripod adaptor

VCT-ST70I

Power supply

You can supply power via the DC IN connector using the power adapter.

Use DC-700/700CE which is the stable power source free from ripple or noise.

CCXC-12P05N

CCXC-12P10N

CCXC-12P25N

Camera module interface board

Camera adaptor

DC-700/700CE

AC

TRIG

Internal signal

output

System Components

5

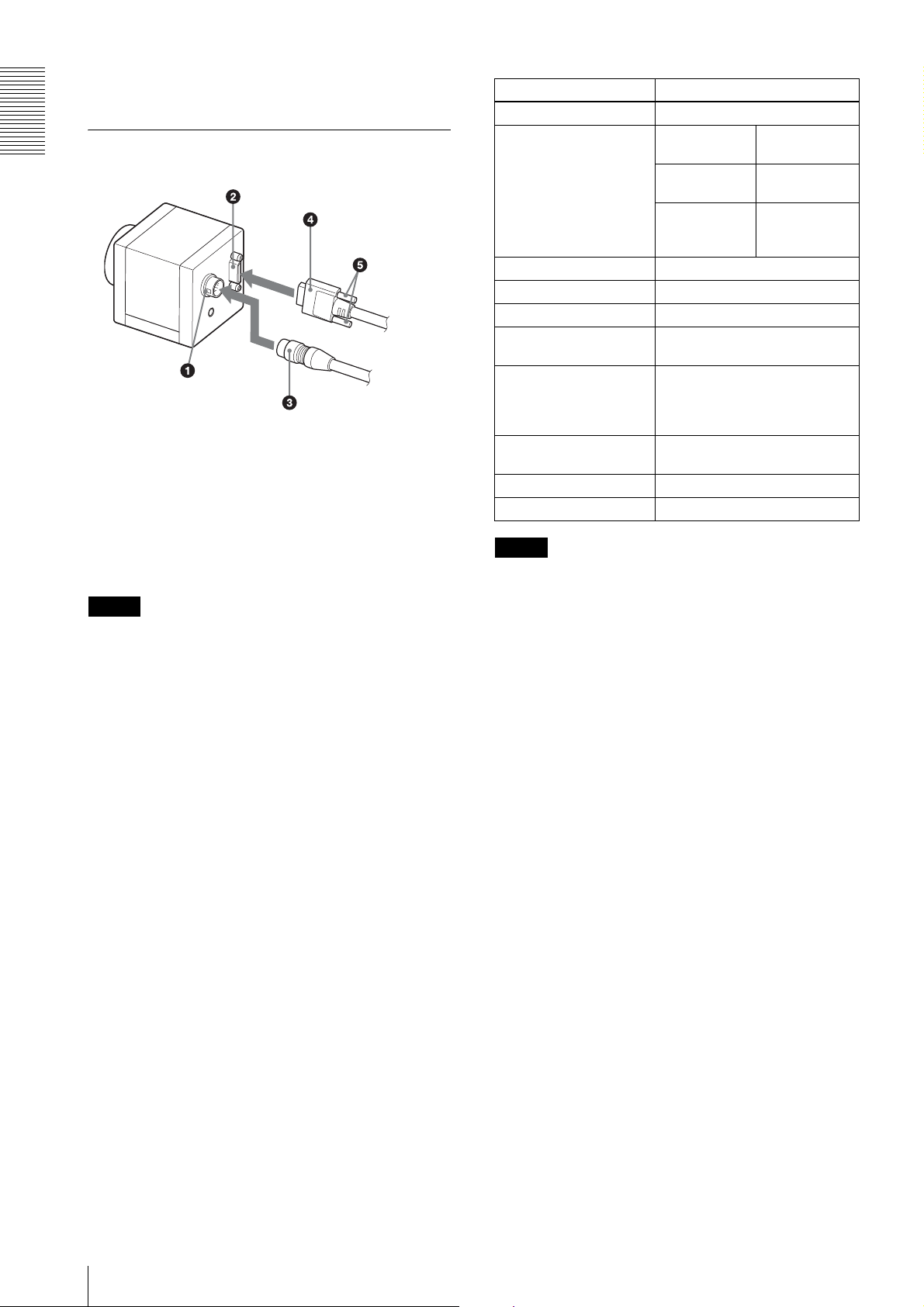

Location and Function of Parts and Operation

Overview

Front/Top/Bottom

Lens mount (C-mount)

Guide screw holes (Top)

LED light screw holes

Guide screw holes / Tripod screw holes (Bottom)

a Lens mount (C-mount)

Attach any C-mount lens or other optical equipment.

Note

The lens must not project more than 10 mm (13/32 inch)

from the lens mount.

A Lens mount face B 10 mm (13/32 inch) or less

When you use the camera with the lens attached, the

resolution of the image output from the camera may

differ according to the performance of the lens. Note it

when you select a lens.

The performance of a lens may change according to the

aperture level.

If the resolution is not enough, adjust the aperture level.

Using a tripod

To use the tripod, install the tripod adaptor VCT-ST70I

(not supplied) on the camera module.

Use a tripod screw with a protrusion (4) extending from

the installation surface, as follows, and tighten it, using

a screwdriver. Be sure that the protrusion (4) does not

exceed 5.5 mm (0.22 in.) in length.

Length 4.5 to 5.5 mm

Length 0.18 to 0.22 inches

Note

If you install a tripod adapter (not supplied), use the

screws (M3 × 8 (4)) provided.

b Guide screw holes (Top)

c LED light screw holes

Use these screw holes to attach the LED light to the

camera module.

Use an adapter appropriate for the LED light as required.

d Guide screw holes / Tripod screw holes (Bottom)

These precision screw holes are for locking the camera

module. Locking the camera module into these holes

secures the optical axis alignment.

When using a tripod, use these four screw holes to attach

a VCT-ST70I tripod adaptor.

Note

Refer to Demensions in page 53 for about the position/

size of the Guide hole and the Reference hole.

6

Location and Function of Parts and Operation

Rear

e DC IN (DC power input) connector (12-pin)

g Status LED

f DIGITAL IF (Interface) connector (26-pin mini connector)

Overview

e DC IN (DC power input) connector (12-pin)

You can connect a camera cable CCXC-12P05N etc. to

input the +12 V DC power supply.

For details on the pin arrangement, see the following

table.

Pin No. Signal Pin No. Signal

1Ground 7GPI3/GPO3

2 DC +12 V 8 GPI4(ISO-)

3 ISO Ground 9 GPO4(ISO)

4 GPI1/GPO1 10 GPI4(ISO+)

5 GPO2(ISO-) 11 GPI2

6 GPO2(ISO+) 12 ISO Ground

Power input

Pin 1 (Ground) and pin 2 (DC +12 V) are used.

Signal input

Pins 4, 7, 10 and 11 (GPI1/3/4/2) are used for GPI input

or trigger input.

When selecting 1 system for GPI (ISO):

– GPI4 (ISO+) (pin 10) and GPI4 (ISO-) (pin 8) are

used.

When selecting 2 systems for GPI:

– GPI1 (pin 4*) and Ground (pin 1) are used.

– GPI3 (pin 7*) and Ground (pin 1) are used.

* Pins 4 and 7 can switch GPI input and GPO output, by

external command. The initial value is GPI.

Signal output

Pins 4, 6, 7 and 9 (GPO1/2/3/4) allow you to select GPO

from the exposure signal, strobe control signal, Hi/Low

fixed value, etc.

When selecting 2 systems for GPO (ISO):

– GPO4 (ISO) (pin 9) and ISO Ground (pins 3 and 12)

are used.

– GPO2 (ISO+) (pin 6) and GPO2 (ISO-) (pin 5) are

used.

When selecting 2 systems for GPO:

– GPO1 (pin 4*) and Ground (pin 1) are used.

– GPO3 (pin 7*) and Ground (pin 1) are used.

* The initial value of pins 4 and 7 is GPI. Switch to GPO

output by external command.

f DIGITAL IF (Interface) connector (26-pin)

You can connect a Camera Link cable to this connector

to control a camera module from a host device utilizing

the serial communication protocol while outputting a

video signal from the camera module. You can input the

external trigger signal via the DIGITAL IF connector

and operate a camera module in the external trigger

mode.

The following table shows the relation between the pin

numbers of the DIGITAL IF connector and the input/

output signals and the like.

Pin No. Signal Pin No. Signal

1 Ground 14 Ground

2X0– 15X0+

3X1– 16X1+

4X2– 17X2+

5 XCLK– 18 XCLK+

6X3– 19X3+

7 SerTC+ 20 SerTC–

8SerTFG– 21SerTFG+

9 CC1– 22 CC1+

10 CC2+ 23 CC2–

11 CC3– 24 CC3+

12 CC4+ 25 CC4–

13 Ground 26 Ground

Location and Function of Parts and Operation

7

Overview

g Status LED (Green)

When power is on, this LED lights up.

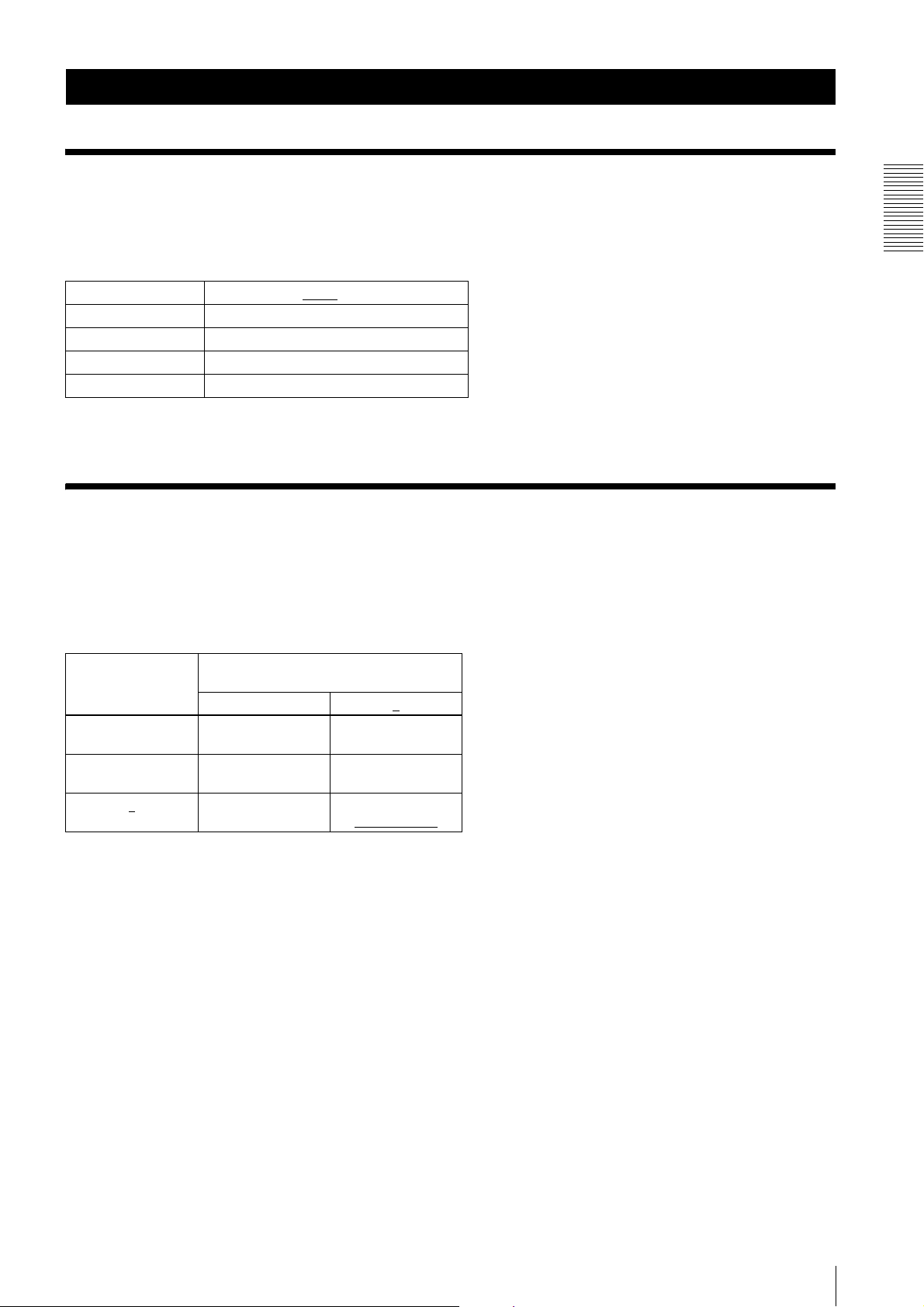

Connecting the cables

DIGITAL IF connector

Camera Link cable

Fastening

screws

DC IN

connector

Camera cable

Connect the camera cable to the DC IN connector and

the Camera Link cable to the DIGITAL IF cable

respectively. When you connect the Camera Link cable,

turn the two fastening screws on the connector to secure

the cable tightly.

Connect the other end of the camera cable to the DC700/700CE and the other end of the Camera Link cable

to the camera module interface board.

Note

This camera does not support PoCL. To prevent the

camera from malfunction, do not supply power from the

Camera Link board.

Controlling the camera from the host

device

You can control the camera from host device such as a

computer. The following table shows the major control

functions.

You can send a command corresponding to the control

items, with parameters for the desired settings, if

necessary, from the host device to control the camera.

Refer to “Camera Control Commands” on page 40 for

details on how to send a command, the commands, and

their parameters.

Control functions Description

Operating mode Free run/Trigger

Shutter speed Free run 1/100,000 sec to

Trigger edge

detection

Trigger pulse

width detection

Gain 0 dB to 18 dB

Partial Scan Variable, 4-line increments

LUT (Look Up Table) OFF/ON (Mode: 5 types)

External trigger input DIGITAL IF connector/DC IN

connector

Video output switch Monochrome model: Mono 8/10/

Binning (Monochrome

camera only)

Defect correction OFF/ON

Shading correction OFF/ON

Note

12-bit

Color model: Raw 8/10/12-bit,

RGB 24-bit

2 × 1, 1 × 2, 2 × 2

2 sec

1/100,000 sec t o

2 sec

Setting by

trigger pulse

width

Make sure to supply power to the camera module and

confirm that the camera module is operating before

inputting a trigger signal. If you input trigger signal to a

camera module without the power supplied, this may

cause a malfunction of the camera module.

Image at partial scan

Depending on the image input board of the camera you

are using, if settings for the boards received image size

and the image size output from a camera do not

conform, picture noise or sync issues may occur.

8

Location and Function of Parts and Operation

Connections

Communication Setting

The serial port assigned to the camera link board is used. The communication system is an asynchronous method

compliant with RS-232C. The following table shows the transmission control specifications. Command inputs are

echoed back. Inputs are not case-sensitive.

Baud rate 115200/57600/38400/19200/9600 [bps]

Data bit 8

Parity None

Stop bit 1

Flow control None

Default values are underlined. (same applies hereinafter)

Camera Link Tap

Connections

1tap output or 2tap output can be selected, regardless of the camera settings. Output clock frequencies are as follows.

Lowering the output clock frequency improves the tolerance to video signal attenuation, which allows the camera link

cable length to be extended. Thus, it is recommended to use with 2tap unless there are board restrictions. Only the

selection of sensor tap1 or 2, or camera link tap1 is available for RGB24-bit output. The output of sensor tap4 is only

available for the selection of camera link tap2.

Sensor Tap

Command

SENSOR-TAP

1 available

2 available

4

Camera Link Tap Command

CAMERALINK-TAP

12

available

Clock 54 MHz

Clock 84 MHz

unavailable available

Clock 27 MHz

available

Clock 42 MHz

Clock 84 MHz

Communication Setting

9

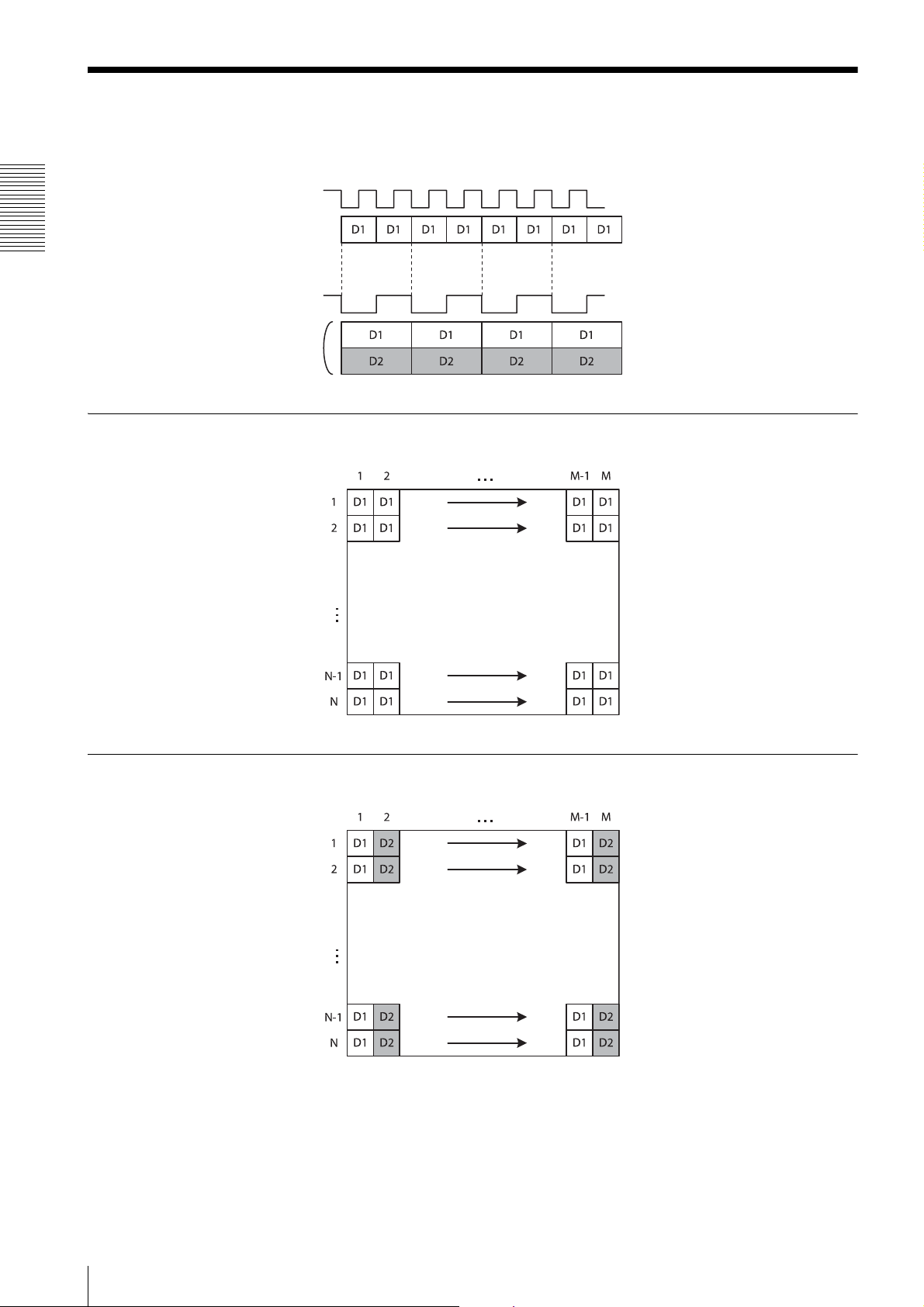

Data Order

Figures below show the data order when an image of M × N pixels is transmitted in camera link tap1 and camera link

tap2.

1tap

Connections

2tap

STROBE

Video output

STROBE

Video output

1tap

M × N pixels

2tap (when sensor tap is 1 or 2)

M × N pixels

10

Data Order

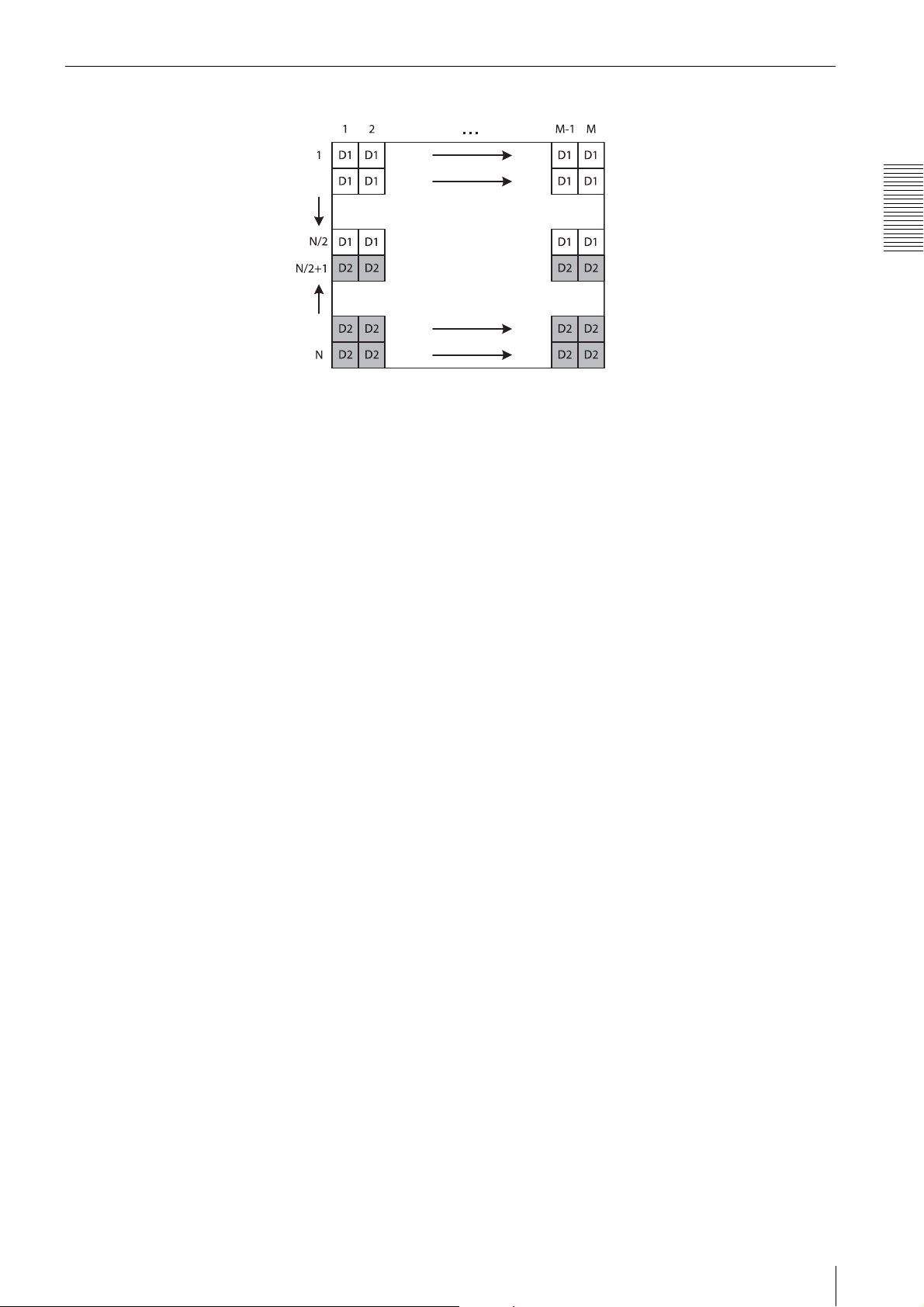

2tap (when sensor tap is 4)

M × N pixels

* The order of the lines output is as follows:

For D1 (upper half of the screen), the order is from Line 1 to Line N/2.

For D2 (lower half of the screen), the order is from Line N to Line N/2 + 1.

Connections

Data Order

11

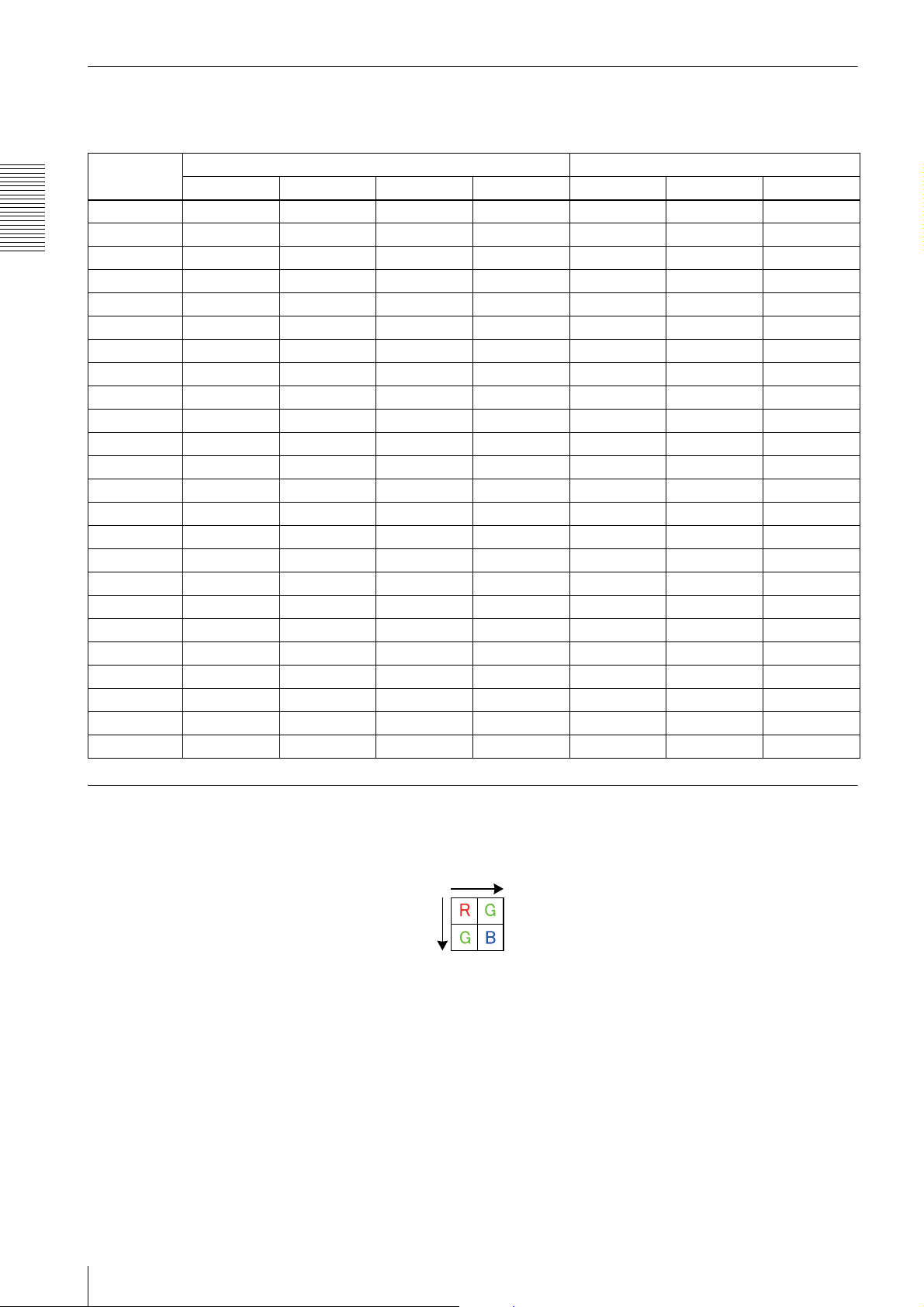

Port assignment

The following table shows the assignment for the three ports (A, B, and C) and the respective video signals (D1, D2,

and DR, DG, DB for RGB24-bit) for 1tap/2tap as defined in the base configuration.

Port 1tap 2tap

8 bit 10 bit 12 bit RGB 24bit 8 bit 10 bit 12 bit

Port A0 D1[0] D1[0] D1[0] DR[0] D1[0] D1[0] D1[0]

Port A1 D1[1] D1[1] D1[1] DR[1] D1[1] D1[1] D1[1]

Connections

Port A2 D1[2] D1[2] D1[2] DR[2] D1[2] D1[2] D1[2]

Port A3 D1[3] D1[3] D1[3] DR[3] D1[3] D1[3] D1[3]

Port A4 D1[4] D1[4] D1[4] DR[4] D1[4] D1[4] D1[4]

Port A5 D1[5] D1[5] D1[5] DR[5] D1[5] D1[5] D1[5]

Port A6 D1[6] D1[6] D1[6] DR[6] D1[6] D1[6] D1[6]

Port A7 D1[7] D1[7] D1[7] DR[7] D1[7] D1[7] D1[7]

Port B0 D1[8] D1[8] DG[0] D2[0] D1[8] D1[8]

Port B1 D1[9] D1[9] DG[1] D2[1] D1[9] D1[9]

Port B2 D1[10] DG[2] D2[2] D1[10]

Port B3 D1[11] DG[3] D2[3] D1[11]

Port B4 DG[4] D2[4] D2[8] D2[8]

Port B5 DG[5] D2[5] D2[9] D2[9]

Port B6 DG[6] D2[6] D2[10]

Port B7 DG[7] D2[7] D2[11]

Port C0 DB[0] D2[0] D2[0]

Port C1 DB[1] D2[1] D2[1]

Port C2 DB[2] D2[2] D2[2]

Port C3 DB[3] D2[3] D2[3]

Port C4 DB[4] D2[4] D2[4]

Port C5 DB[5] D2[5] D2[5]

Port C6 DB[6] D2[6] D2[6]

Port C7 DB[7] D2[7] D2[7]

Color pixel array

In the case of 8-bit, 10-bit, and 12-bit outputs, signals of all pixels are output sequentially according to the Bayer Array

shown below.

In the case of RGB24-bit, R, G, and B are 8 bits respectively per 1 pixel.

12

Data Order

Trigger Signal Input

Trigger signals can be input via the 4th/7th/10th/11th pins of the DC IN connector, the CC1, CC2, CC3, CC4 pins of

the Digital IF connector, or the software command. Switchover of the trigger signal can be changed via the TRG-SRC

command.

command param Trigger signal assigned pin

TRG-SRC 4 DC IN connector 4th pin*

7 DC IN connector 7th pin*

10 DC IN connector 10th pin

11

101 Digital IF connector 22nd [+]/9th [-] (CC1)

102 Digital IF connector 10th [+]/23th [-] (CC2)

103 Digital IF connector 24th [+]/11th [-] (CC3)

104 Digital IF connector 12nd [+]/25th [-] (CC4)

0 Software command (TRG-SOFT)

20 OR of DC IN connector 4th/7th/10th/11th pin

* DC IN connector 4th pin and 7th pin are available only when the GPIO input/output setting is switched to input.

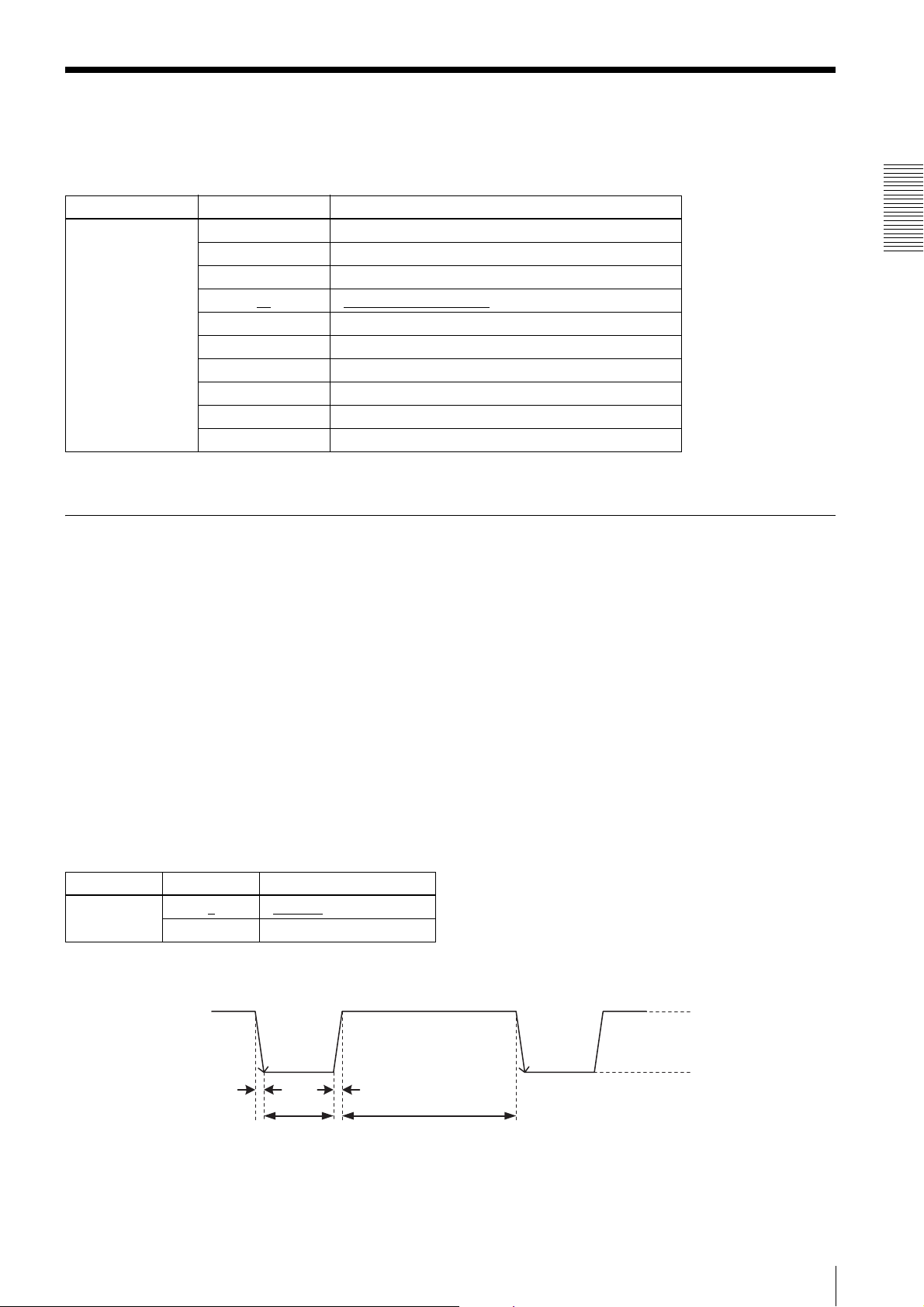

Trigger signal polarity

DC IN connector 11th pin

Connections

Positive refers to a trigger signal polarity activated while rising from Low to Hi, or during the Hi interval. Negative refers

to a trigger signal polarity activated while falling from Hi to Low, or during the Low interval. The default value of a

camera is Negative.

Use the 11th pin to input a trigger signal

The DC IN connector 11th pin is pulled up on the camera side. When a connector is open, the trigger signal is at the

high level and is logically inactive. Note that when Positive of DC IN connector 11th pin is selected as a trigger input,

when the terminal is open, the trigger will be activated.

Use the 4th or 7th pin to input a trigger signal

When input is via the 11th pin, the high level value varies between 2 V to 24 V and 3.5 V to 5.5 V. Low level value is

0 V to 0.4 V.

Use the 10th (ISO+) or 8th (ISO-) pin to input a trigger signal

When input is via the 11th pin, the high level value varies between 2 V to 24 V and 5 V to 24 V. Low level value is 0 V

to 0.4 V.

command param Trigger signal polarity

TRG-POL 0

1 Positive

Negative

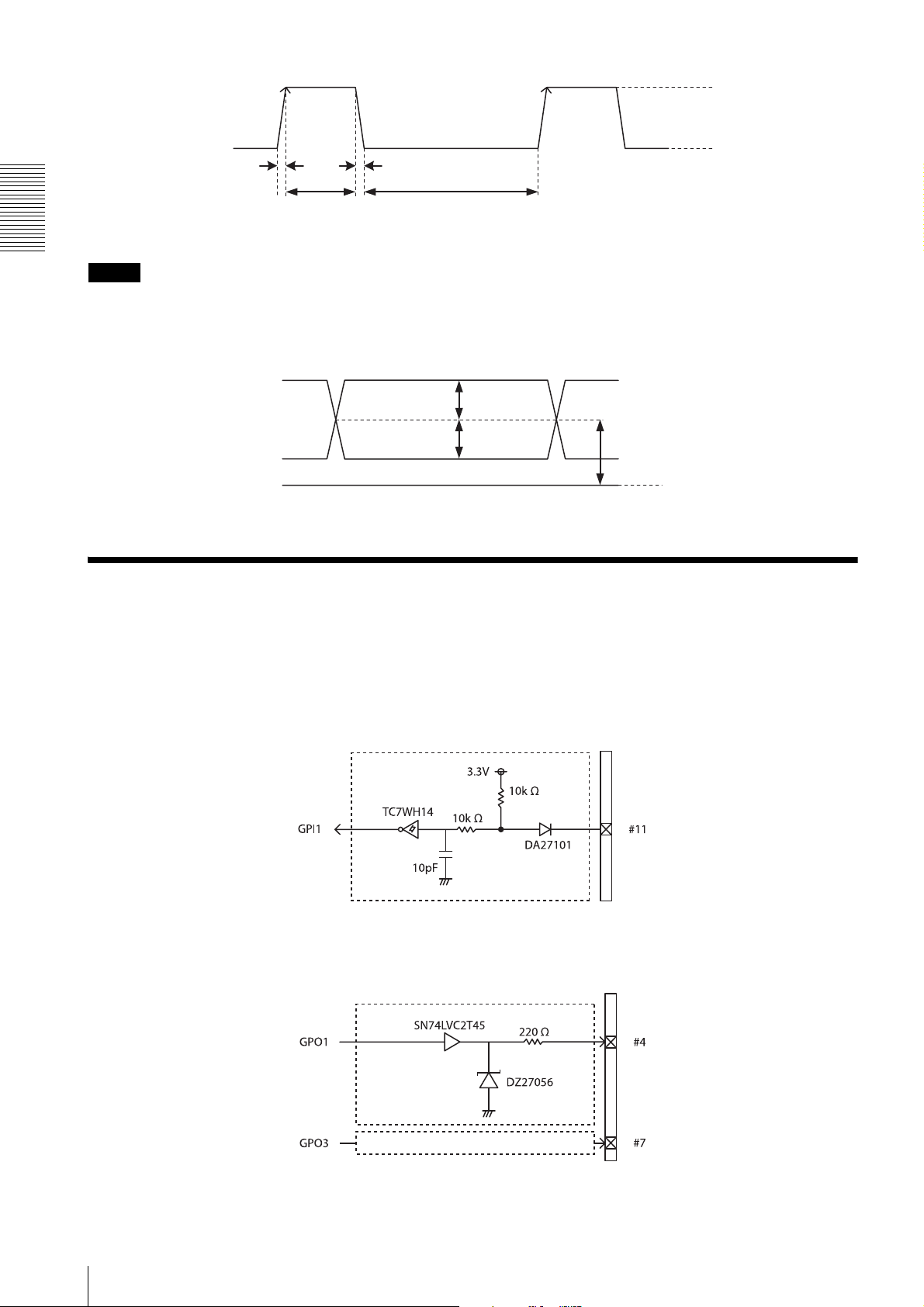

DC IN connector specifications

2.0µs or less

10µs to 2s

2.0µs or less

100µs or more

Trigger input polarity = Negative

2 to 24V

0 to 0.4V

Trigger Signal Input

13

2.0µs or less

2 to 24V

0 to 0.4V

2.0µs or less

10µs to 2s

100µs or more

Trigger input polarity = Positive

Connections

Note

When inputting a trigger signal to the camera using the DC-700, use DC 5 V or less at the logical high level.

Digital IF connector specifications

0.30 to 0.40v

0.30 to 0.40v

1.125 to 1.375v

GND

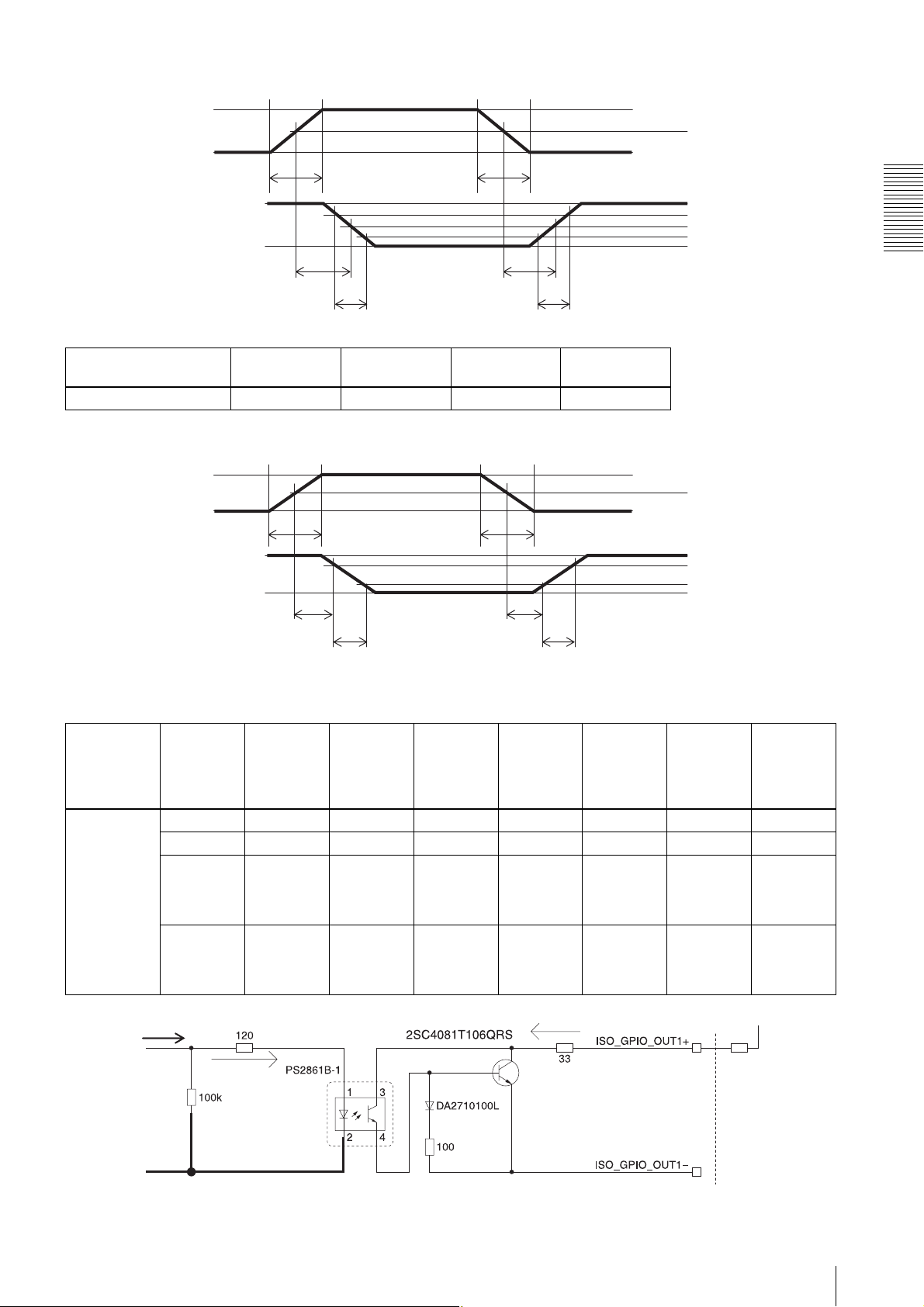

GPIO Connector

The DC IN connector’s 10th and 11th pins are for the GPI connector, the 6th and 9th pins are for the GPO (+) connector,

the 4th and 7th pins are for the GPIO switching connector. The trigger reset connector is the DC IN connector 11th pin.

If you are connecting an external device to each connector, refer to the circuit specifications below.

GPI circuit specifications

GPO circuit specifications

DC IN connector

DC IN connector

As GPO1

14

GPIO Connector

GPIO input (10th pin ISO)

5V

0V

50%

*

*

3.3V

0V

TDF

FT

Example

Input voltage

[V]

5.0 167 297 192 358

TDF

[ns]

FT

[ns]

GPIO output (6th pin ISO or 9th pin ISO)

3.3V

0V

**

3.3V

0.9V

TDF

FT

TDR

[ns]

TDR

TDR

RT

RT

RT

[ns]

90%

50%

10%

50%

90%

10%

Connections

* Rising the input signal as soon as possible.

Example

When connecting to an external power supply, be sure to use a pull-up resistor for a current limit of less than 50 mA.

Normal

temperature

Input from control IC

Supply

voltage

of the

output

[V]

3.3 470 Ω 5.07 0.75 0.49 24 35 0.916

5.0 820 Ω 4.98 0.73 0.63 28 46 0.909

12.0 Two

24.0 Eight

Pull-up

resistor

Use 1/16

W

2200 Ω

resistors

in parallel

8200 Ω

resistors

in parallel

Current

[mA]

TDF

[µs]

FT

[µs]

TDR

[µs]

RT

[µs]

Output

voltage

9.87 0.71 1.05 36 64 1.112

21.85 0.73 1.45 45 76 1.571

External power supply

Pull-up resistor

[V]

GPIO Connector

15

Functions

Functions

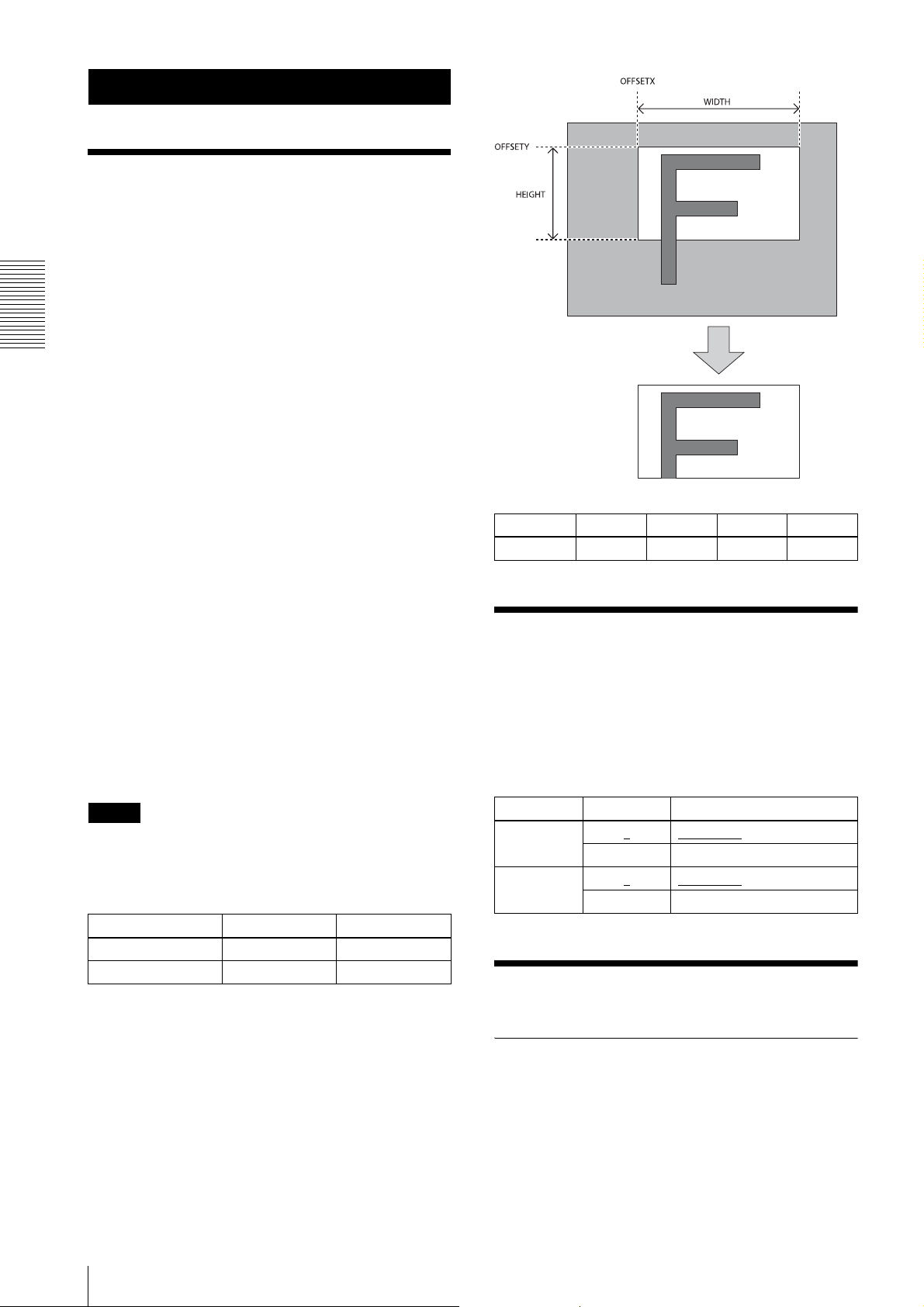

Partial Scan

Only the area selected from the effective pixel area can

be read out. Clearing unnecessary parts at high-speed

allows high-speed reading. The area size is selected by

the HEIGHT and WIDTH commands, and the read

beginning point is selected by the OFFSETX and

OFFSETY commands. Using the ROI command, you

can set HEIGHT, WIDTH, OFFSETX and OFFSETY at

the same time. Reducing HEIGHT increases the frame

rate, but changing WIDTH does not change the frame

rate. Partial scan can be set with or without a trigger.

Binning can be used at the same time.

OFFSETX and OFFSETY relate to WIDTH and

HEIGHT as follows:

OFFSETX + WIDTH ≤ WIDTH (maximum value)

OFFSETY + HEIGHT ≤ HEIGHT (maximum value)

When selecting sensor tap4, a central line divides the

screen into two halves symmetrically for a vertical

division. For the relationship between OFFSETY and

HEIGHT, see the following formula:

OFFSETY × 2 + HEIGHT = Maximum lines

(For XCL-S600 the maximum number of lines is 2208,

for XCL-S900 the maximum number of lines is 2712)

Because the value of OFFSET is set automatically by

HEIGHT and the maximum number of lines, the

command to change OFFSETY is not available.

(Example of XCL-S900)

>SENSOR-TAP 4

>HEIGHT 480 t HEIGHT is 480, OFFSETY is set to

1116 ( = (2712 – 480) ÷ 2)

>OFFSETY 0 t OFFSETY change not available.

Partial scan

command param1 param2 param3 param4

ROI Width Height OffsetX OffsetY

Binning

By adding 2 vertical pixels or 2 horizontal pixels, the

frame rate in vertical binning is increased along with the

sensitivity. The color camera cannot set this. This can be

set with or without a trigger. Partial scan can be used

concurrently and horizontal and vertical can be set at the

same time.

Note

Since the shutter setting has priority, use a shutter speed

high enough to enable partial scan at a higher frame rate.

Configurable range

WIDTH HEIGHT

XCL-S600/S600C 16 ~ 2758 4 ~ 2208

XCL-S900/S900C 16 ~ 3388 4 ~ 2712

Configurable values

OFFSETX, WIDTH: 2-step increments

OFFSETY, HEIGHT: 4-step increments

command param Setting

VBIN 1

2 Vertical binning

HBIN 1

2 Horizontal binning

No binning

No binning

Sensor Tap

Switching sensor tap

This unit has a CCD with 4-channel output which is

available for 4-channel, 2-channel and 1-channel

reading. The reading speed becomes faster as the value

of the channel number increases.

16

Partial Scan

command param Setting

SENSOR TAP 1 1-channel

2 2-channel

4

4-channel

command param Setting

to

BL-ABLIMIT

1 to 512

16383

Setting lower value prevents

excessive detection

Level correction between sensor taps

Since XCL-S600/S600C and XCL- S900/S900C have a

CCD with 4-channel signal outputs, output level

differences may occur during channel reading due to the

characteristic difference between channels. Level

correction between sensor taps can correct the level

differences. A command for one-push (automatically

detecting the level difference and adjusting only once),

continuous (constantly detecting the level difference and

adjusting continuously), and manual correction

(correcting left and right manually) is provided. After

one-push is performed once, the state returns to manual

designation.

command param Setting

BLACKLEV

EL-AUTOBALANCE

(BL-AB)

0

1 One-push (only once)

2 Continuous (consecutive)

Manual designation is performed by the BL-ADJ-1/2

command. The left screen is for TAP1 and the right

screen is for TAP2. One push and continuous commands

automatically set the value for TAP2.

command param Setting

BL-ADJ-1 -255 to 0

BL-ADJ-2 -255 to 0

to 255 Black level correction

to 255 Black level correction

Manual designation

value for left screen

value for right screen

Output Bit Depth

Monochrome cameras can switch between 8 bits, 10

bits, and 12 bits. Color cameras can switch between Raw

output 8 bits, 10 bits, 12 bits, and RGB output 24 bits.

command param Setting

PIXEL-DEPTH 8

/10/12/24 24 is only for color camera

Gain

Analog gain

The analog gain can be set finely in 1 dB unit or bit level

(up to 18 dB). It can be set per the sensor tap as well.

command param Setting

GAIN 0

GAIN-TAP1 0

GAIN-TAP2 0

GAIN-FINE 0

GAINFINE-TAP1

GAINFINE-TAP2

to 18 Gain dB unit (full screen)

to 18 Gain dB unit (left screen)

to 18 Gain dB unit (right screen)

to 512 Gain advanced setting (full

screen)

to 512 Gain advanced setting (left

0

to 512 Gain advanced setting (right

0

screen)

screen)

Functions

Adjusting level correction between sensor taps

The one-push command should be executed after setting

the output level to all black by removing light sources.

When One-push or Continuous is performed as taking

an image normally, the shade difference of an object is

detected as the level difference between taps and level

correction may not work properly on rare occasions. In

this case, the limit value (BL-AB-LIMIT) should be

adjusted so that the level is automatically adjusted to the

proper value. Lowering the value allows preventing

excessive detection but interferes the normal level

correction between taps to work properly. The level

should be adjusted accordingly since the optimal value

differs depending on the environment (such as an object

and light source) and camera settings (such as gain and

shutter).

Digital gain

The digital gain is not implemented in this device.

Auto gain (AGC)

By executing the GAIN-AUTO command, the gain is

automatically adjusted according to the image pickup

environment. AGC works so that the average level in a

detection frame may reach AGC-LEVEL. The AGC

detection frame is set to the central region by default.

The detection frame can be displayed or the detection

area changed.

Output Bit Depth

17

Loading...

Loading...